Coke particle clean combustion stove

A granular and clean technology, applied in the field of high-efficiency, environmentally-friendly and clean combustion stoves, can solve the problems of insufficient and uniform burning of blue carbon fuel, insufficient combustion, local slagging, etc., and achieve the effects of good environmental performance, sufficient combustion, and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

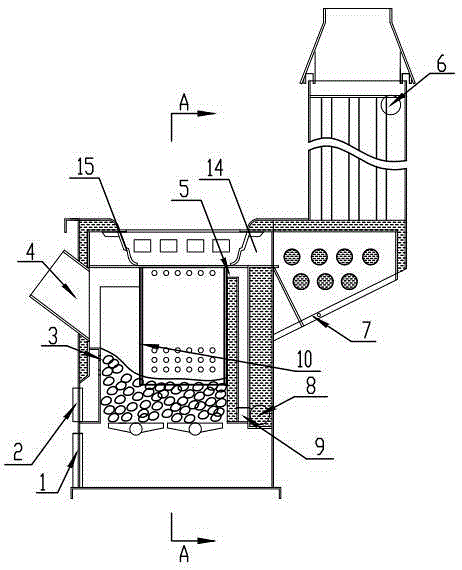

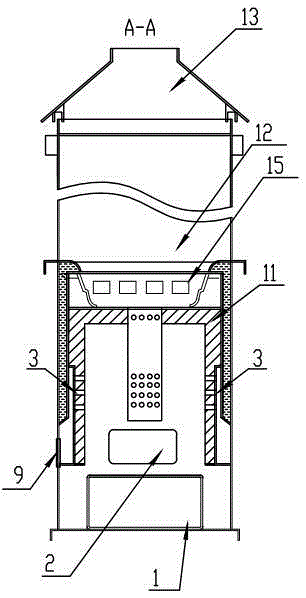

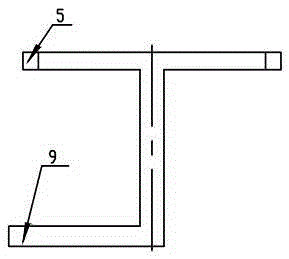

[0029] According to attached figure 1 and 2 It can be seen that the present invention specifically relates to a clean combustion stove with semi-coke particles, which is improved on the basis of the original stove to meet the combustion of semi-coke fuel with high calorific value and high ignition point. The concrete structure of stove comprises furnace body, flue and fire pipe heat-absorbing chamber 12, and the center of furnace body is a combustion chamber, and the outer wall of furnace is a water jacket layer, and the furnace body and fire pipe heat-absorbing chamber 12 are connected, and fire pipe absorbs heat. A chimney is provided on the upper end of the hot chamber 12, and a cap 13 is provided on the chimney. The biggest improvement of the present invention is to improve the structure of the combustion chamber of the furnace body. The combustion chamber is divided into two layers, including the main combustion chamber of the lower layer and the enhanced combustion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com