Transversely closed burning highly effective environment protective energy-saving direct combustion type biomass stove

An environmental protection and energy-saving biomass furnace technology, applied in the direction of biofuels, coke ovens, household furnaces/stoves, etc., can solve the problems of one-time feeding, lack of air supplement, high height, etc., to achieve unique design and fast ignition , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

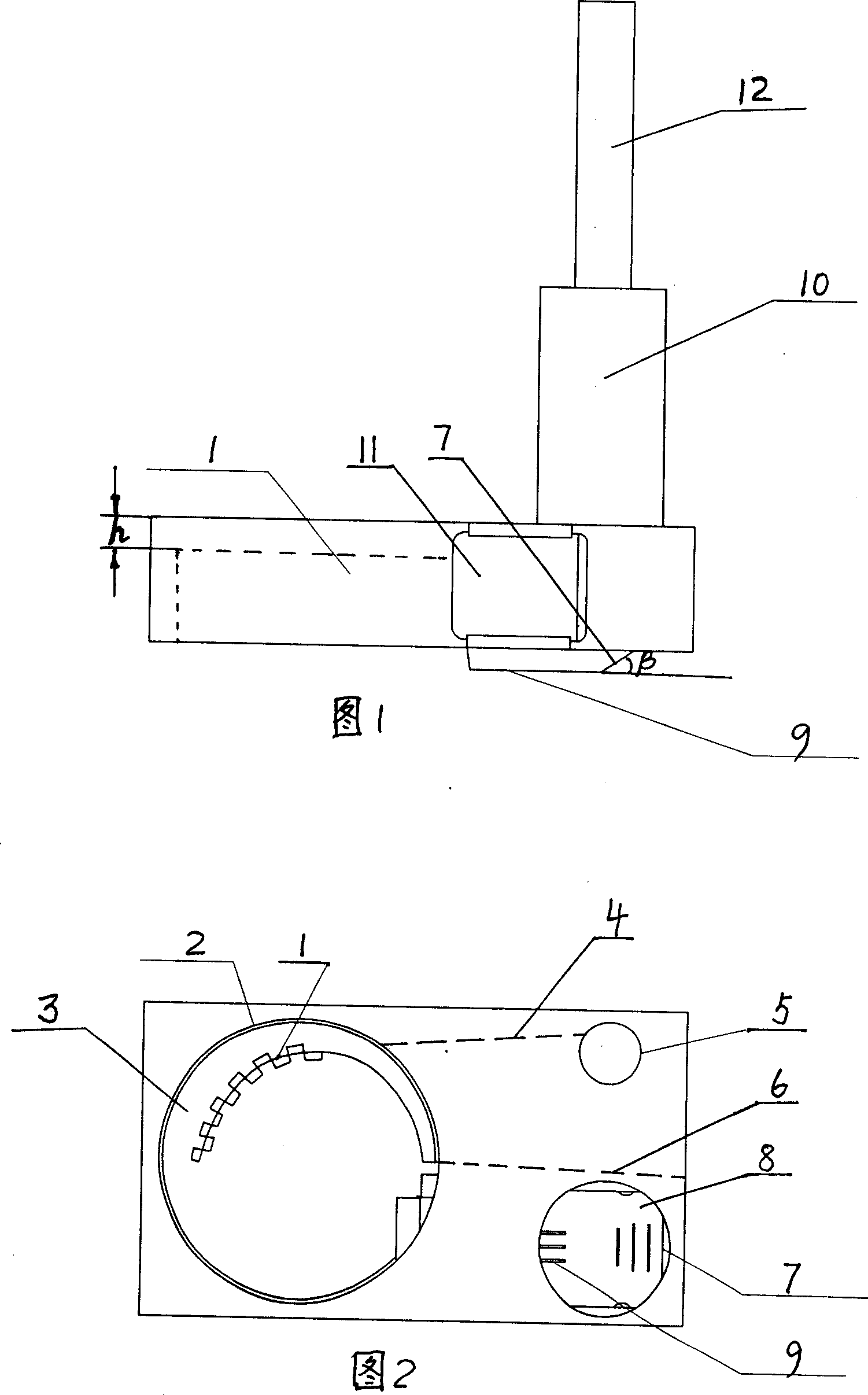

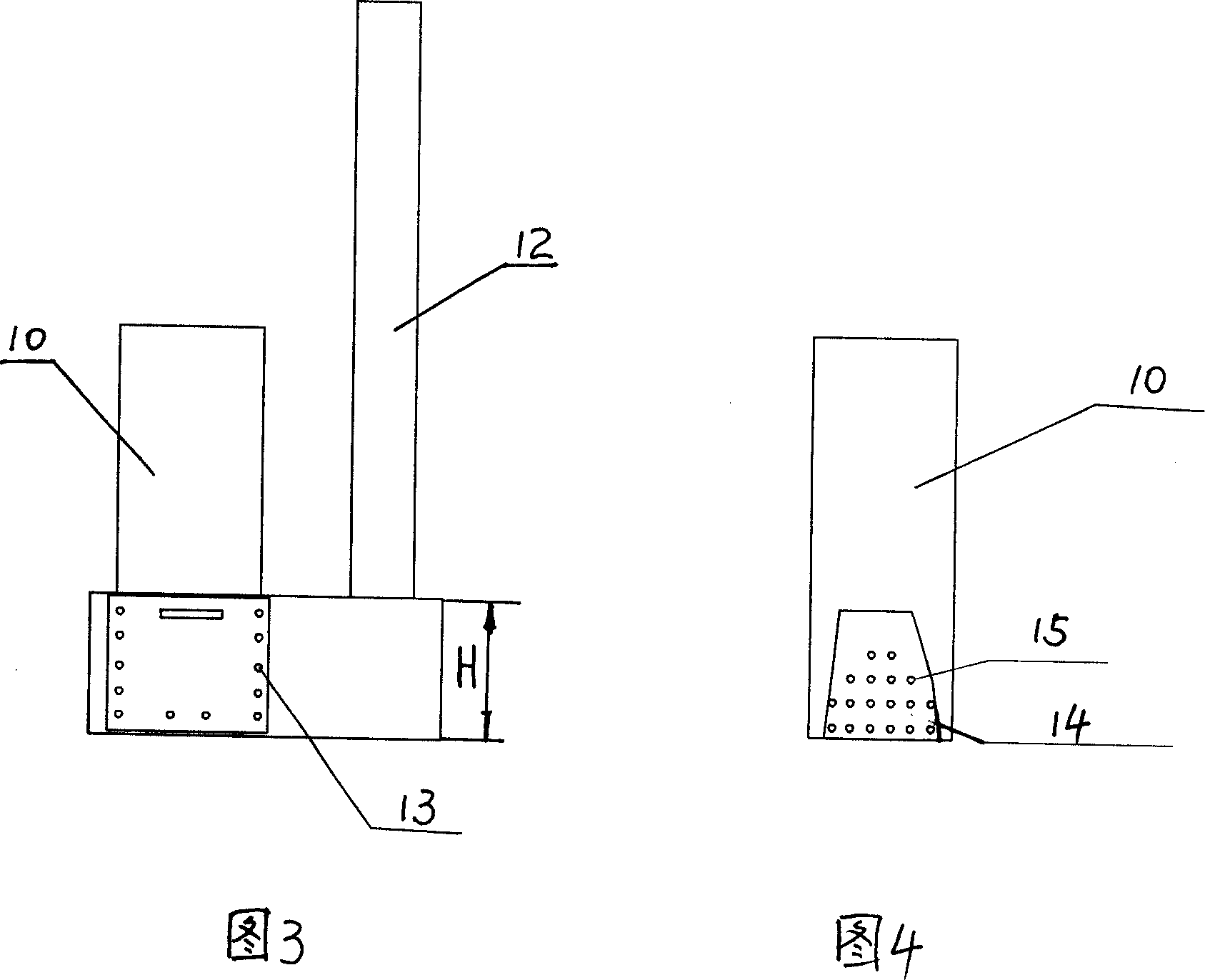

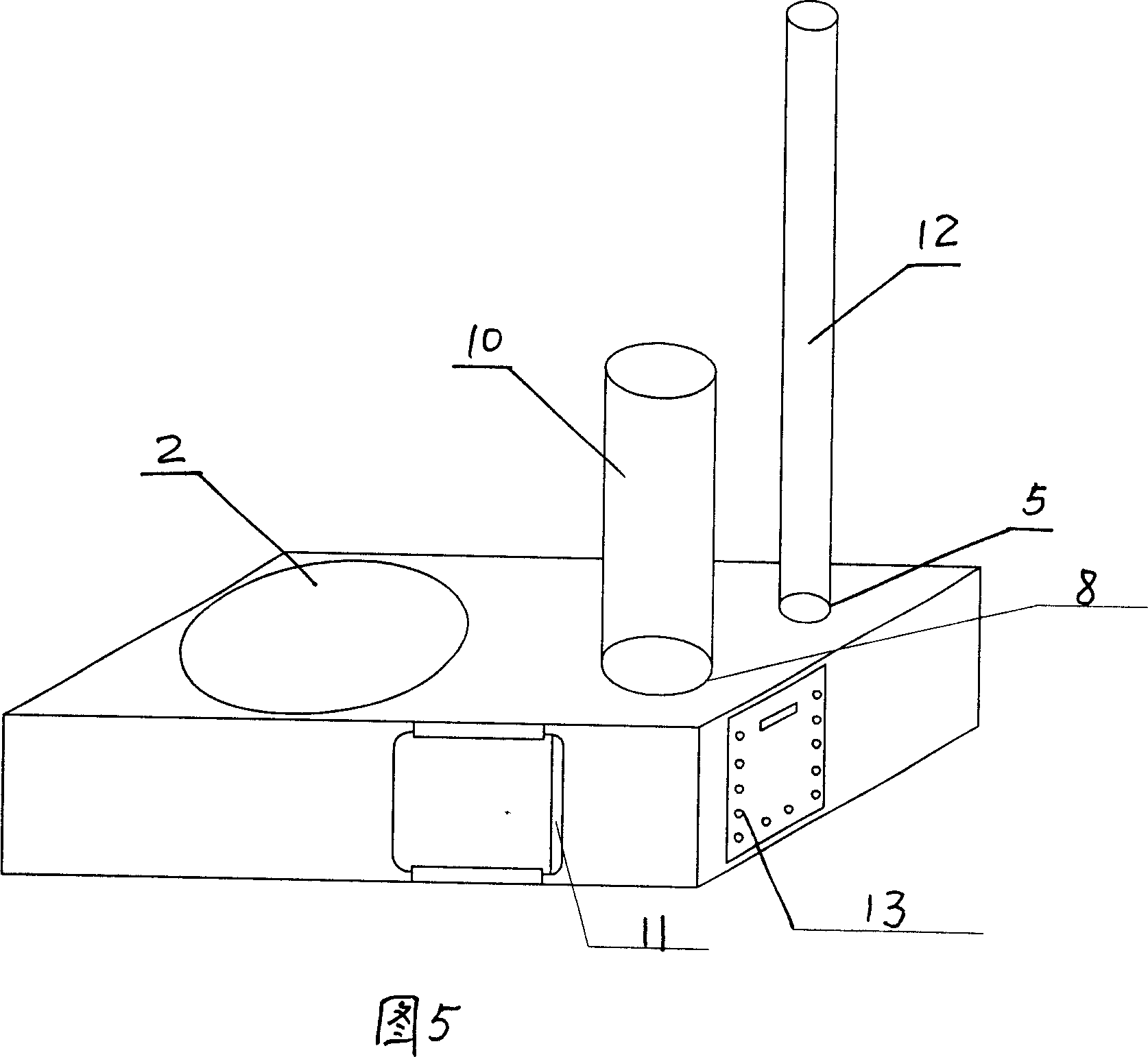

[0018] The structure of the present invention is shown in Figures 1-5: it includes a furnace body consisting of front, rear, left and right side panels, an upper panel and a bottom plate, and the combustion-supporting power extraction cylinder port 5 and the charging port 8 are designed on the upper panel of the furnace body The upper and lower positions of the plane axis at the same end on the right side, the opening of the seat pot mouth 2 is on the same end face of the furnace shell panel on the left side of the midline of the feeding port 8 and the combustion power air extraction cylinder mouth 5, and the air extraction cylinder is installed on the air extraction cylinder mouth 5 12. A cylindrical or square feeding bin 10 is erected in the feeding port 8. The lower end of the feeding bin is placed on the sliding plate grate 7 in the furnace body. There is an air inlet 15 on one side of the lower end wall of the feeding bin, and the other side is cut off. One is the sliding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com