Secondary air distributor for biomass direct combustion furnace

A secondary air, direct-fired furnace technology, applied in the transportation of non-flammable liquid/gas, combustion method, combustion equipment, etc., can solve the problems of inconvenient cleaning and maintenance of the furnace body, long start-up time of cold furnace, unreasonable installation, etc. , to achieve the effect of easy ignition of cold furnace, simple structure and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

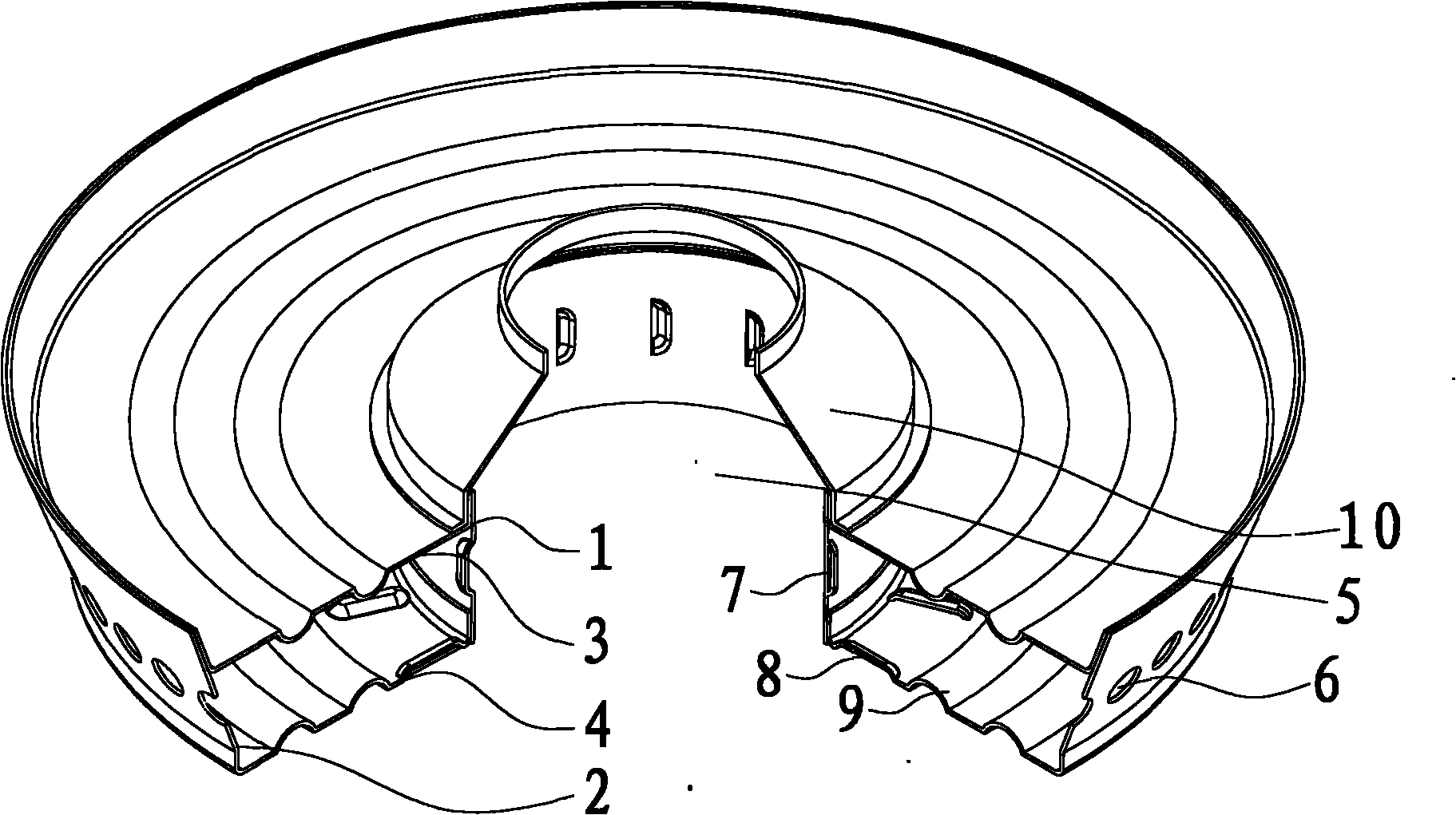

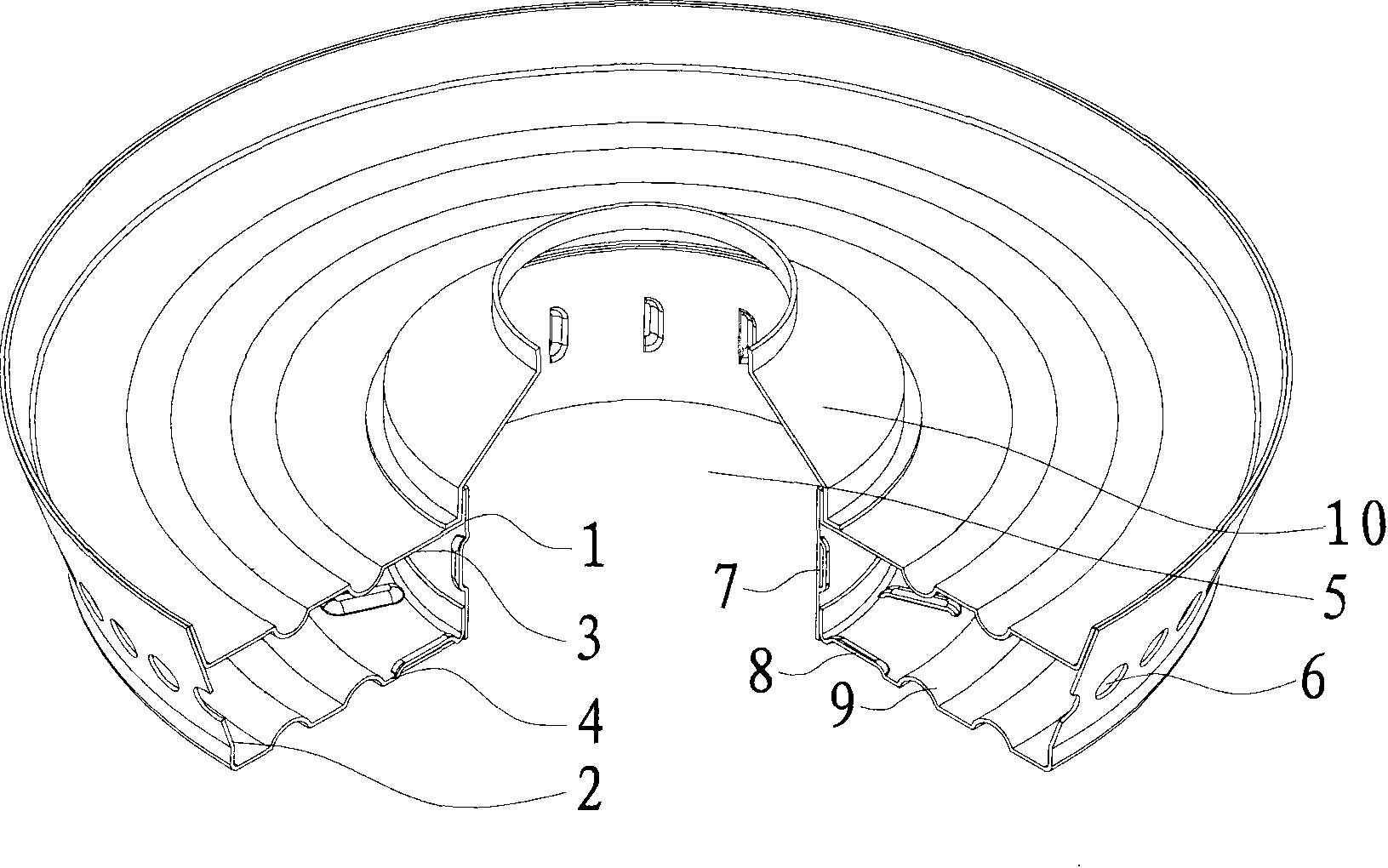

[0011] Embodiment one, the secondary air distributor of biomass direct combustion furnace, such as figure 1 As shown, it is an annular hollow body surrounded by inner wall 1, outer wall 2, upper wall 3 and bottom wall 4, with a fire hole 5 in the middle; Air holes 6; the inner wall 1 has a louver-shaped air outlet 1 7, and the bottom wall 4 has a louver-shaped air outlet 2 8; the upper wall 3 and the bottom wall 4 each have two reinforcing ribs 9.

[0012] When installed and used, the secondary air distributor of the biomass direct-fired furnace is flexibly connected with the furnace body and placed above the furnace cylinder. The outer wall 2 is close to the stepped inner wall of the furnace body, and the air inlet 6 is connected to the external secondary The air is supplied by air, and the inverted conical outer wall 2 can prevent the assembly of the furnace body from being too tight or loose due to heat deformation, and it is easy to take out; because the biomass direct com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com