Method for calcining novel dry-method cement clinker by brown coal

A dry process cement and lignite technology, applied in the field of cement production, can solve the problems of unfavorable lignite comprehensive, effective utilization, difficult to control calcination quality, high cement production cost, and achieve the effects of reducing cement production cost, high temperature and long burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

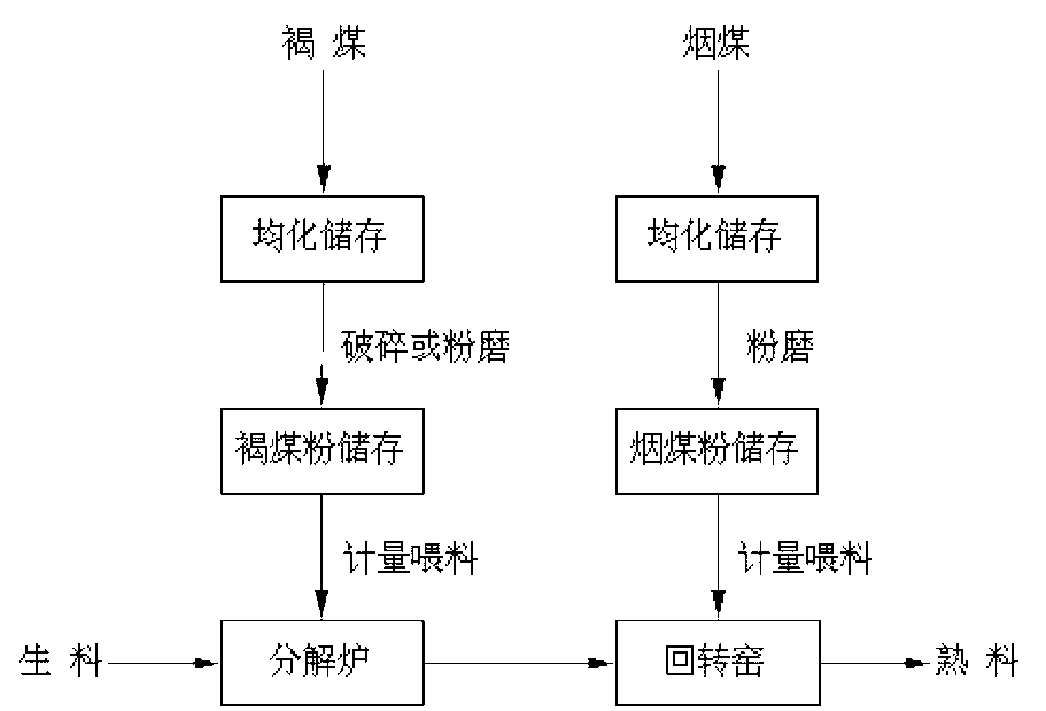

[0022] The incoming lignite and bituminous coal are stored, stacked, and homogenized separately. The lignite is broken into 5mm particles by a ring hammer crusher, stored in a coal bunker, and then fed into the calciner by metering equipment and conveying equipment for combustion. The bituminous coal is ground into pulverized coal by a mill, and fed into the coal injection pipe of the rotary kiln by the metering equipment and conveying equipment for combustion.

Embodiment 2

[0024] The lignite and bituminous coal entering the plant are stored, stacked, and homogenized separately. The lignite is crushed into 3mm particles by an impact crusher, stored in a coal bunker, and then fed into the calciner by metering equipment and conveying equipment for combustion. The bituminous coal is ground into pulverized coal by a mill, and fed into the coal injection pipe of the rotary kiln by the metering equipment and conveying equipment for combustion.

Embodiment 3

[0026] The lignite and bituminous coal entering the factory are stored, stacked, and homogenized separately, and the lignite is ground by Raymond mill to make coal powder with a fineness of 0.08mm and 3% of the remaining 3% of the sieve, which is stored in the coal bunker, and then transported by metering equipment and The equipment is fed into the calciner for combustion. The bituminous coal is ground into pulverized coal by a mill, and fed into the coal injection pipe of the rotary kiln by the metering equipment and conveying equipment for combustion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com