Pressure water reactor nuclear power plant high-radioactivity waste gas normal-temperature delay treatment complete equipment

A technology for pressurized water reactor nuclear power plants and complete sets of equipment, applied in nuclear engineering, radioactive purification, etc., can solve the problems of radioactive gas leakage, difficult maintenance, and high operating costs, and achieve low maintenance costs, high safety and reliability, and manufacturing convenient effect

Inactive Publication Date: 2010-08-25

江苏宝宸净化设备有限公司

View PDF4 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

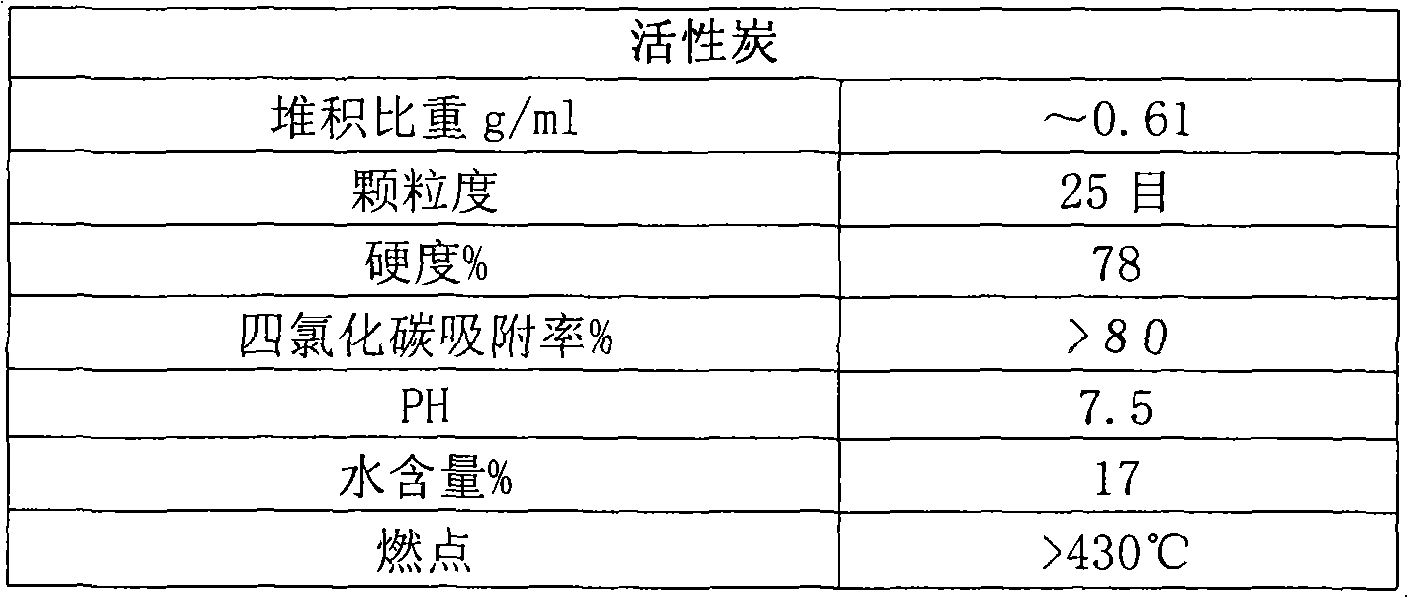

The purpose of the present invention is to design a pressurized water treatment device based on activated carbon adsorption technology in view of the shortcomings of the existing nuclear power plant high-level waste gas pressure treatment device, which has large investment, large area occupation, difficult maintenance, high operating cost and risk of radioactive gas leakage. A complete set of equipment for normal temperature delay treatment of high-level radioactive waste gas from reactor nuclear power plants

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

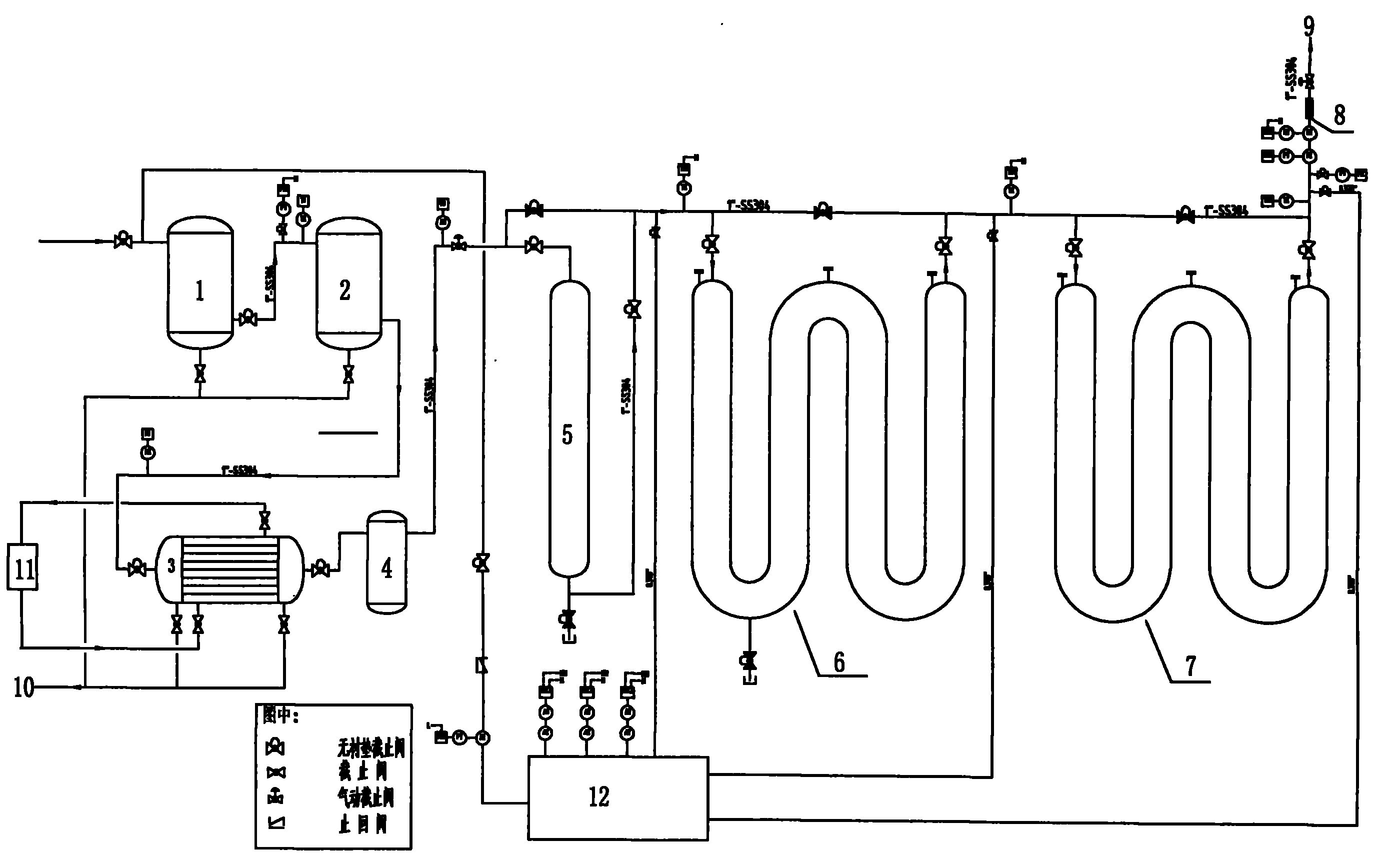

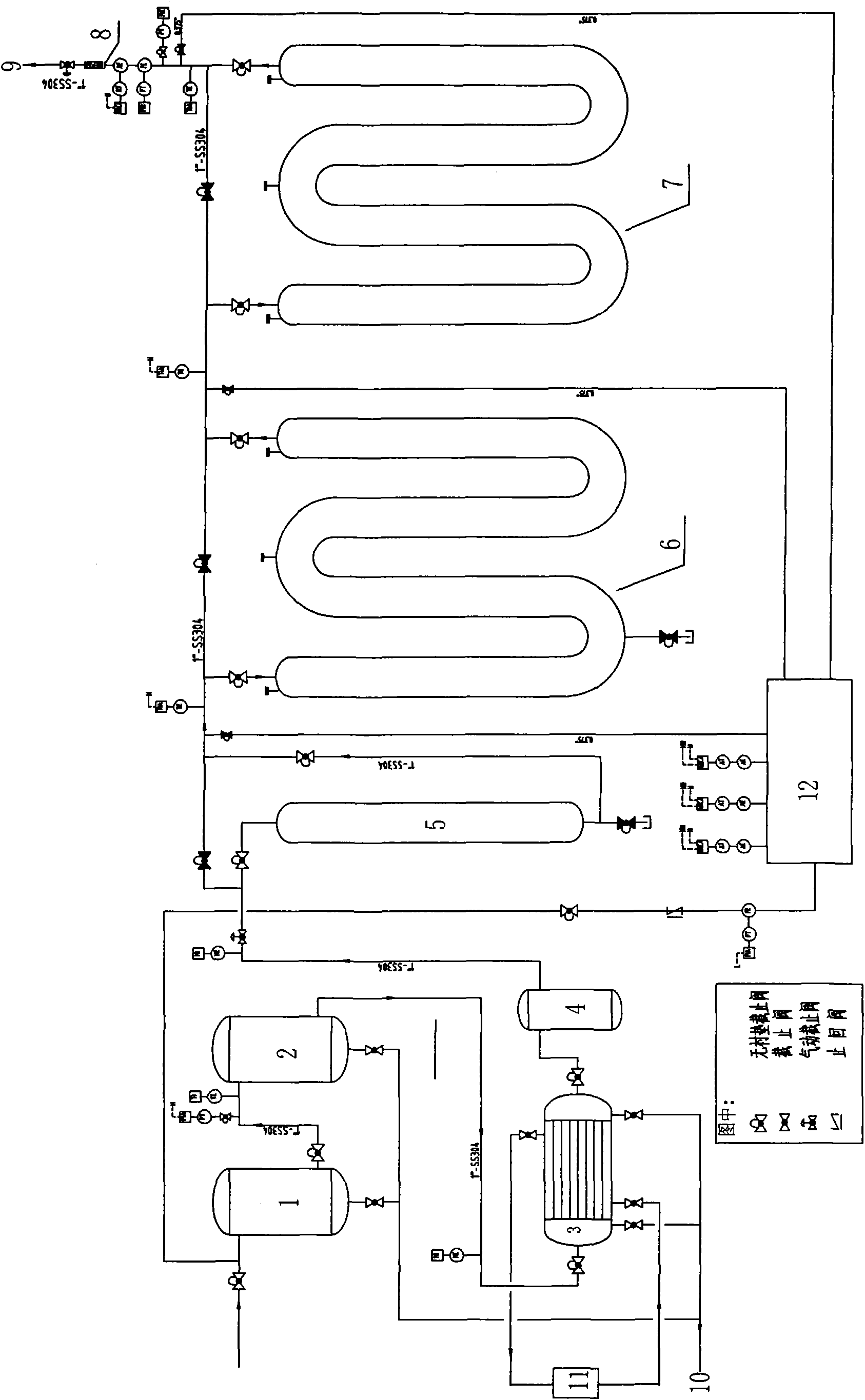

The invention relates to pressure water reactor nuclear power plant high-radioactivity waste gas normal-temperature delay treatment complete equipment, which is characterized in that the equipment mainly consists of a buffer tank (1), a prefilter (2), a drier (3), a heating device (4), a protection bed (5) and at least two delay beds (6) and (7), wherein the protection bed (5) is filled with active carbon, the delay beds (6) and (7) are connected in series, the gas inlet end of the buffer tank (1) is connected with the output end of a groove tank for collecting waste gas through a pipeline, the output end of the buffer tank (1) is connected with the input end of the prefilter (2), the output end of the prefilter (2) is connected with the input end of the drier (3), the output end of the drier (3) is connected with the input end of the heating device (4), the output end of the heating device (4) is connected with the input end of the protection bed (5), the output end of the protection bed (5) is connected with the input end of the delay bed (6), the output end of the delay bed (7) is connected with the input end of an efficient grain filter (8) through a pipeline, and the output end of the efficient grain filter (8) is connected with the corresponding input end of a plant building ventilation system (9). The invention has the advantages of simple structure, ground saving, energy saving, low operation and maintenance cost, safety and reliability.

Description

technical field The invention relates to nuclear power plant equipment, in particular to nuclear power plant waste gas treatment equipment, in particular to a complete set of equipment for normal temperature delay treatment of high-level radioactive waste gas from a pressurized water reactor nuclear power plant. Background technique As we all know, my country's nuclear power industry has gone through more than 20 years of development. At present, the nuclear power plants that have entered commercial operation mainly include: Qinshan Phase I, Phase II, and Phase III, Daya Bay, Ling Ao Phase I, Phase II and Hetian Bay Nuclear Power Plant. The total amount accounts for 1.9% of the country's total power generation, while the global average nuclear power has accounted for 16% of the total power generation, of which the proportion of nuclear power in the United States, Japan, and France has reached 20%, 30%, and 80% respectively. There is still a big gap between my country's nuclea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G21F9/02

Inventor 梁袁平崔鹏翁明辉陈斌

Owner 江苏宝宸净化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com