Novel complete device for room-temperature delay treatment of highly radioactive waste gas of nuclear power station

A complete set of equipment and nuclear power plant technology, applied in nuclear engineering, radioactive purification, etc., can solve problems such as complex operation and maintenance of compressors, risk of leakage of high-pressure storage tanks, and large energy consumption, and achieve international competitiveness, low maintenance costs, and safety high performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

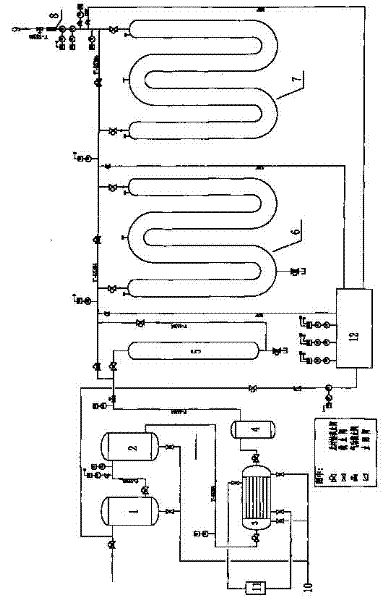

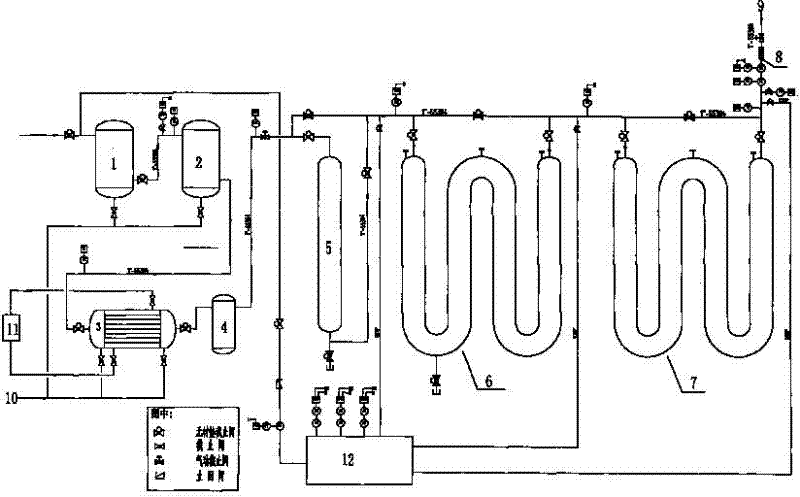

[0027] As shown in Figure 1.

[0028] A complete set of device for normal-temperature delay treatment of high-level radioactive waste gas from a pressurized water reactor nuclear power plant, which mainly consists of a buffer tank 1, a pre-filter 2, a dryer 3, a heater 4, a guard bed 5 and at least two series-connected delay beds 6, 7 Delayed beds 6 and 7 are composed of W-shaped large-diameter tubular containers and activated carbon canned in the containers. The W-shaped (or S-shaped, M-shaped, etc.) structure is used to extend the length of the delayed bed. , so that the high-level waste gas stays in the lagging bed as long as possible to improve the adsorption effect, as shown in Figure 1, the guard bed 5 and the lagging beds 6 and 7 are filled with activated carbon, and the inlet end of the buffer tank 1 Connect to the output end of the tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com