Research and development method of large-size semiconductor diamond wire fine wire cutting technology

A cutting technology and diamond wire technology, which is applied in the research and development field of large-size semiconductor diamond wire fine wire cutting technology, can solve the problems of slow processing speed, large kerf loss, and difficult handling, so as to reduce kerf loss and avoid handling difficulties. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A research and development method of large-scale semiconductor diamond wire fine wire cutting technology, the research and development method comprises the following steps:

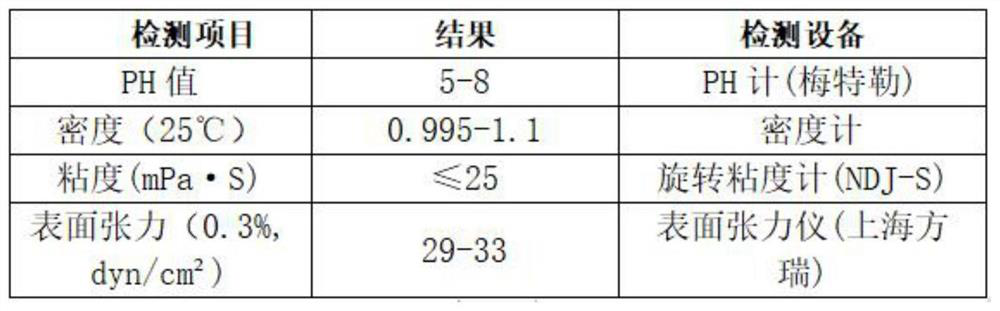

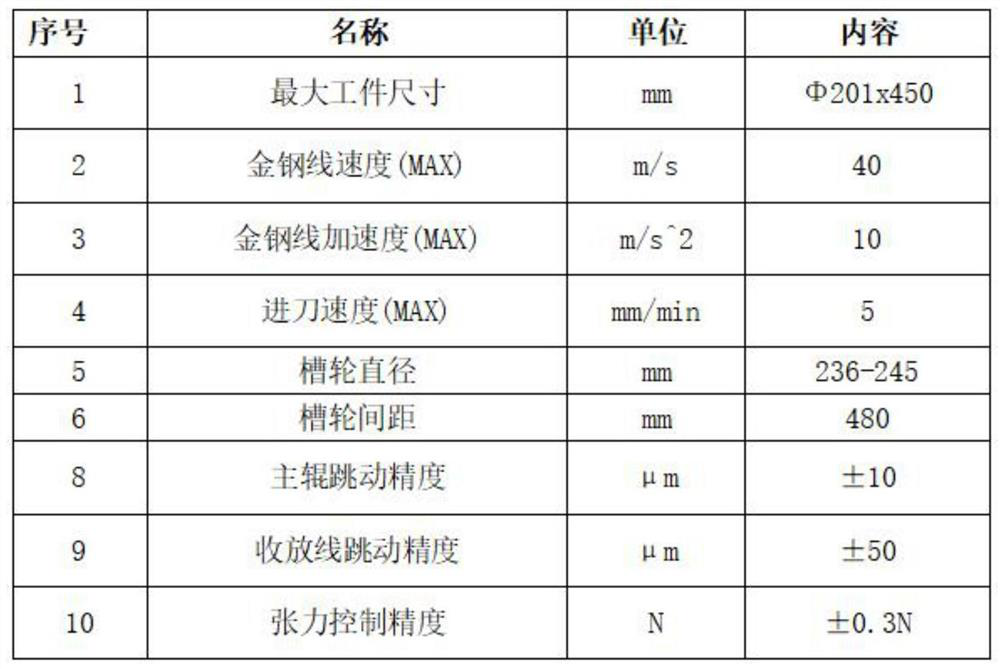

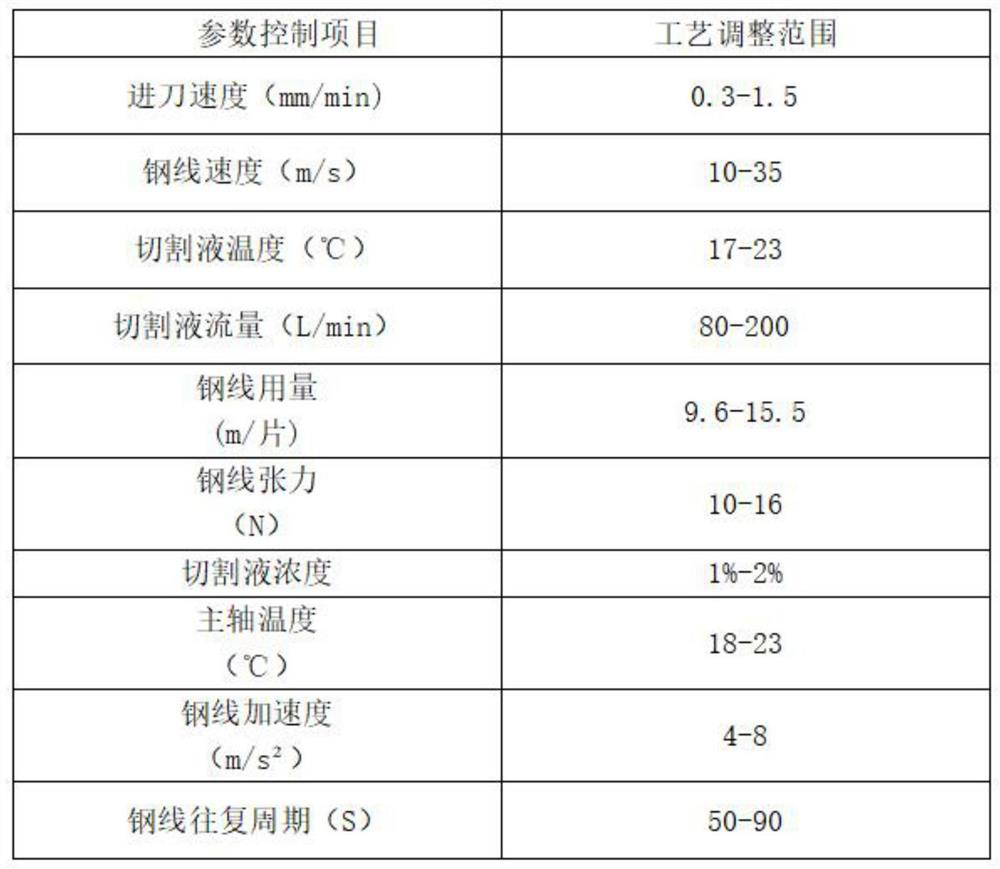

[0031] S1. Firstly, it is necessary to develop cutting fluid. By comparing the parameters and performance of the existing domestic cutting fluid, conduct comparative tests one by one, and cooperate with domestic manufacturers to customize the performance of exclusive cutting fluid. This type of cutting fluid needs to have the main characteristic of low surface tension. And good permeability helps to quickly remove silicon chips during the cutting process, reduce the disconnection rate, and has low foaming performance. This research and development has been compared with the comparative test. A total of 3 domestic cutting fluid material manufacturers have been developed, and all of them have reached The effect of the successful trial, and the successful introduction of a company for mass production e...

Embodiment 2

[0041] A research and development method of large-scale semiconductor diamond wire fine wire cutting technology, the research and development method comprises the following steps:

[0042] S1. Firstly, it is necessary to develop cutting fluid. By comparing the parameters and performance of the existing domestic cutting fluid, conduct comparative tests one by one, and cooperate with domestic manufacturers to customize the performance of exclusive cutting fluid. This type of cutting fluid needs to have the main characteristic of low surface tension. And good permeability helps to quickly remove silicon chips during the cutting process, reduce the disconnection rate, and has low foaming performance. This research and development has been compared with the comparative test. A total of 3 domestic cutting fluid material manufacturers have been developed, and all of them have reached The effect of the successful trial, and the successful introduction of a company for mass production e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com