Sludge treatment complete equipment

A complete set of equipment and sludge treatment technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve problems such as high bacterial content, secondary environmental pollution, and high energy consumption. Achieving low cost, low energy consumption and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

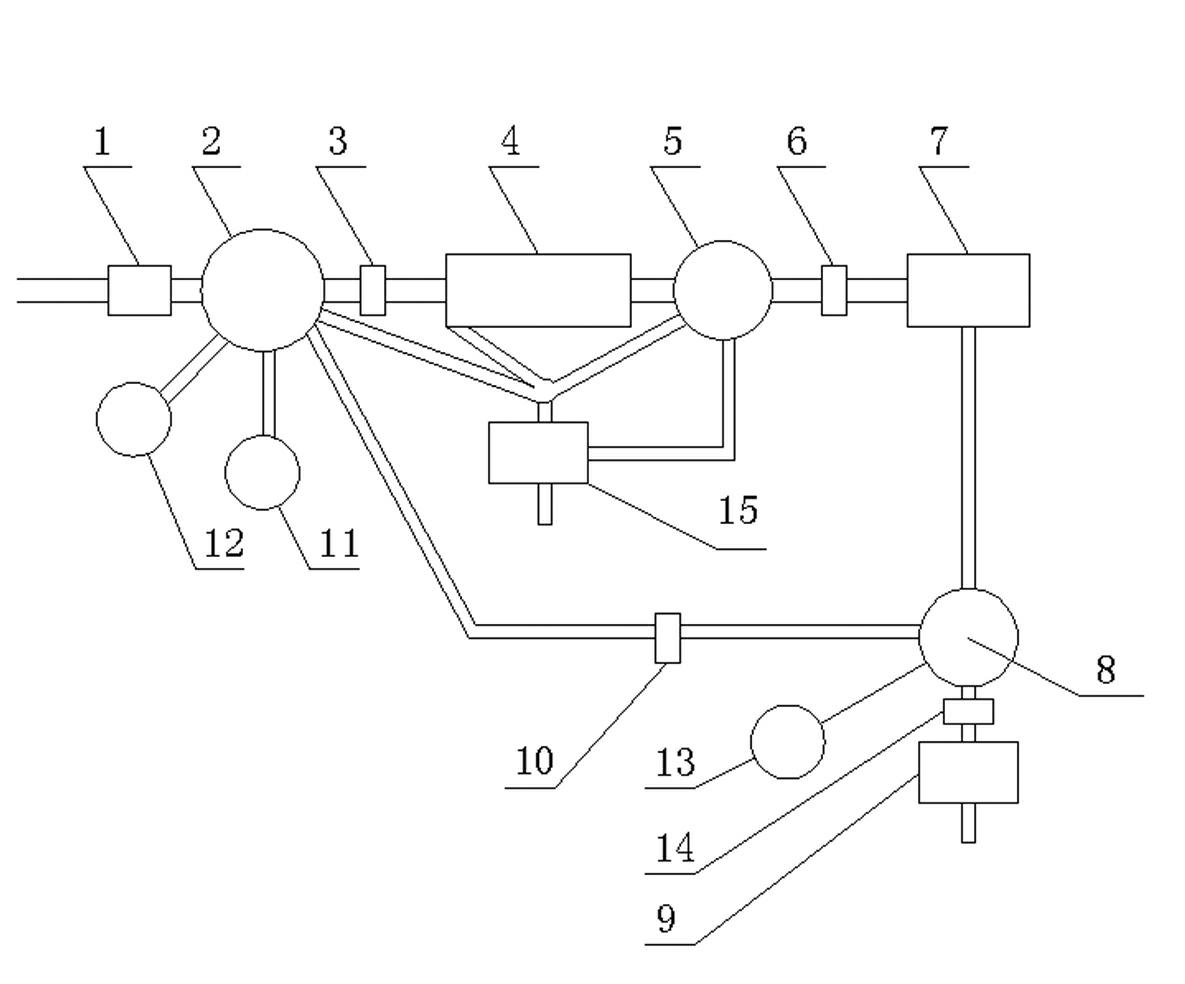

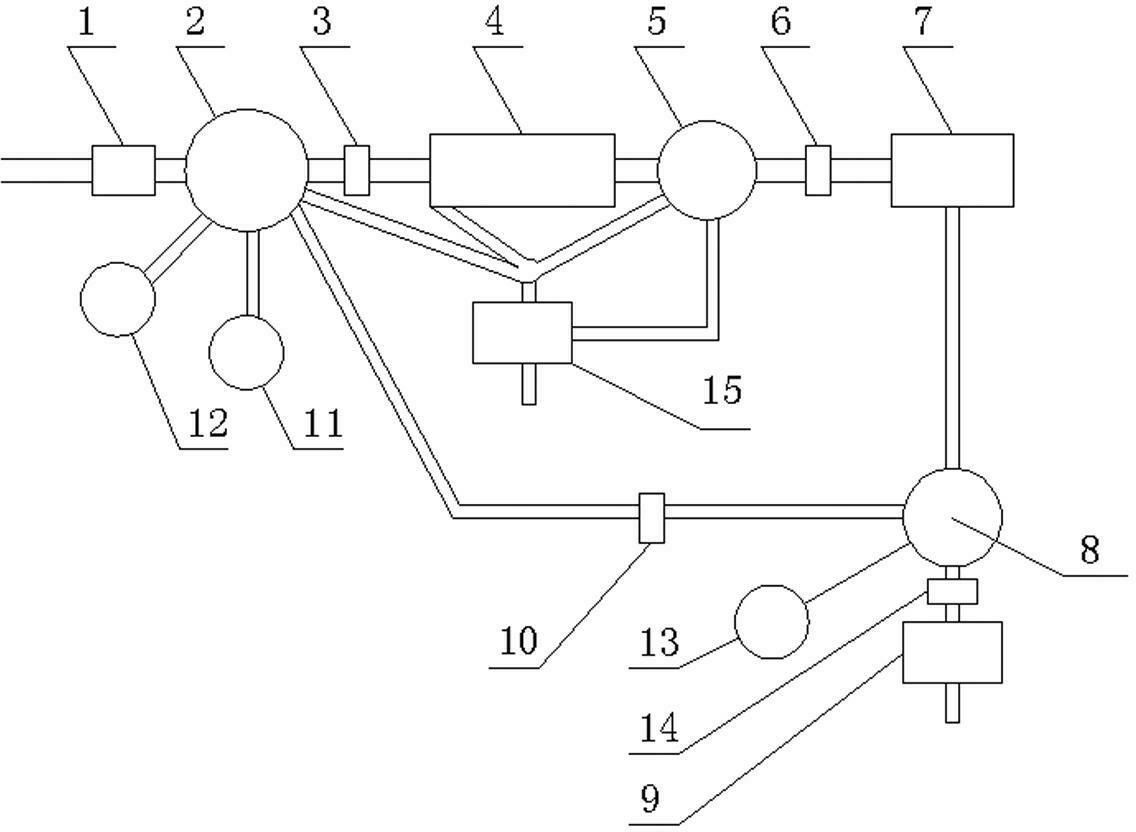

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0012] Referring to the accompanying drawings, this embodiment includes an untreated sludge metering and feeding device 1 for transporting the untreated sludge, a stirring modification device 2 for modifying the untreated sludge, and a mixing and modifying device 2 for transporting the untreated sludge to heat sterilization The metering and feeding device 3 of the odor device 4, the heat sterilization and deodorization device 4 for heat sterilization and deodorization of the sludge to be treated, the transfer tank 5 for storing the sludge and keeping the sludge in a uniform state, and the sludge from the The metering and pumping device I6 of the transfer tank input dehydration device I7, the dehydration device I7 for solid-liquid separation of the sludge in the transfer tank, the liquid pool 8 for holding the liquid obtained after the solid-liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com