Household garbage commercialization treatment method and complete equipment

A technology of domestic waste and treatment methods, which is applied in the field of domestic waste commercialization treatment methods and domestic waste commercialization treatment complete sets of equipment, which can solve the difficulty of site selection, the difficulty of site selection for domestic waste landfills, and the inability to meet the requirements of rapid social development. Environmental protection appeals and other issues, to achieve the effect of easy site selection, low daily operating costs, and low project investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

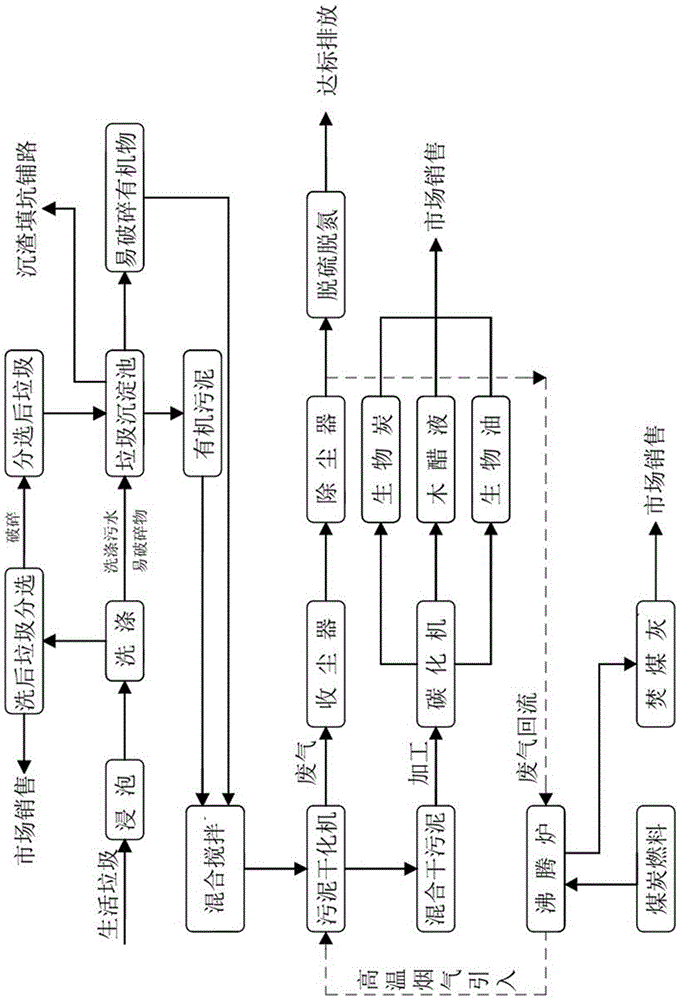

[0033] see figure 1 , the realization process of the domestic waste commercialization treatment method of the present invention is as follows:

[0034] 1) Washing and sorting process:

[0035] Garbage washing machine is used to wash and sort domestic garbage. After garbage washing, the washing sewage and fragile organic matter (including rotten organic matter, paper scraps, wood chips, etc.) flow into the garbage sedimentation tank together;

[0036] Take out the perishable organic matter, paper scraps, and sawdust floating on the surface of the washing sewage in the garbage sedimentation tank, and obtain fragile organic matter with a moisture content of 45-55% after mechanical dehydration, and dry them in the air;

[0037] After the washing sewage is settled in the sewage sedimentation tank and mechanically dehydrated, organic sludge with a moisture content of 75-80% is obtained;

[0038] The lime soil sediment and inorganic matter deposited at the bottom of the garbage sed...

Embodiment 2

[0044] see figure 1 , the commercialization treatment method of household garbage in this embodiment differs from that of Example 1 in that: in the washing and sorting process of garbage, the household garbage is first poured into the circulating washing pool to break the bag, soak, and then use the aerial crane grab Take out the garbage from the soaking tank and pour it into the garbage washing machine, add circulating washing water at the same time, add water to the garbage washing machine for 2 to 3 times, add water and stir, and then put water and stir to wash cycle, the fragile organic matter (including rotten organic matter, paper scraps) , wood chips, etc.) and the washing sewage flow out from the sieve hole of the inner cylinder of the washing machine into the outer cylinder of the washing machine, and after collection, they are discharged from the sewage outlet of the outer cylinder of the washing machine into the garbage sedimentation tank for sedimentation and separa...

Embodiment 3

[0047] see figure 1 The difference between the domestic waste commercialization treatment method of this embodiment and embodiment 1 or embodiment 2 is that: in the garbage washing and sorting process, the garbage larger than 50-60mm in the garbage washing machine after the domestic garbage is washed is removed from the Automatically discharged in the washing machine, stacked in the glass lighting greenhouse to dry, wind sorting, manual sorting, the sorted plastic bottles and most of the plastic bags are crushed and granulated for sale in the market; the sorted glass bottles and metal products are sold in the market , the sorted fabrics and old shoes are broken separately; after sorting, the remaining garbage is broken together and poured into the garbage sedimentation tank for sedimentation, and the organic matter is separated from the inorganic matter such as broken glass and bricks again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com