Sludge treatment complete equipment provided with sludge pre-drying device and method of sludge treatment complete equipment

A technology for sludge treatment and complete sets of equipment, applied in dewatering/drying/concentrating sludge treatment, sludge treatment through temperature control, etc. problems such as mud drying efficiency, to achieve the effect of improving efficiency, facilitating processing operations, and avoiding adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

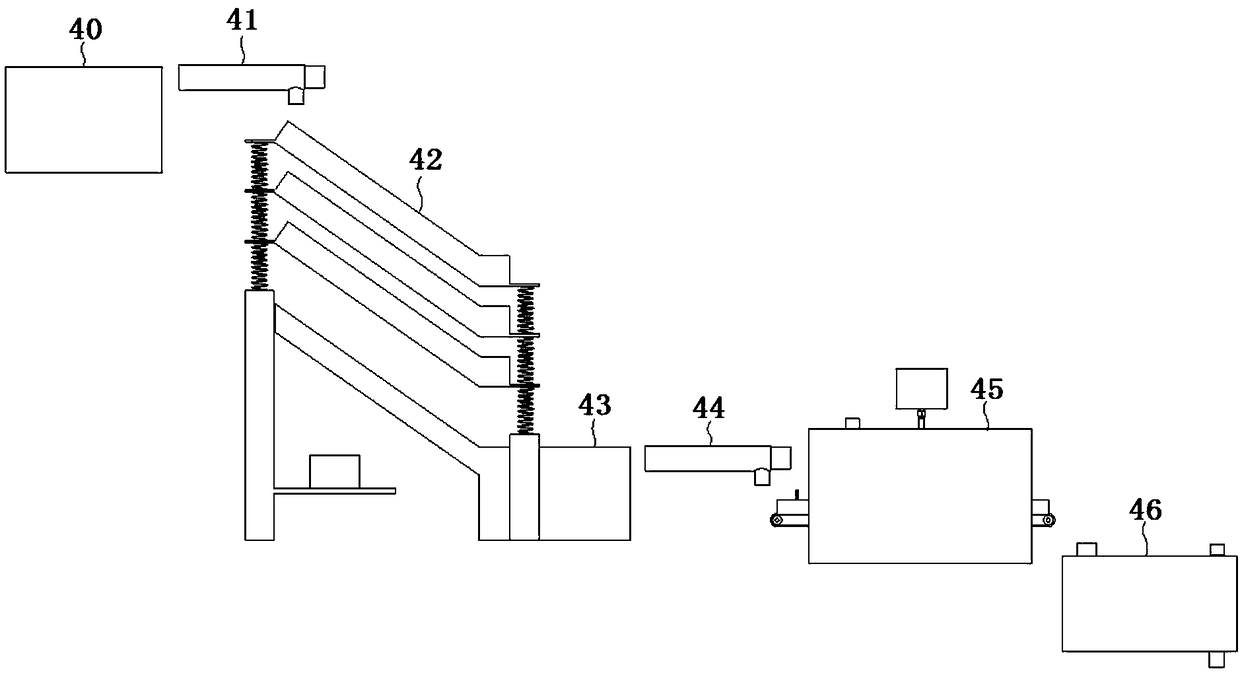

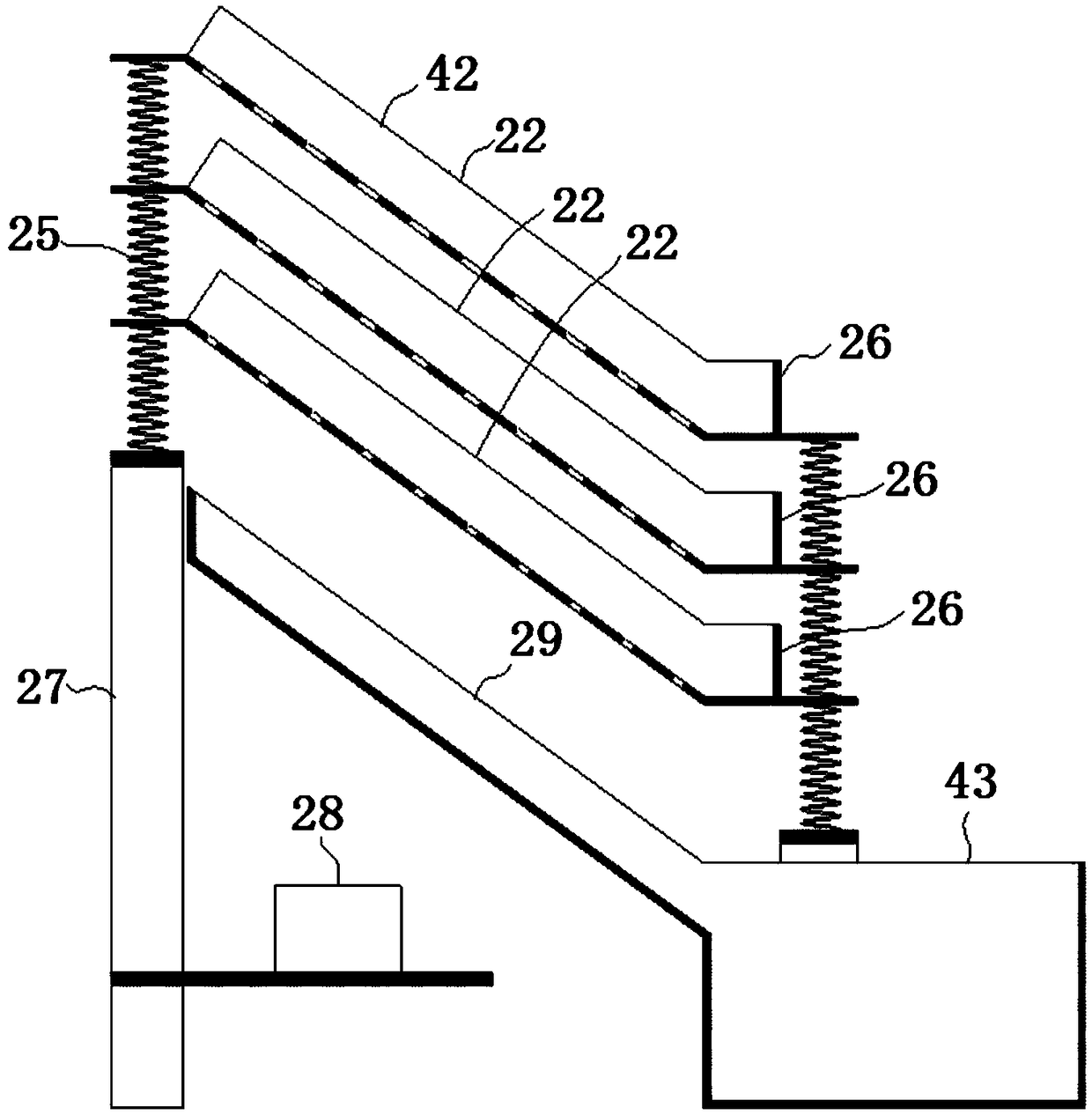

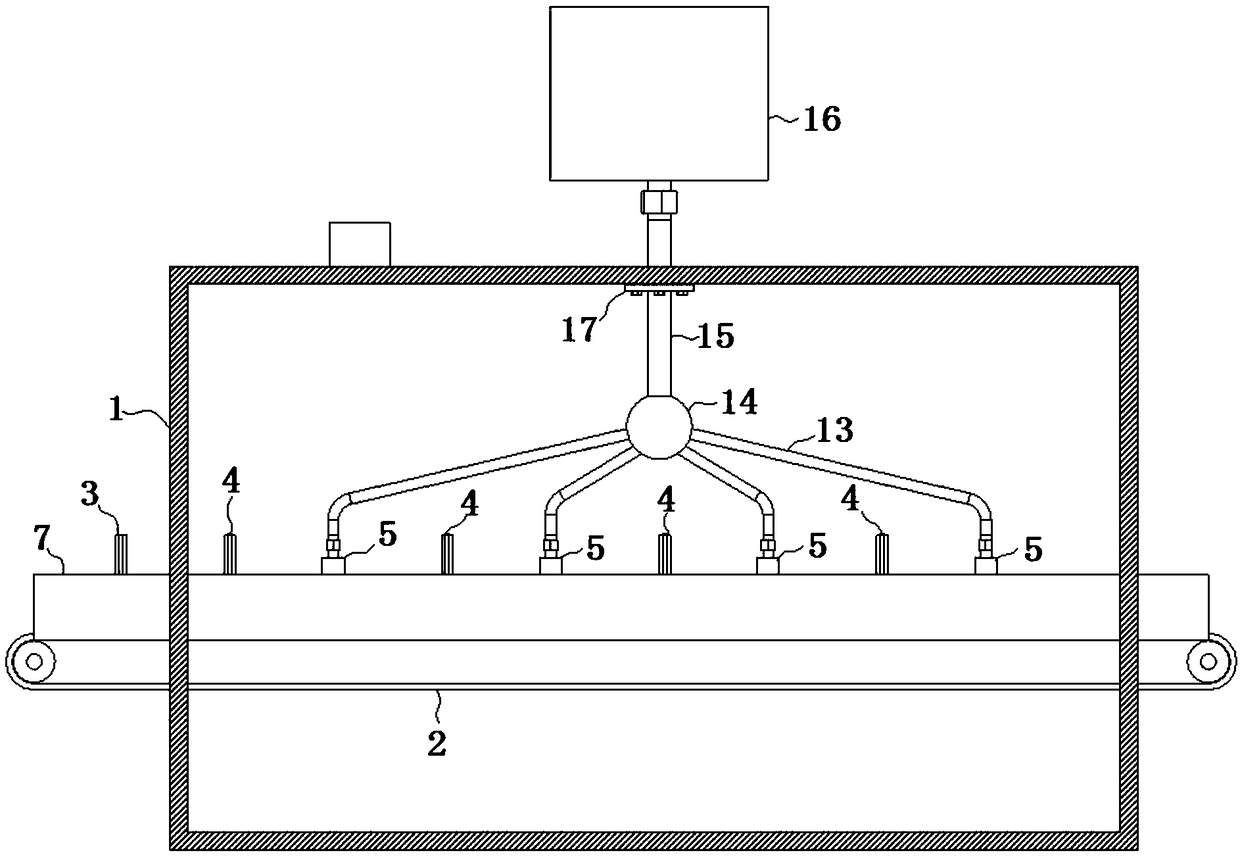

[0050] as attached figure 1 To attach Figure 11As shown, a complete set of sludge treatment equipment with a sludge pre-drying device, including a first screw conveyor 41, a sludge removal device 42, a second screw conveyor 44, a sludge pre-drying device 45 and a sludge drying machine 46; the first screw conveyor 41 is used to transport the sludge in the sludge storage tank 40 to the sludge removal device 42; the sludge removal device 42 has a sludge temporary storage tank 43 and an impurity collection box 26, the sludge removal device 42 can separate sludge and impurities from the sludge mixed with impurities, and collect the separated sludge into the sludge temporary storage tank 43 and collect the separated impurities into the impurity collection box 26; the second screw conveyor 44 is used to transport the sludge in the sludge temporary storage box 43 to the slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com