Oil-containing sludge treatment complete equipment

A complete set of equipment and sludge treatment technology, applied in lighting and heating equipment, combustion methods, mold extrusion granulation, etc., can solve the problems of incomplete treatment and high difficulty in oily sludge treatment, and achieve thorough treatment and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

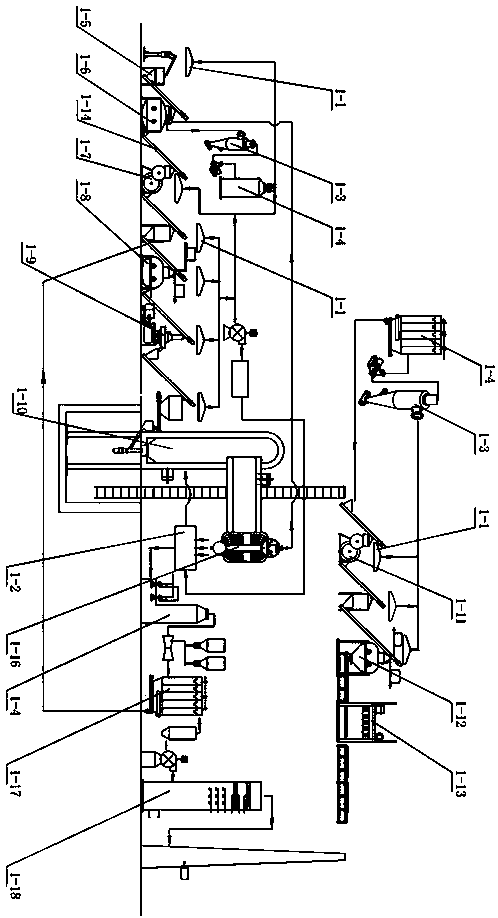

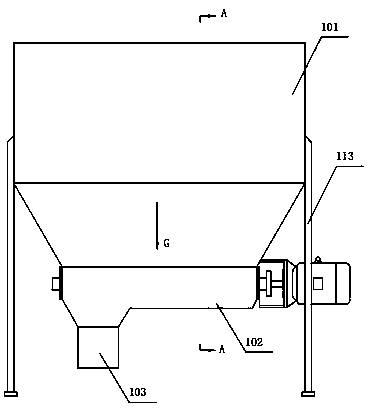

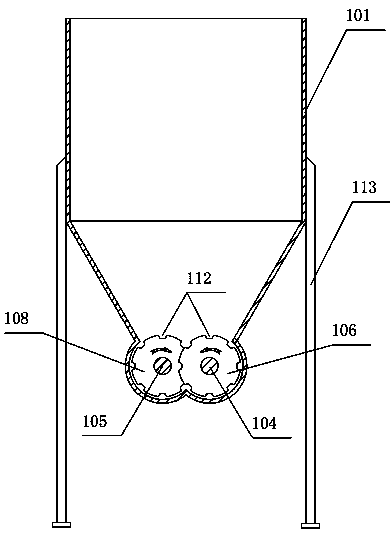

[0053] Reference attached figure 1 As shown, the present invention provides an embodiment of a complete set of oily sludge treatment equipment, which includes silos 1-5, dryers 1-6, pulverizers 1-7, mixers 1-8, Granulator 1-9, incinerator 1-10, ash pulverizer 1-11, ash mixer 1-12, ash brick making machine 1-13, the ash pulverizer can adopt the structure of the above pulverizer, the ash The slag mixer can adopt the structure of the mixer, that is, the pulverizer and the ash grinder have the same structure, and the mixer and the ash mixer have the same structure. Of course, the above-mentioned ash grinder and the ash mixer can adopt the pulverizer and the ash mixer in the prior art. Mixer, between the silo and the dryer, between the dryer and the pulverizer, between the pulverizer and the mixer, between the mixer and the granulator, and between the granulator and the incinerator are respectively equipped with airtight screw Feeder 1-14, the screw feeder includes a screw feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com