Waste water treatment process and treatment appts.

A wastewater treatment and treatment device technology, which is applied in natural water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of high cost of reactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

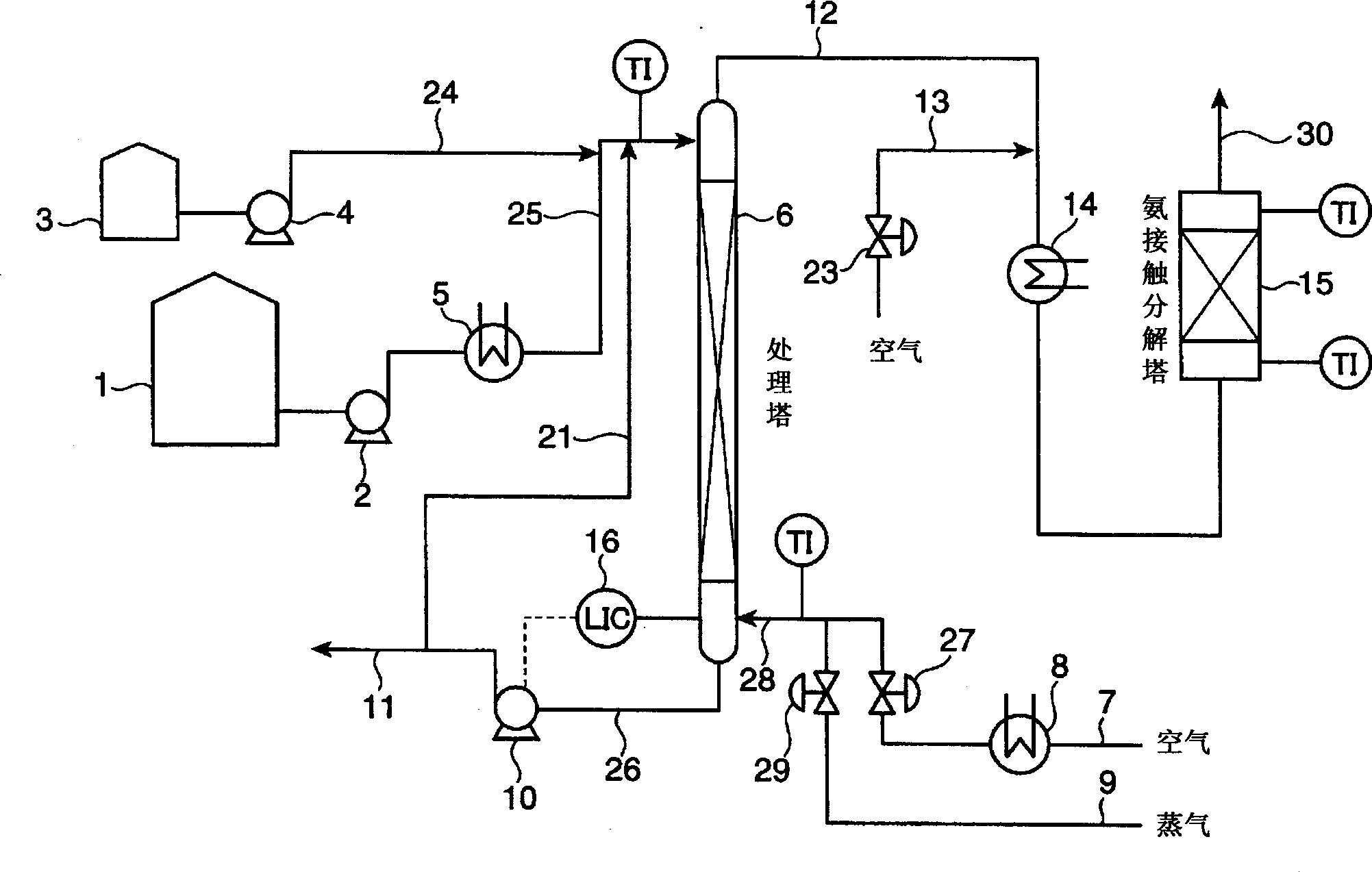

[0081] Prepare synthetic wastewater containing 10,000mg / L of ammonia nitrogen and 10,000mg / L of hydrogen peroxide, and use the wastewater figure 1 The waste liquid treatment device shown is used for treatment.

[0082] First, put the waste water into the waste water supply tank 1, raise the temperature of the waste liquid to 40° C. through the waste water heater 5 at a flow rate of 1 liter / hour by the pump 2, then add alkali, and introduce it from the upper part of the treatment tower 6. Regarding the addition of the above-mentioned alkali, the 25% by mass sodium hydroxide in the alkali storage tank 3 was introduced from the pipe 24 into the pipe 25 by the pump 4, and the above-mentioned waste water and the sodium hydroxide were mixed. Moreover, regarding the addition amount of alkali, the addition amount of the said 25 mass % sodium hydroxide was adjusted so that the concentration of the sodium hydroxide of the said mixed water may be 4,000 mg / L.

[0083] In the above-menti...

Embodiment 2

[0088] Prepare synthetic wastewater containing 5,000mg / L of ammonia nitrogen and 5,000mg / L of hydrogen peroxide, and use the wastewater figure 1 The waste liquid treatment device shown is used for treatment.

[0089] First, as in Example 1, the above-mentioned waste water is put into the waste water supply tank 1, and the waste liquid is raised to 80° C. through the waste water heater 5 at a flow rate of 1 liter / hour by the pump 2, and then alkali is added, and the waste liquid is discharged from the treatment tower. 6 upper supply. Regarding the addition of the above-mentioned alkali, the 25% by mass sodium hydroxide in the alkali storage tank 3 is introduced into the pipeline 25 by the pump 4, and then the above-mentioned waste water and the sodium hydroxide are mixed. Also, regarding the addition amount of alkali, different from Experimental Example 1, the addition amount of the above-mentioned 25% by mass sodium hydroxide was adjusted so that the concentration of sodium ...

Embodiment 3

[0095] Except not adding aqueous sodium hydroxide solution, others were processed as in the above-mentioned embodiment 1.

[0096] As a result, the hydrogen peroxide concentration in the treated water discharged from the pipeline 11 was 800 mg / L, the ammonia concentration (ammonia ion concentration in terms of nitrogen) was 45 mg / L, and the pH was 10.5.

[0097] Also, the ammonia concentration in the gas discharged from the pipeline 30 is 1 ppm (volume) or less, and the nitrogen oxide (NOx) concentration is 12 ppm (volume). Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com