Recovery treatment complete device for soft sheet materials

A technology of recycling and complete sets of equipment, which is applied in the direction of solid waste removal, solid separation, and separation of solids from solids with airflow, which can solve problems such as high labor costs, secondary pollution, and large floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

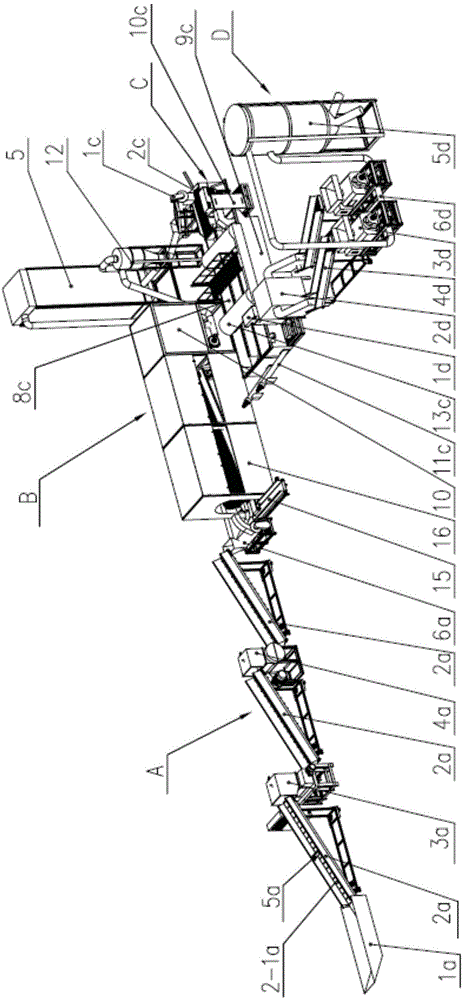

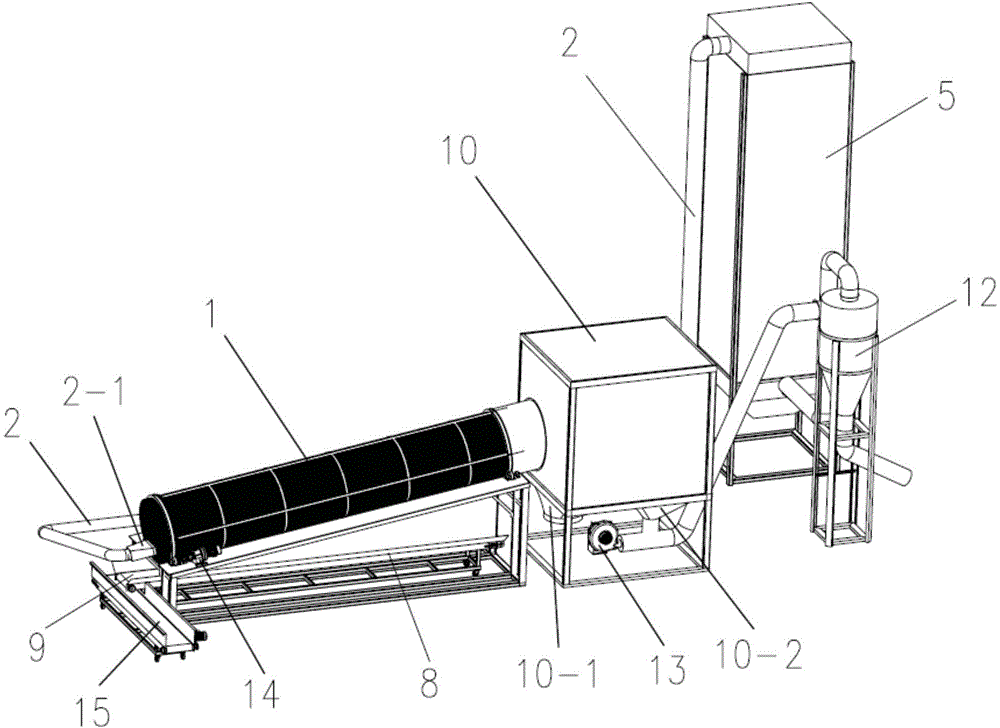

[0056] See figure 1 , The complete set of equipment for the recovery and treatment of soft flake materials of the present invention is mainly formed by connecting the crushing part A, the impurity separation part B, the cleaning part C and the dehydration briquetting part D in sequence.

[0057] See figure 1 The crushing part A mainly includes a feeding hopper 1a, a shredder 3a, a crusher 4a and a sanding machine 6a arranged in sequence, and each part is connected by a material conveying mechanism 2a. The feeding hopper 1a is used for feeding materials to be processed. The material conveying mechanism 2a is mainly composed of a conveyor belt 2-1a, a power mechanism and a material guide groove. The conveyor belt 2-1a is arranged with a material shifting plate perpendicular to the belt surface for shifting animal materials forward. In order to remove metal impurities in the material, a magnet 5a is installed above the conveyor belt 2-1a between the feeding hopper 1a and the shredde...

Embodiment 2

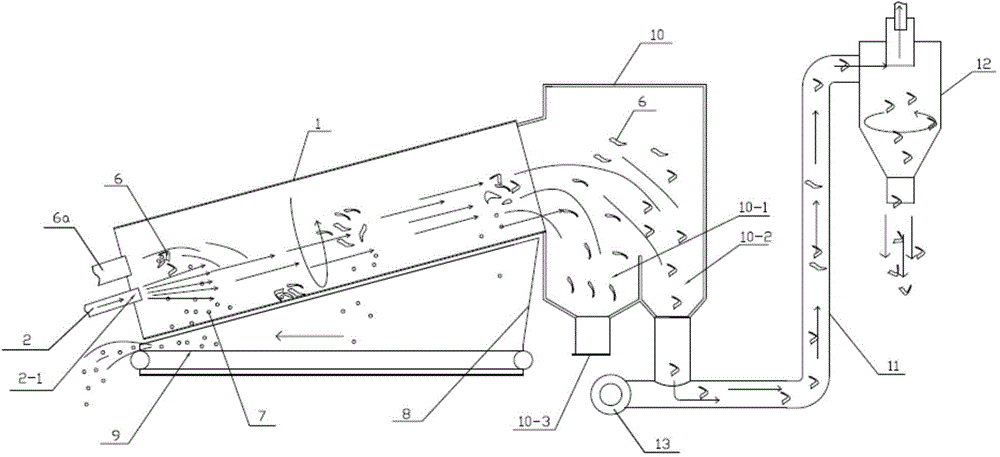

[0075] See Picture 9 with Picture 10 The difference between this embodiment and Embodiment 1 is that in this embodiment, a pulse air flow device 3 is provided above the upper part of the separation cylinder 1, and the pulse air flow device 3 includes an air compressor, a compressed air storage tank, The pulse air supply pipe, the pulse valve and the pulse air distribution pipe. The pulse air distribution pipe is provided with a tuyere 3-3, which is arranged directly to the separation cylinder 1; the air compressor and the compressor The air storage tank delivers high-pressure air flow to the pulse air distribution pipe through the pulse air supply pipe. The pulse valve is arranged at the tuyere 3-3, and the pulse air flow is obtained through the on and off of the pulse valve. The effect of using the above-mentioned pulse air flow device 3 is: 1. Prevent the sieve hole from being blocked. During the working process, the separated impurities 7 and the unseparated soft flakes 6 ...

Embodiment 3

[0079] See 11~ Figure 13 In this embodiment, a hanging chain 4 is provided in the inner wall of the separation cylinder 1 to replace the pulse air flow device 3 in the second embodiment to prevent the sieve from being blocked and improve the separation effect. The hanging chains 4 arranged on the inner wall of the separating cylinder 1 are in multiple groups. The hanging chains 4 are metal chains. The multiple groups of hanging chains 4 are distributed along the axis of the separating cylinder 1. Each group of hanging chains 4 includes Multiple hanging chains 4 distributed in the circumferential direction. The working principle is: when the separation drum 1 is in a static state, the hanging chain 4 at the upper part of the separation drum 1 naturally sags, and the hanging chain 4 at the bottom of the separation drum 1 lies on the separation drum 1; the separation drum 1 continuously When the separation drum 1 rotates one round, the working process of each hanging chain 4 is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com