Tea-flavor type noodles and preparation method thereof

A noodle and aroma technology, applied in the fields of food science, food ingredients, application, etc., can solve the problems of affecting the uniformity and taste of noodles, low, generally not higher than 2%, high-cost tea addition, etc. The risk of being oxidized, the effect of facilitating extraction and avoiding sedimentation and accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

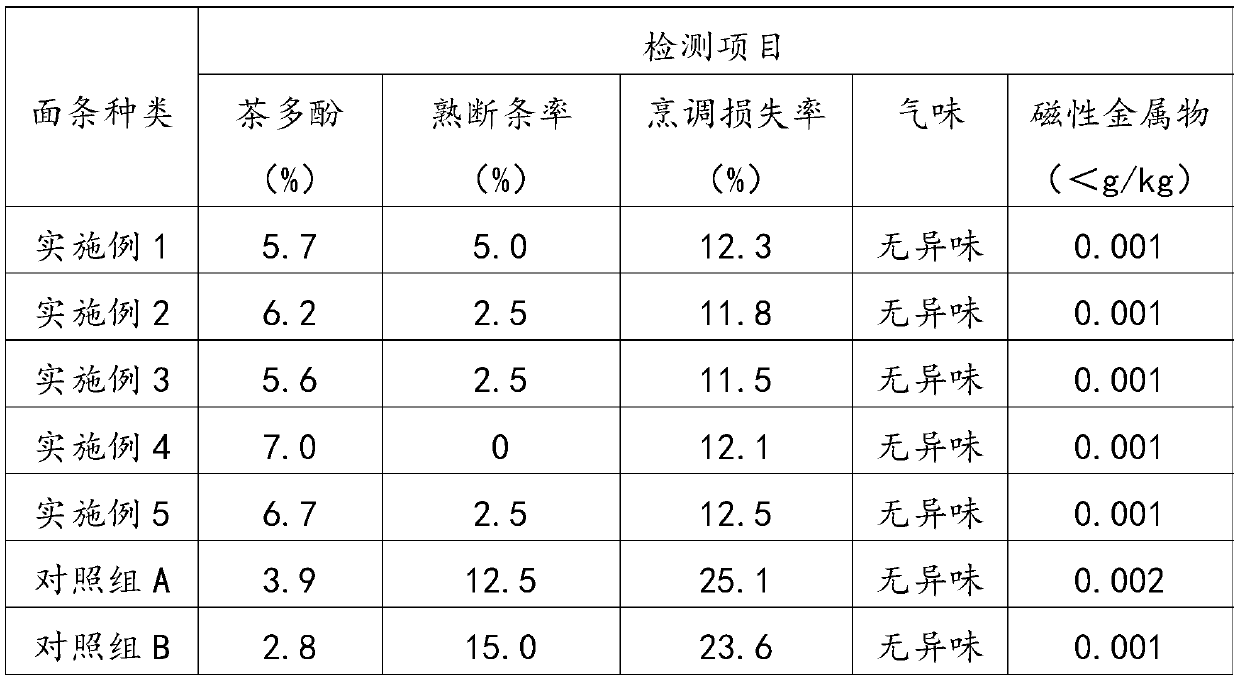

Examples

Embodiment 1

[0022] A tea-flavored noodle, wherein the raw materials are in parts by weight: 100 parts of flour, 20 parts of starch, 8 parts of tea dregs, 3 parts of edible salt, 3 parts of compounding agent and 2 parts of yeast.

[0023] A kind of tea-flavored noodles, its preparation method comprises the steps:

[0024] S1: Pick and weigh the fresh tea dregs remaining after the tea leaves have been extracted by water, after centrifugal dehydration, put them into the drying box for air-drying and dehydration treatment;

[0025] S2: Put the above-mentioned dried tea dregs into a grinder and process them into 55-mesh particles by crushing and grinding, and add the obtained raw material powder into an ethanol solution with a weight ratio of 5 times and a content of 12% to mix evenly, and then Under the conditions of 0.5MPa and 75°C, high-pressure extraction is carried out, and CO is passed into the ethanol solution at a rate of 8L / min during the extraction process. 2 , after 60 minutes of e...

Embodiment 2

[0035] A tea-flavored noodle, wherein the raw materials are in parts by weight: 90 parts of flour, 15 parts of starch, 8 parts of tea dregs, 3 parts of edible salt, 2 parts of compounding agent and 2 parts of yeast.

[0036] A kind of tea-flavored noodles, its preparation method comprises the steps:

[0037] S1: Pick and weigh the fresh tea dregs remaining after the tea leaves have been extracted by water, after centrifugal dehydration, put them into the drying box for air-drying and dehydration treatment;

[0038] S2: put the above-mentioned dried tea residue into a grinder and process it into 50-mesh particles by crushing and grinding, and add the obtained raw material powder into an ethanol solution with a weight ratio of 5 times and a content of 12% to mix evenly, and then Under the conditions of 0.6MPa and 76°C, high-pressure extraction is carried out, and CO is passed into the ethanol solution at a rate of 9L / min during the extraction process. 2 After extracting for 70 ...

Embodiment 3

[0048] A tea-flavored noodle, wherein the raw materials are in parts by weight: 100 parts of flour, 15 parts of starch, 8 parts of tea dregs, 2 parts of edible salt, 3 parts of compounding agent and 1 part of yeast.

[0049] A kind of tea-flavored noodles, its preparation method comprises the steps:

[0050]S1: Pick and weigh the fresh tea dregs remaining after the tea leaves have been extracted by water, after centrifugal dehydration, put them into the drying box for air-drying and dehydration treatment;

[0051] S2: put the above-mentioned dried tea dregs into a grinder and process them into 60-mesh particles by crushing and grinding, and add the obtained raw material powder into an ethanol solution with a weight ratio of 5 times and a content of 12% to mix evenly, and then Under the conditions of 0.7MPa and 77°C, high-pressure extraction is carried out, and CO is passed into the ethanol solution at a rate of 10L / min during the extraction process. 2 After extracting for 80 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com