Patents

Literature

92results about How to "Reduce the risk of oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

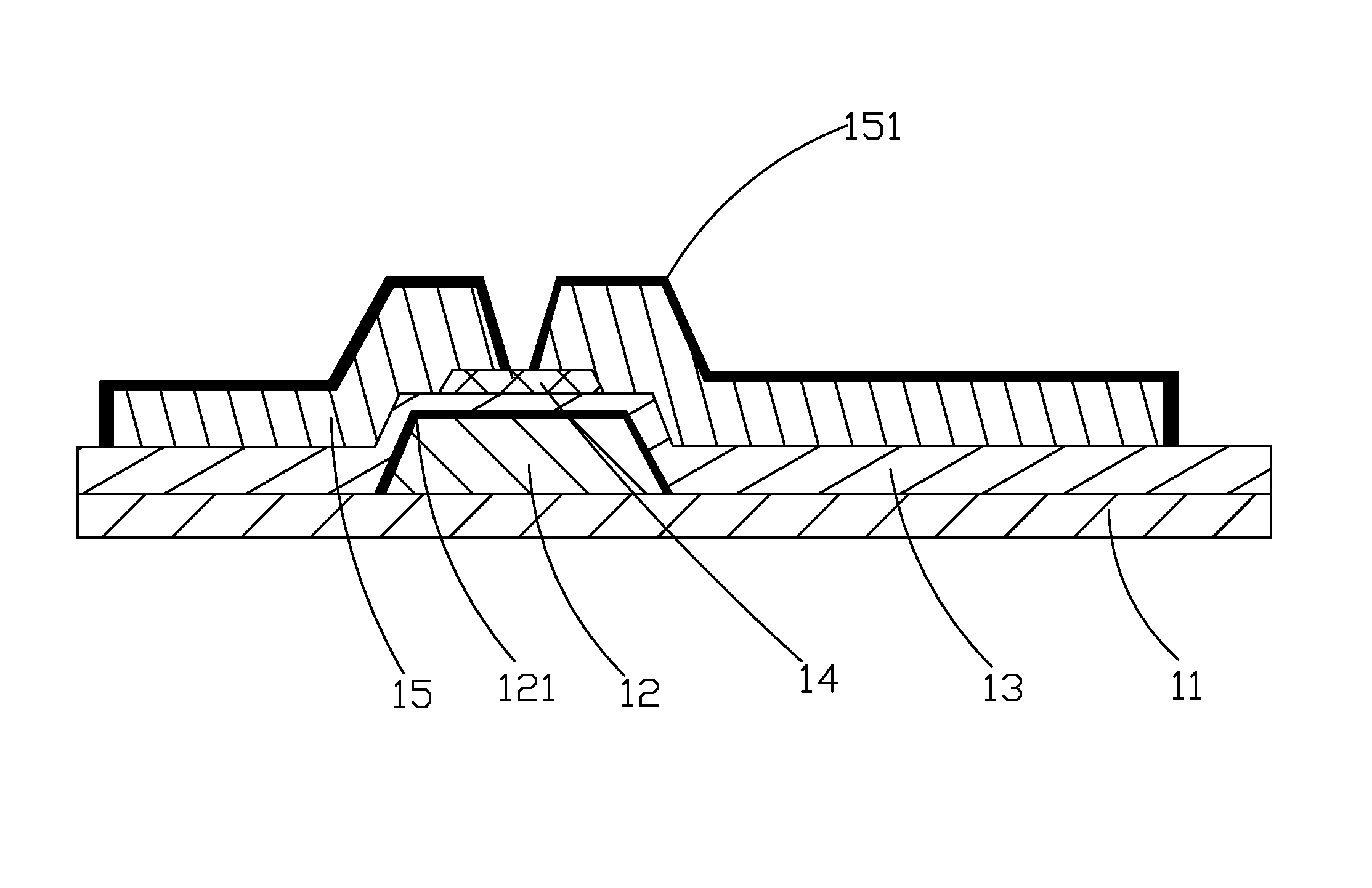

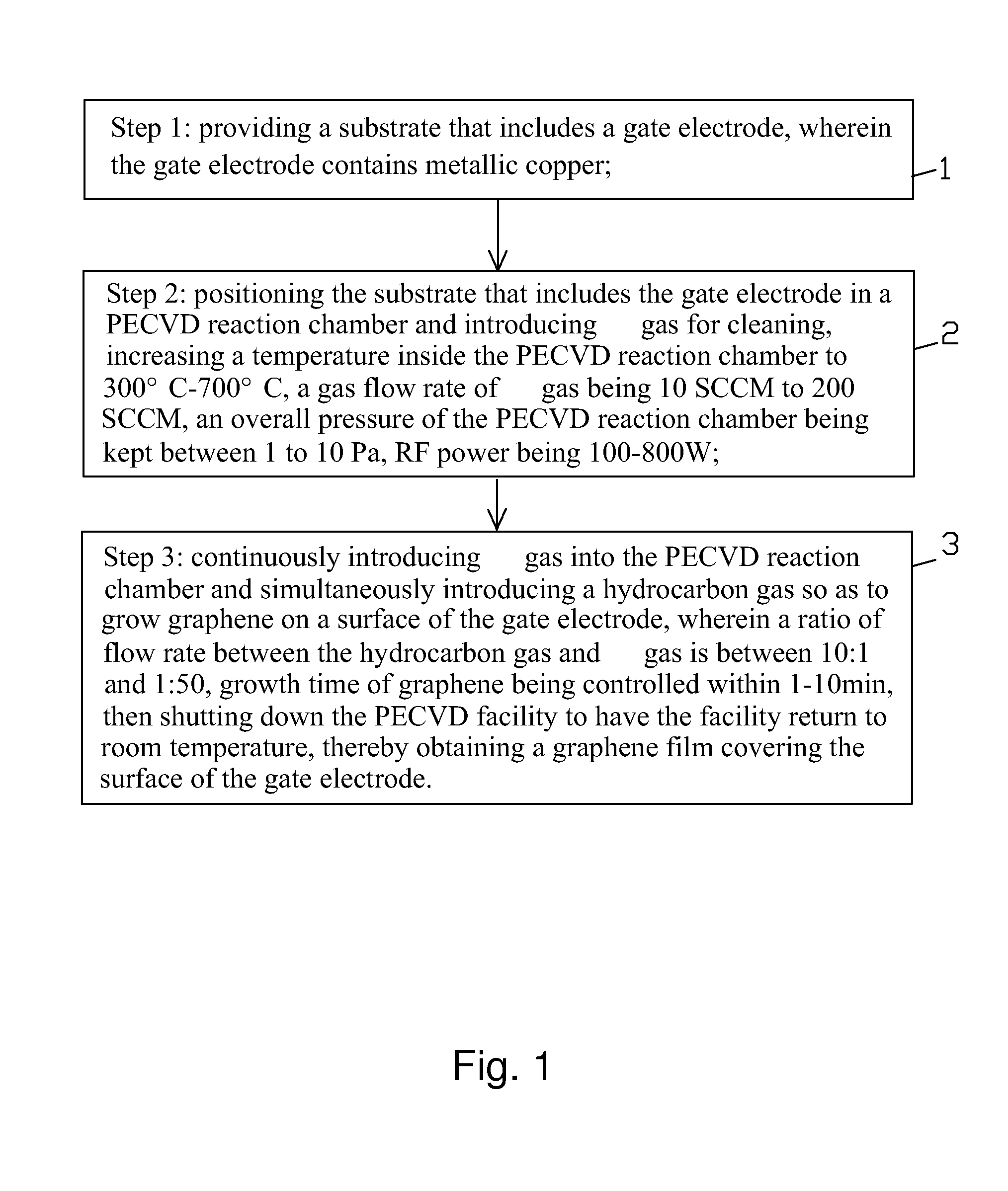

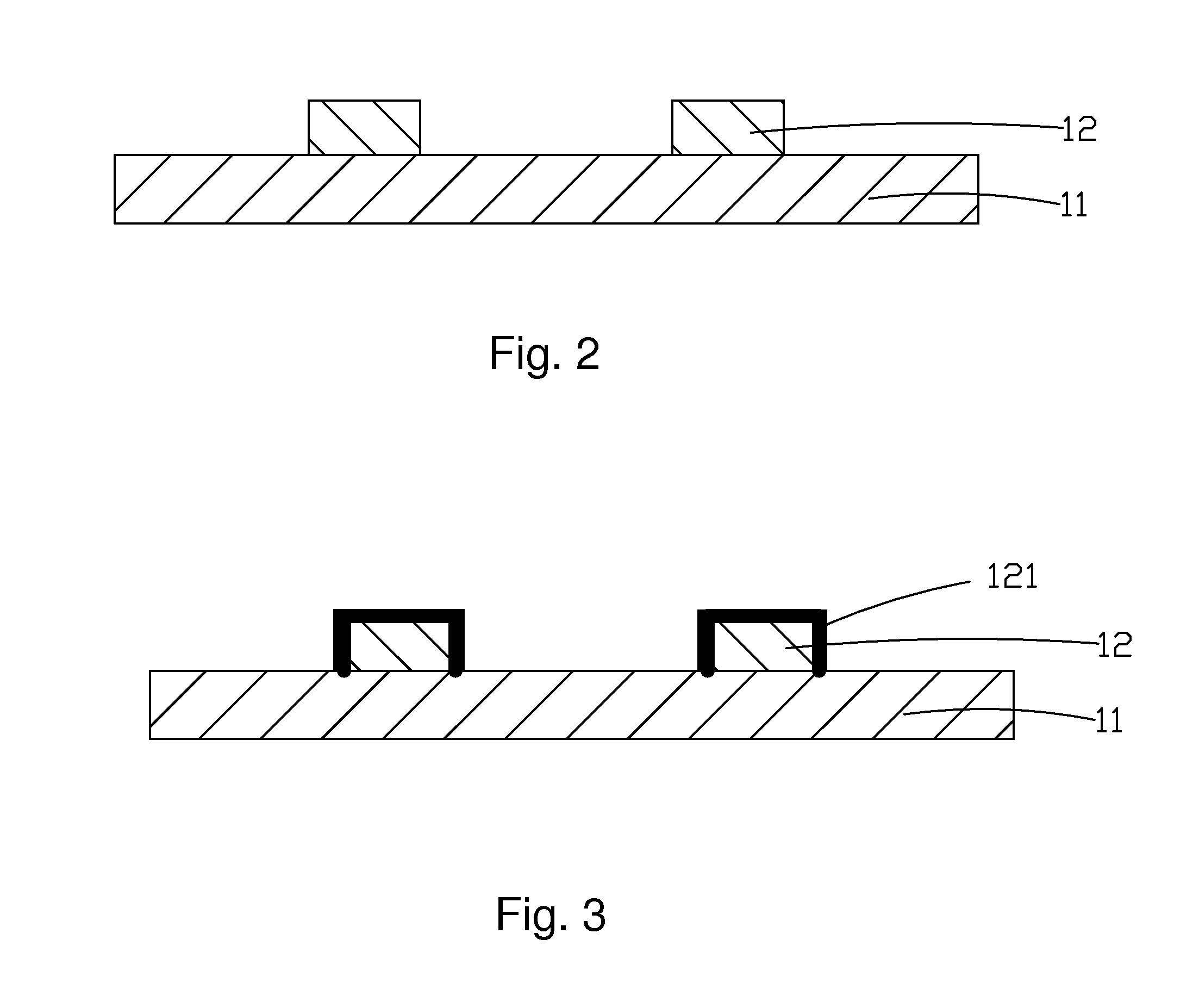

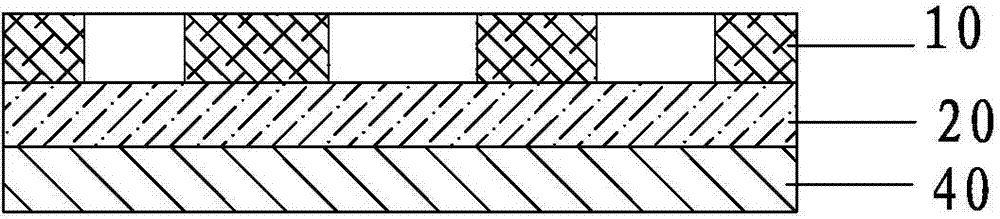

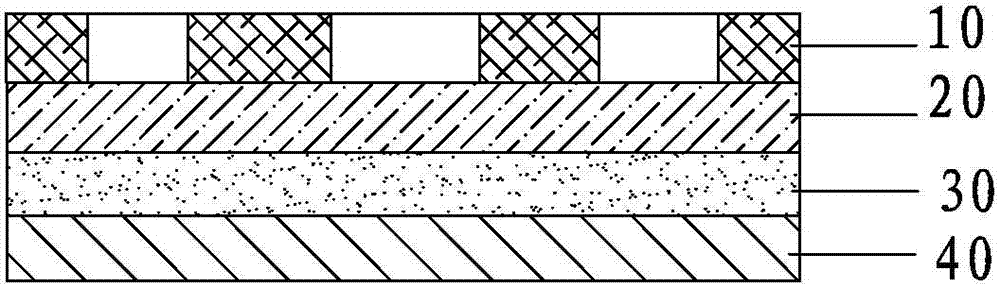

Method for growing graphene on surface of gate electrode and method for growing graphene on surface of source/drain surface

ActiveUS9543156B1Deposition process is enhancedLow costSemiconductor/solid-state device manufacturingSemiconductor devicesManufacturing technologyGas phase

The present invention provides a method for growing graphene on a surface of a gate electrode and a method for growing graphene on a surface of a source / drain electrode, in which a low-temperature plasma enhanced vapor deposition process is adopted to grow a graphene film, of which a film thickness is controllable, on a gate electrode or a source / drain electrode that contains copper, and completely coincides with a pattern of the gate electrode or the source / drain electrode. The manufacturing temperature of graphene is relatively low so that it is possible not to damage the structure of a thin-film transistor to the greatest extents and the supply of carbon sources that is used wide, having low cost and a simple manufacturing process, where existing PECVD facility of a thin-film transistor manufacturing line can be used without additional expense. The gate electrode or the source / drain electrode is covered with graphene and is prevented from contact with moisture and oxygen thereby overcoming the problem of a conventional TFT manufacturing process that a gate electrode or a source / drain electrode that contains copper is readily susceptible to oxidization. Further, the high electrical conductivity of graphene makes it possible not to affect the electrical performance of the entire device.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

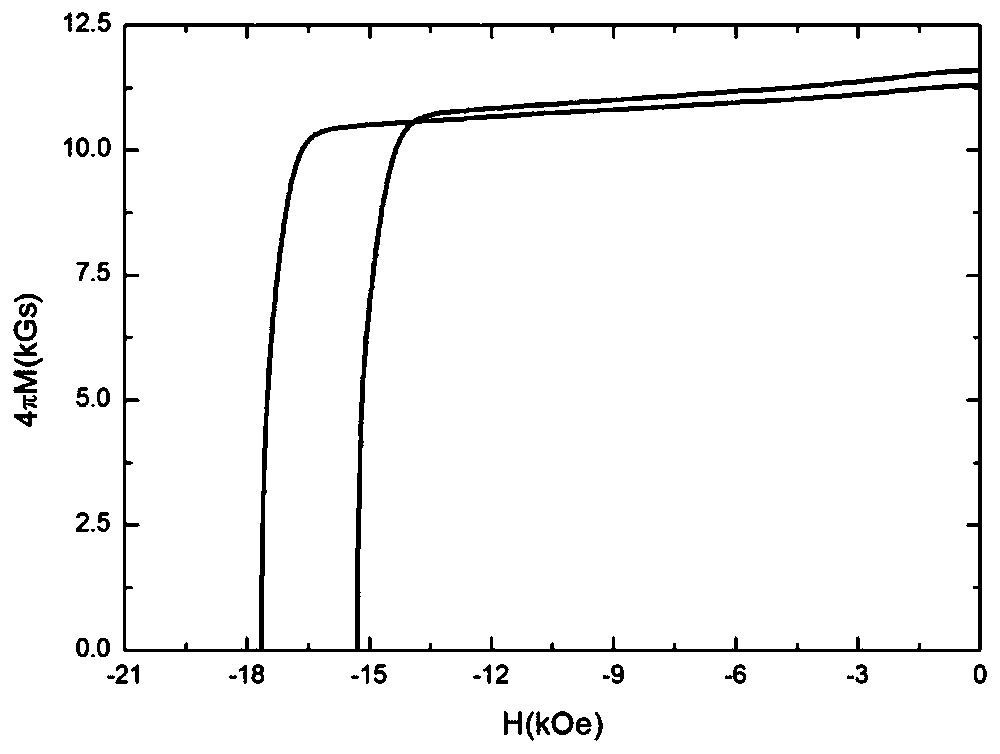

Cerium-containing magnet with high coercivity and preparation method thereof

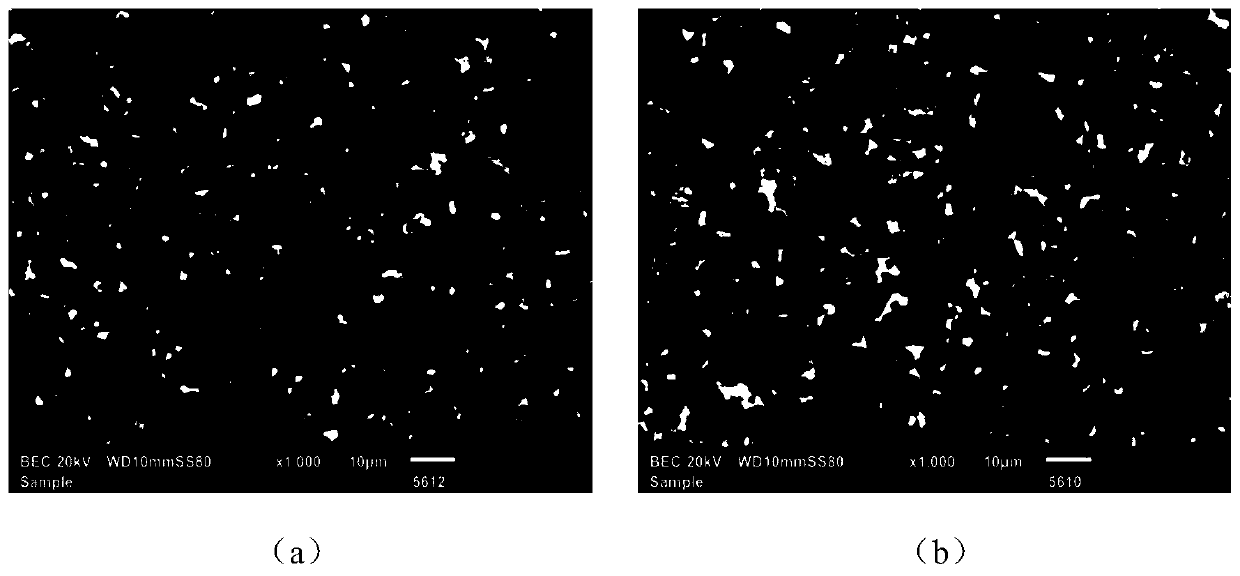

ActiveCN110853856AReduce the risk of oxidationSimplify the manufacturing processInductances/transformers/magnets manufactureMagnetic materialsCeriumAlloy

The invention discloses a preparation method of a cerium-containing magnet with high coercivity. The method comprises steps that raw materials of the Ce-containing main alloy are blended; raw materials of the grain boundary optimization auxiliary alloy are blended; the raw materials of the Ce-containing main alloy and the raw materials of the grain boundary optimization auxiliary alloy are subjected to vacuum smelting and rapid hardening melt-spinning treatment correspondingly, and a Ce-containing main alloy rapid hardening sheet and a boundary optimization auxiliary alloy rapid hardening sheet are obtained; the Ce-containing main alloy rapid hardening sheet and the grain boundary optimization auxiliary alloy rapid hardening sheet are mixed according to a weight ratio of 1:x, then hydrogendecrepitation treatment and jet milling treatment are performed to obtain mixed powder, lubricating agent is added into the mixed powder and mixed to obtain mixture; magnetic field orientation compression of the mixture is performed, and isostatic cool pressing is performed to obtain a green body; sintering of the green body is performed, and then tempering heat treatment is performed to obtain acerium-containing magnet. The method is advantaged in that the preparation process is effectively simplified, and the risk that the auxiliary alloy is oxidized can be effectively reduced.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

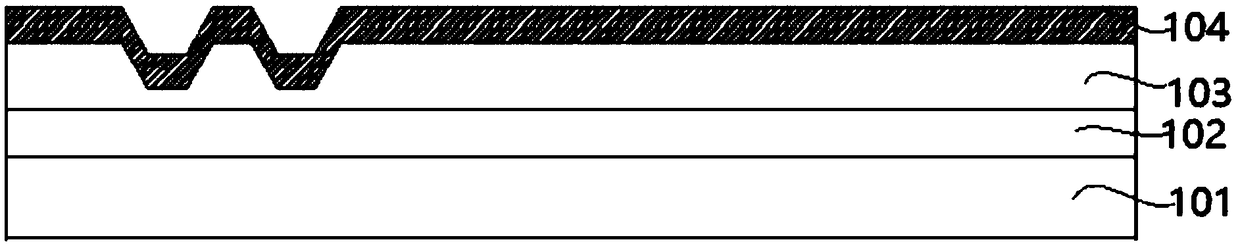

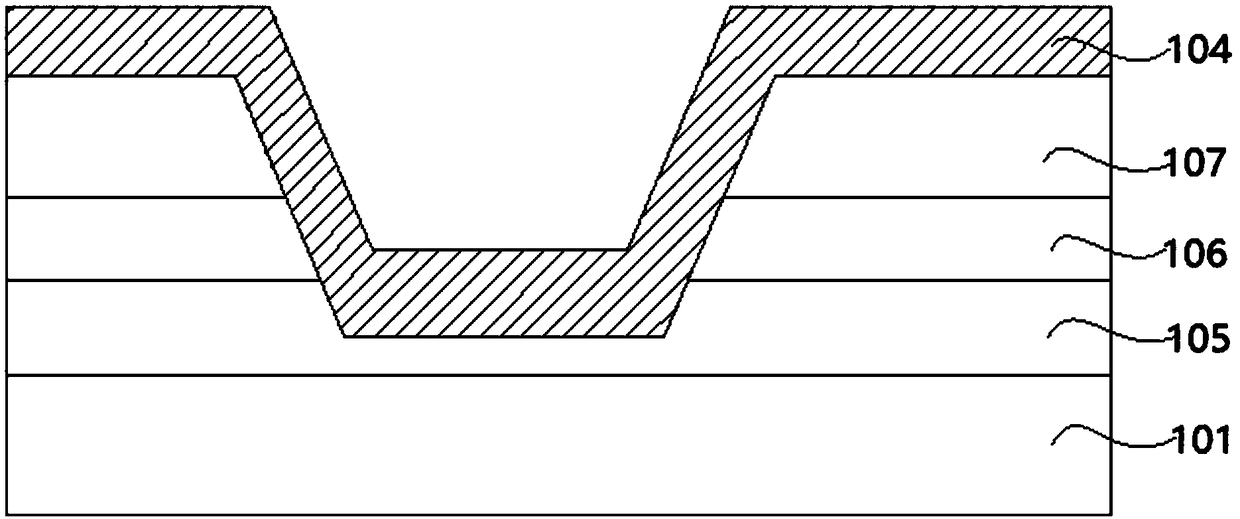

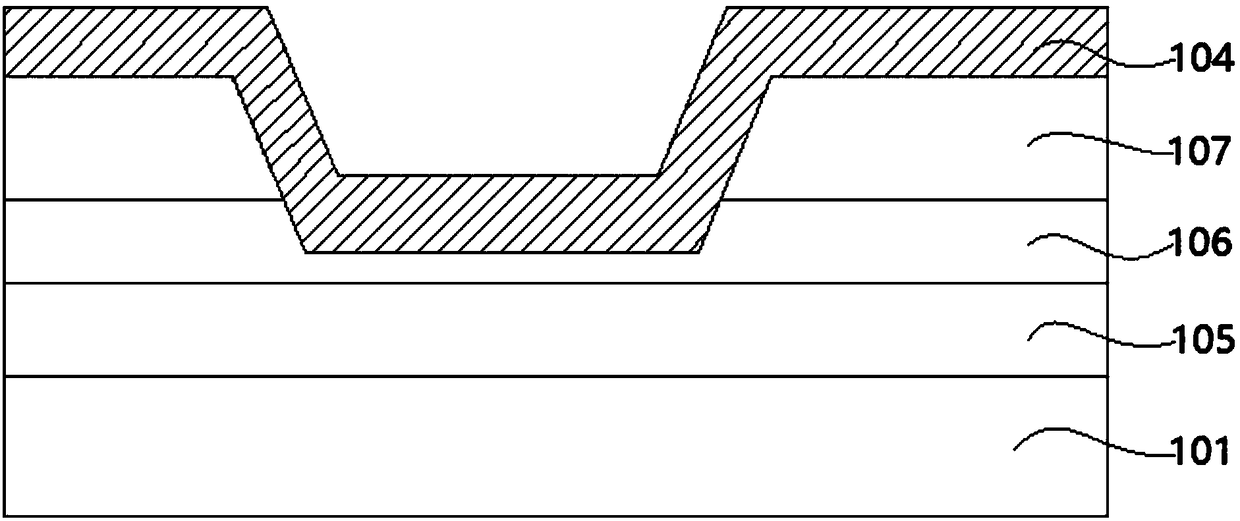

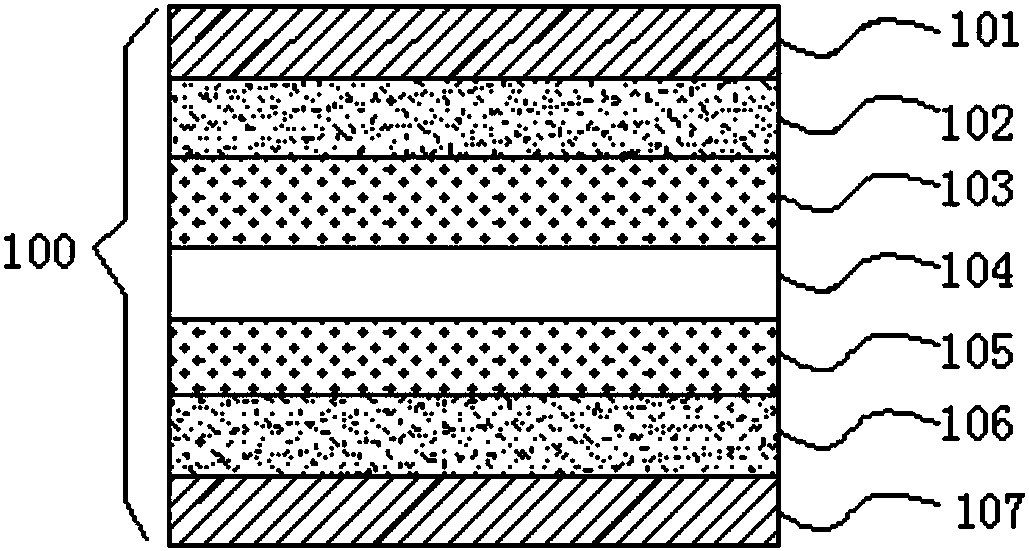

OLED display device

ActiveCN109065552AIncrease the difficulty of infiltrationImprove the ability to isolate water and oxygenSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The invention provides an OLED display device, comprising a flexible substrate, wherein the flexible substrate comprises a display region and a non-display region located at one end of the display region; A TFT layer and an OLED light emitting lay are arranged on the flexible substrate, and a part of the TFT layer located in the non-display region is provided with at least two grooves; An encapsulating film layer including a first inorganic layer, an organic layer, and a second inorganic layer which are overlapped, the first inorganic layer and the second inorganic layer extending from the display region to a non-display region, and the first inorganic layer and the second inorganic layer cover the trench.: An OLED display device according to the present invention has beneficial effects that At least two grooves are etched on the TFT layer in the non-display region, which makes water and oxygen permeation more difficult, thereby enhancing the ability of the encapsulation film layer toisolate water and oxygen, reducing the risk of the devices inside the OLED display device being oxidized, and at the same time, relieving the substrate crack propagation stress.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

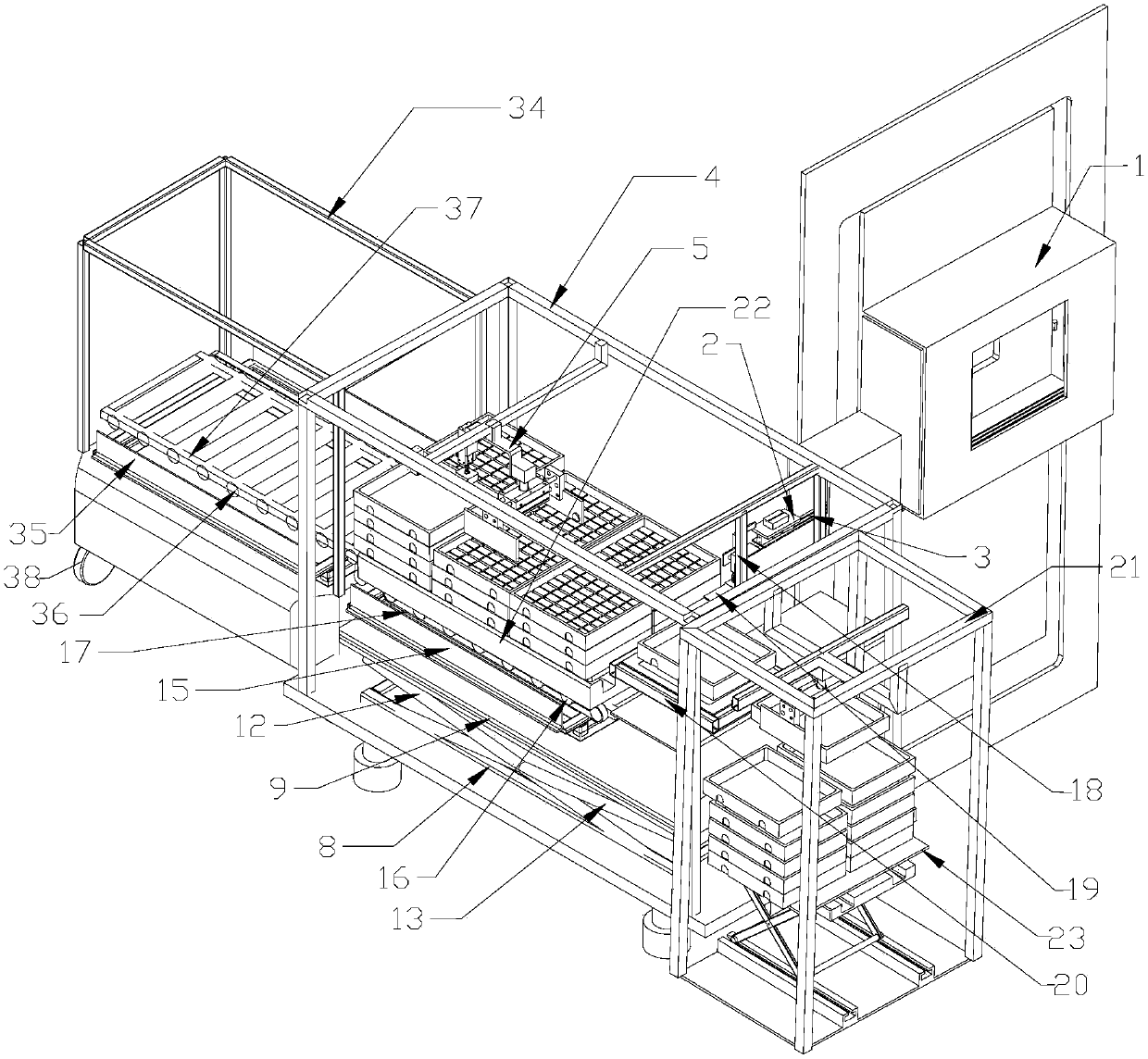

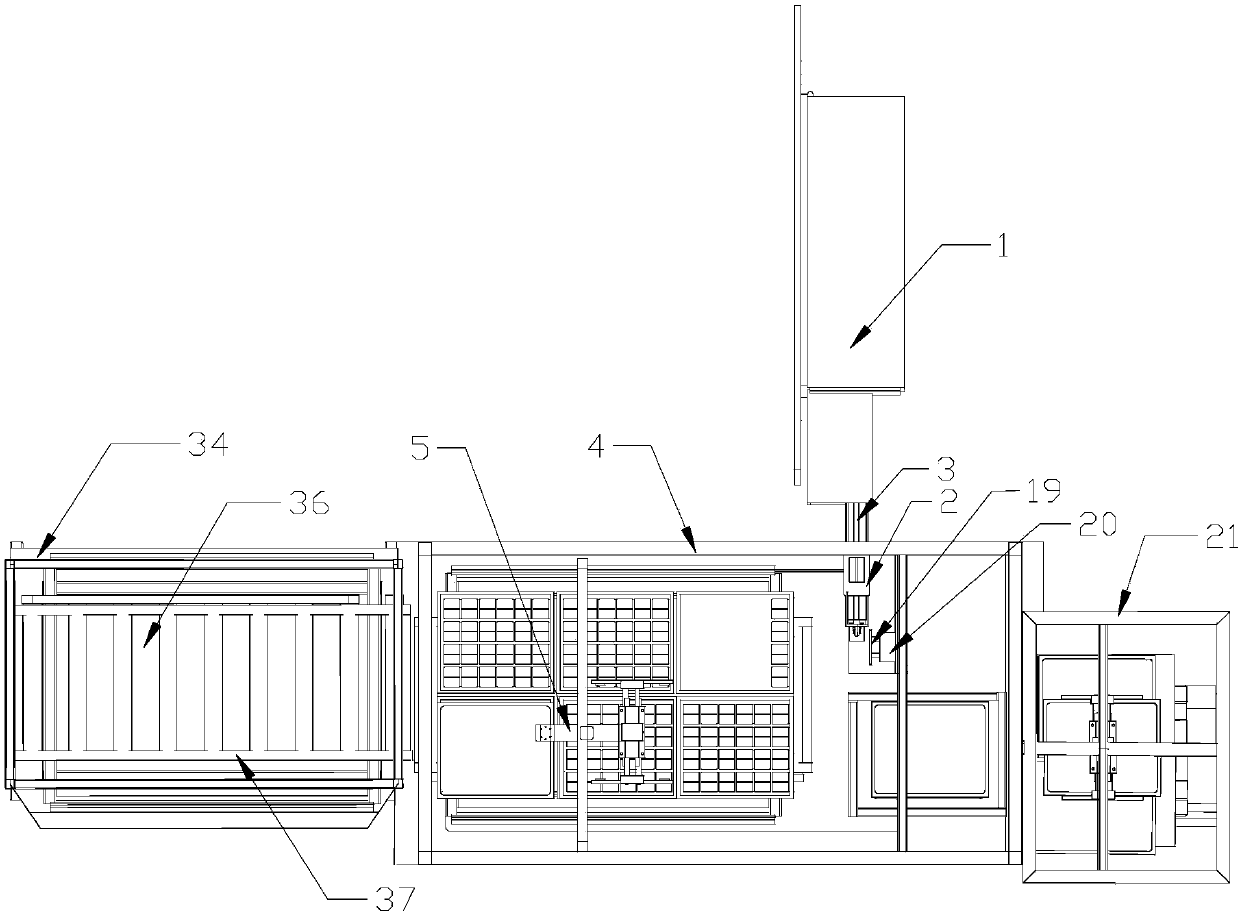

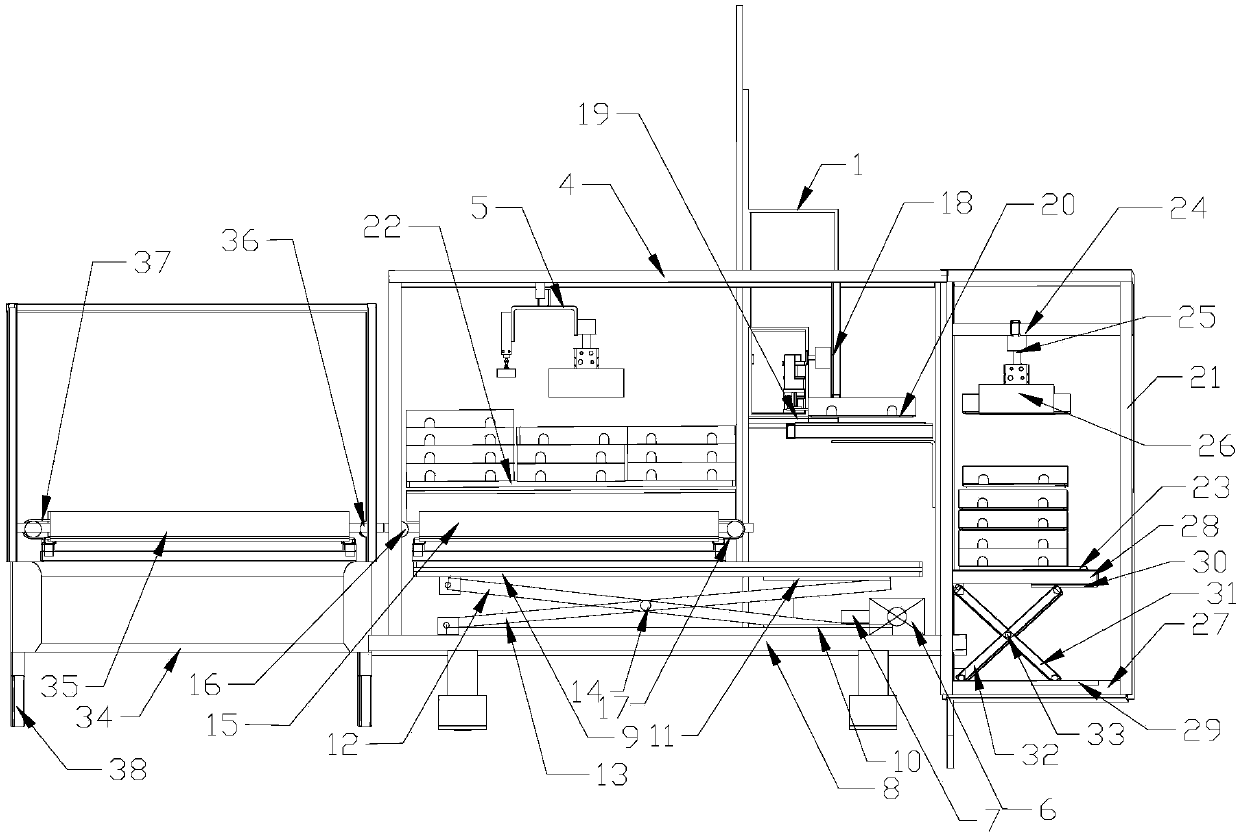

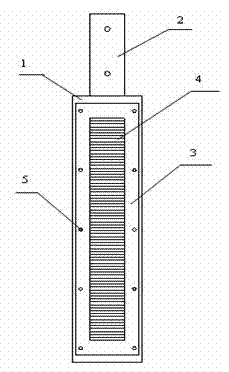

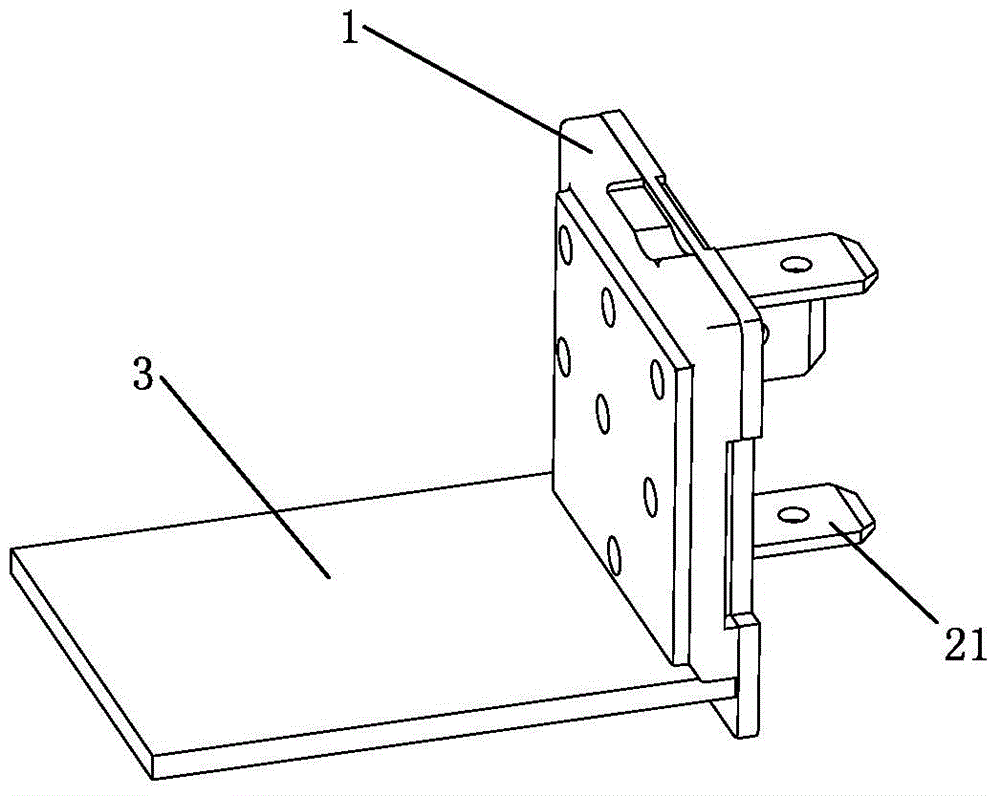

Material stacking and transferring system for sintered Nd-Fe-B formed blanks

ActiveCN107857129AReduce the number of handlingReduce weightStacking articlesStorage devicesMetallurgyMaterials science

The invention discloses a material stacking and transferring system for sintered Nd-Fe-B formed blanks. The material stacking and transferring system comprises a controller, a feeding device, a material and pot stacking device, a pot storage device and a transferring trolley. The feeding device is used for conveying the sintered Nd-Fe-B formed blanks output by a forming press into the material andpot stacking device, the pot storage device is used for storing to-be-used sintering pots, and the material and pot stacking device is used for transferring the sintering pots in the pot storage device into the material and pot stacking device, then arranging the sintering pots in sequence, stacking the sintered Nd-Fe-B formed blanks into the sintering pots in sequence and conveying the sinteringpots in which the sintered Nd-Fe-B formed blanks are stacked into the feeding trolley, and the feeding trolley is used for receiving the sintering pots in which the sintered Nd-Fe-B formed blanks arestacked and conveying the sintering pots to the position of a sintering furnace. The material stacking and transferring system has the beneficial effects that the oxidization risks are small, the transferring efficiency is high, the labor intensity is low, the labor cost is low, meanwhile, the transferring damage rate can be reduced, material waste is avoided, and environment pollution is reduced.

Owner:NINGBO YUNSHENG +2

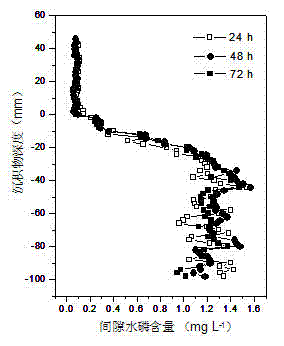

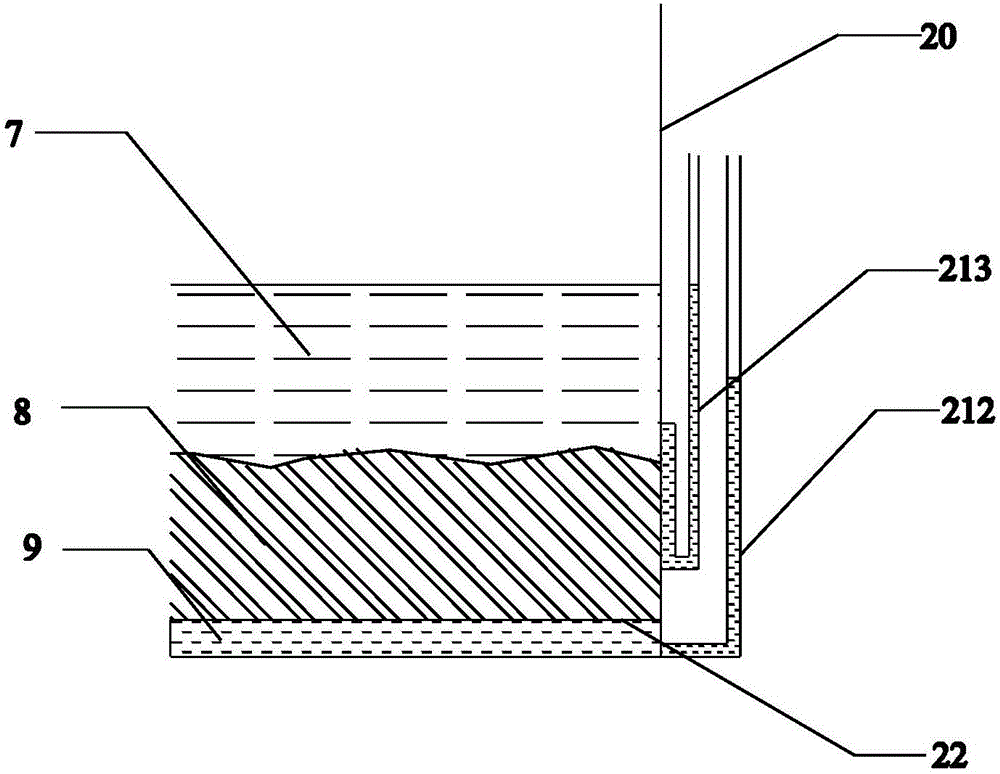

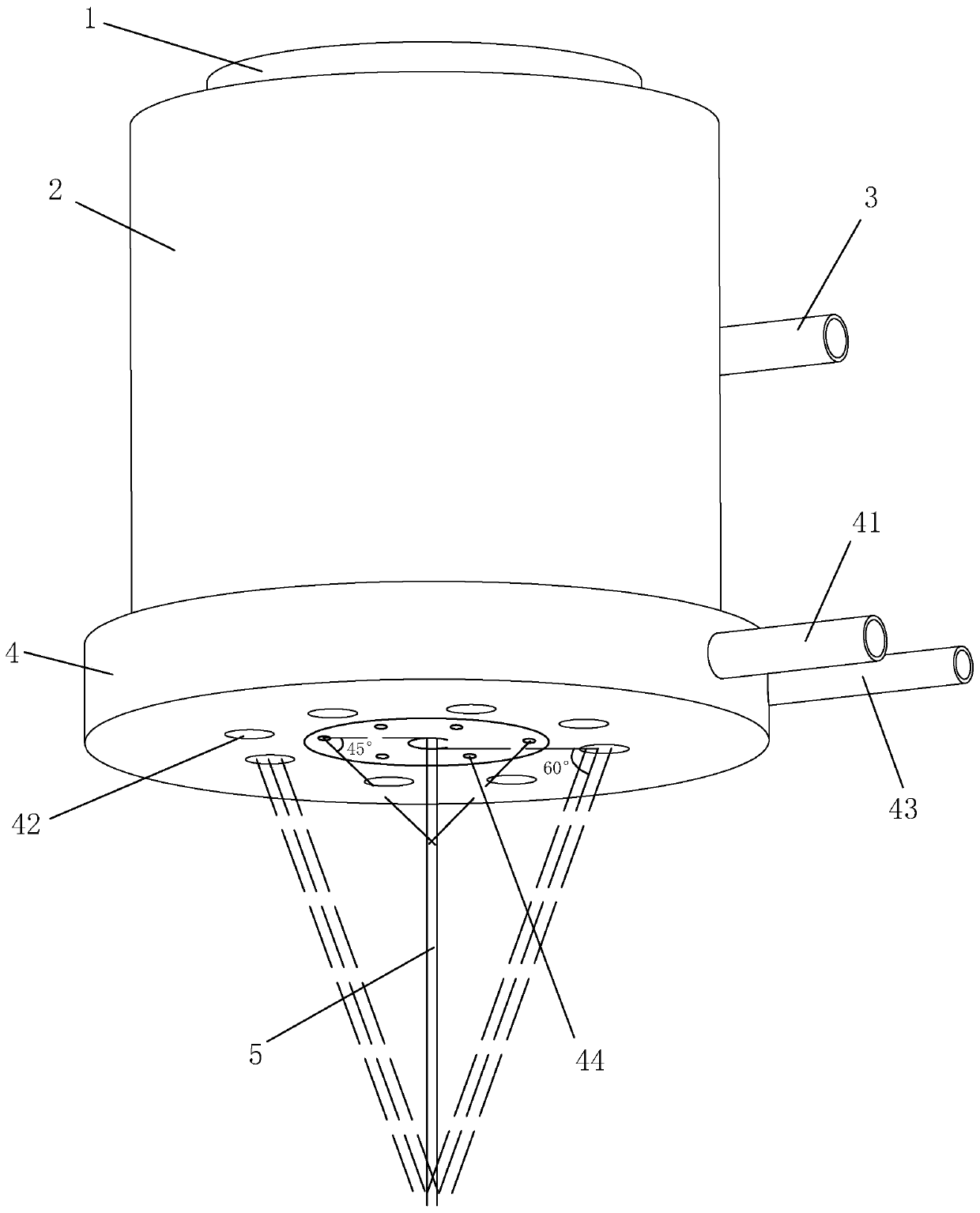

Device and method for acquiring and storing sediment pore water sample

ActiveCN102507262AIncrease vertical resolutionReduce the risk of oxidationWithdrawing sample devicesPreparing sample for investigationIonMembrane configuration

A device for acquiring and storing a sediment pore water sample comprises a main body and sampling grid chambers, wherein a group of horizontal grooves are distributed on the main body in a grid manner, a 0.45mum aperture permeation membrane is covered on the surface of the main body, the periphery of the permeation membrane is fixed by a frame on the main body, and the grooves are filled with water to form the sampling grid chambers with a length 10-30mm, a width 1mm, a volume 10-30muL and an interval 1.0mm. The device is vertically inserted into sediment and taken out when ion diffusion is balanced, and the pore water sample in the sampling grid chamber is cooled into ice and freezing-stored under the air isolation condition. After the device is taken out, defreezing is carried out at room temperature under the air isolation condition, and the permeation membrane is pierced to get the pore water sample sucked out from the sampling grid chamber for analysis. The inventive device and method have pore water collection vertical resolution 2mm and balance time 1-3 days in sediment, and the pore water sample can be stored in the device for at least three months.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

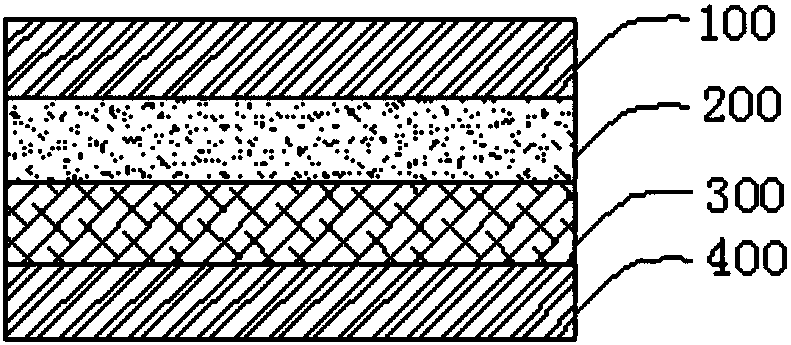

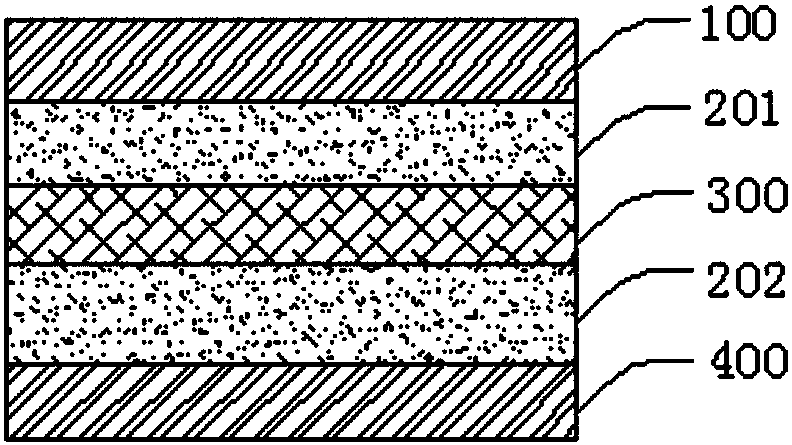

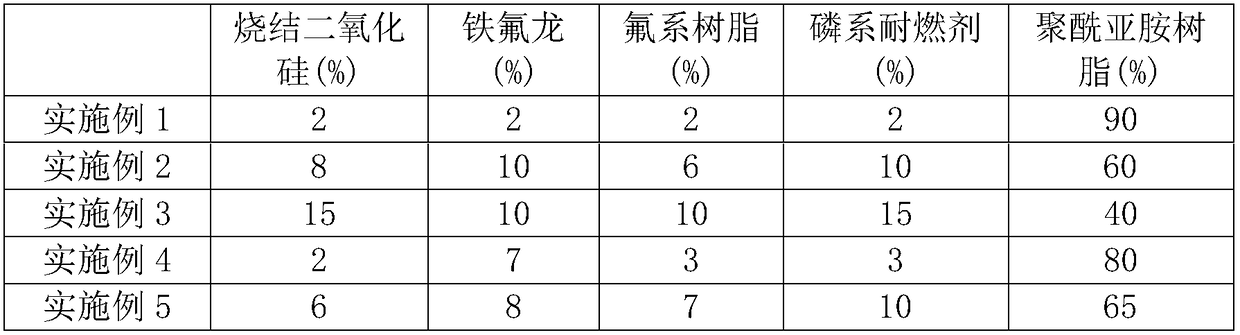

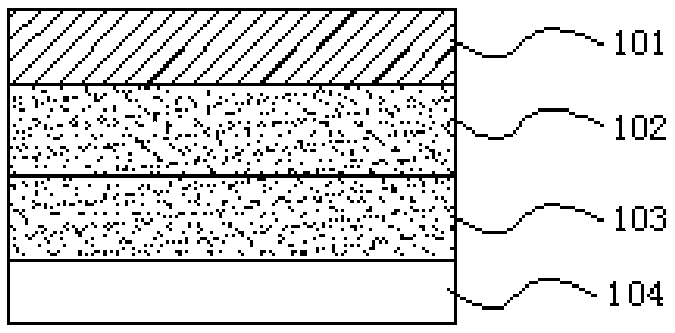

Covering film for flexible copper-clad plate, and single/double flexible copper-clad plate utilizing covering film

InactiveCN103612457AReduce thicknessReduce the risk of oxidationSynthetic resin layered productsMetal layered productsElectricityDielectric

The invention relates to the technical field of a copper-clad plate, and in particular provides a covering film for a flexible copper-clad plate and a single / double flexible copper-clad plate utilizing the covering film. The covering film or the flexible copper-clad plate comprises a low-dielectric insulation base film layer of which the Dk is 2.0-3.0 and the Df is 0.001-0.015 and a low-dielectric insulation adhesive layer of which the Dk is 2.3-3.0 and the Df is 0.001-0.015; the covering film not only has high flexibility, low thickness and low Dk / Df but also has the press temperature being lower than 220 DEG C; a flexible circuit board prepared from the covering film has high-frequency and high-speed characteristics at the same time; the covering film is widely used for the fields of 3G / 4G smart phones, interphones, radar, base stations and the like.

Owner:GUANGDONG SHENGYI SCI TECH

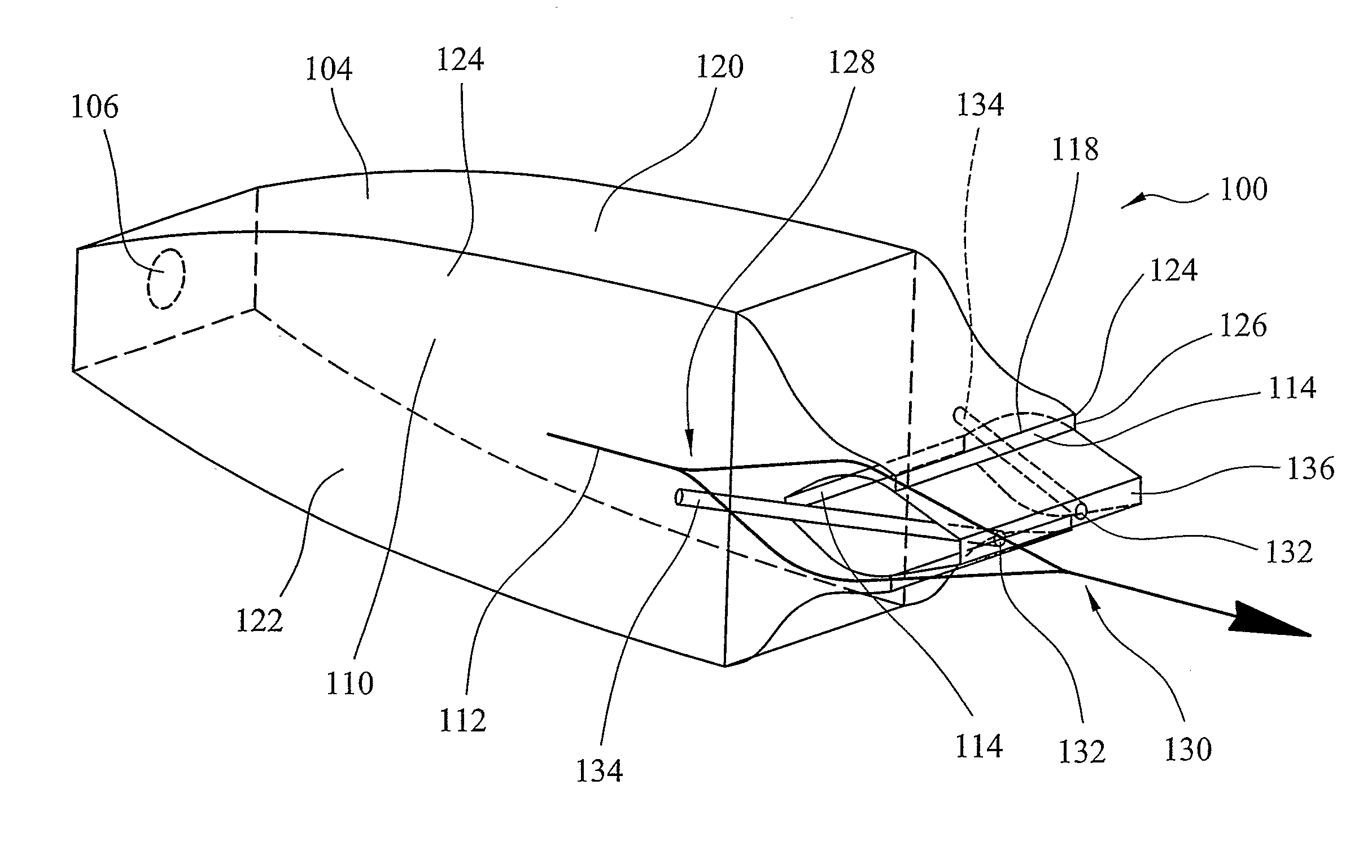

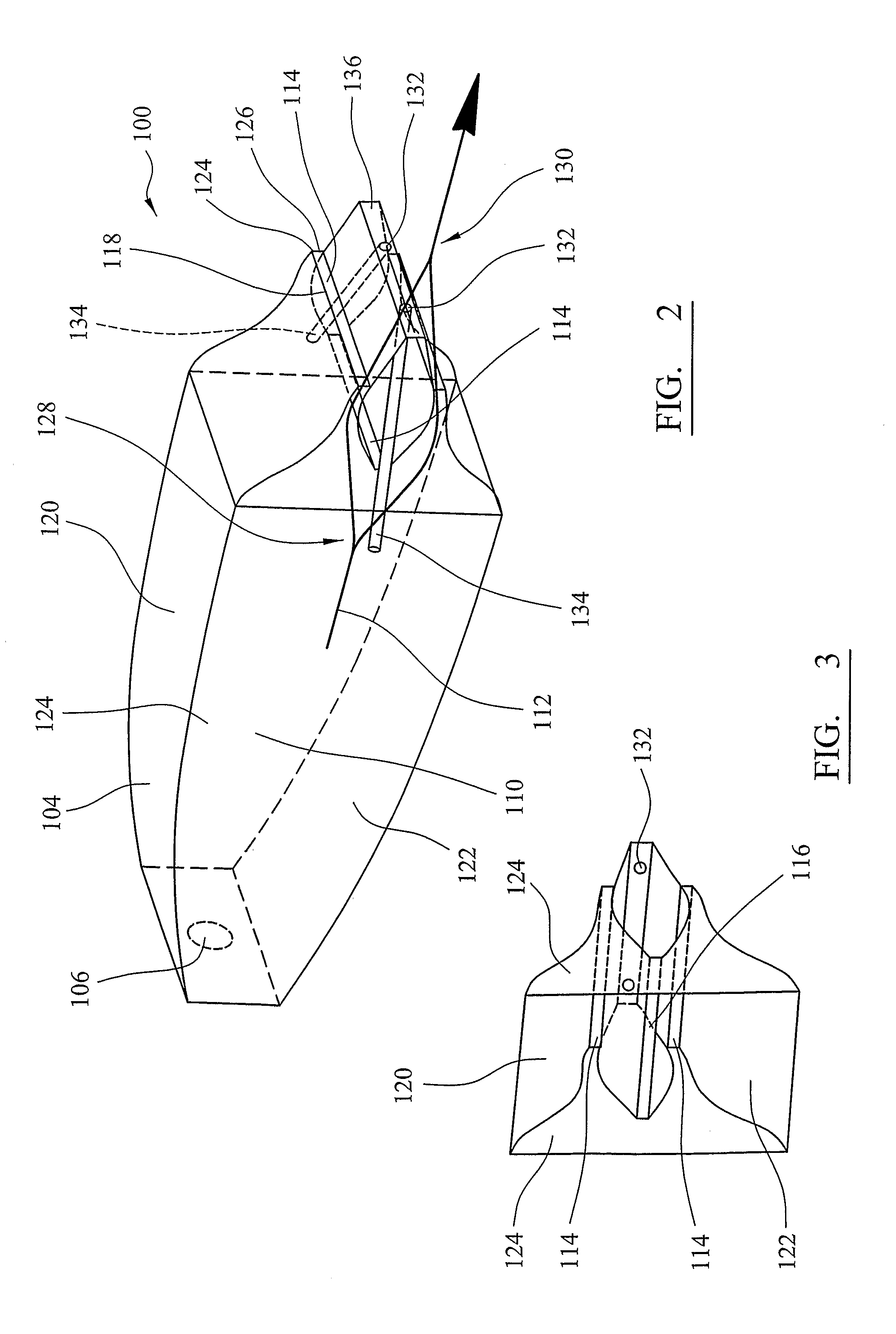

Nozzle For A Thermal Spray Gun And Method Of Thermal Spraying

ActiveUS20120082797A1Reducing loss of energy/temperatureImprove jetting stabilityMolten spray coatingSpray nozzlesThermal sprayingCombustion chamber

A nozzle for a thermal spray gun and a method of thermal spraying are disclosed. The nozzle has a combustion chamber within which fuel is burned to produce a stream of combustion gases. The streams of heated gases exit through a pair of linear exhausts which are located on either side of an aerospike. The streams converge outside the nozzle and powdered coating material is introduced into the converging streams immediately downstream of the aerospike. The coating material is heated and accelerated before impacting on a substrate to be coated.

Owner:MONITOR COATINGS

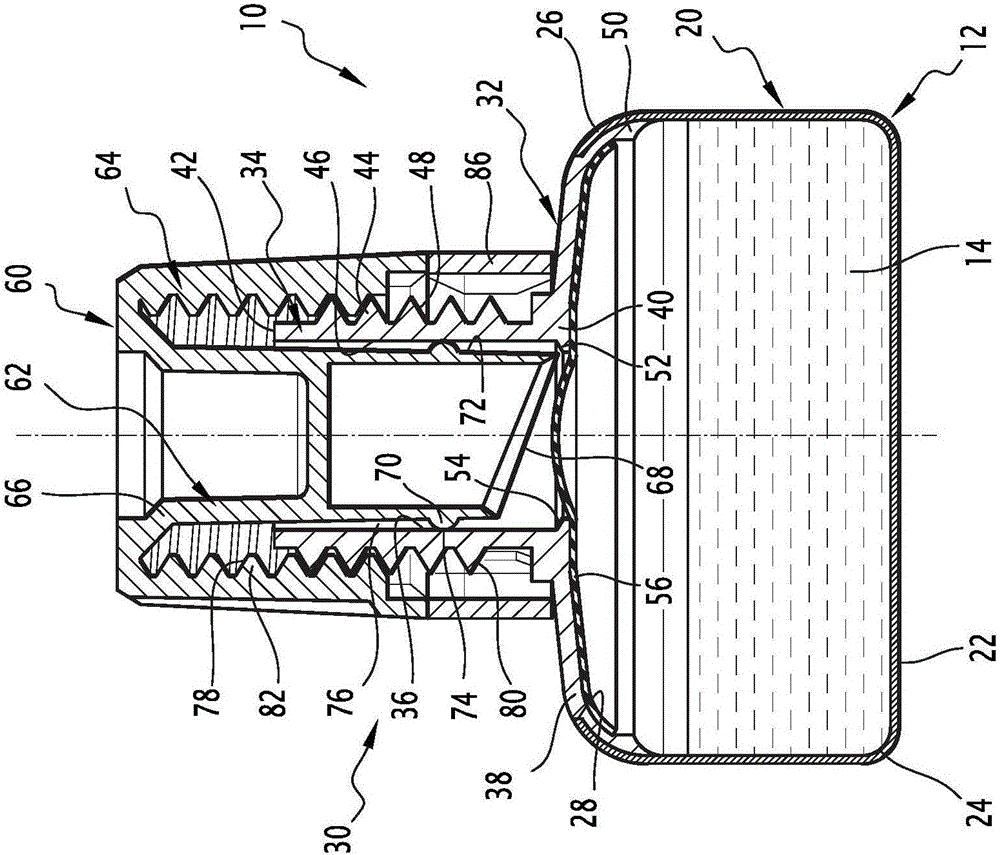

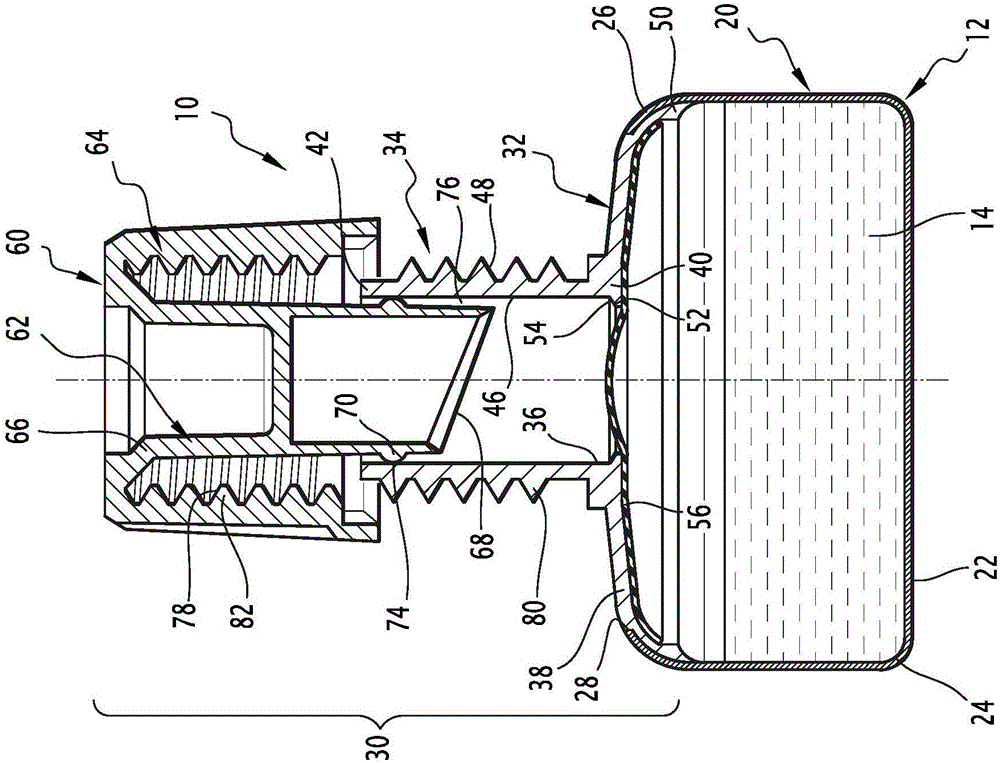

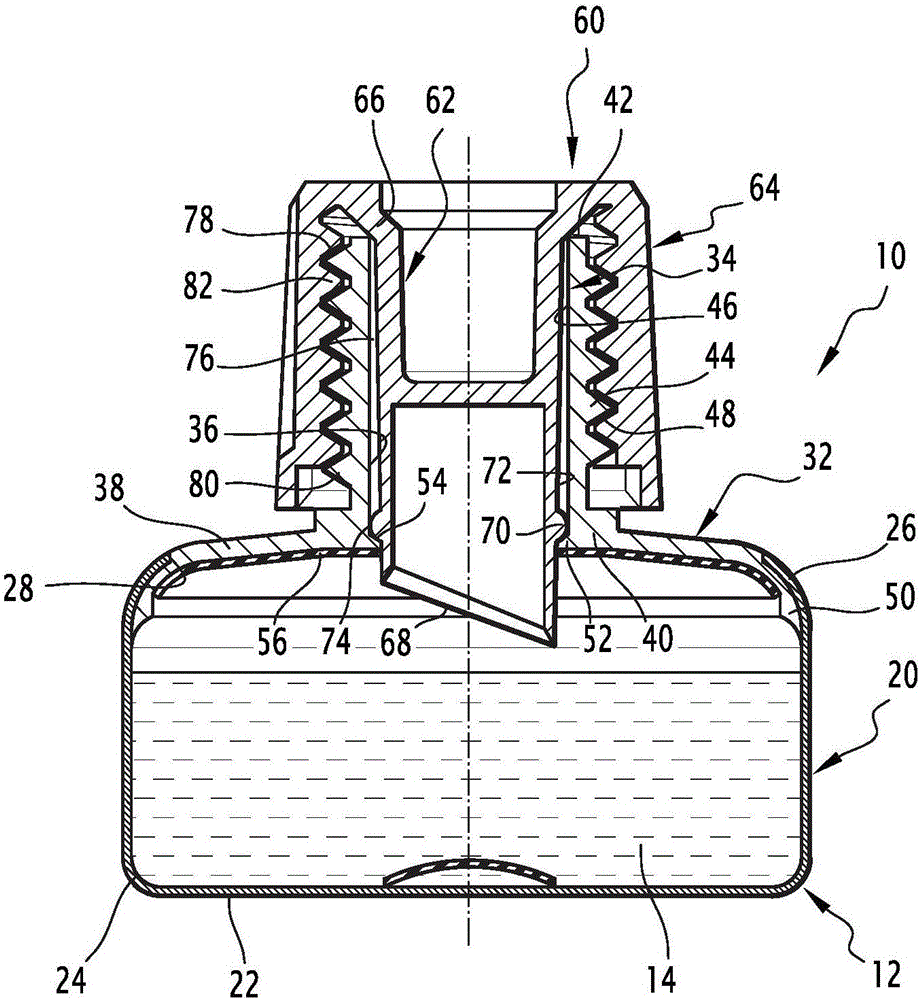

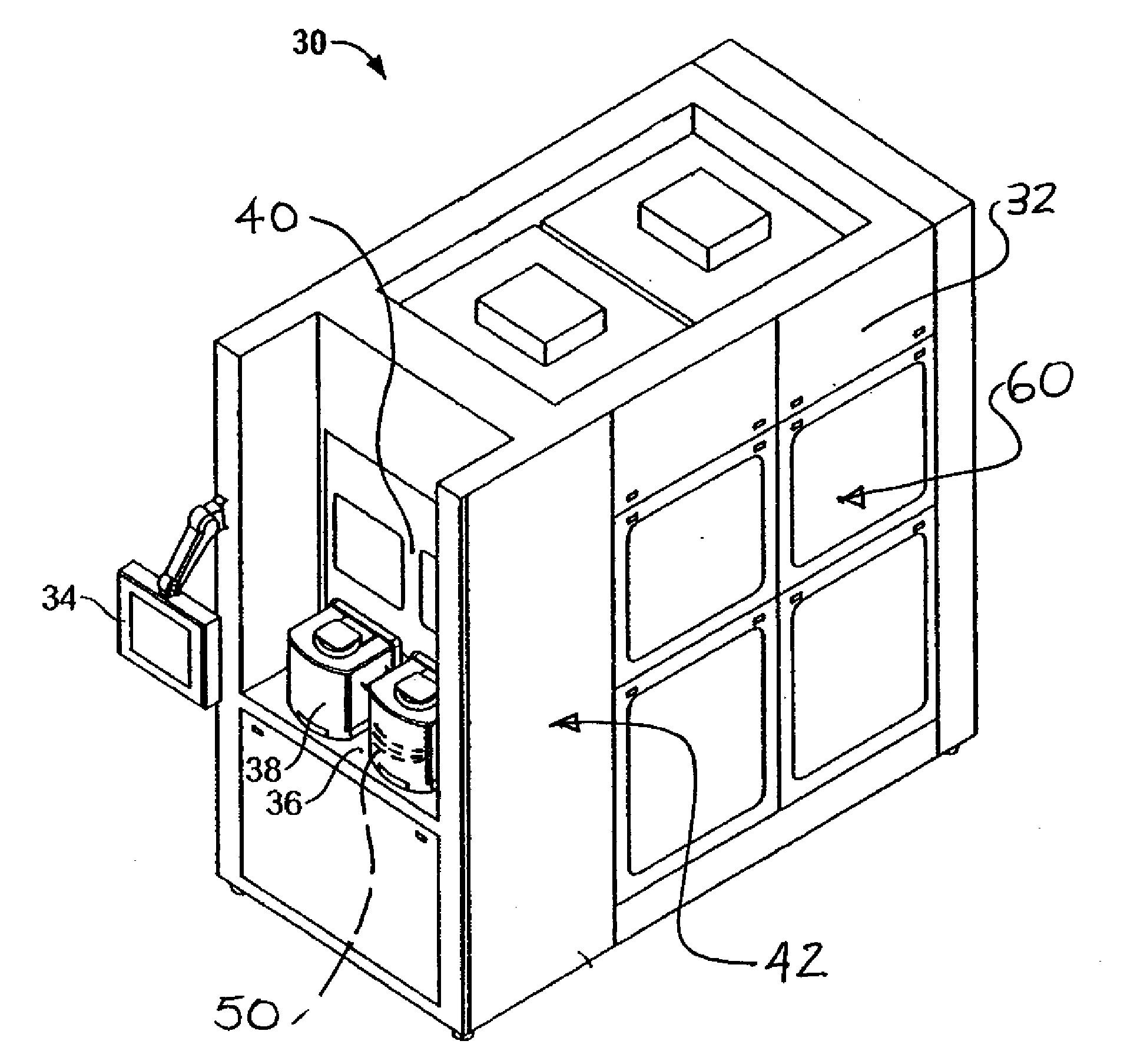

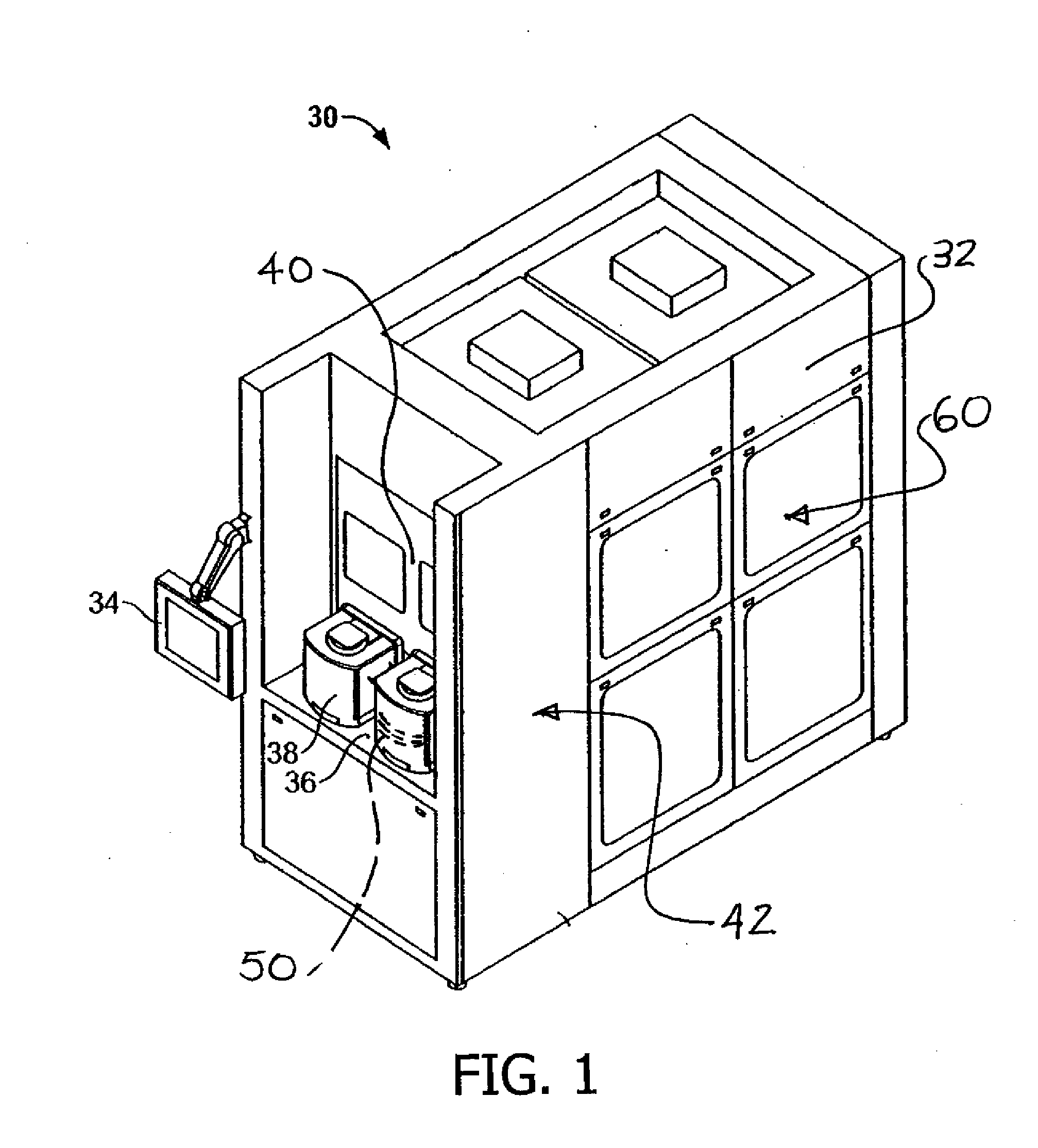

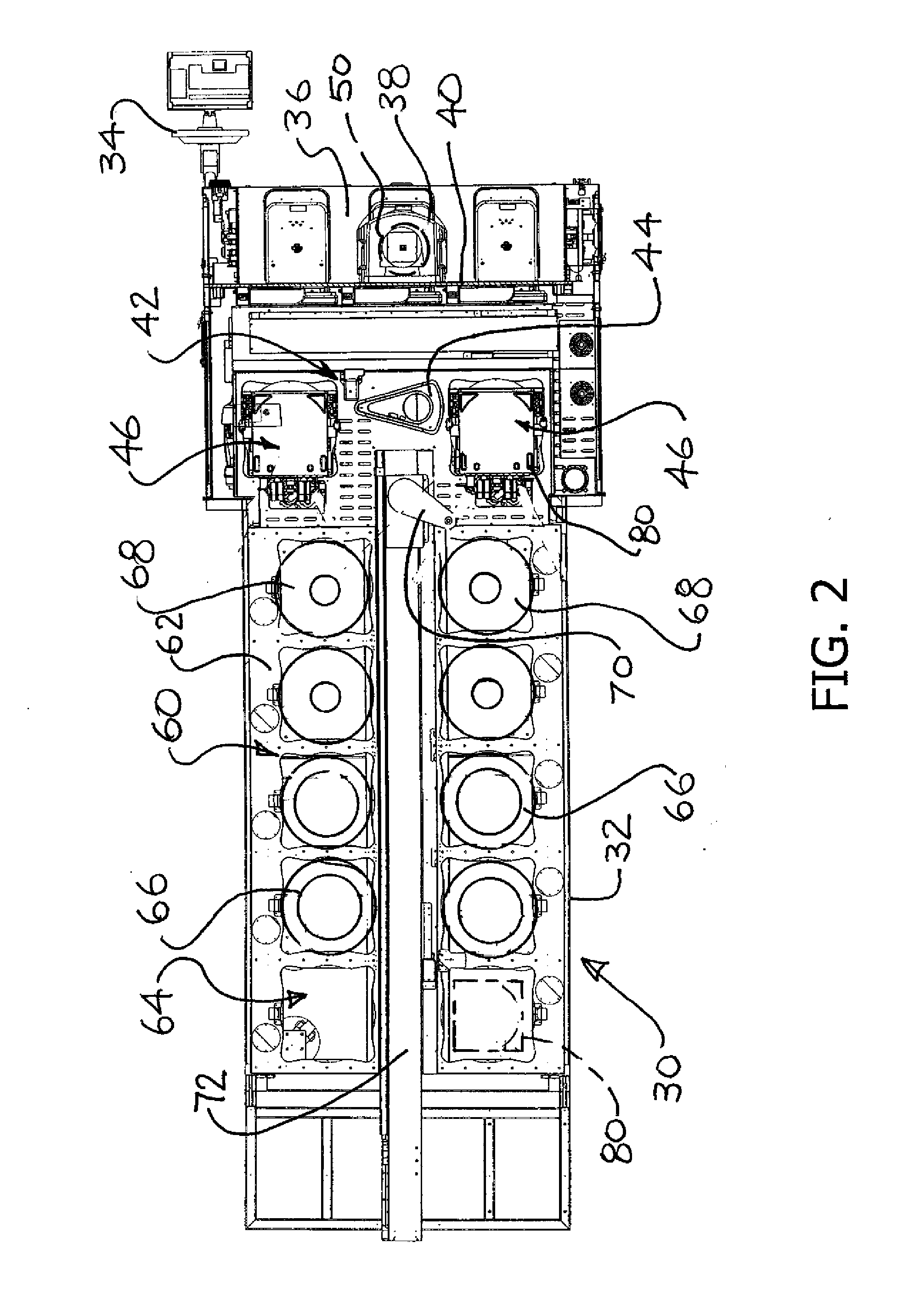

Head for dispensing a cosmetic product, including a scraping device, and associated packaging device

ActiveCN105764806AReduce the risk of oxidationRestrictions address production costsCapsClosure capsBiomedical engineeringEngineering

The invention relates to a head (30) for dispensing a cosmetic product, which includes: a device (31) for dispensing the cosmetic product, which has a tubular duct (34) defining a passage (36) for the cosmetic product, and a stopper (6) for blocking the passage (36), which is movable between a position that clears the passage (36) and a position that blocks the passage (36), the stopper (60) including a finger (62) and a skirt (64), the outer surface (48) of the duct (34) and the inner surface (78) of the skirt (64) having complementary engagement means (80, 82) for the rigidly connecting the stopper (60) to the dispensing device (32). The finger (62) supports a peripheral scraping device (70) projecting radially from a peripheral surface (72) of the finger (62), the scraping device (70) having at least one circumferential line (74) suitable for being in contact with the duct (34) when the stopper (60) is in a blocked position.

Owner:LOREAL SA

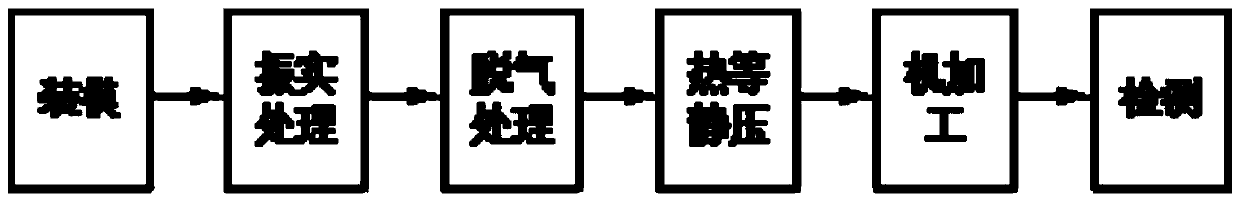

Iron-cobalt-tantalum alloy sputtering target material and preparation method thereof

PendingCN111560587AMeet quality requirementsReduce energy consumptionTransportation and packagingVacuum evaporation coatingCobaltMachining

The invention relates to an iron-cobalt-tantalum alloy sputtering target material and a preparation method thereof. The preparation method comprises the steps of (1) loading iron-cobalt-tantalum alloypowder with a target atomic ratio into a die, then sealing the die, and carrying out tap compaction treatment; (2) degassing the die subjected to the tap compaction treatment; (3) carrying out hot isostatic pressing treatment on the degassed die under 750-900 DEG C to obtain a crude product of the iron-cobalt-tantalum alloy sputtering target material; and (4) machining the obtained crude productof the iron-cobalt-tantalum alloy sputtering target material to obtain the iron-cobalt-tantalum alloy sputtering target. The preparation method has the advantages of simple process, low cost and the like; and in addition, the prepared iron-cobalt-tantalum alloy sputtering target material not only has the density of 98% or above, the bending strength of 700 MPa or above, the magnetic flux of 30% orabove and the oxygen content of 600 ppm or below, but also has good machining performance.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Single wafer anneal processor

InactiveUS20080203083A1Avoids thermal cyclingEasy to processBaking ovenSemiconductor/solid-state device manufacturingCopperCold plate

A thermal processor is adapted for annealing substrates. The processor has a sealed process chamber. Air is excluded from the process chamber during processing to avoid oxidation of substrate surfaces, such as copper surfaces. The substrate temperature is controlled by selectively positioning the substrate between a hot plate and a cold plate operating at steady state conditions. During loading and / or unloading, the air flow is induced over the substrate. This keeps the substrate at a temperature low enough to avoid oxidation, even though the heater may remain on.

Owner:SEMITOOL INC

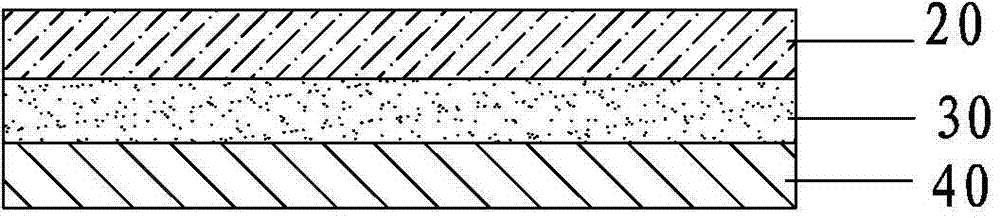

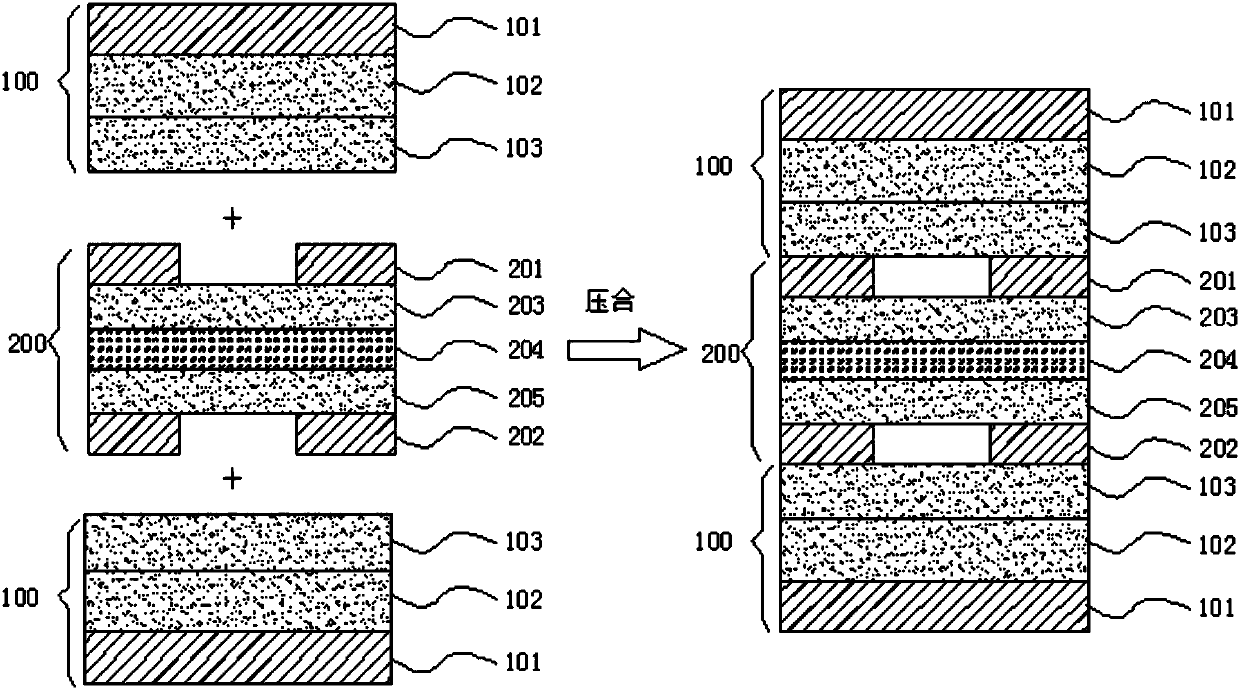

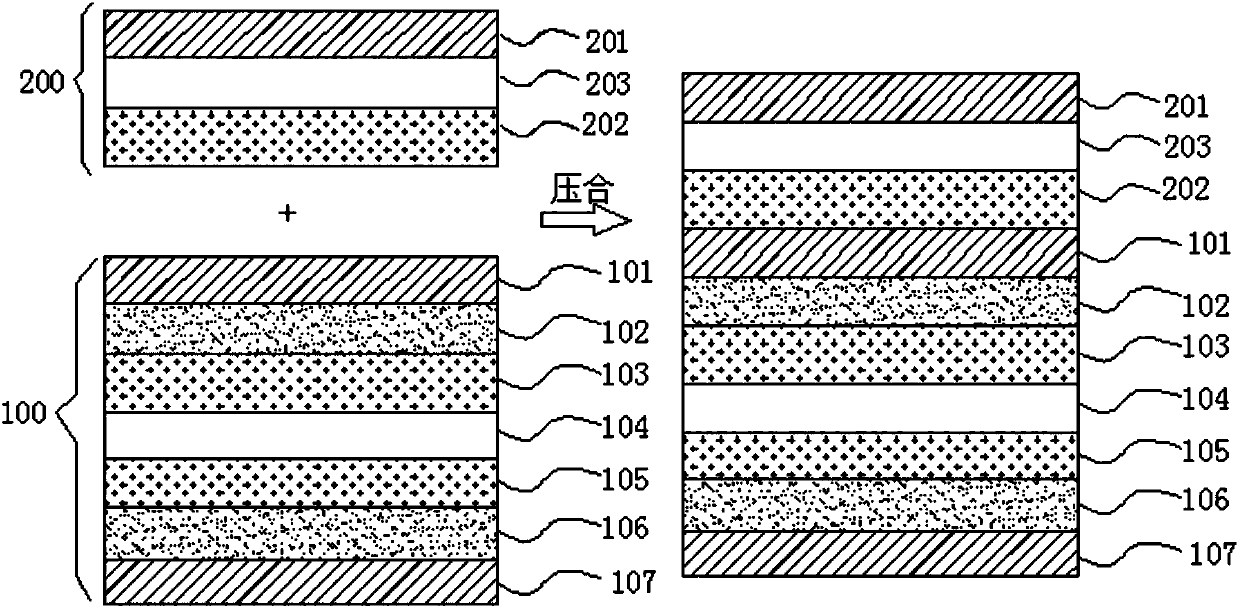

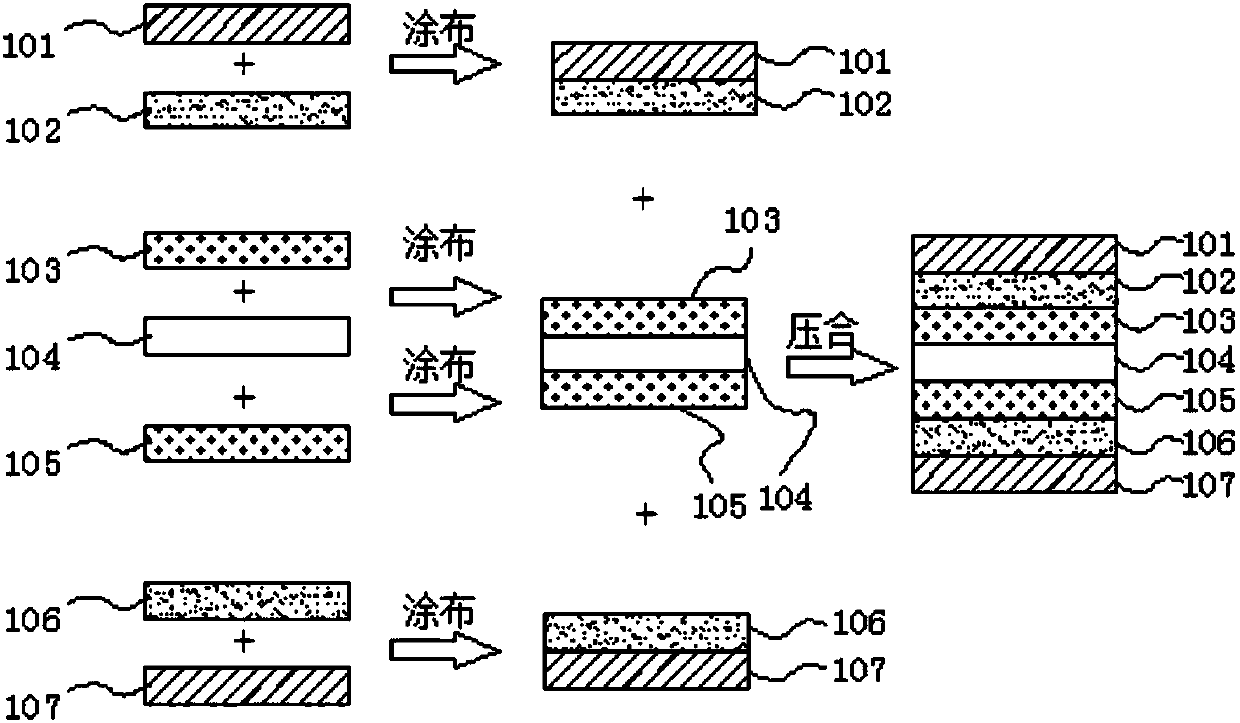

Compound type LCP (Liquid-Crystal Polymer) high-frequency high-speed double-sided copper foil substrate and preparation method thereof

ActiveCN108859316ALow and stable Dk/Df performanceReduce skin effectLamination ancillary operationsDielectric materialsCopper foilAbsorption rate

The invention discloses a compound type LCP (Liquid-Crystal Polymer) high-frequency high-speed double-sided copper foil substrate. The compound type LCP high-frequency high-speed double-sided copper foil substrate comprises one or more LCP core layer, one or more extremely-low dielectric adhesive layer and two copper foil layers, the LCP core layer and the extremely-low dielectric adhesive layer are arranged between the two copper foil layers, wherein the thickness of the each LCP core layer is 5 to 50 micronmeters; the thickness of the each extremely-low dielectric adhesive layer is 2 to 50 micrometers; the thickness of the each copper foil layer is 1 to 35 micrometers, the extremely-low dielectric adhesive layers are adhesive layers of which Dk values are 2.0 to 3.0 (10GHz) and Df valuesare 0.002 to 0.010 (10GHz). The compound type LCP high-frequency high-speed double-sided copper foil substrate disclosed by the invention has the advantages of good electricity, low roughness, stabledk / df performance under a high-temperature moisture environment, ultra-low water absorption rate, good UV laser drilling ability, low rebounding force for high-density assembly and excellent mechanical performance; in addition, based on a current coating technology, the coating thickness of about 50 micrometers at most only can be required. According to the preparation method disclosed by the invention, the substrate, of which the thickness is 100 micrometers or above, can be easily obtained.

Owner:KUSN APLUS TEC CORP

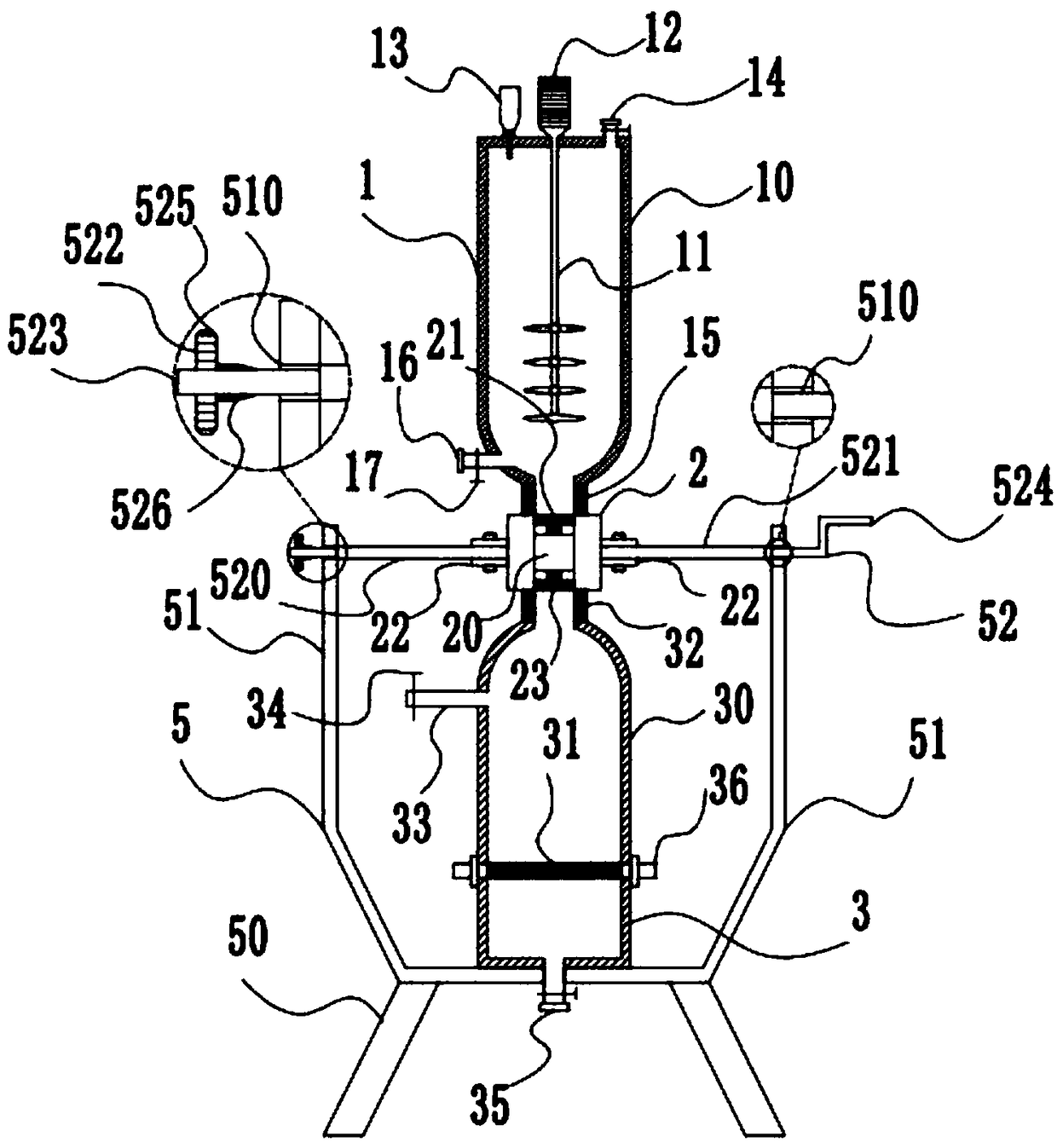

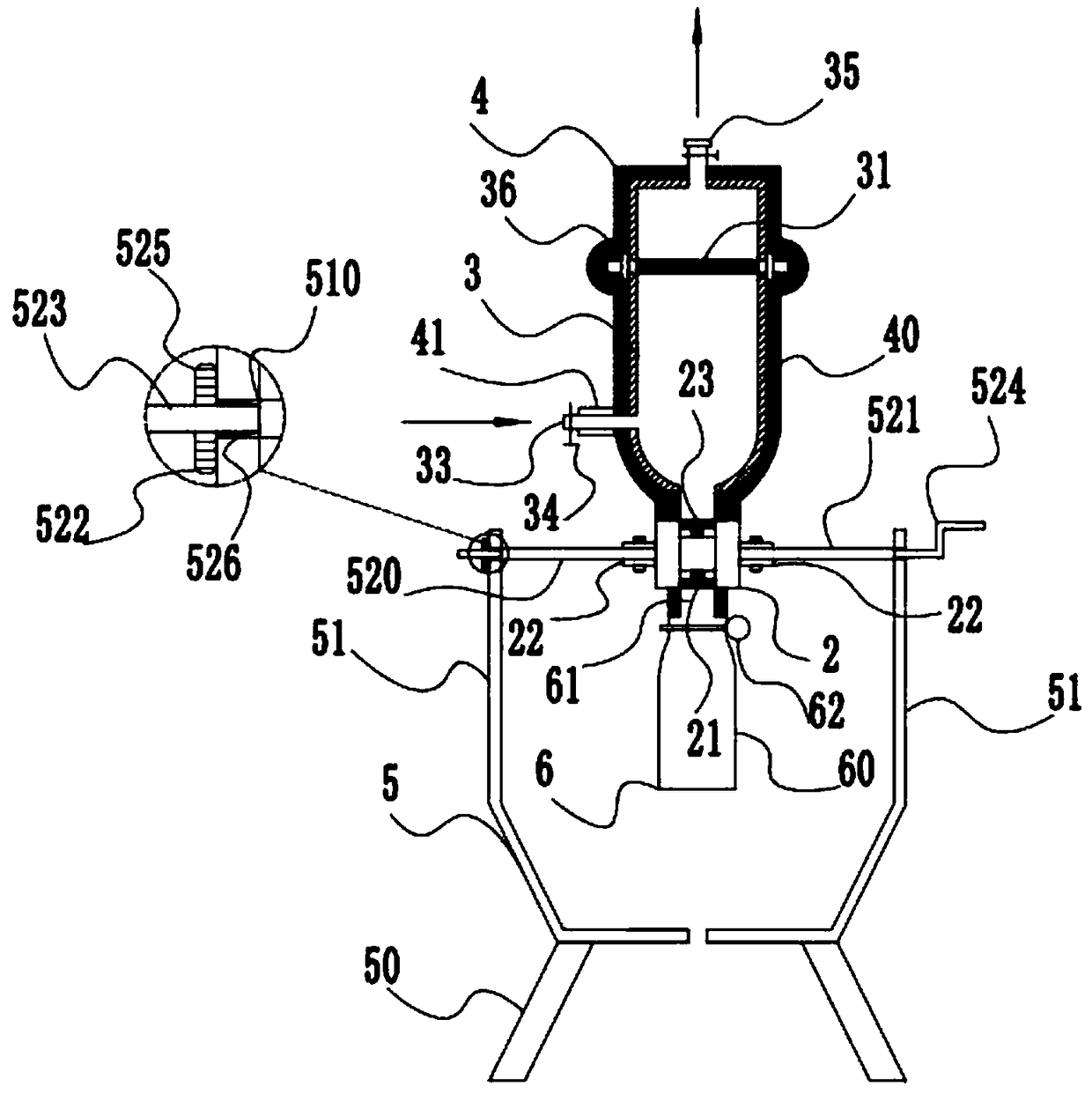

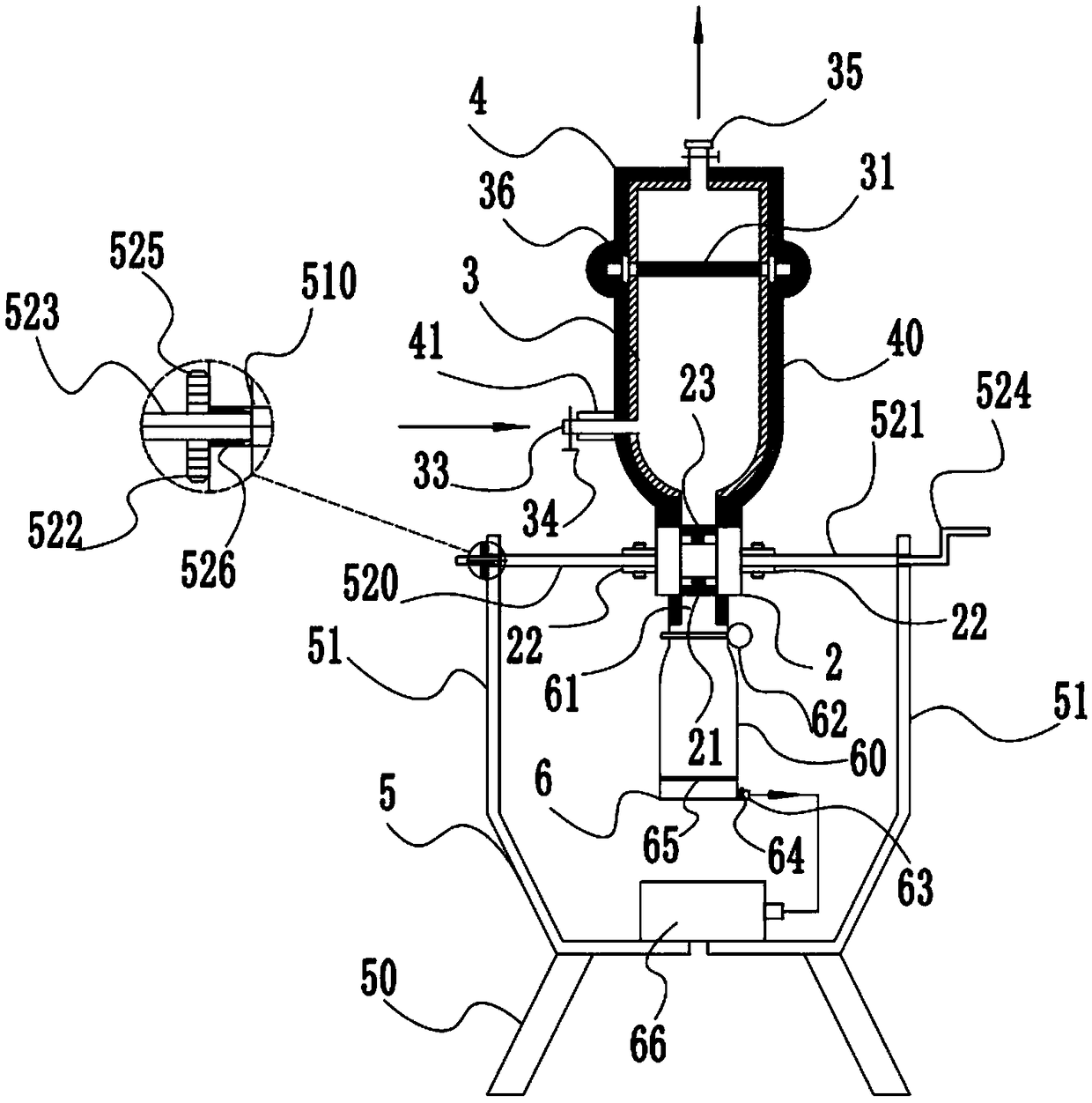

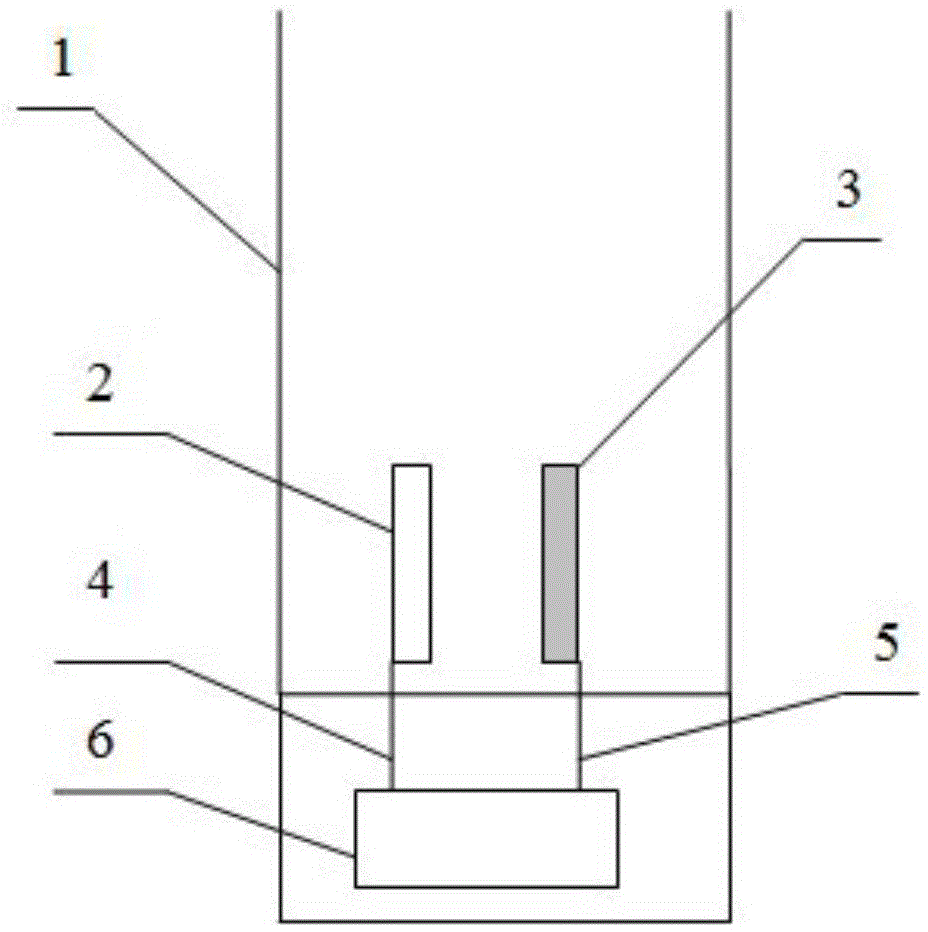

Integrated device for preparing nano zero-valent iron in laboratory and preparation method

InactiveCN109433129AEasy to observeConvenient experimentReverse osmosisChemical/physical/physico-chemical stationary reactorsMaterial transferFerric

The invention discloses an integrated device for preparing nano zero-valent iron in a laboratory and a preparation method. The integrated device comprises a reaction and preparation device, a connecting device, a separating and cleaning device, a heating and drying device and a fixing and supporting device, wherein the separating and cleaning device is fixed on the bottom of the fixing and supporting device; the reaction and preparation device is connected to the upper portion of the separating and cleaning device through the connecting device, and is used for carrying out preparation, separating and cleaning processes of samples; the connecting device is connected with the fixing and supporting device through a turnover mechanism, and is used for overturning the separating and cleaning device at an angle of 180 degrees; the heating and drying device is additionally mounted on the outside of the separating and cleaning device which overturns at an angle of 180 degrees, and is used forcarrying heating and drying processes; and the separating and cleaning device is connected with a negative-pressure collecting device which is used for a material transferring process. In a word, reaction, cleaning, drying and collection are integrated, in the whole process, exposed transfer does not exist, and material oxidation risks are reduced.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

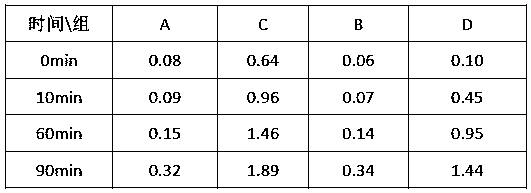

Preparation method of stable amino acid-ferrous complex

ActiveCN110128307AReduce the risk of oxidationPrevent oxidationSulfide preparationFerrous saltsCoordination complex

The invention discloses a preparation method of a stable amino acid-ferrous complex. The amino acid-ferrous complex is prepared from optimized amino acid and a ferrous salt according to a molar ratioof 1:1 in the presence of iron powder under the condition of a water system. An auxiliary agent is used to achieve the effects of regulating the pH value, digesting the iron powder, and carrying out secondary complexation or chelating on free ferrous, so that after the obtained reaction liquid is subjected to spray drying, the stable amino acid-ferrous complex is obtained. A high-level ferrous content and a low-level oxidation rate (ferric iron content) are achieved, and relatively good antioxidant capacity is achieved in a water solution, so that excellent stability is exhibited, oxidation resistance of a ferrous complex product in a storage and transportation process is improved, and efficient utilization of the ferrous product is facilitated. According to the preparation process of themethod, the steps of filtering the iron powder and digesting the iron powder by adding inorganic acid are optimized, no three wastes (waste gas, waste water and industrial residue) are generated, cleaning can be carried out continuously, and in addition, the used auxiliary agent can also provide favorable nutritional ingredients.

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

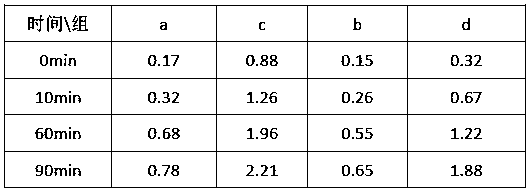

Aronia melanocarpa mixed fruit juice having efficacy of resisting oxidation and preparation method of aronia melanocarpa mixed fruit juice

The invention provides aronia melanocarpa mixed fruit juice having efficacy of resisting oxidation and a preparation method of the aronia melanocarpa mixed fruit juice. According to the aronia melanocarpa mixed fruit juice, aronia melanocarpa rich in anthocyan and kiwi fruits rich in vitamin C are used as raw materials, and through technologies of performing cleaning, performing squeezing to obtain juice, performing extraction on fruit residues, performing superhigh pressure sterilization, performing bacteria-free cold-filling and the like, the mixed fruit juice rich in anthocyan and vitamin Cis prepared. The aronia melanocarpa mixed fruit juice has favorable efficacy of resisting oxidation, and has favorable efficacy of preventing cardiovascular and cerebrovascular diseases, resisting ageing and the like.

Owner:陕西思尔生物科技有限公司

Copper paste capable of achieving low-temperature high-density sintering

The invention relates to the field of metal composite materials, in particular to copper paste capable of achieving low-temperature high-density sintering. The copper paste comprises spherical copperparticles, flake copper particles, flake indium particles and high-link resin; and the ratio of the two kinds of copper particles is more than 80%, the ratio of the indium particles is 10%-20%, and the ratio of the high-link resin is 0-10%. According to the copper paste body, under the non-pressure condition, the sintering temperature can be as low as about 180 DEG C to 250 DEG C, and the densityis more than 95% after sintering.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

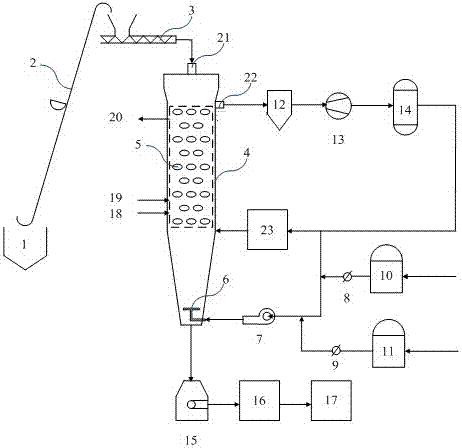

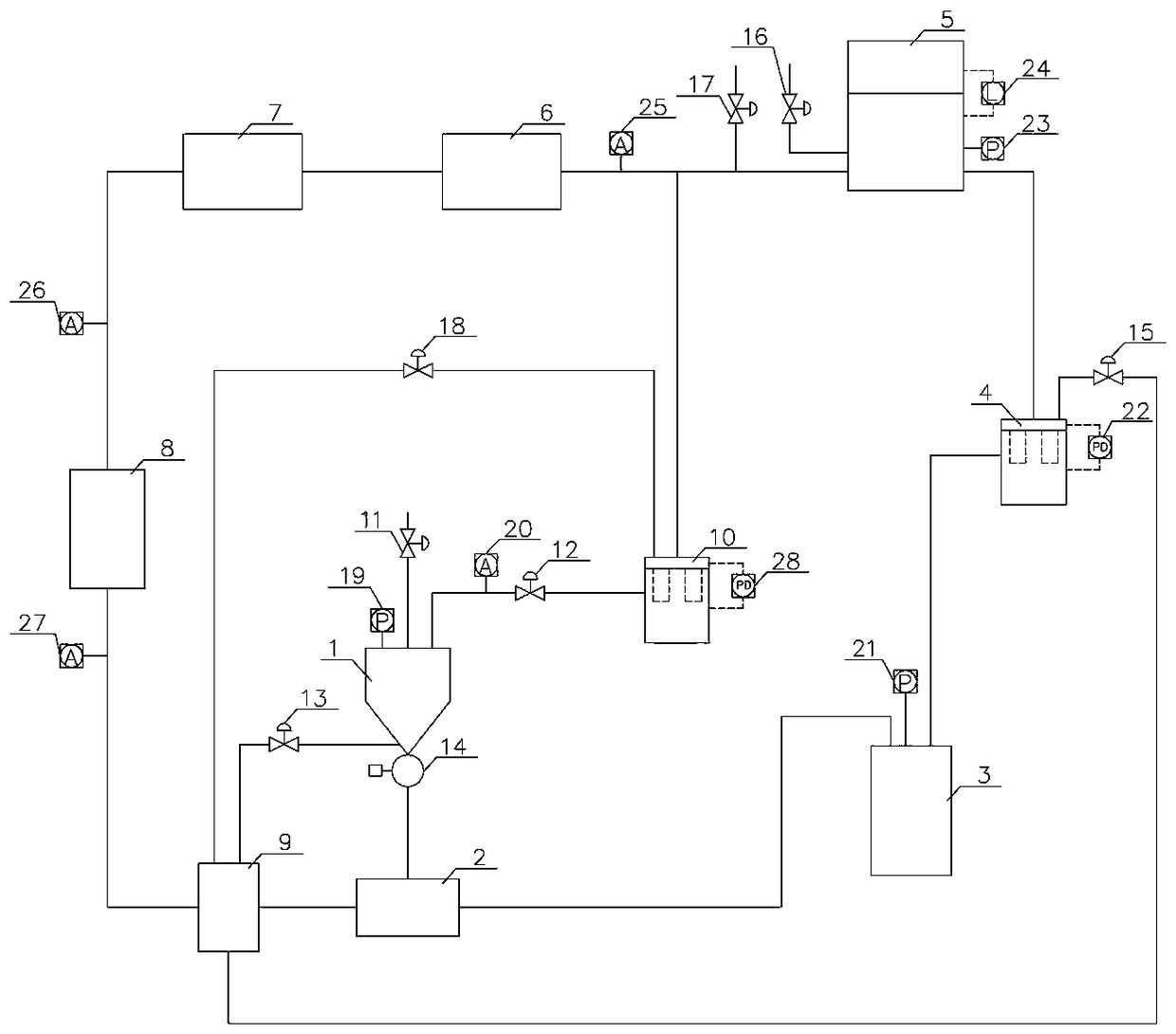

Mineral-powder rapid reducing system

The invention relates to a rapid reduction system for producing direct reduced iron from powdery ore, comprising: a rapid reduction reactor, a heating system, a feed system, a discharge system, and a reduction gas system, the temperature distribution in the device is uniform, and the reduction tail gas circulation is adopted The method of utilization realizes the recycling of reducing gas resources, adopts multi-layer air inlets, the distribution of reducing gas is more uniform, and the hot reducing gas entering the reactor can directly continue to undergo reduction reaction with unreacted ore powder, which is beneficial Improve the metallization rate in the reduction product and enhance the reduction effect.

Owner:SHENWU TECH GRP CO LTD

Negative prelithiated electrode and preparation method thereof

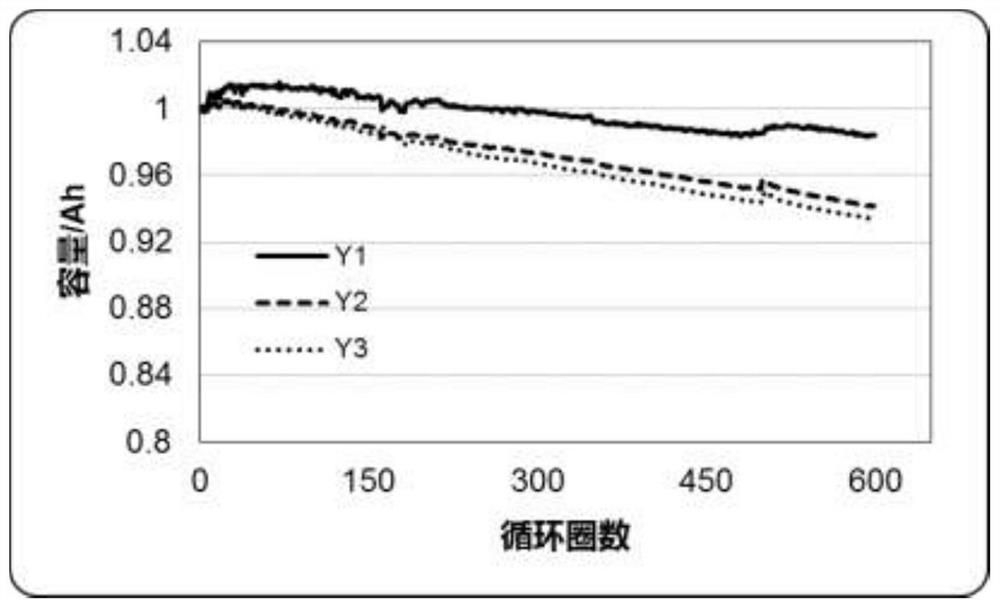

InactiveCN112038577AReduce the risk of oxidationImprove first-time efficiencySecondary cellsElectrode collector coatingOrganic solventElectrical polarity

The invention discloses a negative prelithiated electrode. The negative prelithiated electrode comprises a metal current collector, and an active substance layer, a lithium supplementing layer and a functional polymer film protection layer which sequentially coat the surface of the metal current collector, wherein a functional polymer is a polymer containing a lithium-philic polar functional group. The invention discloses a preparation method of the negative prelithiated electrode. The preparation methodcomprises the following steps: S1, coating the surface of the metal current collector withthe active substance, and carrying out prelithiation treatment to obtain an intermediate electrode; and S2, mixing and stirring the functional polymer and an organic solvent for 6-10h, conducting standing for 12-24h, uniformly coating the surface of the intermediate electrode with a formed supernatant, and performing vacuum drying at 45-85 DEG C to obtain the negative prelithiated electrode. The risk that the lithium supplementing layer of the prelithiated electrode is oxidized can be effectively reduced, and the initial efficiency, the energy density, the cycling stability and the safety performance of a lithium ion battery are improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

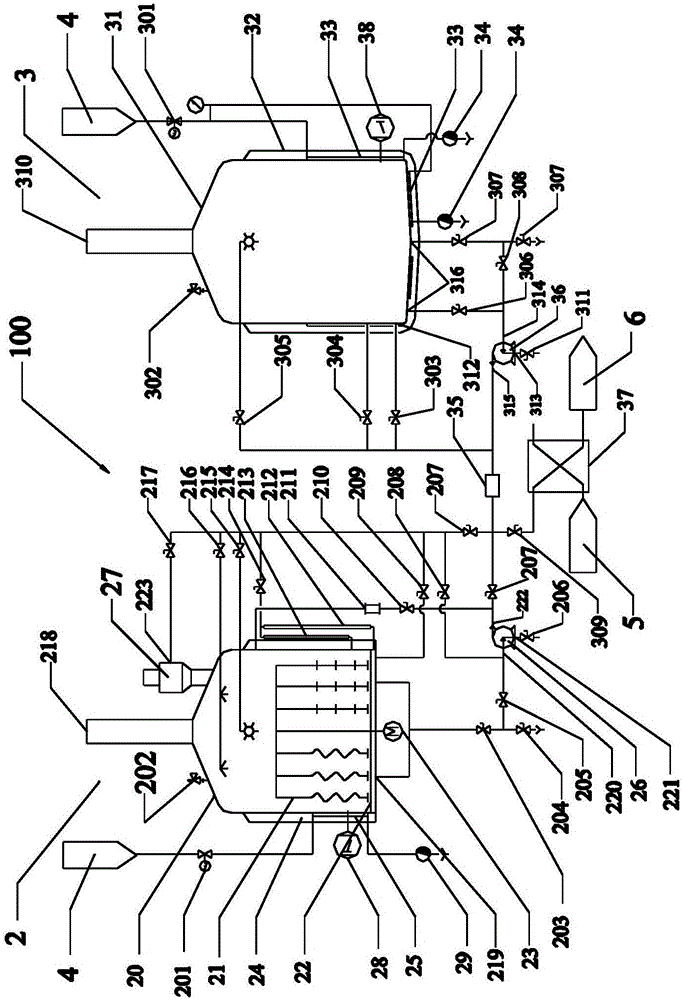

Brewing liquid preparation device

PendingCN106833998ASmall footprintSimplify piping and systemsWort preparationProcess engineeringMechanical engineering

The invention discloses a brewing liquid preparation device. The brewing liquid preparation device comprises a boiling and settling tank and a saccharifying and filtering tank, the saccharifying and filtering tank is communicated with the boiling and settling tank, the saccharifying and filtering tank comprises a saccharifying and filtering tank body, a grain raking component, a filter screen and a first heating device; the first heating device is fixed on the saccharifying and filtering tank body, the grain raking component and the filter screen are mounted in the saccharifying and filtering tank body, and the grain raking component is located above the filter screen. The device is designed into a structure with two devices, namely the saccharifying and filtering tank and the boiling and settling tank, the first heating device is arranged on the saccharifying and filtering tank body, a heating tank is not needed, the device is simplified, and the conveying of a brewing liquid with particles is avoided; the grain raking component has the complex functions of stirring, raking grains and discharging grains, then the brewing liquid is guaranteed to be heated evenly when stirred in the saccharifying process, the spent grain is loosened while the filtering characteristic of a grain layer is not changed in the filtering process, so that the optimal filtering quality is reached, the filtering speed is accelerated, and the risk of oxidation of the brewing liquid is reduced.

Owner:GUANGZHOU GDE MACHINERY CO LTD

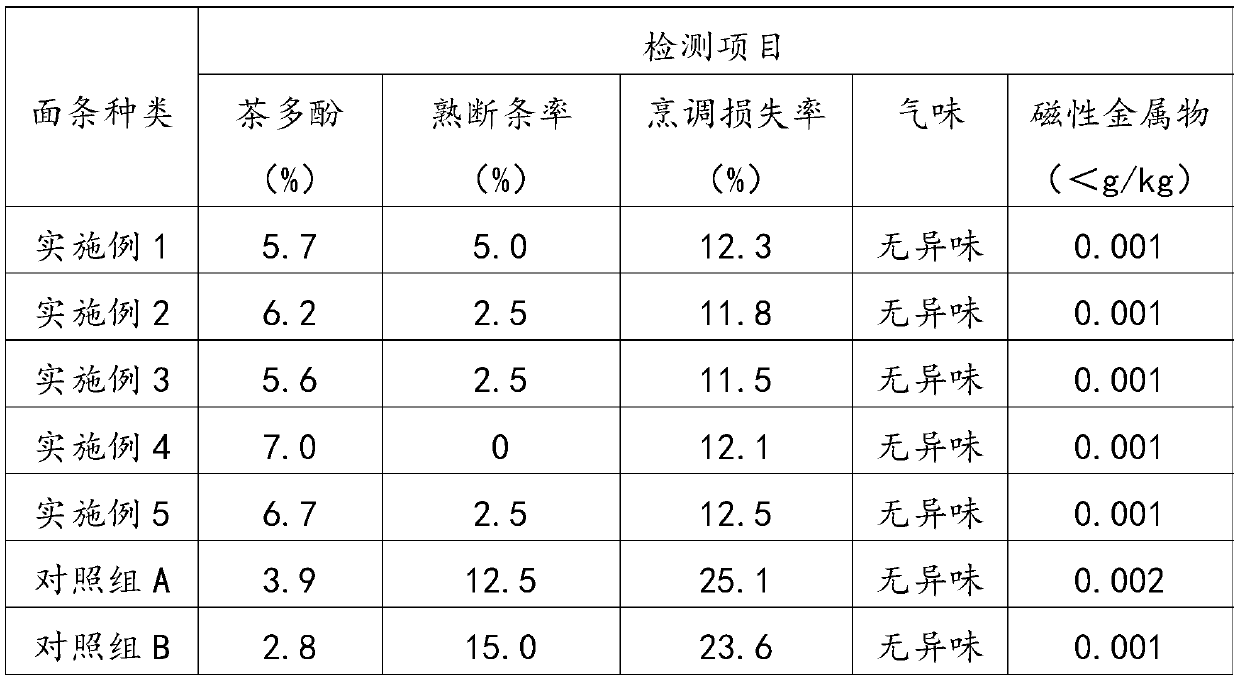

Tea-flavor type noodles and preparation method thereof

The invention relates to the technical field of food processing, in particular to tea-flavor type noodles and a preparation method thereof. The tea-flavor type noodles are prepared from flour, starch,tea residues, edible salt, a mixed preparation and yeast. By smashing and grinding the tea leaves, effective tea leaf ingredients in the tea residues are dissolved and extracted, the content of fibers in the tea residue powder is reduced, and the problem is solved that after common tea residues are directly added to dough, the gluten structure is broken, and the strength of the noodles is reduced.

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

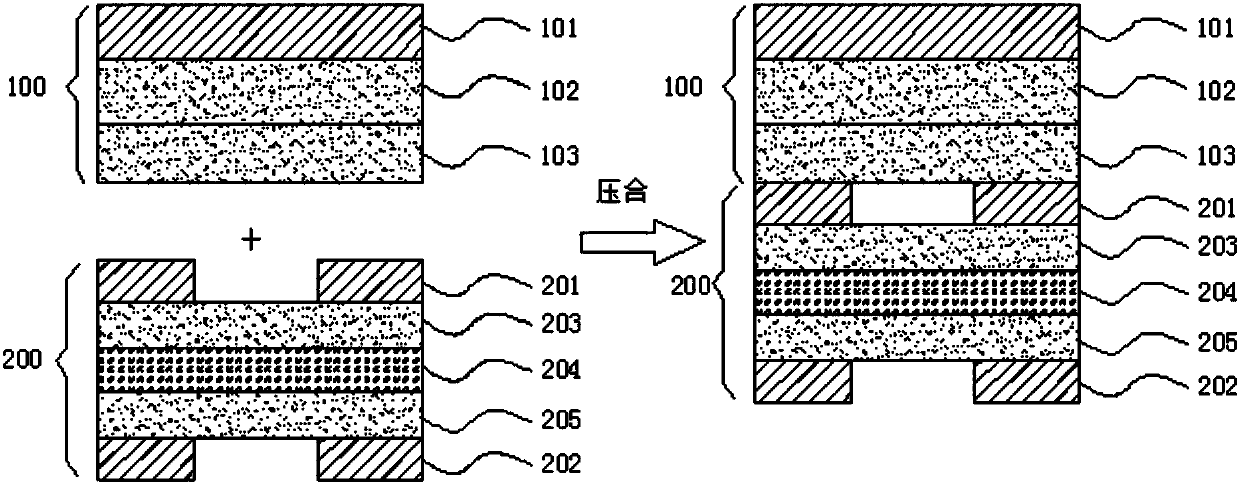

FPC multilayer board based on high-frequency FRCC and high-frequency double-sided board and manufacturing process thereof

PendingCN110366330AConditions that are not easy to retractLaser drilling process is easy to implementCircuit susbtrate materialsMultilayer circuit manufacturePressure transmissionManufacturing technology

The invention discloses an FPC (Flexible Printed Circuit) multilayer board based on a high-frequency FRCC and a high-frequency double-sided board. The FPC multilayer board comprises at least one FRCCand at least one double-sided board, wherein the FRCC and the double-sided board are pressed together; the FRCC comprises a first copper foil layer, a first low dielectric glue layer and a second lowdielectric glue layer; the double-sided board is at least one of a PI type double-sided board and an LCP type double-sided board. According to the invention, the FRCC without the LCP layer is matchedwith the high-frequency PI type double-sided board or the LCP type double-sided board to manufacture a three-layer to six-layer FPC, the process flow for manufacturing the FPC is simple, the laser drilling process is better, the situation of retraction is not easy to occur, the FPC has lower hygroscopicity and lower Dk and Df electrical properties, fast press equipment or pressure transmission equipment can be matched, the FPC has the cost advantage, the thick film manufacturing technology is provided, and meanwhile, the FRCC with the simpler interface and the lower cost is used in the FPC multilayer board structure based on the high-frequency FRCC and the high-frequency double-sided board.

Owner:KUSN APLUS TEC CORP

Method for preparing electrode

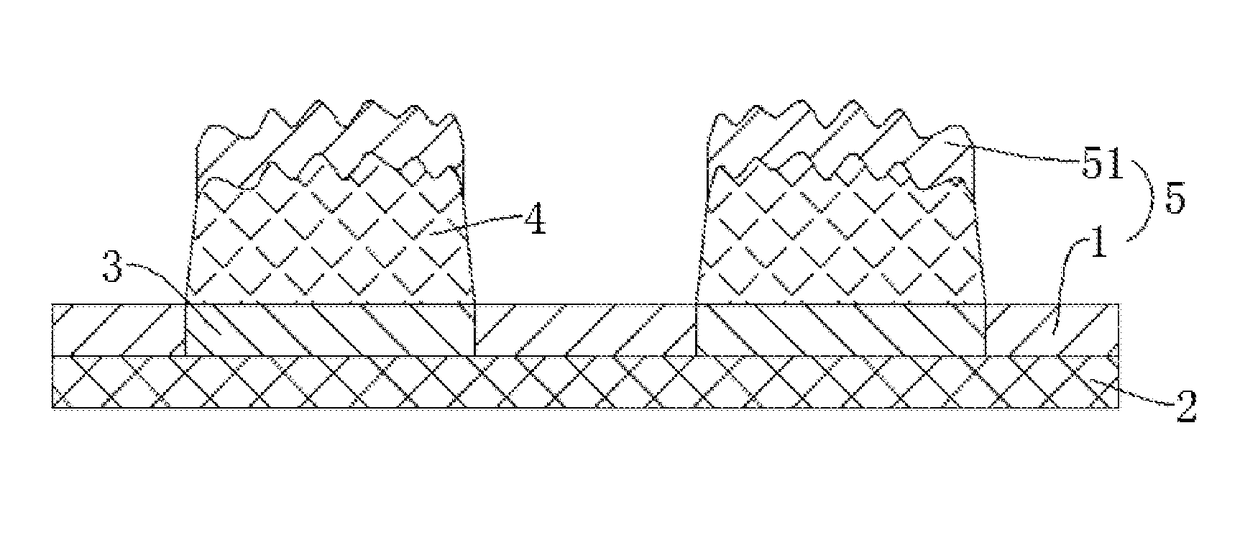

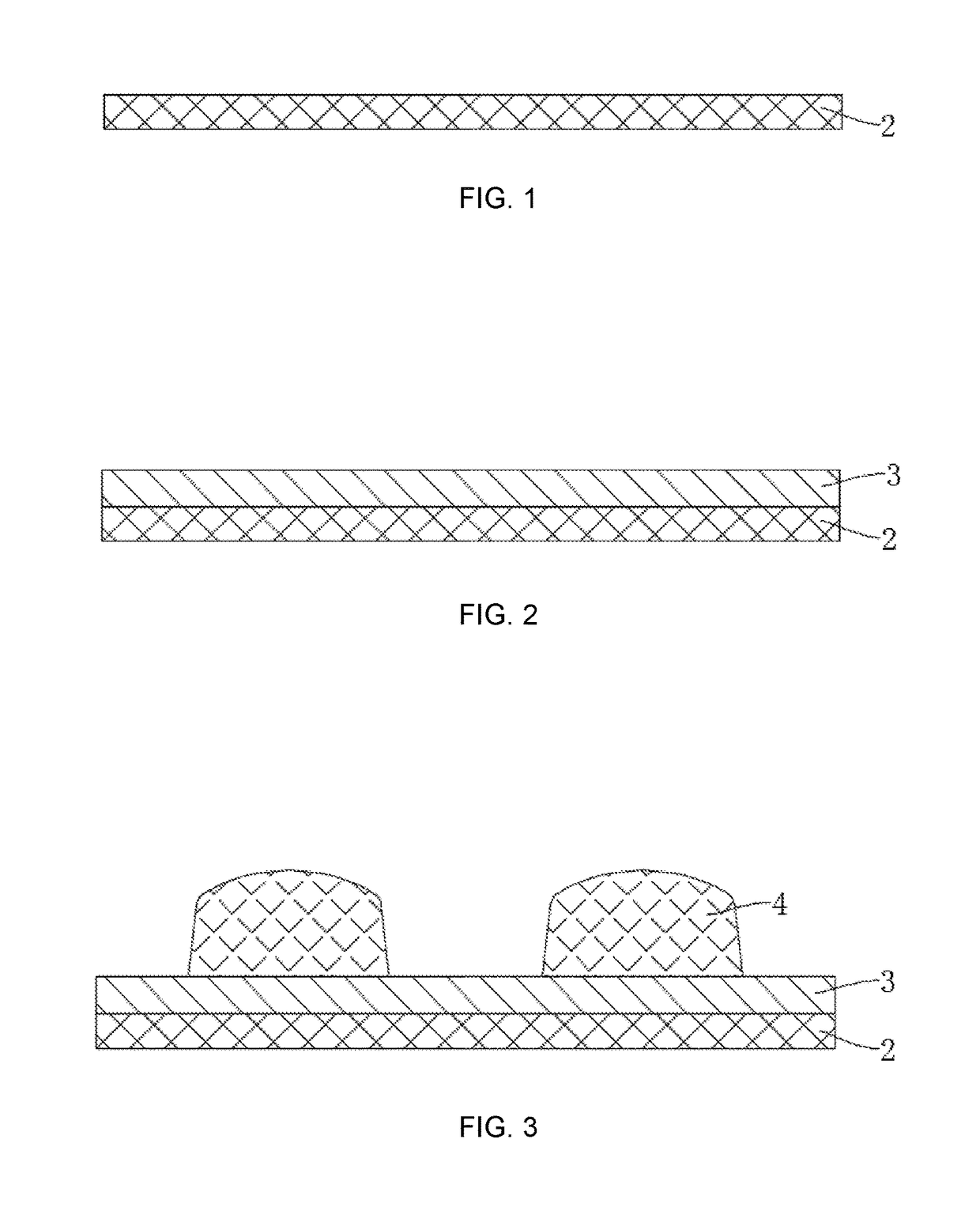

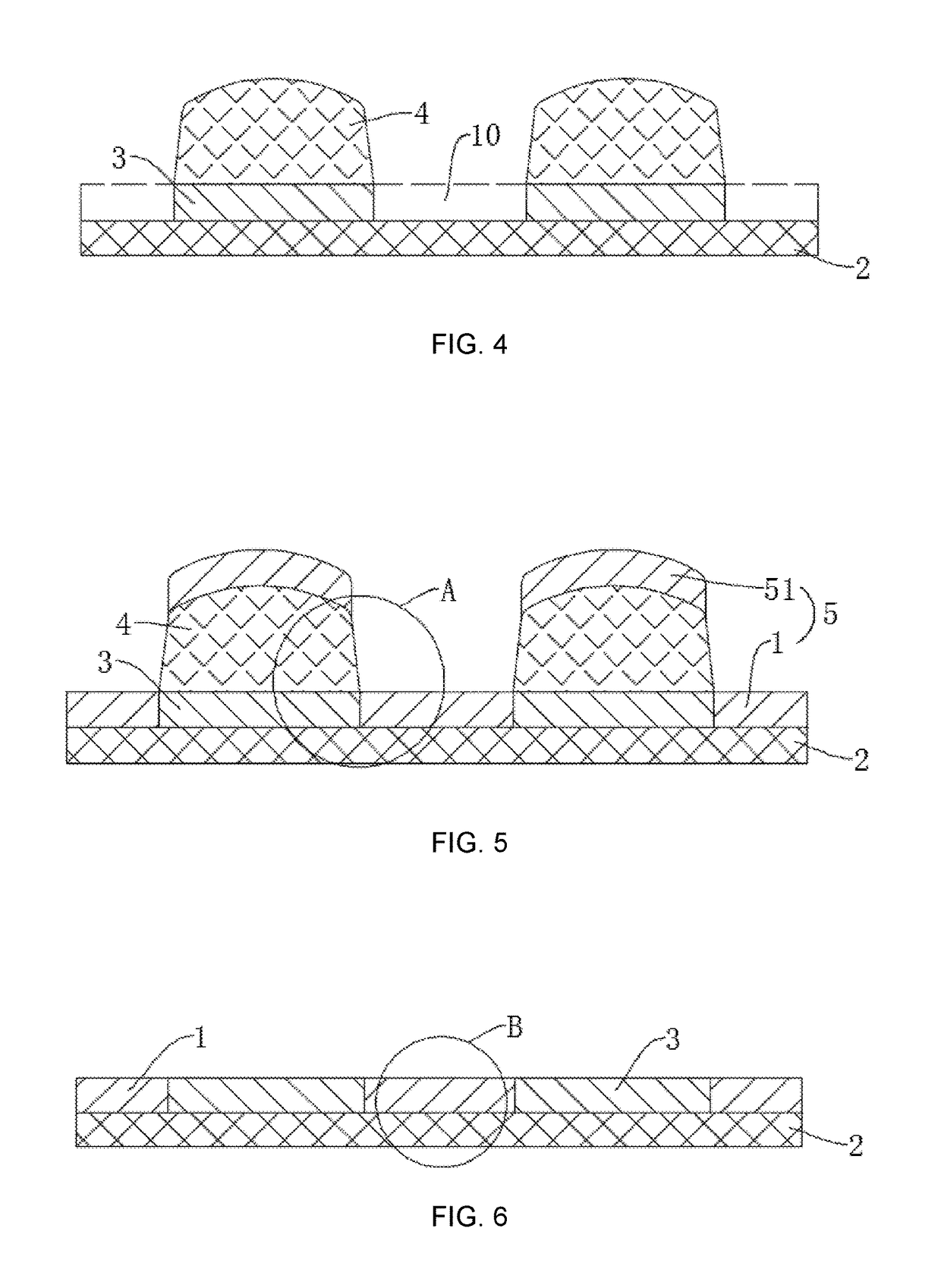

ActiveUS9899221B2Easy to controlLow production costSolid-state devicesSemiconductor/solid-state device manufacturingResistPhotoresist

The present disclosure discloses a method for preparing electrode including: providing a substrate; forming a buffer layer on the substrate; forming a patterned photoresist on the surface of the buffer layer away from the substrate, the photoresist has a bottom surface and a top surface disposed opposite and a side connected between the bottom surface and the top surface, the bottom surface is bonded to the buffer layer; by dry etching, the portions of the photoresist not covered by the buffer layer is removed to form a receiving area; depositing a conductive film, the conductive film layer includes a waste material forming on the top surface and an electrode filling in the receiving area; and stripping the waste material and the photoresist. The yields of the method for preparing electrode of the present disclosure is high.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Blue-light copper-gold powder for metal spraying and preparation method thereof

The invention discloses a blue-light copper-gold powder for metal spraying and a preparation method thereof. The method comprises the following components of, by mass, 70-74% of copper, 22-28% of zincand 1-2% of polyethylene glycol solution; and after the procedures of smelting, ball milling, grading and polishing, colored alloy pigment with different particle sizes scaly-shaped structures is obtained, wherein the particle sizes range from 2 micro to 40 micro, and the appearance of the colored alloy pigment is blue light. According to the method, the addition of an adhesive or other compositions is reduced, the blue-light copper-gold powder is made into a scaly shape which is in a micron-grade and in a blue-light color, the use performance is more facilitated, meanwhile, the risk of oxidation is also reduced.

Owner:苏州月宫科技有限公司

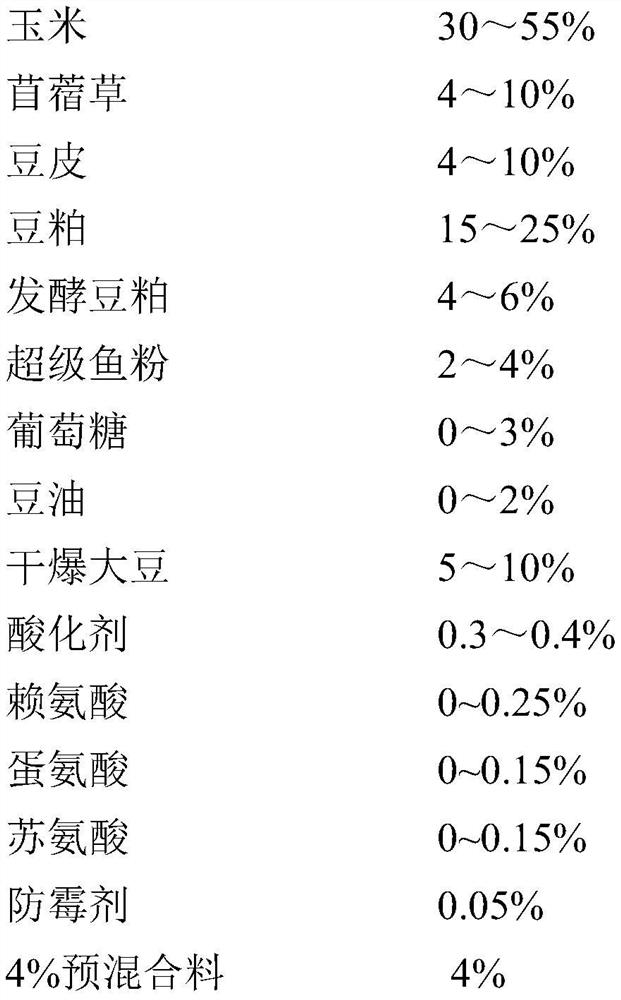

Lactating feed for improving reproductive performance of sows by using dry blasting soybeans and preparation method for lactating feed

InactiveCN111772032APrevent fat oxidationStrong aromaFood processingFood preservationBiotechnologyNutrition

The invention discloses a lactating feed for improving the reproductive performance of sows by using dry blasting soybeans and a preparation method for the lactating feed. The feed comprises 30%-55% of corn, 4%-10% of alfalfa grass, 4%-10% of soybean hulls, 15%-25% of soybean meal, 4%-6% of fermented soybean meal, 2%-4% of super fish meal, 0-3% of glucose, 0%-2% of soybean oil, 5%-10% of dry blasting soybeans, 0.3%-0.4% of acidifier, 4% of 4% premixed feed, wherein the dry blasting soybeans are prepared by processing raw soybeans with high temperature through a high-temperature pre-curing processing technique; the dry blasting soybeans can effectively reduce the anti-nutritional factors, antigen protein and unhealthy oligosaccharides in the soybeans; the protein of the dry blasting soybeans wraps fat, so that oil oxidation is reduced, and the utilization rate of the protein and oil is greatly improved; and the dry blasting soybeans have a strong smell. The digestion and absorption rateof the protein and fat of the lactating feed using dry blasting soybeans is effectively improved, and the reproductive performance of the sows during the lactating period is improved.

Owner:SHANGHAI XINNONG FEED

Cadmium telluride production process

ActiveUS7749480B2Reduce the risk of oxidationMetal selenides/telluridesBinary selenium/tellurium compoundsMercury cadmium tellurideTe element

Owner:5N PLUS INC

Preparation method of high-purity sugammadex sodium

ActiveCN111978435AReduce the risk of oxidationSuppress generationOrganic active ingredientsMuscular disorderInositol pentaphosphateSugammadex Sodium

The invention discloses a preparation method of high-purity sugammadex sodium. The high-purity sugammadex sodium is prepared from inositol phosphate and derivatives thereof. The specific process comprises the following steps of adding a specific type of protective agent into a crude sugammadex sodium product, and performing recrystallizing under the protection of inert gas to obtain a pure sugammadex sodium product, wherein the protective agent is selected from the inositol phosphate and the derivatives thereof, such as inositol hexaphosphate and salts or esters thereof, partial degradation products of the inositol hexaphosphate, such as inositol pentaphosphate, inositol tetraphosphate, inositol triphosphate, inositol diphosphate and inositol monophosphate, and one or a mixture of two or more of the above-mentioned substances and salts or esters thereof in any proportion. The method is simple and convenient to operate, high in product purity, good in safety, few in anaphylactic reaction, good in economical efficiency and more suitable for industrial production.

Owner:HEFEI BOSIKC PHARMTECH CO LTD

Pneumatic conveyer with nitrogen recycling function

A pneumatic conveyer with a nitrogen recycling function is characterized in that the bottom of a buffer chamber is connected with a pneumatic conveying unit via an adjustable rotary valve, the pneumatic conveying unit is connected with a storage chamber via a pipeline, the storage chamber is connected with a storage chamber dust collector via a pipeline, the storage chamber dust collector is connected with a constant pressure gas reservoir via a pipeline, the constant pressure gas reservoir is connected with a gas compressor via a pipeline, the gas compressor is connected with a gas dryer viaa pipeline, the gas dryer is connected with a nitrogen maker via a pipeline, the nitrogen maker is connected with a gas buffer tank via a pipeline, and the gas buffer tank is connected with the pneumatic conveying unit via a pipeline to form a circulation loop. The pneumatic conveyer has the advantages that conveying can be achieved for fragile materials and organic materials having high requirement on moisture, conveying process safety is greatly improved, and the content of water in materials is effectively controlled; nitrogen circulation is provided for the conveying process, nitrogen is produced with low oxygen content, processing time of the nitrogen maker is effectively extended, and conveying cost is reduced.

Owner:湖北甘宁石化新材料股份有限公司

Stainless steel powder machining technology

The invention relates to the technical field of powder metallurgy, in particular to a stainless steel powder machining technology. The stainless steel powder machining technology comprises the following machining steps that smelting is conducted, specifically, solid stainless steel is added into an intermediate frequency furnace and heated to be melted; glass cullet is added on the surface layer of molten stainless steel through a furnace opening of the intermediate frequency furnace, so that the surface layer of the molten stainless steel is completely covered with the glass cullet; heating and smelting continue being conducted till the glass cullet and the solid stainless steel are all melted; water atomization powder manufacturing is conducted, specifically, the molten stainless steel is poured into a tundish, flows into a high-pressure spray disc from the bottom of the tundish and falls into an atomization barrel after flowing out from the high-pressure spray disc; in the atomization barrel, high-pressure water sprayed out from the high-pressure spray disc impacts a molten stainless steel column, and the molten stainless steel column is broken into stainless steel powder; and dehydration and drying are conducted, specifically, the stainless steel powder is subjected to dehydration and drying in sequence, and the product stainless steel powder is obtained. By adopting the machining technology, the risk that the stainless steel powder is oxidized can be reduced, and accordingly, the oxygen content of the stainless steel powder is reduced.

Owner:石家庄京元粉末材料有限责任公司

Device for generating hydrogen-rich water through electrolysis

InactiveCN105585081AReduce the risk of oxidationExtended service lifeWater/sewage treatmentResidual chlorineTitanium

The invention provides a device with a titanium-based gold-plated electrode for generating hydrogen-rich water through electrolysis, and belongs to technical field of electrochemistry. The device comprises an electrolytic tank, a negative electrode, a positive electrode and a controllable electrolytic power supply, wherein the negative electrode, the positive electrode and the controllable electrolytic power supply are put in the electrolytic tank. The negative pole and the positive pole of the controllable electrolytic power supply are connected with the negative electrode and the positive electrode through wires respectively; a stainless steel electrode is adopted as the negative electrode, and the titanium-based gold electrode is adopted as the positive electrode. Compared with an existing DSA positive electrode composed of Ir, Ru, Ti and oxides thereof, by means of the titanium-based gold-plated positive electrode, the quantity of residual chlorine generated in the electrolytic process is significantly decreased.

Owner:LIFEWATER CORP

Composite fluorine polymer high-frequency high-transmission dual-side copper foil substrate and fabrication method thereof

PendingCN110062520ALow dielectric constantLow dielectric lossLiquid surface applicatorsDielectric materialsUv laserInsulation layer

The invention discloses a composite fluorine polymer high-frequency high-transmission dual-side copper foil substrate and a fabrication method thereof. The dual-side copper foil substrate sequentiallycomprises a first copper foil layer, a first insulation polymer layer, a first extremely-low dielectric glue layer, a core layer, a second extremely-low dielectric glue layer, a second insulation polymer layer and a second copper foil layer from top to bottom, wherein the first insulation polymer layer and the second insulation polymer layer both are fluorine polymer layers, the first insulationpolymer layer and the second insulation polymer layer both are insulation layers with Dk values being 2.0-3.50 and Df values being 0.0002-0.001, and the first copper foil layer and the second copper foil layer both are low-profile copper foil layers with Rz values being 0.1-1.6 micrometers. The dual-side copper foil substrate and an FPC have favorable electricity and also have the advantages of cost, relatively short processing flow, low thermal expansion coefficient, stable dk / df performance under a high-temperature humidity environment, ultralow water absorption rate, favorable UV laser drilling capability, low elastic force, high-density assembly and excellent mechanical property.

Owner:KUSN APLUS TEC CORP

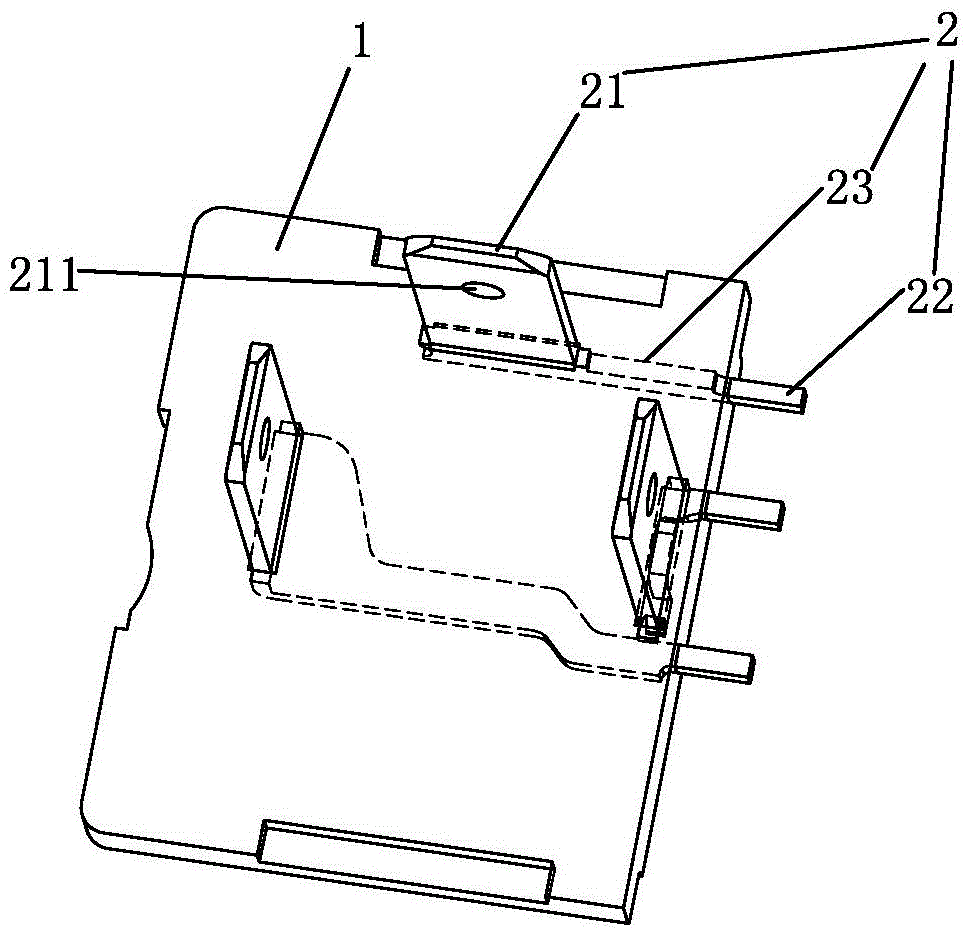

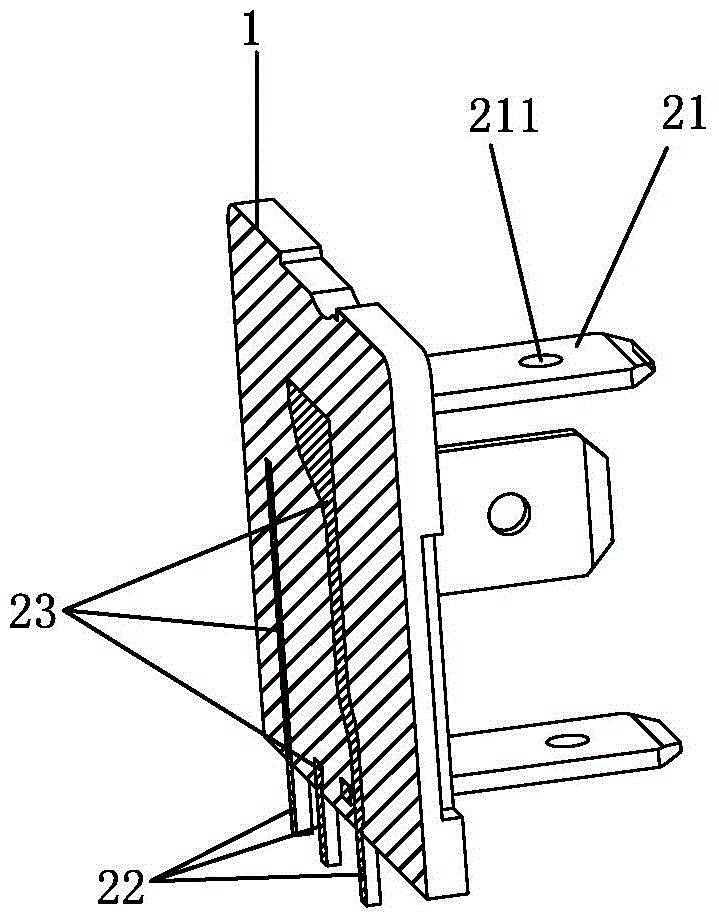

Combined converting terminal and automotive relay

The invention discloses a combined converting terminal and an automotive relay. The combined converting terminal includes a plate-shaped insulating body, and at least two connecting terminals; wherein the at least two connecting terminals are embedded and molded in the insulating body during injection molding of the insulating body respectively, and the connecting terminals are in electrical insulation with each other; and each connecting terminal includes a first terminal, a second terminal and a third terminal, the first terminal and the second terminal extend out from adjacent two surfaces of the insulating body, and the first terminal is electrically connected to the second terminal through the third terminal. The automotive relay includes a PCB assembly and the combined converting terminal; the second terminals of the at least two connecting terminals are pins respectively and are inserted into at least two pin inserting holes arranged in the PCB assembly respectively; and the distance between the second terminals of the at least two connecting terminals fits the distance between the at least two pin inserting holes of the PCB assembly. According to the invention, the connections between various connecting terminals and the insulating body are more solid and are not easy to loosen and fall off.

Owner:XIAMEN HONGFA AUTOMOTIVE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com