Iron-cobalt-tantalum alloy sputtering target material and preparation method thereof

A sputtering target, tantalum alloy technology, applied in sputtering coating, metal processing equipment, metal material coating technology and other directions, can solve the problems of difficult product machining, high product hardness, generation of pores, etc. The effect of mass production, low gas impurity content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

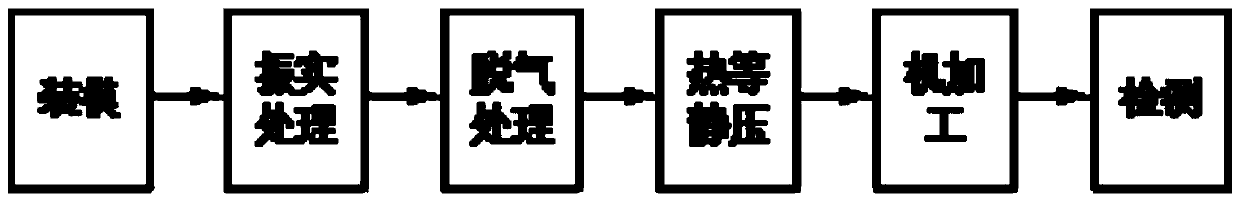

[0064] figure 1 A flowchart showing the method for preparing an iron-cobalt-tantalum alloy sputtering target provided by the present invention specifically includes the following steps:

[0065] (1) Pack the iron-cobalt-tantalum alloy powder with the target atomic ratio into the mold and seal it, and carry out vibration treatment;

[0066] (2) the mold after step (1) is shaken is carried out degassing process;

[0067] (3) hot isostatic pressing the mold degassed in step (2) at 750-900° C. to obtain a crude iron-cobalt-tantalum alloy sputtering target;

[0068] (4) Machining the crude iron-cobalt-tantalum alloy sputtering target material obtained in step (3), and then performing quality inspection and size inspection of density, bending strength, magnetic flux, oxygen content, and obtaining qualified iron-cobalt Tantalum Alloy Sputtering Target.

[0069] For ease of understanding the present invention, the present invention enumerates embodiment as follows:

Embodiment 1

[0071] This embodiment provides a method for preparing an iron-cobalt-tantalum alloy sputtering target, the preparation method comprising the following steps:

[0072] (1) The iron-cobalt-tantalum alloy powder of the target atomic ratio is prepared by gas atomization method, wherein the atomic ratio of Co is 28%, the atomic ratio of Ta is 17%, and the atomic ratio of Fe is 55%, and then loaded into the pre-cleaned The stainless steel sheath is sealed and sealed. The stainless steel cover plate and the sheath are welded by argon arc welding for sealing and vibration treatment. The vibration time is 3min, the vibration amplitude is 10mm, and the vibration frequency is 50 times / min;

[0073] (2) Put the vibrated mold in step (1) into a heating furnace, heat it to 300°C, and control the vacuum degree below 5.0E-3Pa, and perform a degassing treatment for 8 hours;

[0074] (3) Put the mold degassed in step (2) into a hot isostatic pressing furnace, first carry out cold pressurized s...

Embodiment 2

[0077] This embodiment provides a method for preparing an iron-cobalt-tantalum alloy sputtering target, the preparation method comprising the following steps:

[0078] (1) The iron-cobalt-tantalum alloy powder of the target atomic ratio is prepared by gas atomization method, wherein the atomic ratio of Co is 28.5%, the atomic ratio of Ta is 18%, and the atomic ratio of Fe is 53.5%, and then loaded into the pre-cleaned The stainless steel sheath is sealed and sealed. The stainless steel cover plate and the sheath are welded by argon arc welding for sealing and vibration treatment. The vibration time is 5min, the vibration amplitude is 8mm, and the vibration frequency is 150 times / min;

[0079] (2) Put the vibrated mold in step (1) into a heating furnace, heat to 450°C, and control the vacuum degree below 5.0E-3Pa, and perform degassing treatment for 6 hours;

[0080](3) Put the mold degassed in step (2) into a hot isostatic pressing furnace, first carry out cold pressurized sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com