FPC multilayer board based on high-frequency FRCC and high-frequency double-sided board and manufacturing process thereof

A double-sided, multi-layer board technology, applied in the direction of multi-layer circuit manufacturing, circuit substrate materials, metal pattern materials, etc., can solve the problems of long pressing time, complicated procedures, and poor mechanical strength of FPC manufacturing lamination equipment. It achieves the effects of easier realization of laser drilling process, simple structure and composition, and saving of processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

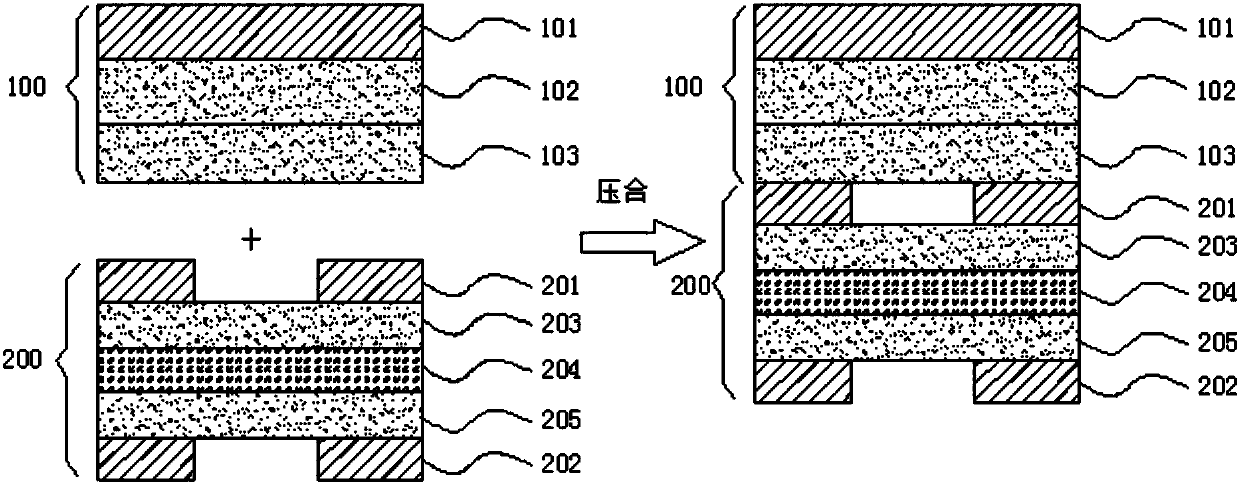

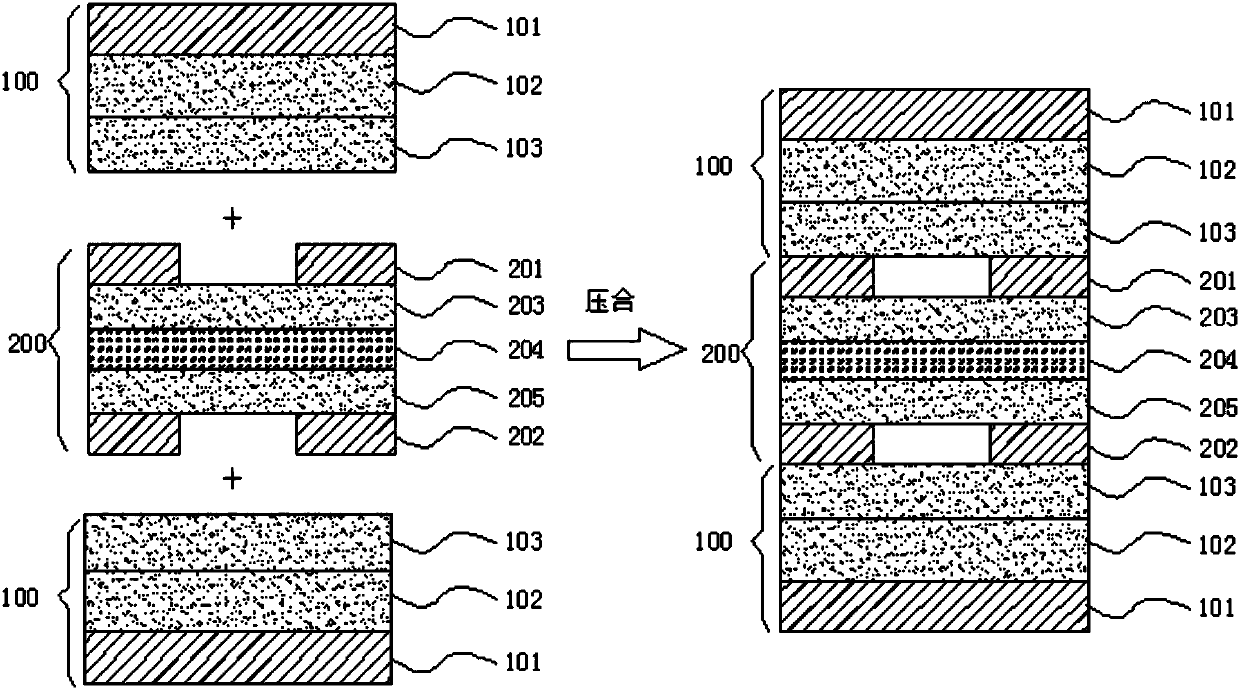

[0069] Embodiment: A kind of FPC multi-layer board based on high-frequency FRCC and high-frequency double-sided board comprises at least one FRCC100 and at least one double-sided board 200, and is pressed and bonded between described FRCC and described double-sided board;

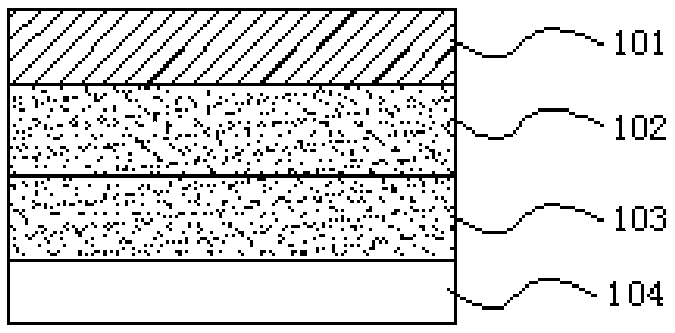

[0070] The FRCC 100 sequentially includes a first copper foil layer 101, a first extremely low dielectric adhesive layer 102 and a second extremely low dielectric adhesive layer 103; the FRCC refers to a Dk (dielectric constant) value of 2.00-3.50 ( 10GHz), and the Df (dielectric loss factor) value of 0.002-0.010 (10GHz) high-frequency FRCC;

[0071] The double-sided board is at least one of a PI-type double-sided board and an LCP-type double-sided board; the double-sided board 200 includes a second copper foil layer 201 and a third copper foil layer 202. When, it also includes an upper very low dielectric adhesive layer 203, a PI core layer 204 and a lower extremely low dielectric adhesive layer 205 locate...

Embodiment approach 1

[0098] Embodiment 1: A FPC multilayer board based on high-frequency FRCC and high-frequency double-sided board, the FPC multilayer board is an FPC three-layer board, such as diagram 2-1 and Figure 3-1 shown, where diagram 2-1 It is an FPC three-layer board structure formed by laminating a FRCC with a PI-type double-sided board. From top to bottom, there are FRCC and PI-type double-sided boards; Figure 3-1 It is an FPC three-layer board structure formed by laminating a FRCC with an LCP double-sided board. From top to bottom, there are FRCC and LCP double-sided boards.

Embodiment approach 2

[0099] Embodiment 2: A FPC multilayer board based on high-frequency FRCC and high-frequency double-sided board, the FPC multilayer board is an FPC four-layer board, such as Figure 2-2 and Figure 3-2 As shown, the structure is similar to Embodiment 1, where Figure 2-2 is a four-layer FPC board structure formed by laminating two FRCCs with a PI-type double-sided board, and the order from top to bottom is FRCC, PI-type double-sided board and FRCC ; Figure 3-2 It is an FPC four-layer board structure formed by laminating two FRCCs with one LCP double-sided board. From top to bottom, there are FRCC, LCP double-sided board and FRCC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com