Mineral-powder rapid reducing system

A fast, mineral powder technology, applied in the field of metallurgy, can solve the problems of easy bonding of fine-grained mineral powder, carbon precipitation hindering normal operation, low reduction speed, etc., to improve metallization rate, enhance reduction effect, reduce The effect of the risk of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

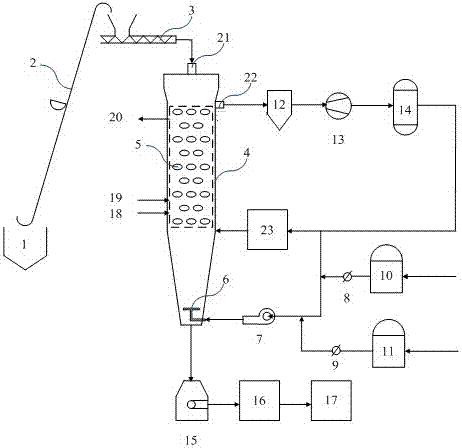

[0061] This embodiment includes the following structures:

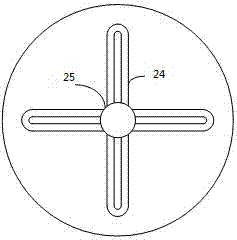

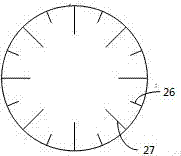

[0062] Rapid reduction reactor: The rapid reduction reactor 4 has a circular cross section and can be divided into a feed section, a reduction section and a cooling section. The need for pressurization within the unit. Wherein, the feed section is located at the top of the reactor 4; the reduction section is located between the feed section and the cooling section, and its inside is arranged in multiple layers along the height direction of the fast reduction reactor. The thermal storage radiant tubes 5 parallel to each other in the horizontal direction have a conical cooling section and are located at the bottom of the reactor 4, which facilitates the powdery material to slide down to the product outlet and avoid local accumulation of the product; a cloth is arranged inside the cooling section of the reactor 4 The wind plate 6 allows the reducing gas to uniformly enter the reactor and undergo a reduction reaction wit...

Embodiment 2

[0072] Rapid reduction reactor: The rapid reduction reactor 4 has a circular cross section and can be divided into a feed section, a reduction section and a cooling section. The need for pressurization within the unit. Wherein, the feed section is located at the top of the reactor 4; the reduction section is located between the feed section and the cooling section, and its inside is arranged in multiple layers along the height direction of the fast reduction reactor. The thermal storage radiant tubes 5 parallel to each other in the horizontal direction have a conical cooling section and are located at the bottom of the reactor 4, which facilitates the powdery material to slide down to the product outlet and avoid local accumulation of the product; a cloth is arranged inside the cooling section of the reactor 4 The wind plate 6 allows the reducing gas to uniformly enter the reactor and undergo a reduction reaction with the ore powder. In addition, the side wall at the top of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com