Process for producing natural fruit-juice perfume synergist using passion flower as raw material

A technology of passion fruit fresh fruit and flavor enhancer, applied in the field of food processing, can solve the problems of inconvenient storage, transportation, use, difficulty in maintaining the flavor, taste and color deterioration of passion fruit, etc., and achieves shortening drying time, reducing The effect of water capture and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

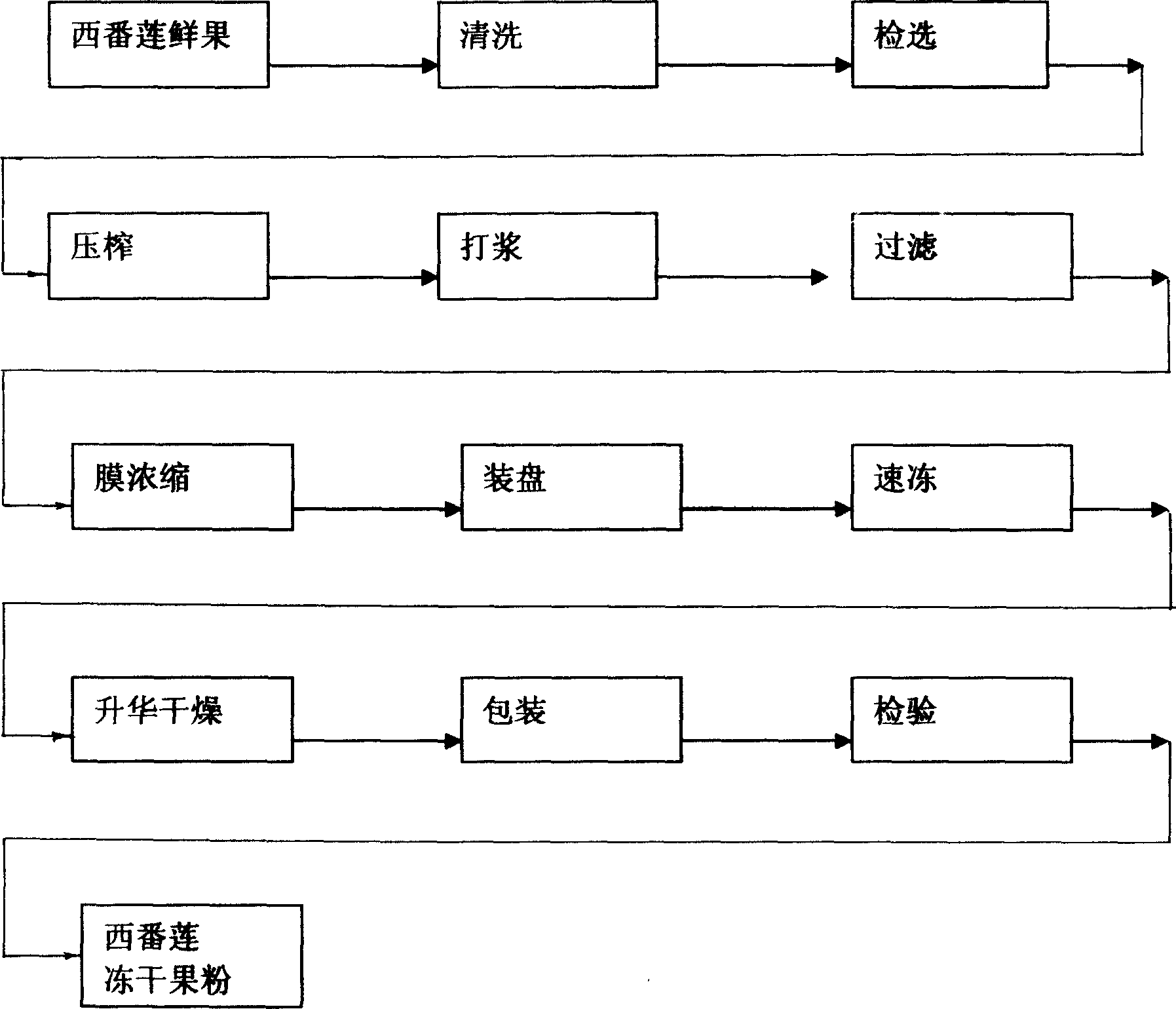

Image

Examples

Embodiment 1

[0018] Adopt Passiflora prostrata 800kg, circulate through nanofiltration membrane concentrating equipment, pressure 0.3MPa, obtain the Passiflora concentrated juice 400kg of solid 30 ° of Bx. Put it into a stainless steel plate with a thickness of 10mm, enter the quick-freezing tunnel, and reach -35°C after 2 hours, and it has been formed, and then enter the freeze-drying warehouse for sublimation drying, the vacuum degree is 10Pa, and the temperature of the drying plate rises from -10°C to 40°C after 10 hours , a total of 23 hours of drying time, packaged rapidly after leaving the warehouse, the humidity in the packaging room is less than 30%, and 120kg of passion fruit freeze-dried fruit powder with a moisture content of less than 3% is obtained altogether.

Embodiment 2

[0020] Adopt Passiflora prostrata 950kg, circulate through nanofiltration membrane concentrating equipment, pressure 0.28MPa, obtain the Passiflora concentrated juice 400kg of solid 30 ° of Bx. Put it into a stainless steel plate with a thickness of 12mm, enter the quick-freezing tunnel, reach -35°C after 3 hours, and have formed, then enter the freeze-drying warehouse for sublimation drying, vacuum degree 12Pa, the temperature of the drying plate rises from -10°C to 40°C after 10 hours , a total of 25h drying time, packaged rapidly after going out of the warehouse, the humidity in the packaging room is less than 30%, and 131kg of passion fruit freeze-dried fruit powder with a moisture content lower than 3% is obtained altogether.

Embodiment 3

[0022] Adopt passion fruit puree 850kg, circulate through nanofiltration membrane concentrating equipment, pressure 0.25MPa, obtain the passion fruit concentrated juice 400kg of solid 32 ° of Bx. Put it into a stainless steel plate with a thickness of 15mm, enter the quick-freezing tunnel, reach -35°C after 4 hours, and have been formed, and then enter the freeze-drying warehouse for sublimation drying, vacuum degree 10Pa, the temperature of the drying plate rises from -10°C to 40°C after 10 hours , the drying time is 24.5 hours in total, and it is packaged quickly after leaving the warehouse.

[0023] Humidity in the packing room is less than 30%, and 125kg of passion fruit freeze-dried fruit powder with moisture content lower than 3% is obtained altogether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com