Combined converting terminal and automotive relay

A technology of automotive relays and terminals, applied in circuits, electrical components, coupling devices, etc., can solve the problems of inconvenient plugging and unplugging, high terminal space occupation rate, and affecting electrical performance, so as to reduce space occupation rate and save assembly process , The effect of easy plugging and unplugging operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

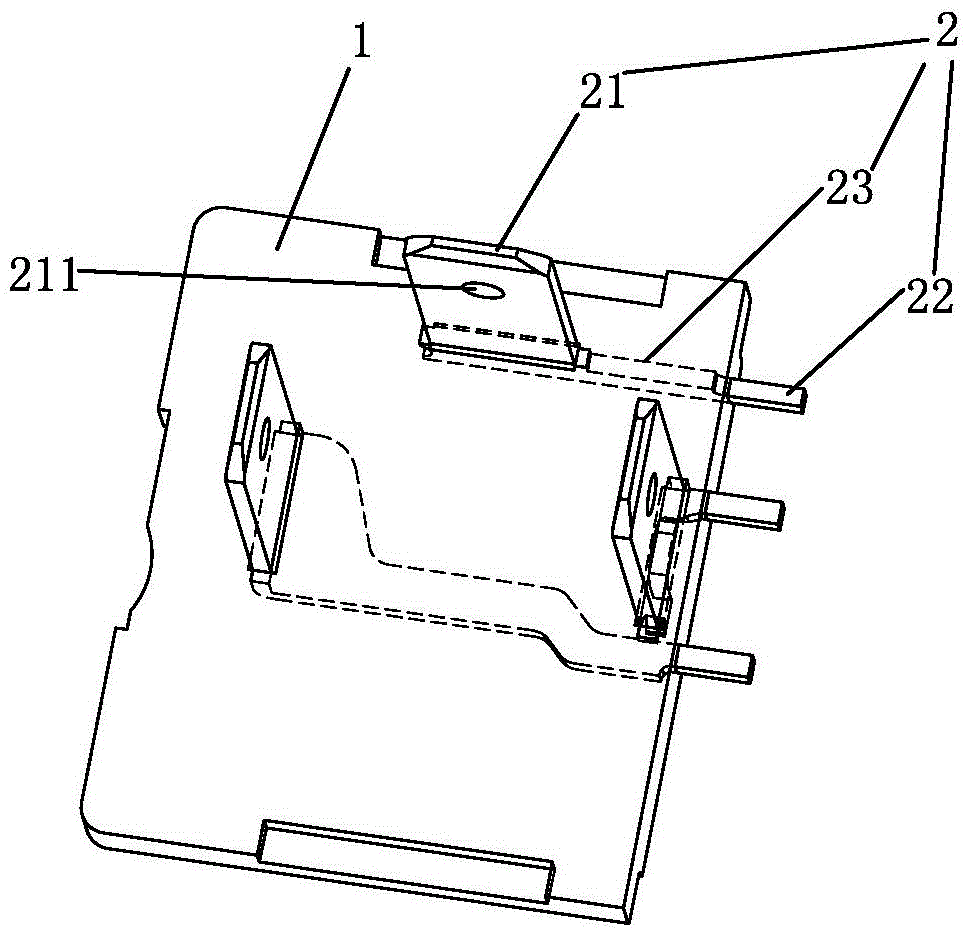

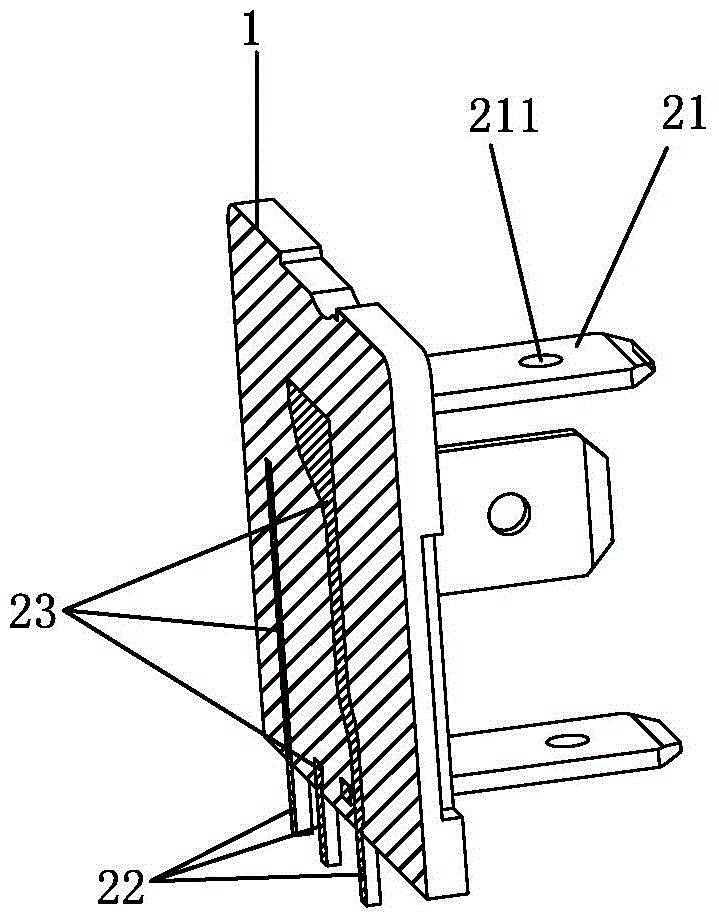

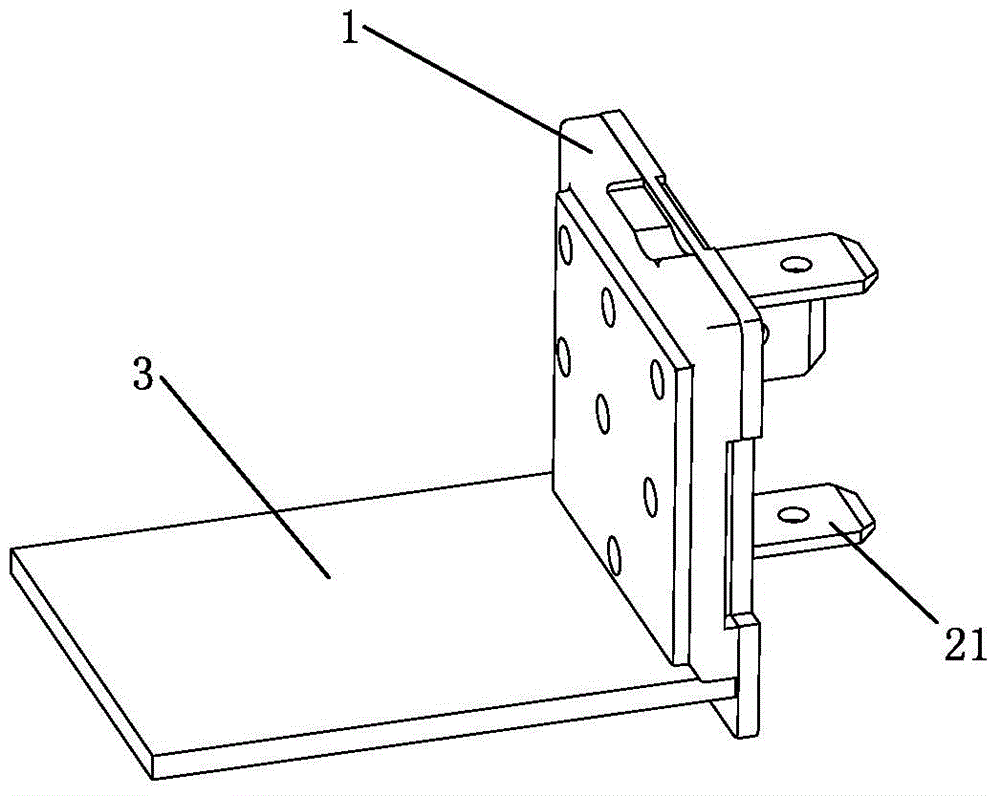

[0029] See figure 1 , figure 2 As shown, a combined conversion terminal of the present invention includes a plate-shaped insulating body 1 and three connecting terminals 2. The three connecting terminals 2 are respectively insert-molded in the insulating body 1 when the insulating body 1 is injected, and each The connecting terminals 2 are electrically insulated from each other; each connecting terminal 2 includes a first terminal 21, a second terminal 22 and a third terminal 23 respectively, and the first terminal 21 and the second terminal 22 extend from two adjacent surfaces of the insulating body 1, And the first terminal 21 is electrically connected to the second terminal 22 through the third terminal 23 .

[0030] In this embodiment, the first terminals 21 of the three connecting terminals 2 extend from the same surface of the insulating body 1, and the second terminals 22 of the three connecting terminals 2 extend from the same surface of the insulating body 1. exten...

Embodiment 2

[0045] See Figure 5-Figure 8 As shown, a combined conversion terminal of the present invention has nine connection terminals 2, and the first terminals 21 of the nine connection terminals 2 are located on the same surface of the insulating body 1, and the second terminals 22 of the nine connection terminals 2 are also Located on the same surface of the insulating body 1 and on two adjacent surfaces of the insulating body 1 with the first terminal 21 , the third terminals 23 of the nine connecting terminals 2 are all embedded in the insulating body 1 .

[0046] Due to the miniaturization requirements of automotive relays, the size of the insulating body 1 is limited. Therefore, the first terminals 21 of some connecting terminals 2 overlap in the direction perpendicular to the PCB assembly. In order to ensure that the connecting terminals 2 are electrically insulated from each other and the second terminals 22 are along the Arranged in a "" shape, the third terminals 23 in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com