Integrated device for preparing nano zero-valent iron in laboratory and preparation method

A nano-zero-valent iron and preparation device technology, which is applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve the problems of limited single separation amount, large loss, and long separation time, so as to reduce material Oxidation risk, effect of enhancing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

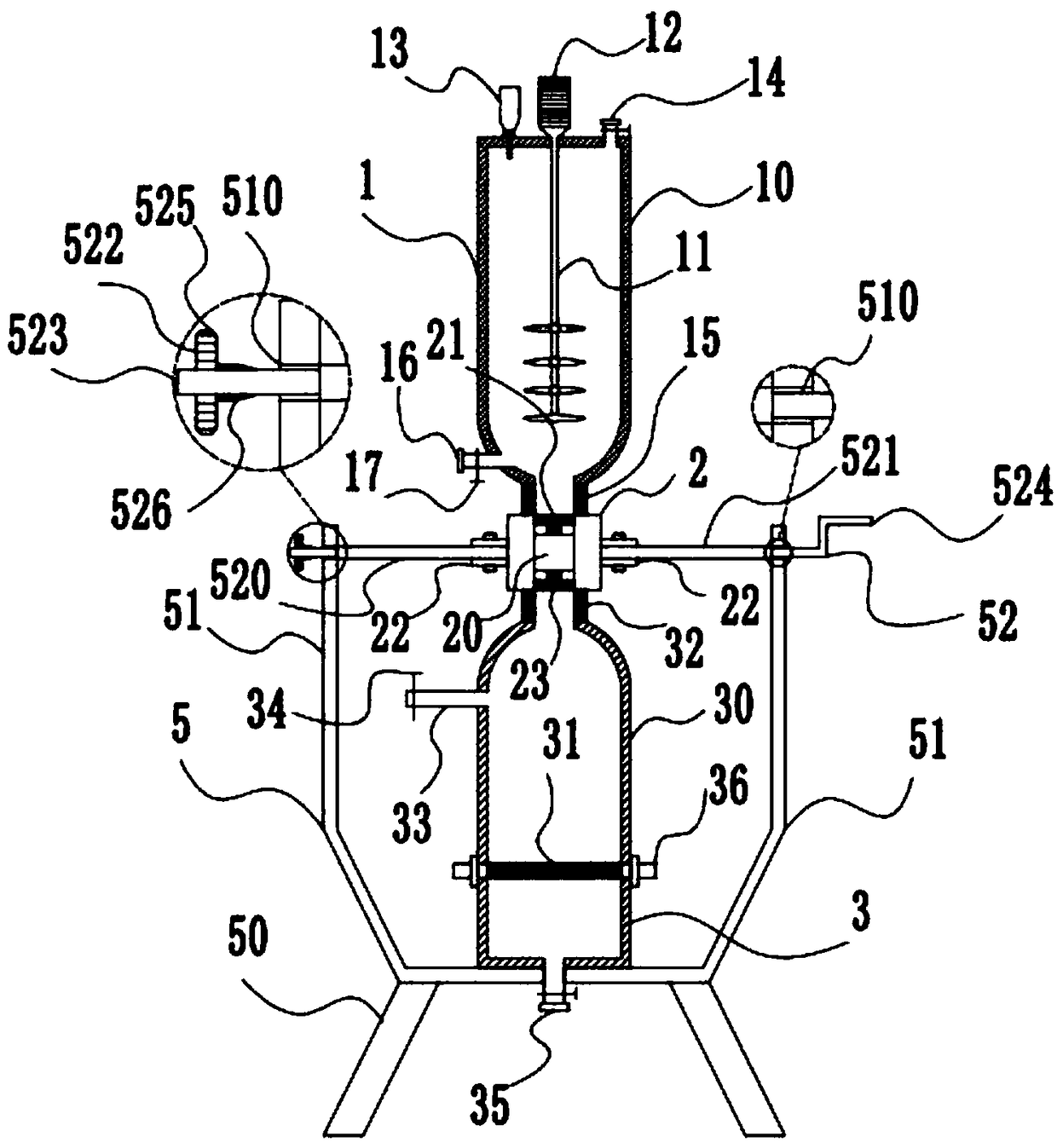

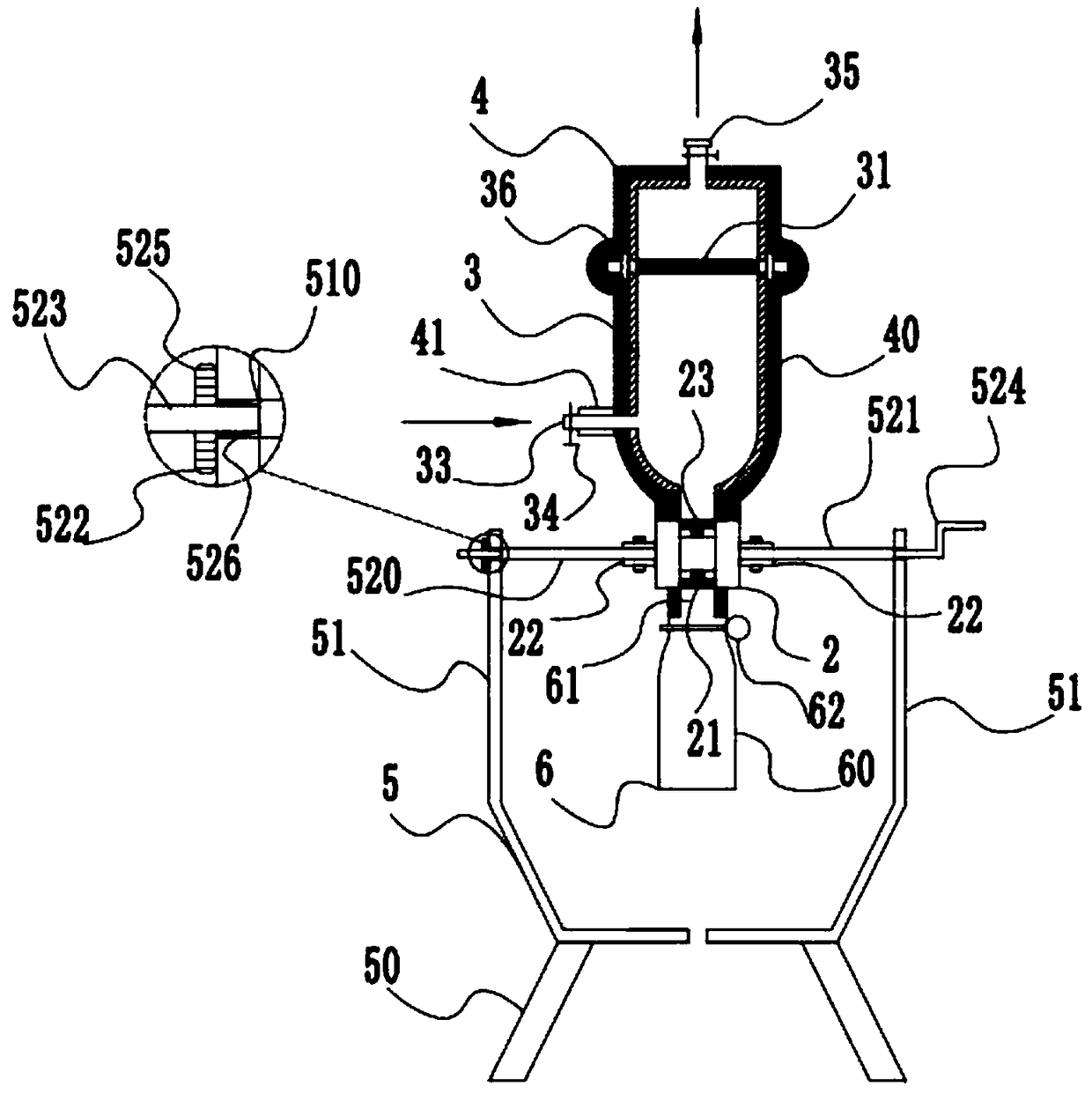

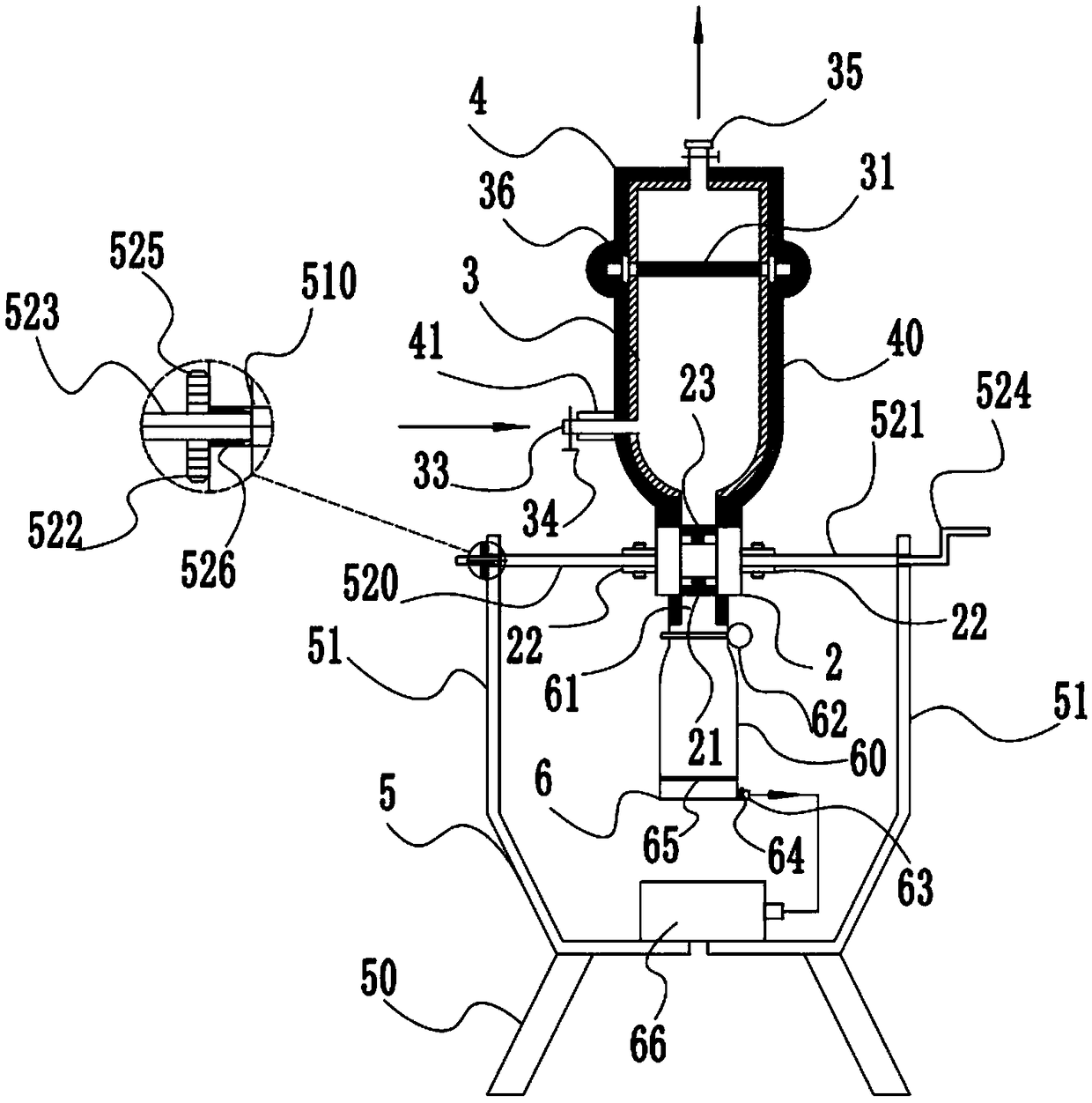

[0036] Such as figure 1 As shown, an integrated device for preparing nano-zero-valent iron in the laboratory includes a reaction preparation device 1, a connecting device 2, a separation and cleaning device 3, a heating and drying device 4, and a fixed support device 5; the reaction preparation device 1 includes Tank body one 10, stirring rod 11, stirring motor 12, separatory funnel 13, the top of tank body one 10 is provided with liquid inlet one 14, the bottom center position is provided with liquid outlet one 15, the side wall of tank body one 10 The lower part is provided with air inlet one 16, air inlet one 16 is provided with air inlet valve one 17, stirring motor 12 is arranged on tank body one 10 top center position, stirring rod 11 is positioned at tank body one 10 inside, and stirring rod 11 The upper end is connected to the output shaft of the stirring motor 12, the separatory funnel 13 is arranged on the top side of the tank body 10, and the lower end of the separa...

Embodiment 2

[0048] The present invention is substantially the same as embodiment 1, the difference is:

[0049] The method for preparing nanometer zero-valent iron by utilizing the above-mentioned integrated device comprises the following steps:

[0050] 1 sample preparation process: close the main valve 21 and the auxiliary valve 23, open the valve on the inlet valve-17 and the inlet-14, import the ferrous sulfate heptahydrate solution from the inlet-14, and enter the ferrous sulfate heptahydrate solution from the inlet-16 Introduce nitrogen to aerate for 5 minutes, turn on the stirring motor 12, drive the stirring rod 11 to fully stir the solution, add the reducing agent through the separatory funnel 13, and control the dropping rate of the reducing agent to 3 drops / s until the dropping of the reducing agent is completed , the reaction is prepared into a sample, the stirring motor 12 is closed, the main valve 21 and the auxiliary valve 23 are opened, and the solution containing the samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com