Rotary-sifting watermill polishing machine for rice

A technology of polishing machine and water mill, which is applied in grain milling, grain finishing, grain processing, etc. It can solve the problems of increasing the rate of broken rice, insufficient heat generated by rice friction, and reducing the rate of rice output, so as to increase the frequency of contact friction , Improve the polishing effect and reduce the power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

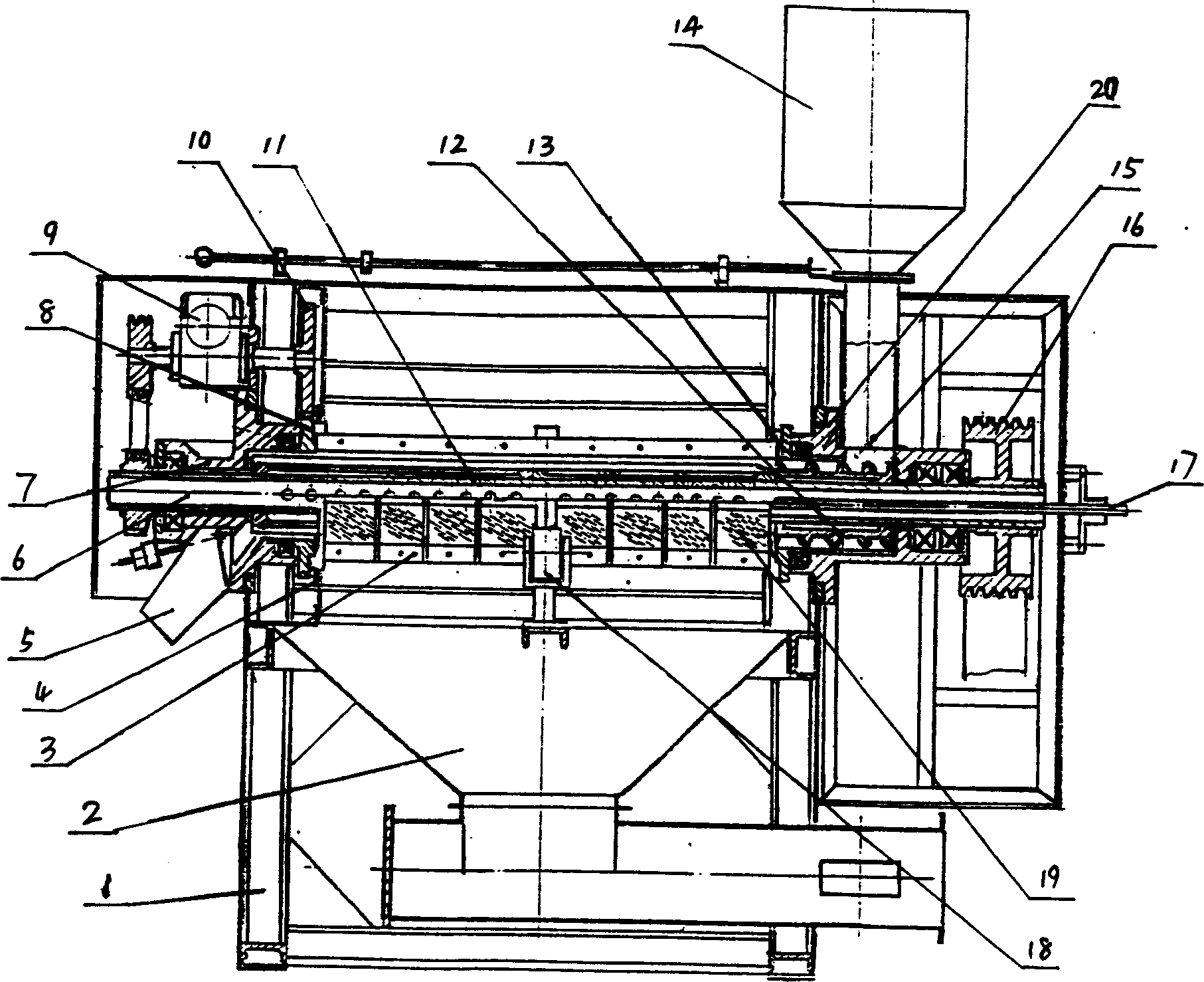

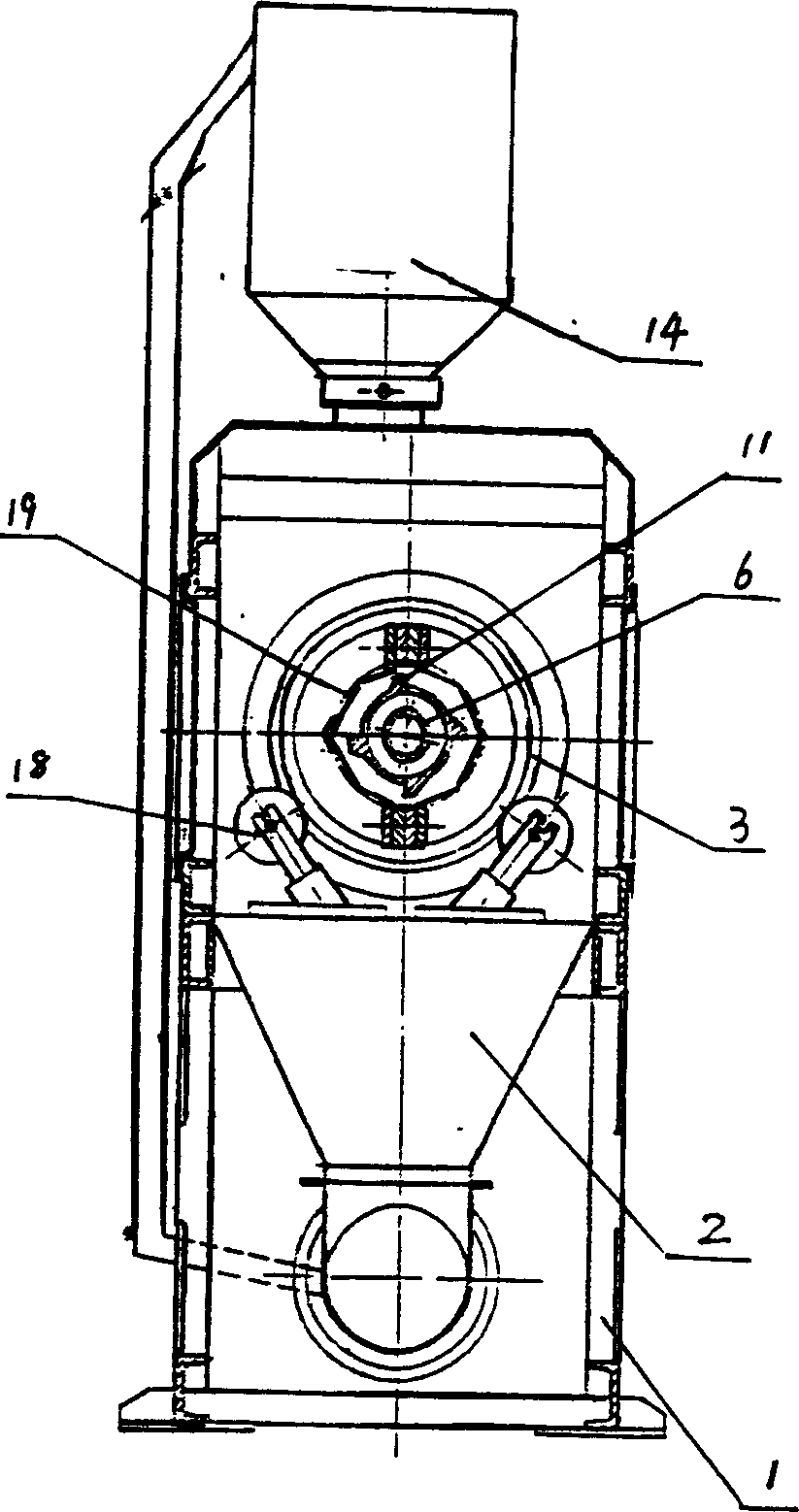

[0009] A kind of rotary sieve rice water mill polishing machine comprises frame 1, chaff collecting bucket 2, discharge port 5, main shaft 6, polishing roller, screw conveying roller 12 and rice sieve 19, and chaff collecting bucket 2 is arranged on the below of rice sieve 19, The inside of the main shaft 6 is a cavity, one end of the atomizing water pipe 17 is inserted into the cavity, and the other end is connected with the atomized water source outside the main shaft 6, and the main shaft 6 is fixed on the On the frame 1, the rice sieve bracket 3 and the rice sieve 19 are all sleeved on the main shaft 6, the rice sieve bracket 3 is fixedly connected with the rice sieve 19, the radial section of the rice sieve 19 is a regular polygon, and the rice sieve bracket 3 One end of the shaft is connected to the driven gear 8, and the other end is connected to the feed bush 13, and the feed bush 13 and the driven gear 8 are respectively set on the bearings in the main shaft feed beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com