Patents

Literature

108 results about "Watermill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A watermill or water mill is a mill that uses hydropower. It is a structure that uses a water wheel or water turbine to drive a mechanical process such as milling (grinding), rolling, or hammering. Such processes are needed in the production of many material goods, including flour, lumber, paper, textiles, and many metal products. These watermills may comprise gristmills, sawmills, paper mills, textile mills, hammermills, trip hammering mills, rolling mills, wire drawing mills.

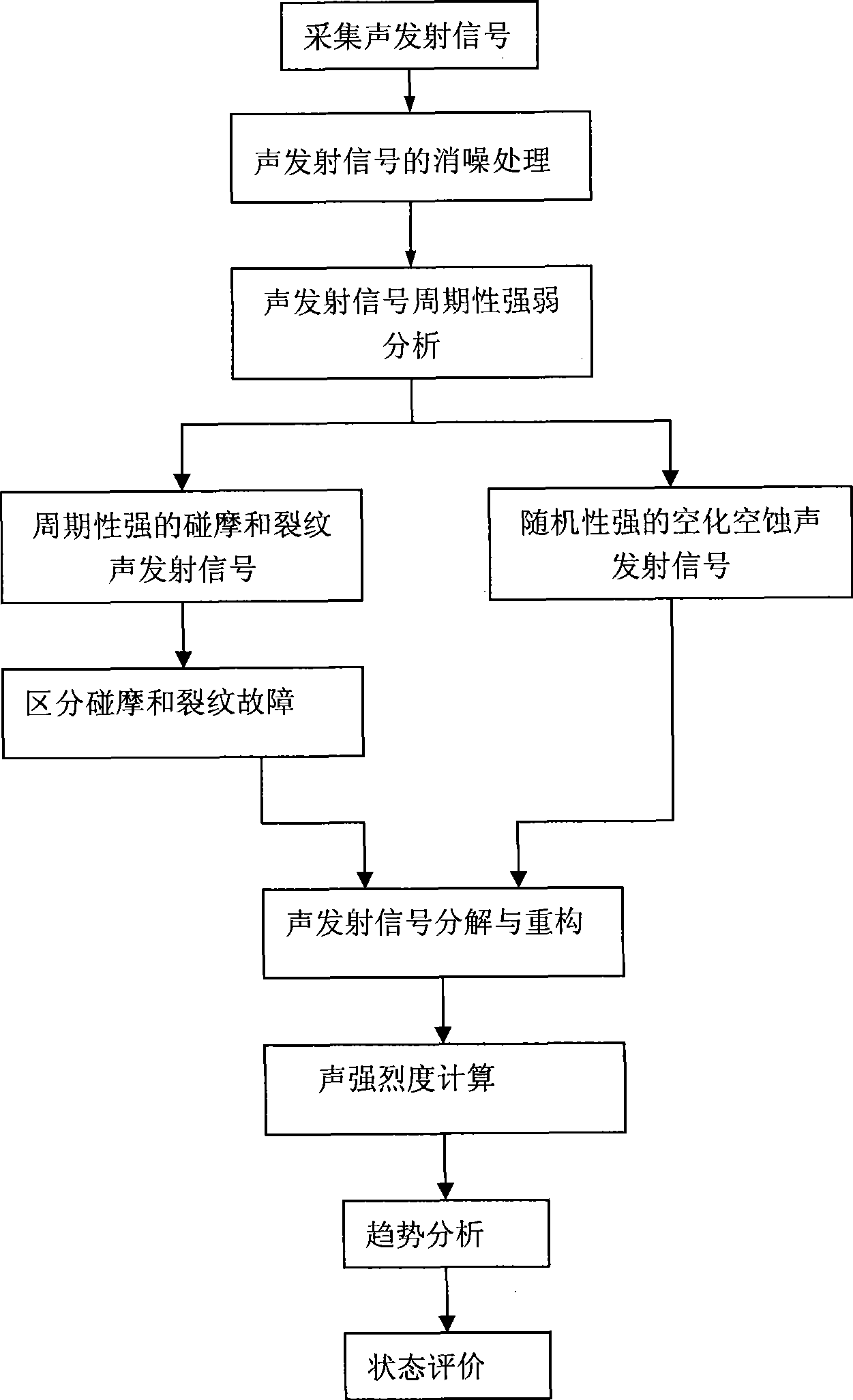

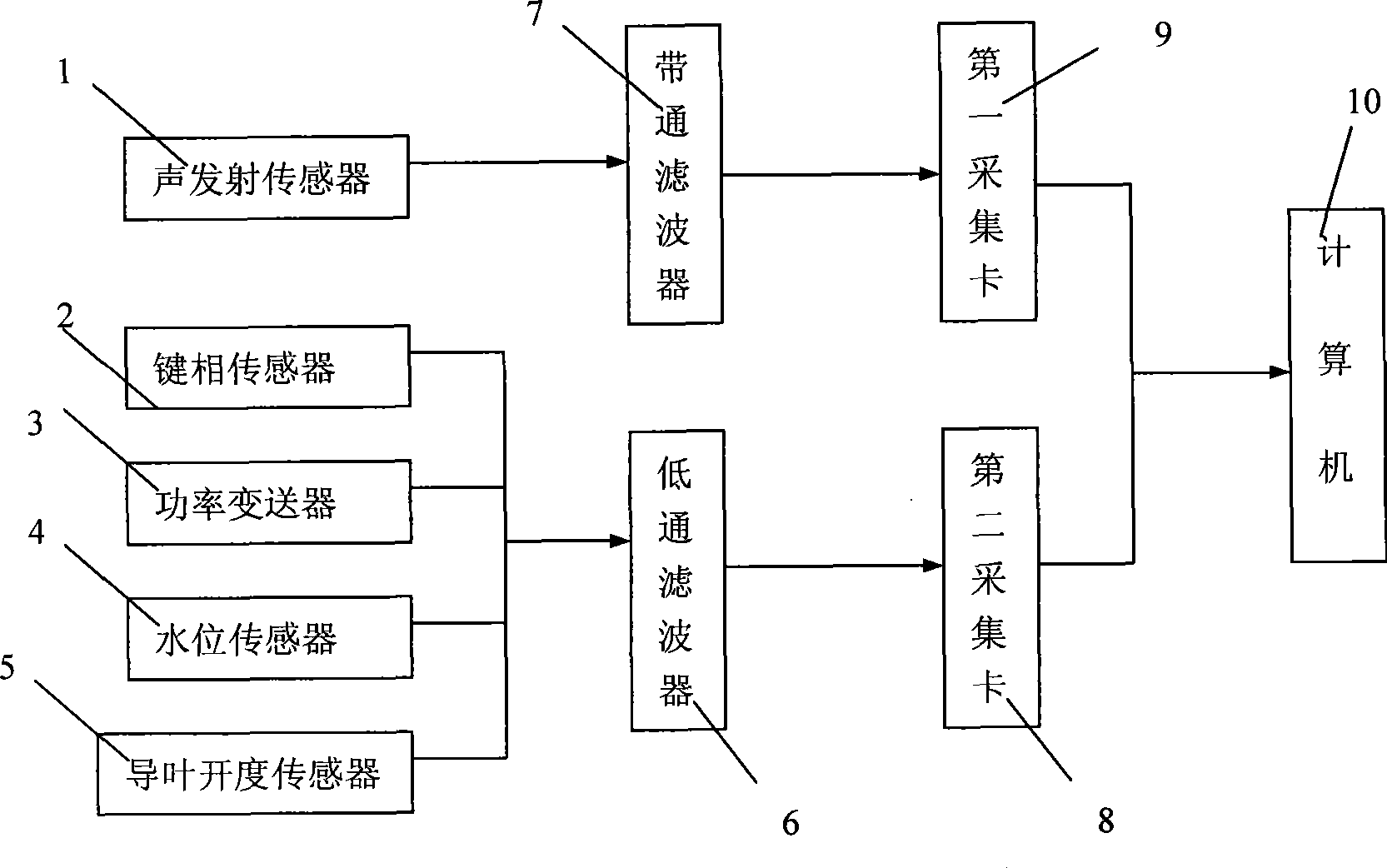

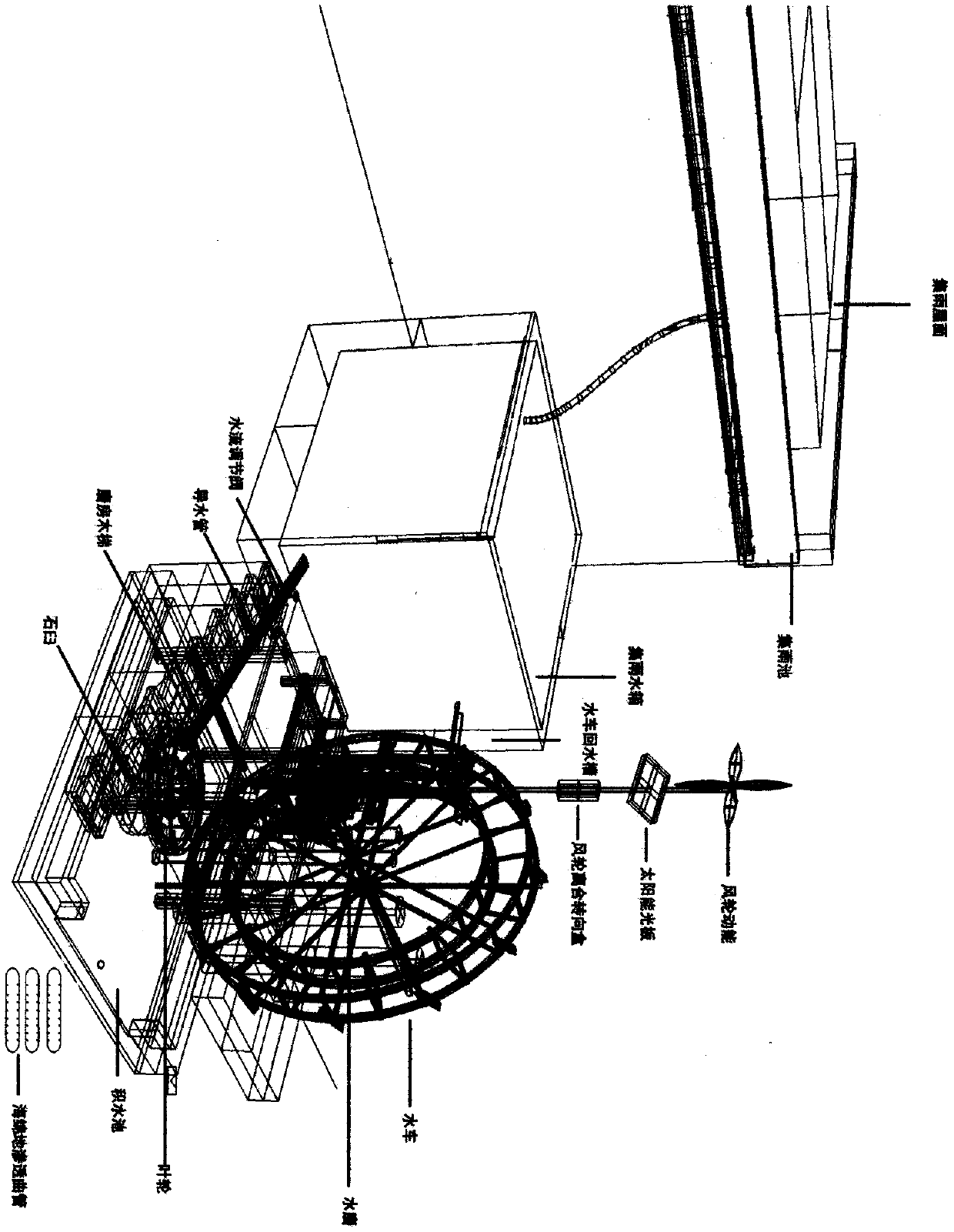

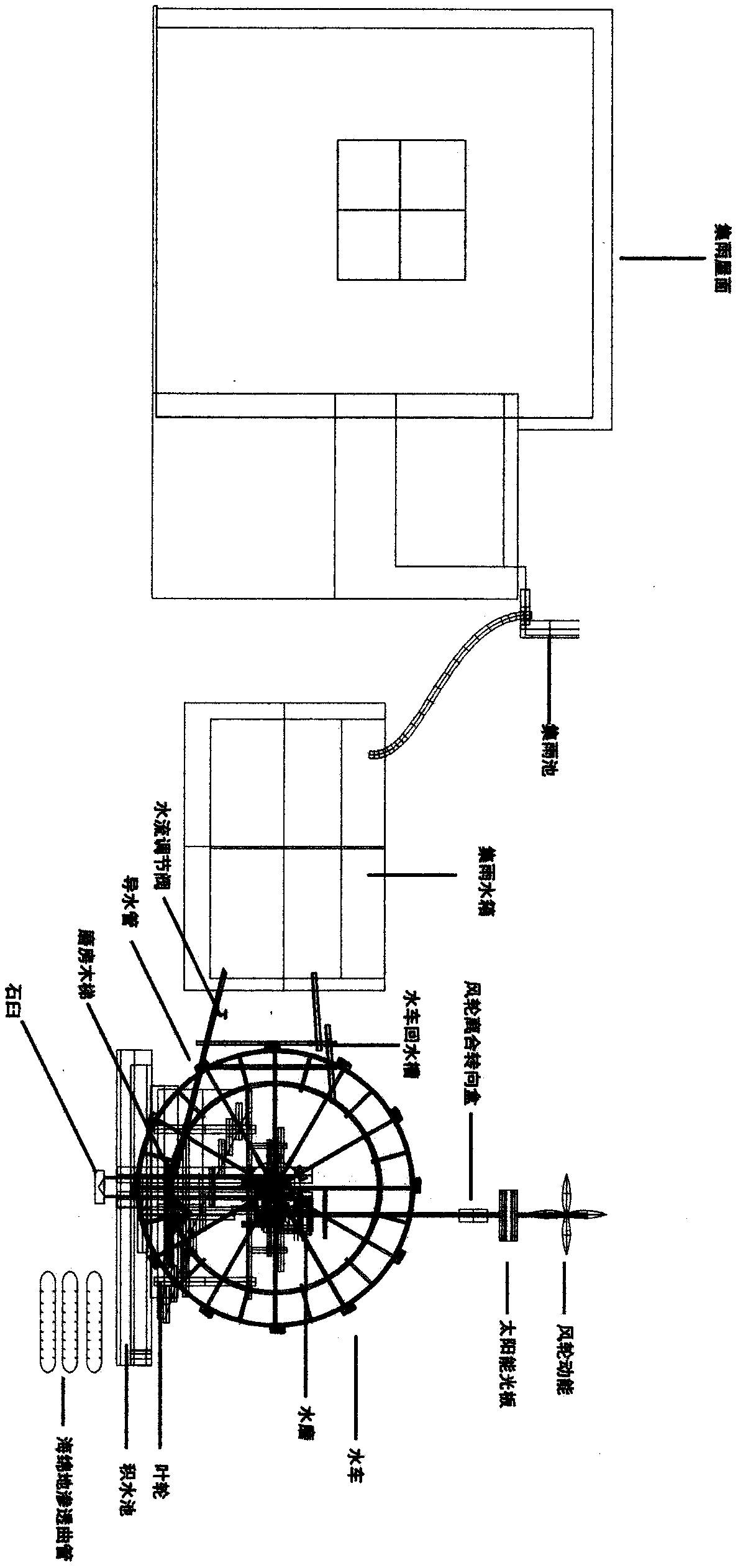

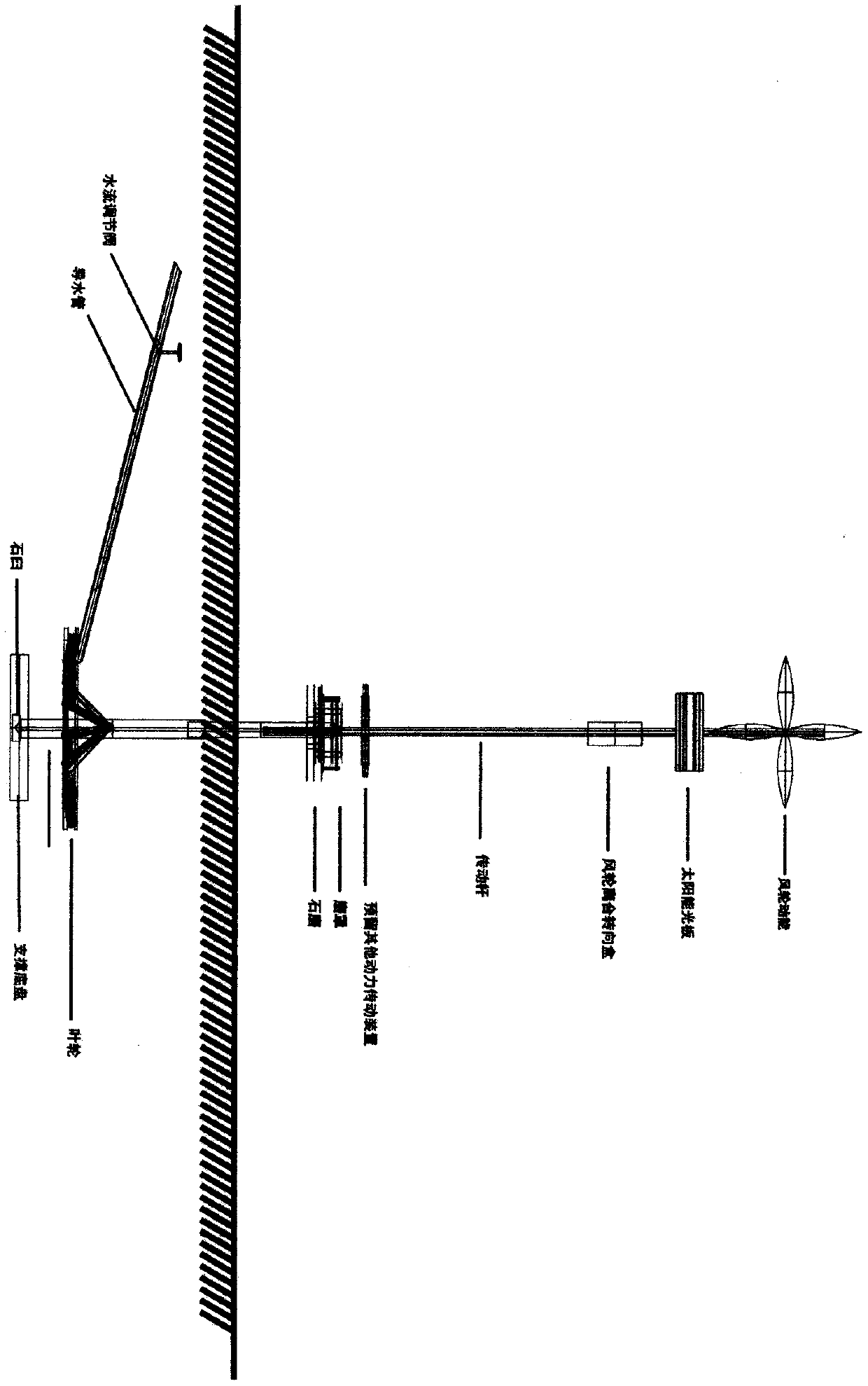

Failure diagnosis method and apparatus of hydroturbine based on acoustic emission technology

InactiveCN101435799AAvoid Low Frequency Noise InterferenceContinuous acquisitionAnalysing solids using sonic/ultrasonic/infrasonic wavesFrequency spectrumCavitation

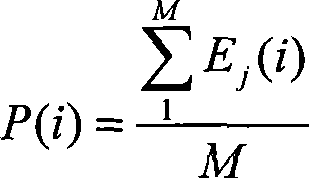

The invention discloses a hydroturbine fault diagnosis method and a hydroturbine fault diagnosis device based on acoustic emission technology. The method applies the acoustic emission technology to the fault diagnosis of a hydroturbine set, obtains acoustic emission signals on a hydroturbine draft tube and guide vanes of a watermill chamber through an acoustic emission sensor, eliminates noise by adopting morphological filtering technology, adopts the pulse repetition rate to analyze the intensity of the periodicity of the acoustic emission signals, combines spectrum analysis and waveform nearness analysis to identify common rub impact, cracks as well as cavitation and cavitation erosion states, and applies wavelet packet technology for the decomposition and reconstruction of the signals to calculate the acoustic intensity of acoustic emission and perform the trend analysis of parameters of the acoustic intensity along with the working condition such as active power, water head and guide vane opening, further to comprehensively know the operation state and performances of a hydroturbine generator set and guide the operation of a hydroturbine.

Owner:TSINGHUA UNIV

Slim slab low carbon steel special for continuous casting crystallizer protected slag and production processes with same

The invention relates to a metallurgical accessory product used for continuous casting of mild-steel thin sheet slab and relates to a premelting crystallizer covering slag technology specifically used for continuous casting of mild-steel thin sheet slab. The invention comprises premelting materials, fusing agent materials and carbonaceous materials; wherein, the fusing agent materials include Li2CO3, K2CO3, MnCO3 and NaF, etc. The manufacturing technique adopted by the invention includes of gasifying the qualified premelting materials, fusing agent materials and carbonaceous materials into a storage hopper and then carrying through microcomputer material mixing per 6T according to a specific mixture ratio for the covering slag; putting into a mixer for mixing and fetching a semi-finished product for detecting; after qualified, putting into a globe mill for dry milling; putting into an levigator to mill and produce slurry; extracting materials, spraying and granulating; packing and warehousing the qualified products. Compare with import slags, the invention has no cohesion and ingot bleeding and the manufacturing technique anterograde of the invention far exceeds that of the import slag. The invention has the advantages of few slag strips and active reaction as well as small frame in the crystallizer.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Mirror processing method for stainless steel plate and polishing machine adopted in the same

The invention provides a mirror processing method for a stainless steel plate and a polishing machine adopted in the same. The processing method includes the steps of coarse grinding, polishing, cleaning and drying. In the coarse grinding step, a water grinding mode is adopted, a grinding head assembled by coarse grinding cloth serves as a grinding tool, and an oxidation layer on the surface of the stainless steel plate is grinded away. In the polishing step, a grinding head bound by wool felt and sponges serves as a grinding tool, mixed liquid of hydrogen nitrate and hydrargyri oxydum rubrum serves as polishing liquid, and the stainless steel plate is polished into a mirror plate. In the cleaning step, fresh water is sprinkled to the surface of the stainless steel mirror plate, brushing is carried out through hairbrushes and brush rollers, and dirt on the plate surface is removed. In the drying step, heating is carried out through an electric baking lamp tube to remove moisture on the surface of the mirror plate. The mirror processing method is simple; the corresponding polishing machine is combined, and the mirror effect on the surface of the stainless steel is achieved through the polishing liquid in cooperation with preset polishing time.

Owner:ZHAOQING HONGWANG METAL IND

Grinding process for bamboo ware and bamboo strip

InactiveCN101402212ANot easy to deform and breakImprove processing utilizationVeneer manufactureGrinding machinesFiberWatermill

The invention relates to a grinding process for bamboo products, namely bamboo splints, and belongs to a bamboo splints processing method. Cut surface green bamboo chips are subjected to stewing, fiber forming, water milling, bleaching and drying to obtain the bamboo splints. The water milling treatment can effectively remove burrs and stains on the surfaces of the bamboo splints, so that the produced bamboo splints have smooth surfaces without the burrs and do not prick the hand; and the waste materials obtained after the water milling can be directly used for paper making, so that no pollution is caused and the environmental protection is ensured. The processed bamboo splints can be widely used in bamboo products such as bamboo mats, bamboo pillows, bamboo curtains, bamboo carpets, bamboo-splint woven handicraft articles and so on.

Owner:JIANGXI NANFENG ZHENYU IND GRP

Method of processing stone surface

The invention discloses a method for processing a stone surface, which comprises the following processes: the natural stone with a pore is first smoothly milled by a mill. The milled stone is cleanly washed and is dried by a drier or natural wind. A part of the pores is then sealed by a gummed paper according to the needs. The rest pores are filled by the milled powder and then is smoothly milled by the mill. The next process is to tear off the gummed paper in the pore and then a glue solution is coated on the pores. A gold powder or silver powder or other luminous substance is filled on the glue solution. After the glue solution is dried, the surface of the stone is coated by a layer of paint with an ability of butter resistance; finally, a layer of resin is coated on the painted stone surface. After a levigation using the mill, the stone surface is polished and waxed, then the stone with a golden flickering or silver flickering or starlight flicking surface is obtained. The stone manufactured by the process method in the invention has the advantages of simple process, being able to retain the nature characteristic of the natural stone and add the flickering effect.

Owner:DONGGUAN DIANYA FURNITUR

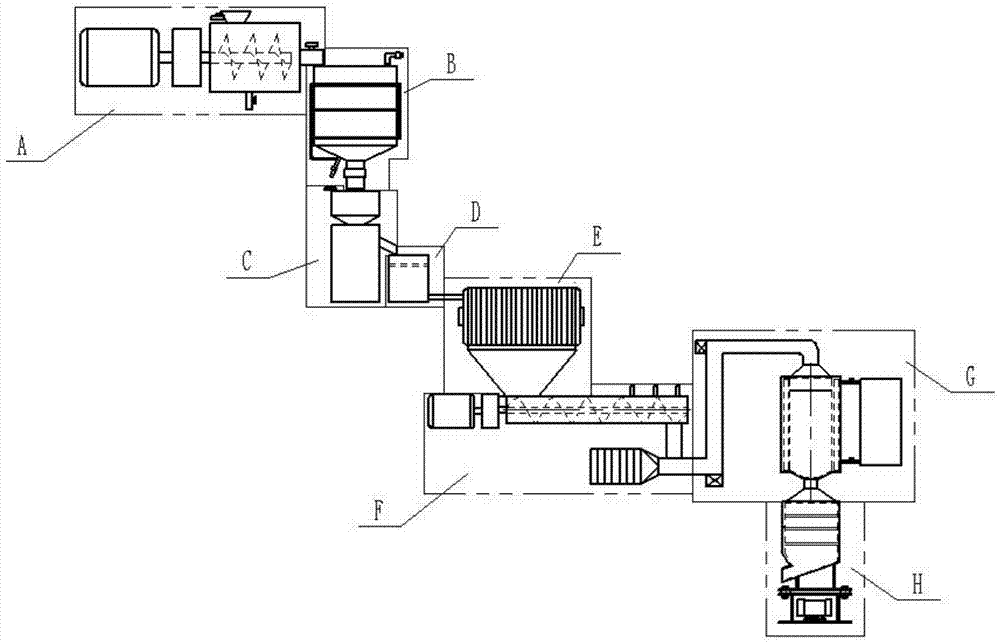

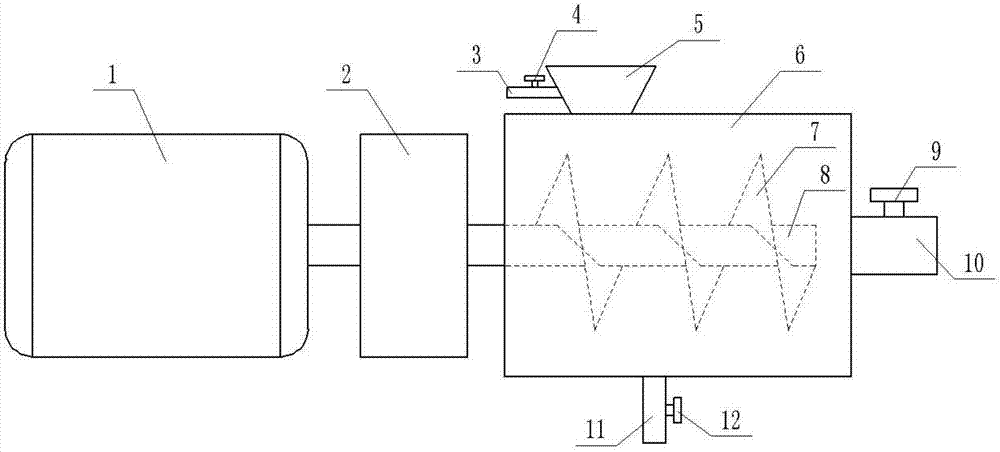

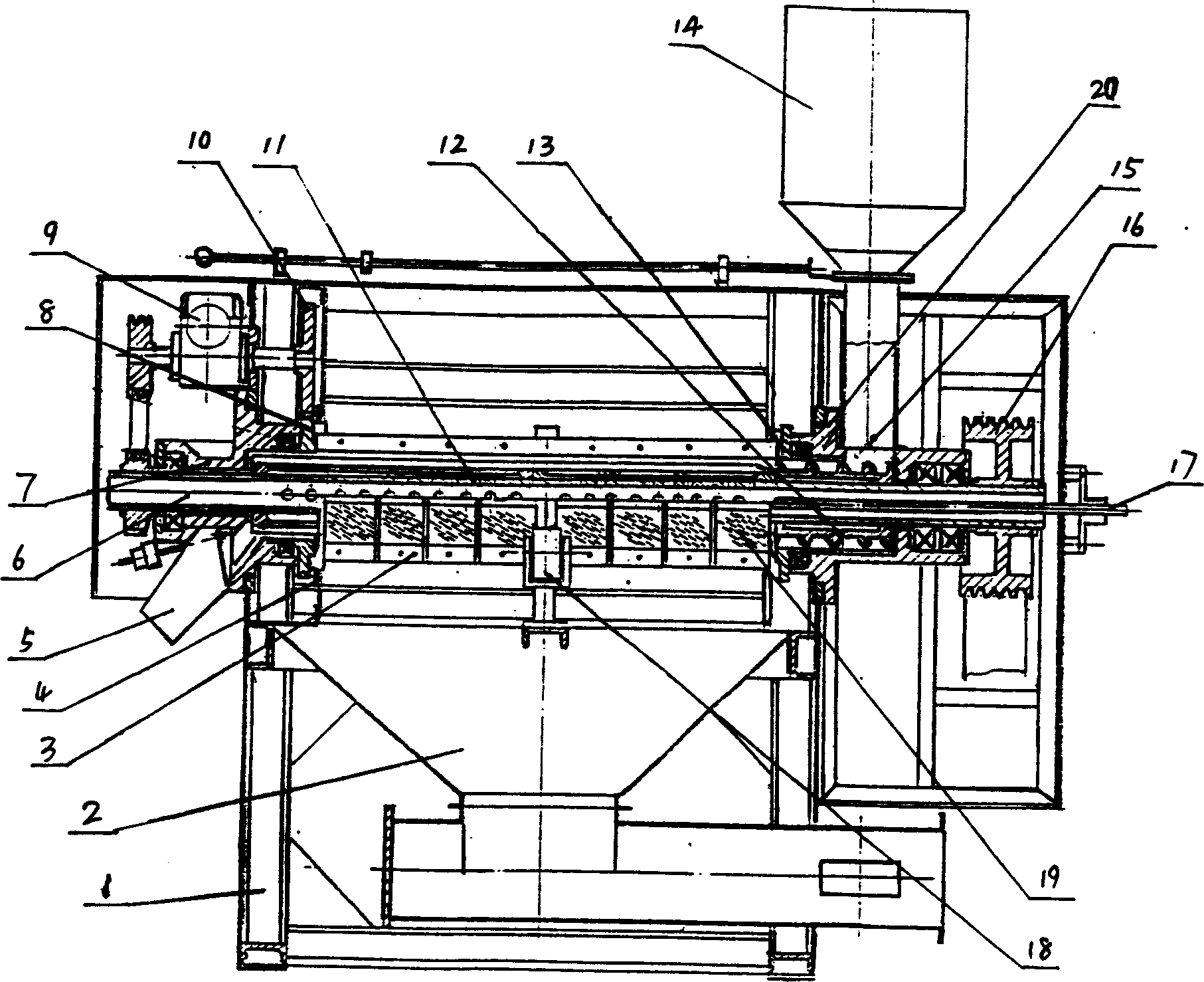

Water grinding rice flour processing system and process method

The invention discloses a water grinding rice flour processing system. The water grinding rice flour processing system comprises a washing device, an immersing device, a grinding machine, a filtering device, a dehydrating device, a drying device, a cooling device and a sieving device, wherein the immersing device is arranged under a discharging hole of the washing device; the grinding machine is arranged under a discharging hole of the immersing device; the filtering device is arranged under a pulp outlet of the grinding machine; the dehydrating device is arranged on the right side of the filtering device; a pulp outlet of the filtering device is connected with the inlet of a plate frame filter press of the dehydrating device; the drying device is arranged under the dehydrating device; the outlet of a collection hopper of the dehydrating device is connected with a feeding hole of the drying device; the cooling device is arranged on the right side of the drying device; a feeding hole of the cooling device is connected with a hot air pipe of the drying device; and the sieving device is arranged just under a trumpet-shaped discharging hole of the cooling device. According to the water grinding rice flour processing system, all the devices are integrally designed and an automatic rice flour production line is provided; and the automatic degree is high, the production efficiency is high, the manpower is saved and the production quality is reliable.

Owner:CHANGSHA XUEHUANG GRAIN & OIL

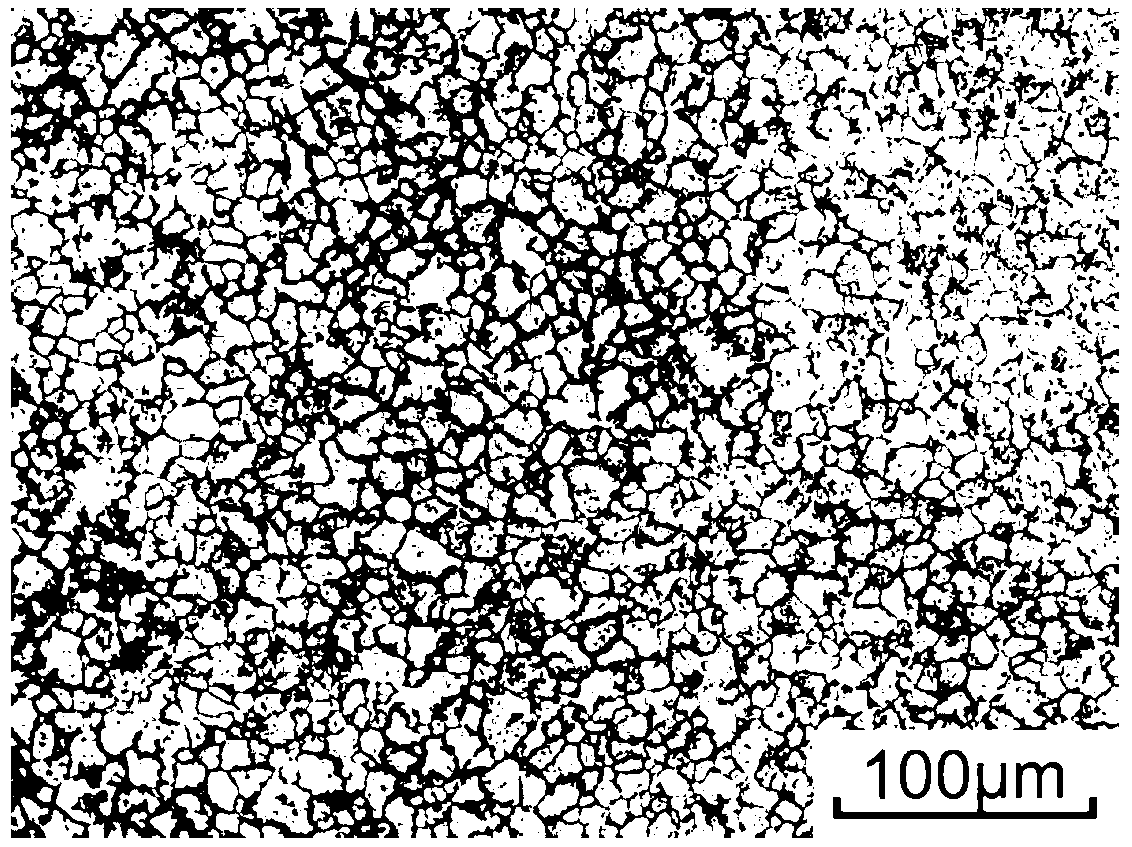

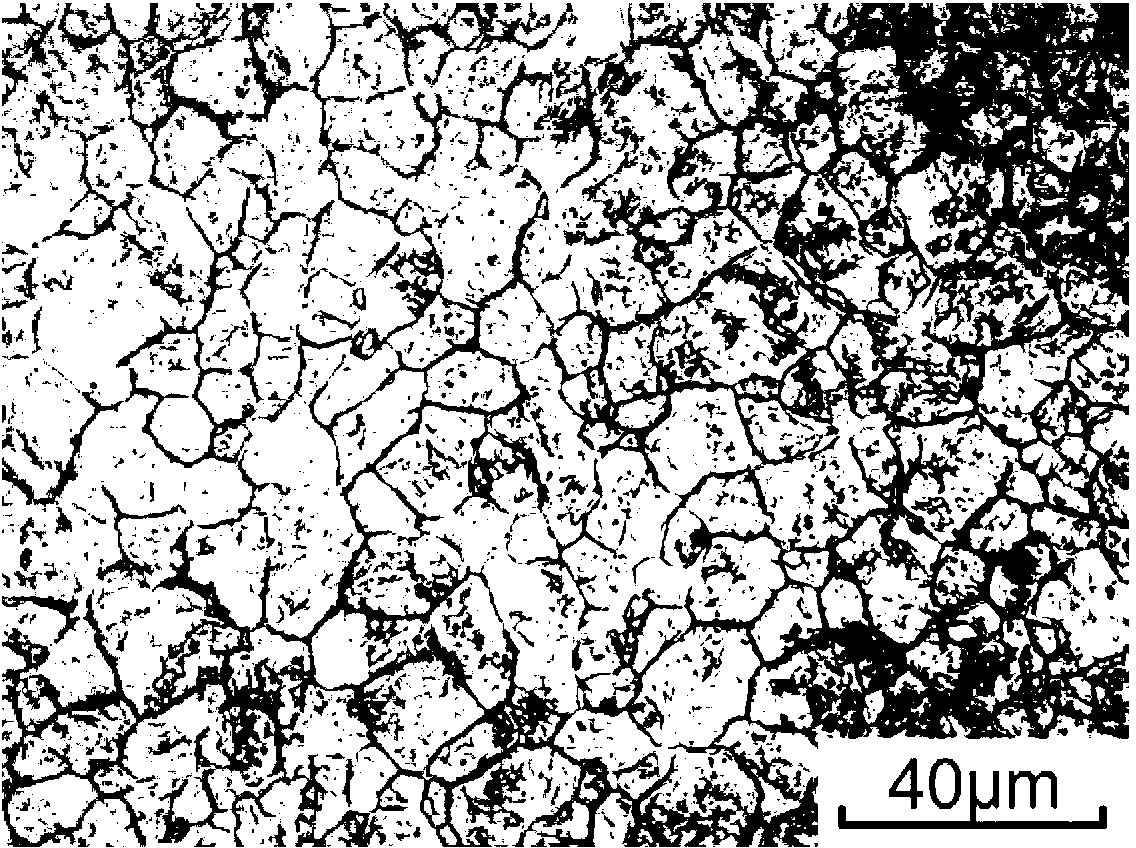

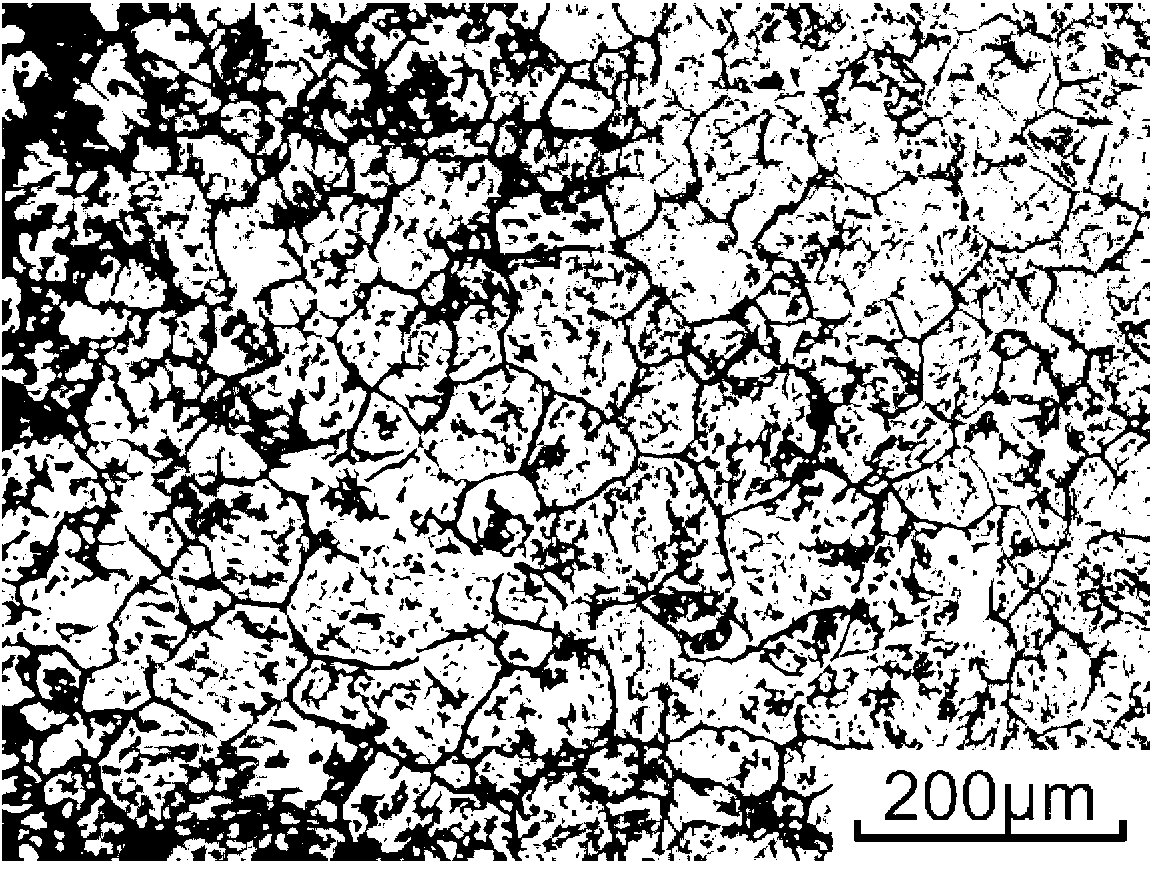

Method for displaying and treating Cr12 type martensitic heat-resistant steel primary austenite grain boundary

InactiveCN103234801AObservation does not affectPreparing sample for investigationAustenite grainOxidation zone

The invention relates to the technical field of metallographic phase preparation, and in particular relates to a method for displaying and treating Cr12 type martensitic heat-resistant steel primary austenite grain boundary by high-temperature oxidation and room temperature erosion. The method comprises four steps of preparing a polished sample, carrying out heat treatment, finely grinding and polishing, and etching. The method concretely comprises the steps of: firstly, preparing the sample, and grinding one of the planes of the sample to be smooth; then, putting the sample into a heating furnace, carrying out heat preservation under the condition of the temperature and time parameters to be researched, and quenching after heat preservation; carrying out water milling on the sample, keeping a certain angle between the polished surface and abrasive paper during water milling, guaranteeing that the surface of the sample is provided with a matrix-oxidation zone transition area, polishing, etching by an erosion reagent, cleaning by alcohol and then blowing the product to be dry; and observing the clear primary austenite grain boundary under a microscope. According to the technical scheme of the method, the implementation is simple and convenient; and after the technical scheme is implemented, the material primary austenite grain boundary is not influenced by a matrix metallographic structure simultaneously when being clearly and integrally displayed.

Owner:UNIV OF SCI & TECH BEIJING +1

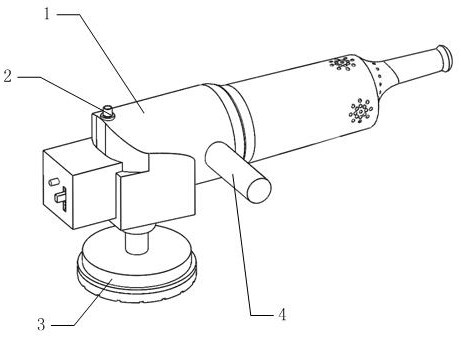

One-step forming wire drawing and water milling machine

InactiveCN101637930ATake advantage ofLabor savingCane mechanical workingGrinding machinesProduct processingWatermill

The invention discloses a one-step forming wire drawing and water milling machine and relates to a bamboo product processing device. The one-step forming wire drawing and water milling machine comprises a water milling machine, a wire drawing machine and a base, wherein the water milling machine and the wire drawing machine are respectively fixed on the base; a discharging opening of the wire drawing machine corresponds to a feed inlet of the water milling machine; and the working surfaces of the water milling machine and the wire drawing machine are kept in the same level. The wire drawing step and the water milling step of bamboo strips are finished together, thereby increasing the working efficiency. The rail design of the water milling machine makes the working surfaces of milling wheels fully used, thereby reducing the production cost.

Owner:JIANGXI NANFENG ZHENYU IND GRP

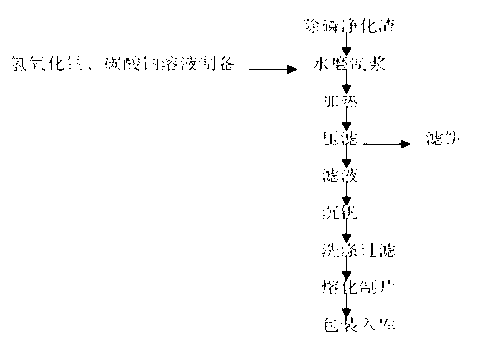

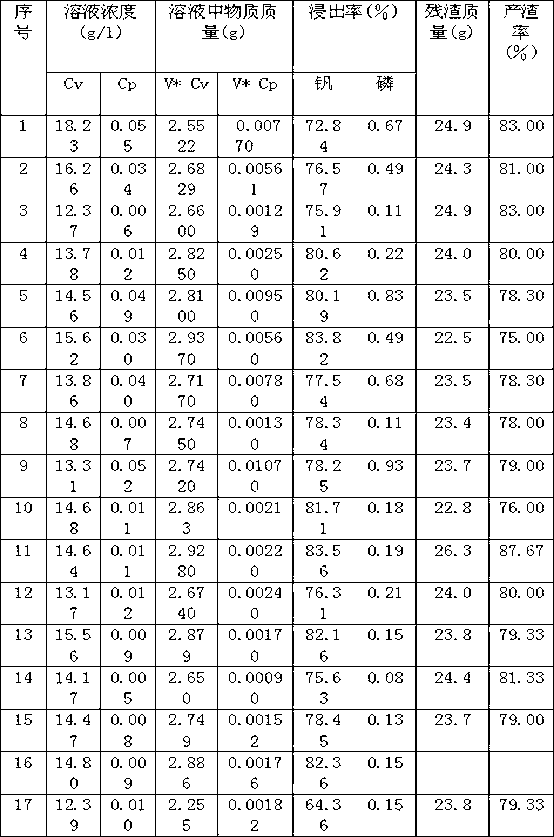

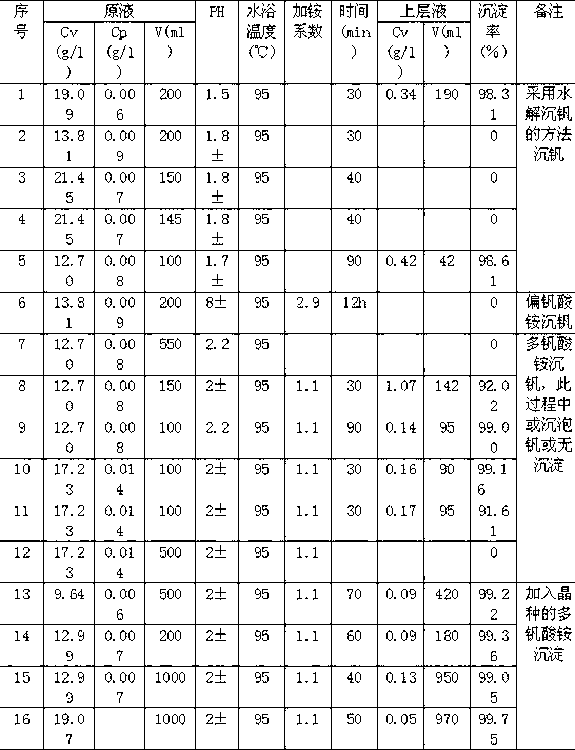

Process of purifying dephosphorization slag to extract vanadium in vanadium pentoxide production

InactiveCN103060575AInhibition of dissolutionFacilitate displacement reactionProcess efficiency improvementSlagLiquid storage tank

The invention discloses a process of purifying dephosphorization slag to extract vanadium in vanadium pentoxide production, i.e. a technology of purifying the dephosphorization slag to extract vanadium in the vanadium pentoxide production. The process comprises the following steps of: (1) taking the dephosphorization slag; (2) pulping through a water mill: pulping the dephosphorization slag though either a wet ball mill or a pulping machine; (3) heating: heating the solution to 85-95 DEG C through steam and then stirring; (4) filter pressing: carrying out solid-liquid separation; (5) filtrate: pumping the separated solution into a settling tank for settling and then entering a liquid storage tank; (6) vanadium precipitation: regulating the pH value of the solution to 2-2.5 through sulfuric acid, adding ammonia chloride according to an ammonia adding coefficient of 1.1, and heating supernatant through the steam till vanadium concentration is less than 0.08g / l to obtain ammonium polyvanadate; (7) washing and filtering; (8) melting and preparing pieces; and (9) packaging and putting into storage. The process of purifying the dephosphorization slag to extract vanadium in the vanadium pentoxide production solves the problems that a good deal of vanadium resource is lost in process of producing vanadium pentoxide, and the vanadium recovery effect is bad and vanadium can not be effectively recycled in the prior art.

Owner:XICHANG NEW VANADIUM & TITANIUM

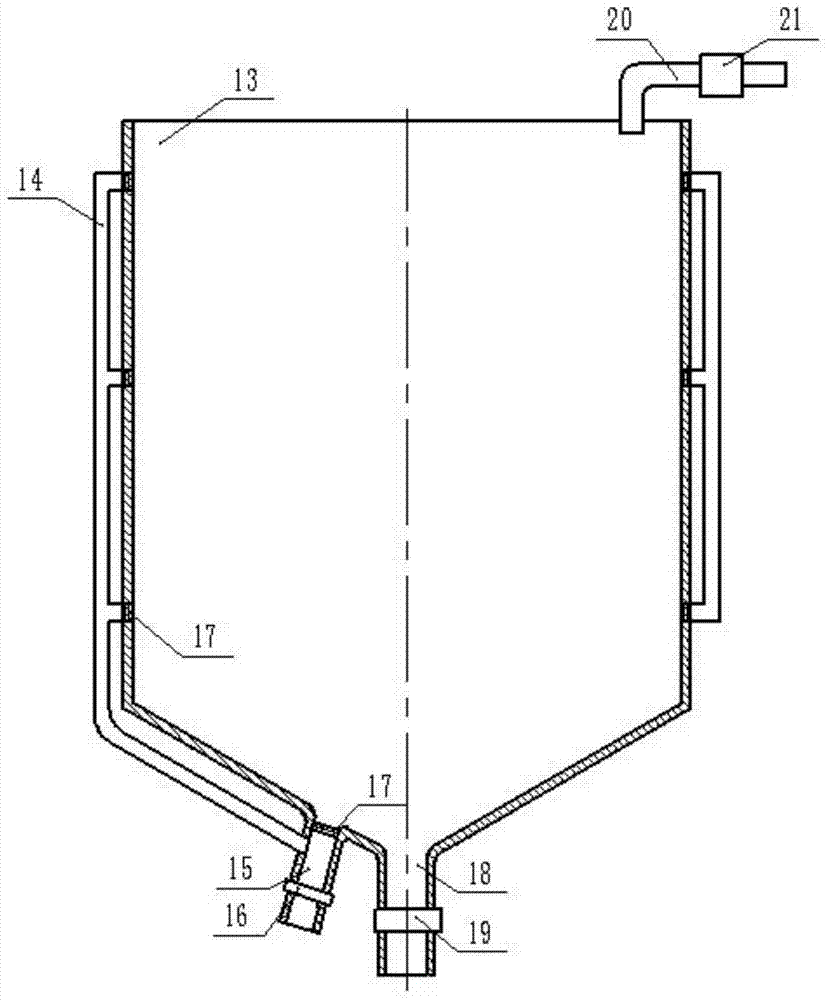

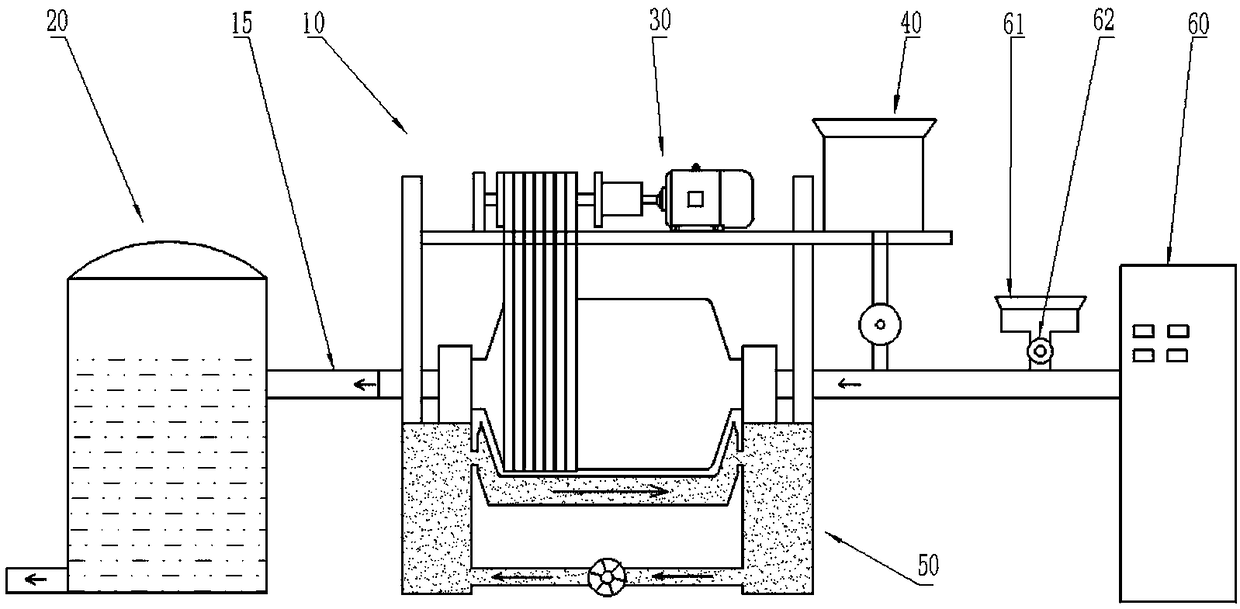

Method and production equipment for preparing glutinous rice flour through water milling method

InactiveCN104773861AGuaranteed pureReduce manufacturing costMultistage water/sewage treatmentFood preparationChemical additionRice flour

The invention discloses production equipment for preparing glutinous rice flour through a water milling method. The production equipment comprises a feeding drum, the feeding drum is connected with a water milling device, and the two sides of the water milling device are provided with a discharge pipe and a water inlet pipe respectively. The water inlet pipe is connected with a water tank, and the lower end of the water milling device is provided with a water collecting groove. The water collecting groove is connected with a filtering device through a water exhaust pipe, and the filtering device is connected with the water tank through a recycling pipe. The invention also discloses a method for preparing glutinous rice flour by the water milling method. The method comprises the steps of clearing, soaking, grinding, dewatering, drying and the like. The production equipment for preparing glutinous rice flour through the water milling method has the advantages that the structure is simple, the use is convenient, waster water in the water milling process can be recycled effectively, a screen and a fine sand layer serve as a filter layer and a purification layer, a physical mode is used to conduct water filtering and purifying, no chemical addition agent exists, pollution is free, and the purity of the glutinous rice flour is guaranteed; at the same time, the glutinous rice flour in the impurity are recycled again, and thereby the purpose of saving water and lowering the production cost of the glutinous rice flour is achieved.

Owner:YANGXIAN YONGHUI AGRI IND DEVCO LTD

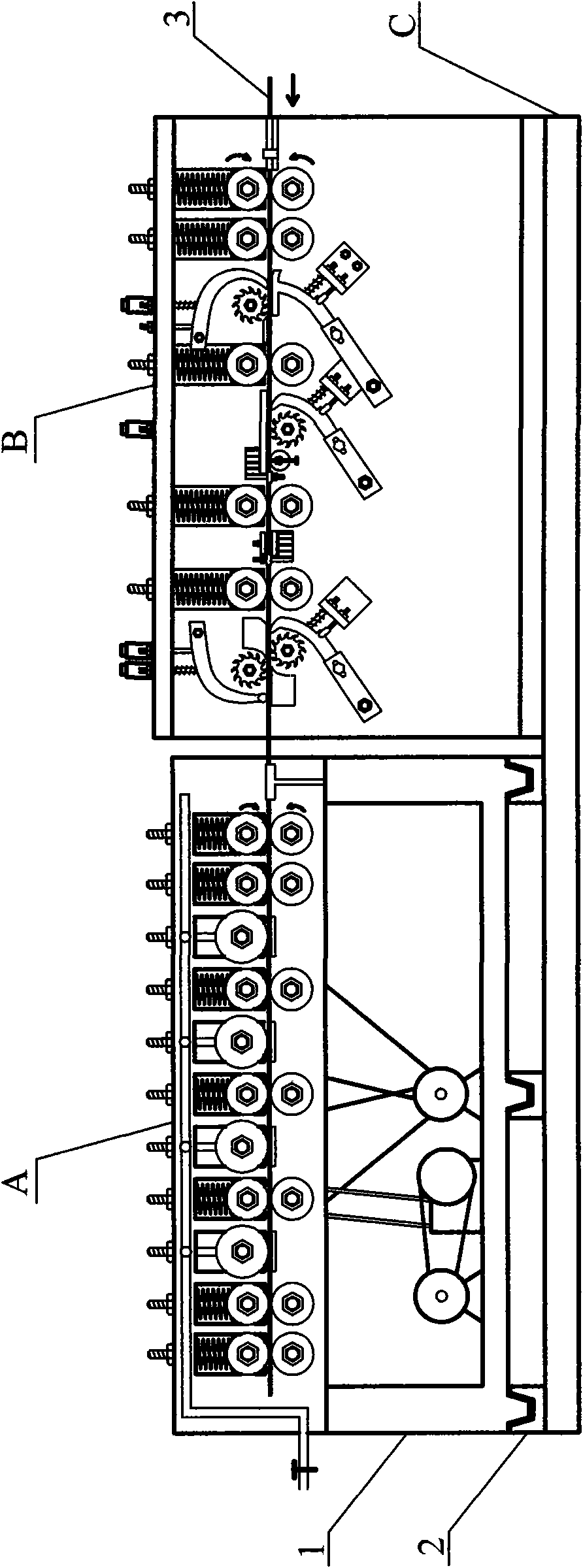

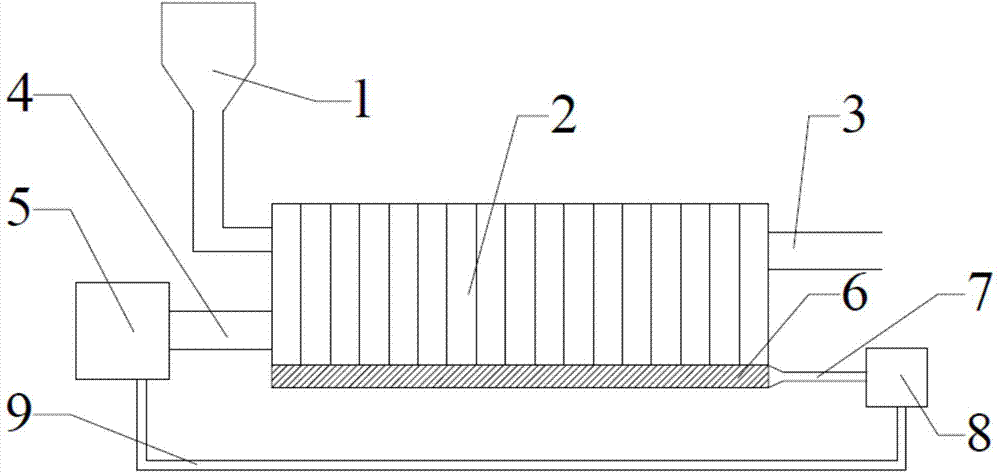

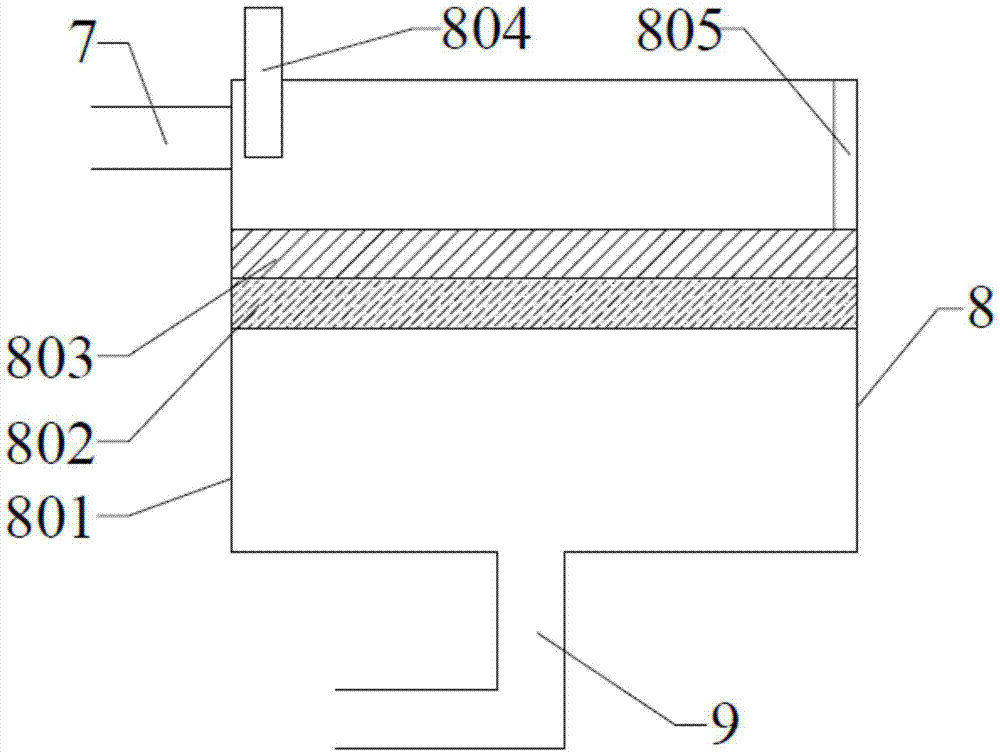

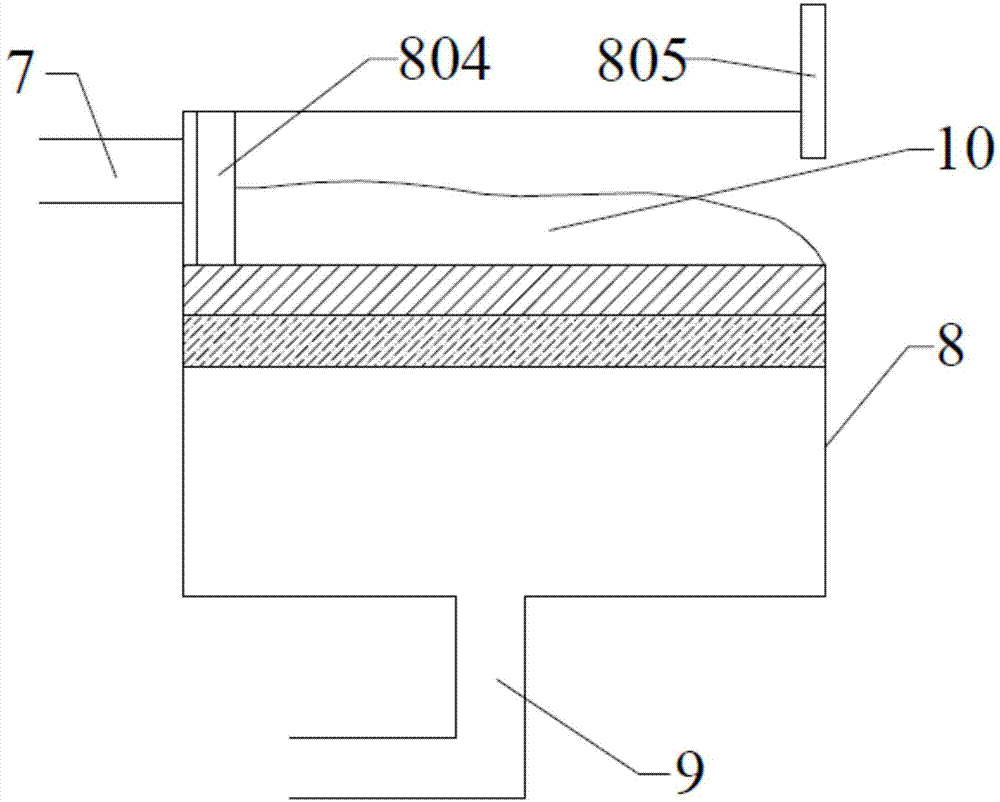

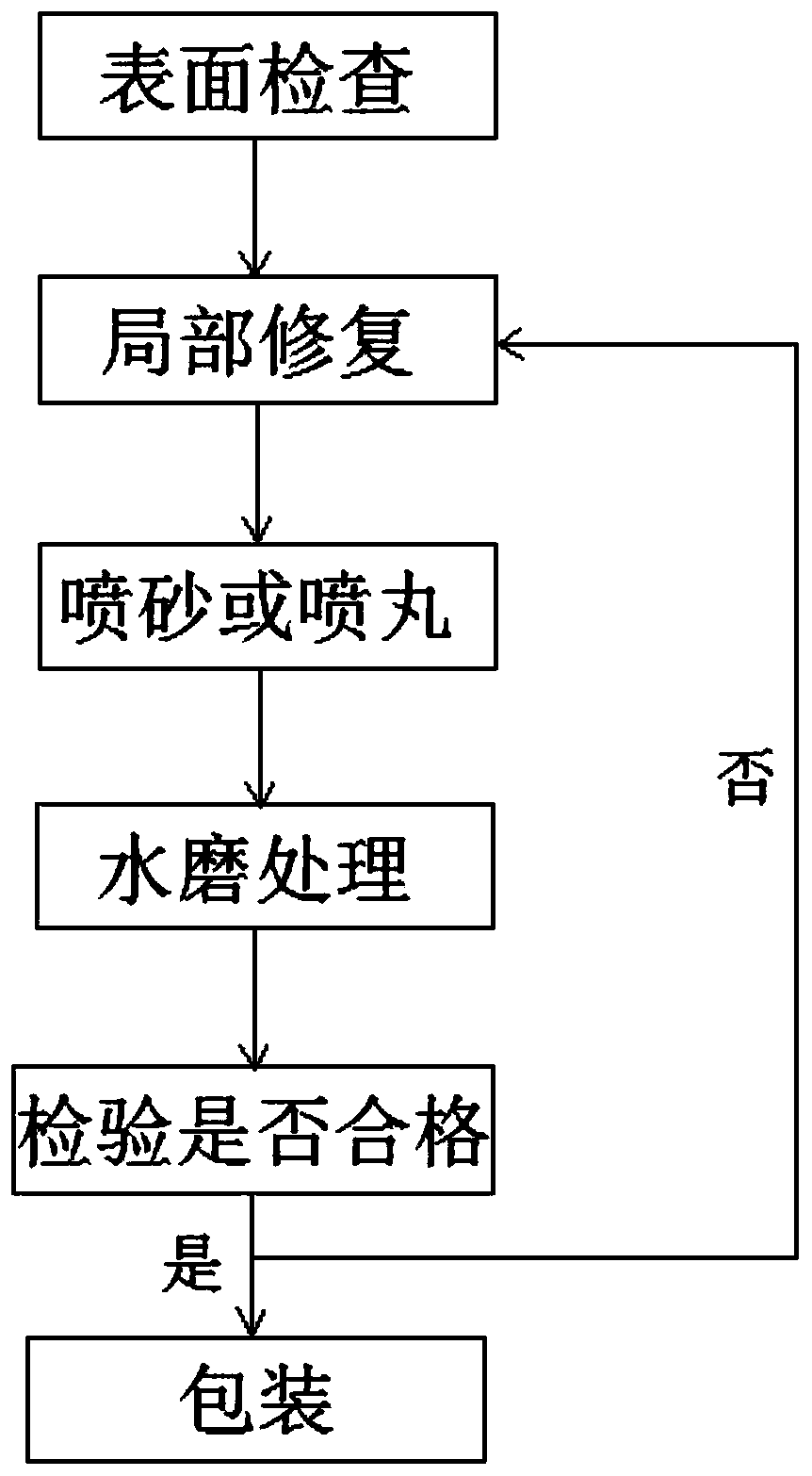

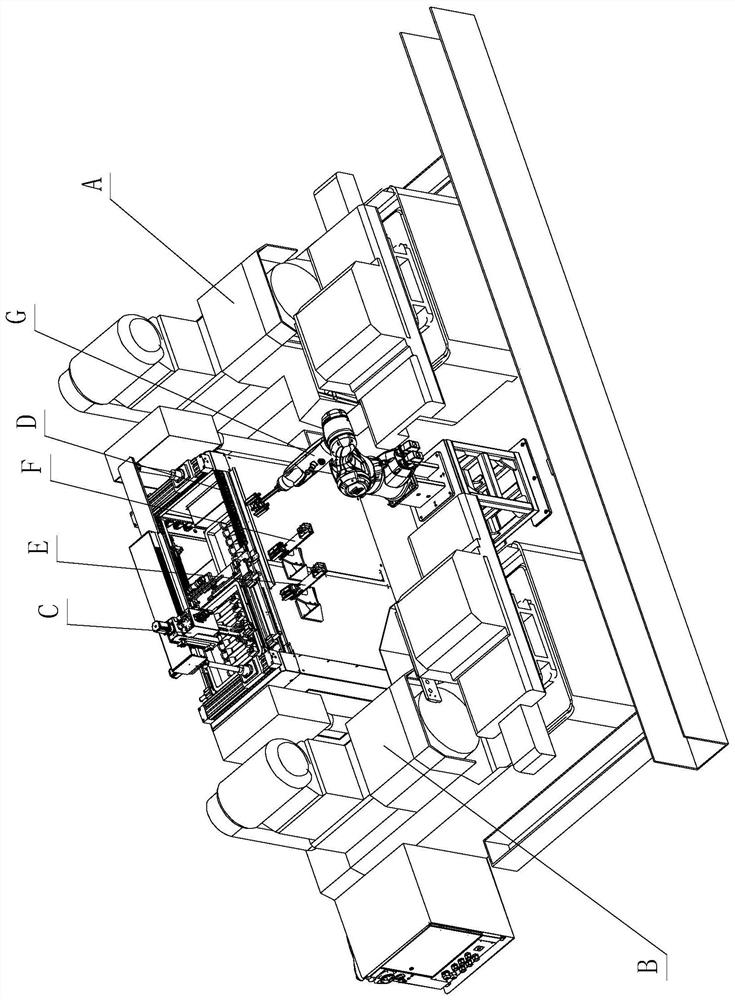

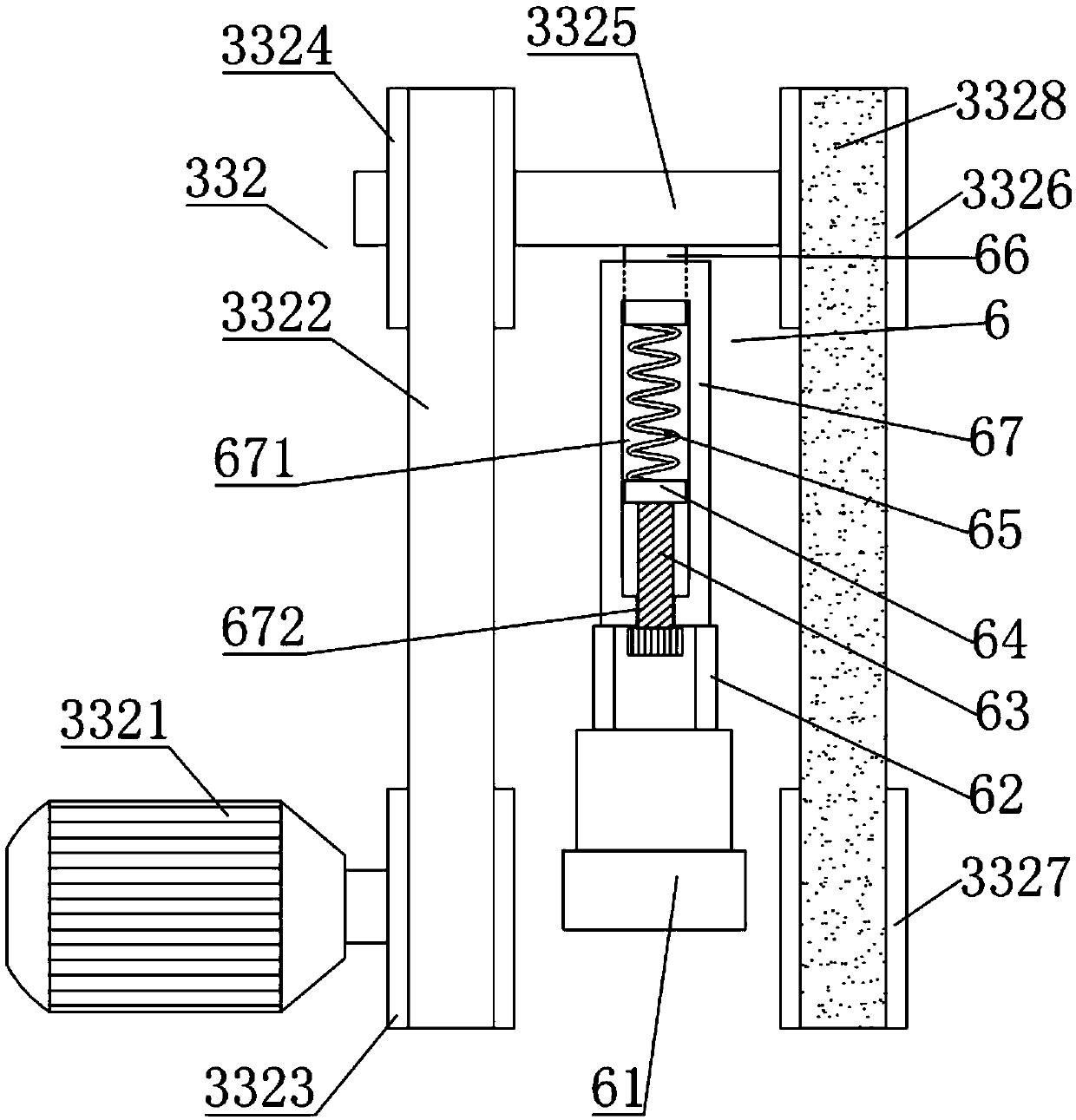

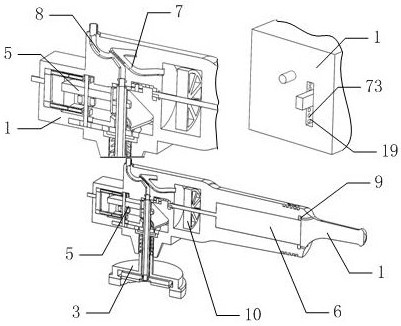

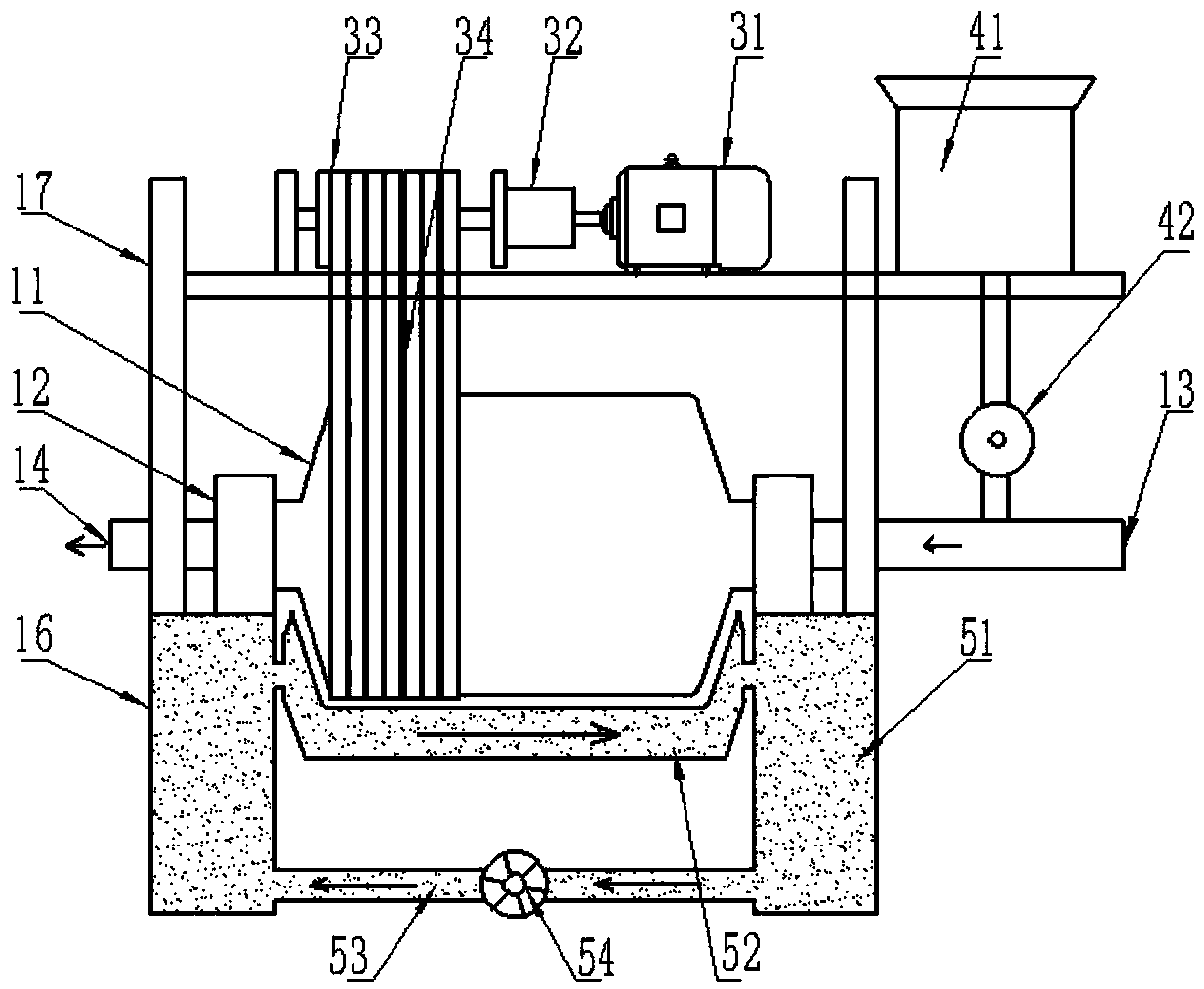

Process method and water milling equipment used for treating metal plate surface

PendingCN110640599AReduce hardnessFlat surfaceGrinding drivesGrinding machinesSand blastingGrinding wheel

The invention provides a process method and water milling equipment used for treating a metal plate surface. The process method includes partial restoration, sand blasting or shot blasting treatment and water milling treatment. Defects on the surface of a material are detected by naked eyes, a grinding wheel and / or a thousand impeller and / or a welding machine are / is utilized to smooth the defects to make the surface of the material flat, secondly, sand blasting or shot blasting treatment is carried out, one of a sand blasting machine or a shot blasting machine is used for conducting oxide skin breaking on the surface of the material, surface consistency is formed, the surface of a plate after sand blasting or shot blasting treatment is dark and is possibly defective, in order to allow people to see the defects on the surface of the material, a worker uses the water milling equipment to remove oxide skin, the surface of the material is brightly colored, in this way, the problem that the defects on the surface of the material are covered up due to the color of the surface of the plate is avoided, at the same time, the use of acid is avoided to remove the oxide skin on the surface of the plate, and the pollution to the environment is reduced.

Owner:安徽中钢联新材料有限公司

Coal ash based wood fiber artificial fireproof plate and manufacturing method thereof

InactiveCN105569507AImprove toughnessIncrease profitSolid waste managementFireproof doorsWood veneerFiber

The invention discloses a coal ash based wood fiber artificial fireproof plate and a manufacturing method thereof. The fireproof plate comprises a raw material, a fireproof material, and a wood panel. The raw material is formed by the materials in the following parts by weight: 100-120 parts of coal ash, 50-60 parts of wood fiber powders, 120-140 parts of water, 5-15 parts of tackifier, 3-10 parts of crack and permeation resistance agent, 5-10 parts of stabilizer, 20-40 parts of kaolinite, and 10-30 parts of lime putty powders. The fireproof material is a magnesium board. The wood panel is a wood plate or a wood veneer. The steps of the manufacturing method comprise mixing and stirring, high-temperature sintering, water mill cutting, and sticking facing, etc. The coal ash is used as a base material to be processed into a door sheet, and the door sheet is added with the wood fiber powders, so as to improve tenacity of a coal ash sintered plate, and enhance plasticity and flintiness, and improve use ratio of coal ash. In a manufacturing process, the magnesium board which has excellent fireproof performance is added, so as to effectively improve the fireproof performance of the door sheet.

Owner:HEILONGJIANG HUAXIN FURNITURE

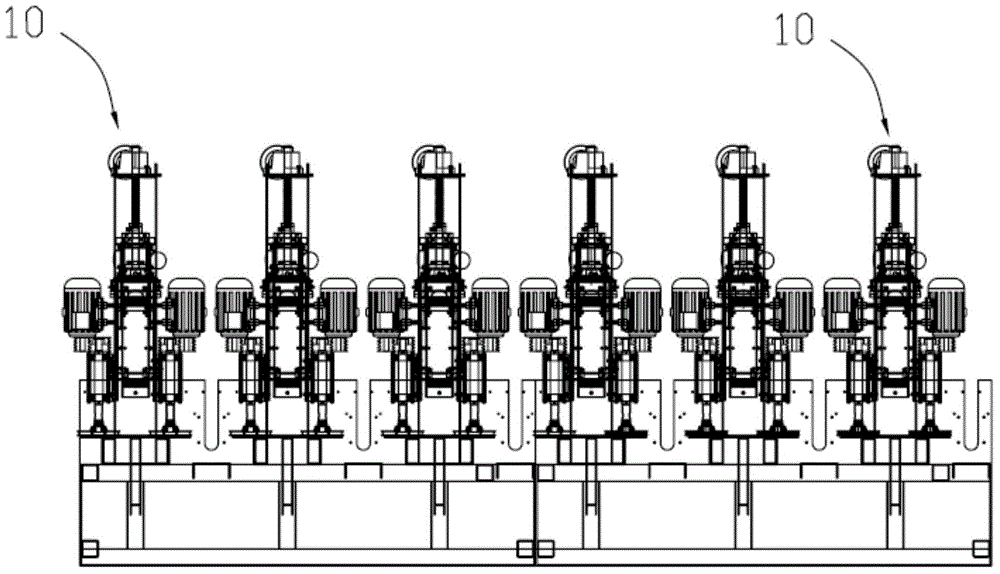

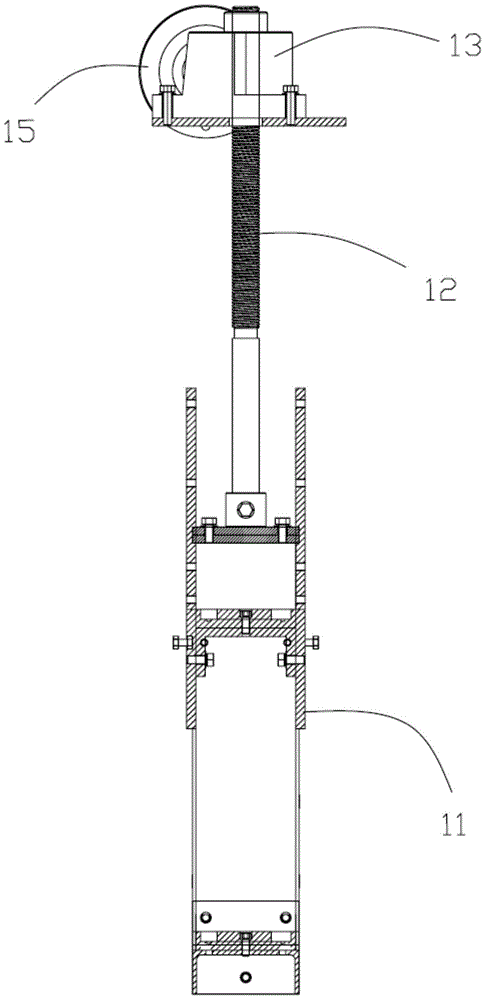

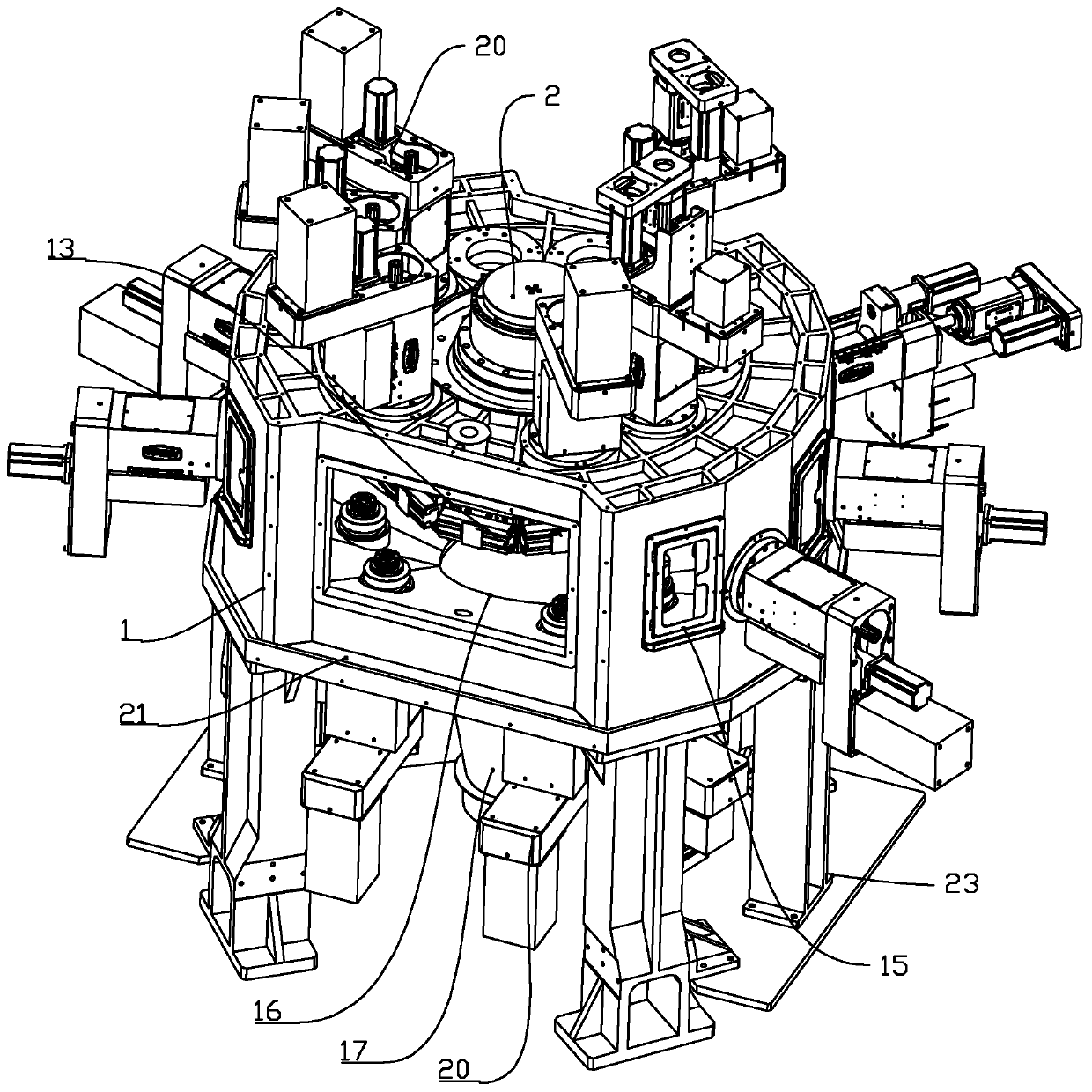

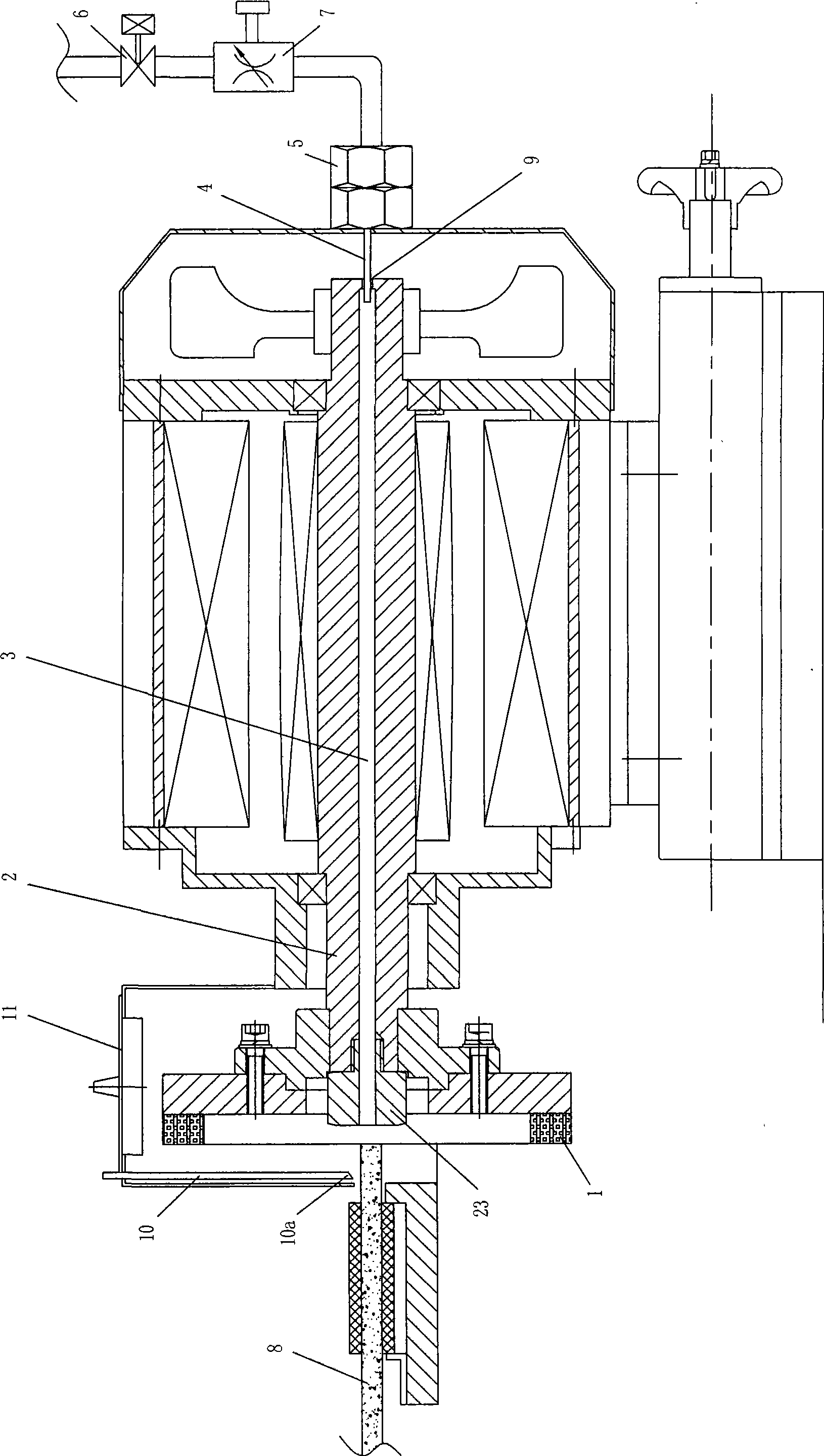

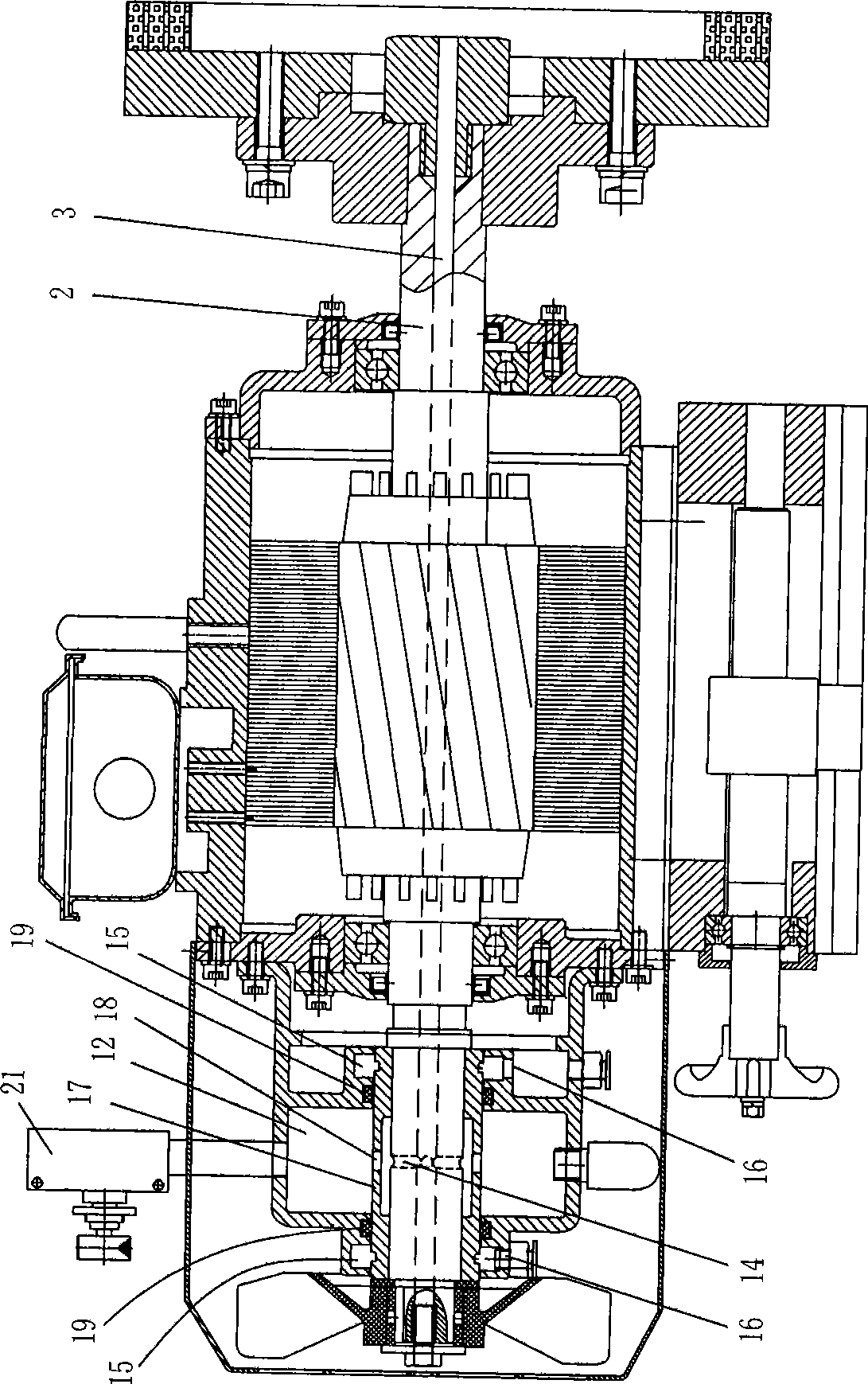

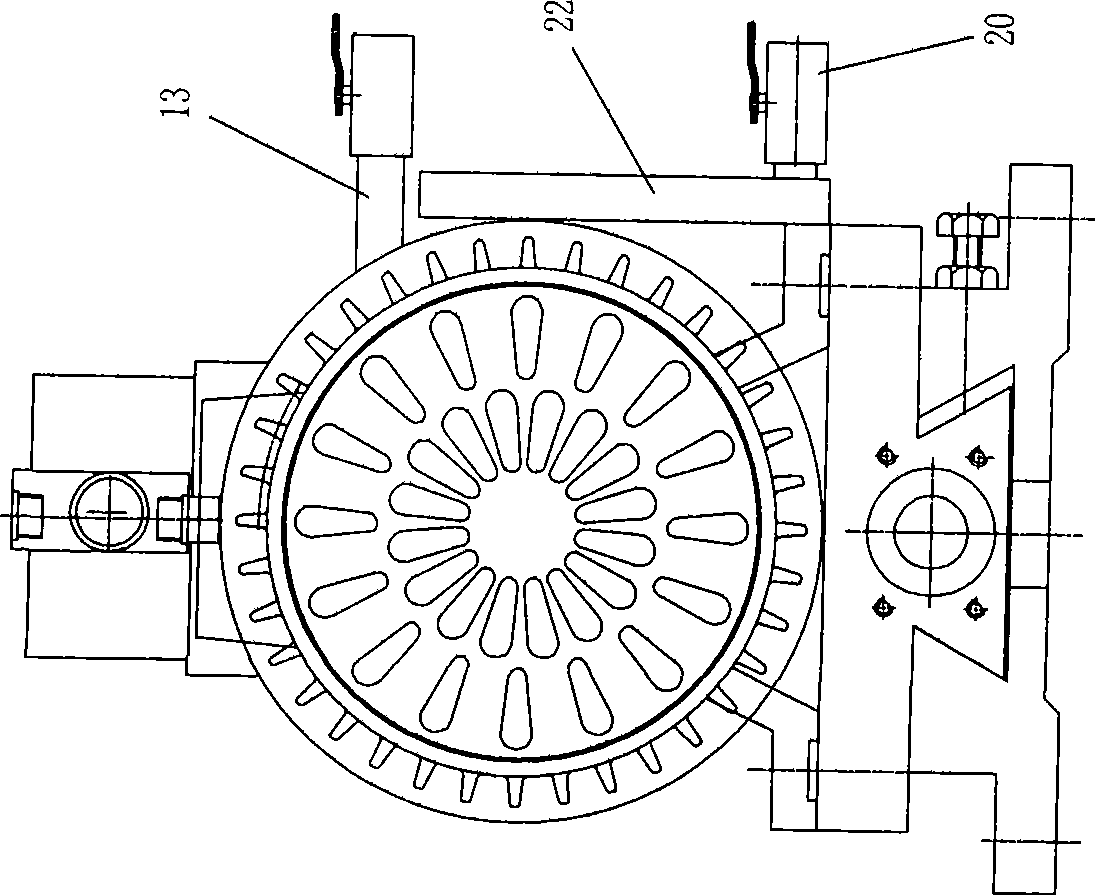

Inverted watermill

PendingCN110116312AOutstanding and Beneficial Technical EffectsImprove efficiencyLarge fixed membersMaintainance and safety accessoriesPull forceWater wheel

The invention belongs to the technical field of machine tools, and in particular, relates to an inverted watermill. The inverted watermill comprises a bed frame; an oil pressure tooth type cutting table is suspended in the bed frame; a main shaft is mounted under the oil pressure tooth type cutting table; a shaft sleeve sleeves the outer periphery of the main shaft, and is tightly connected with the lower end surface of the oil pressure tooth type cutting table; multiple bearing springs for converting tension to pressure are arranged between the main shaft and the shaft sleeve; and the bearingsprings butt between the lower end surface of the outer edge of the main shaft and the upper end surface of the inner edge of the shaft sleeve. Through design of the inverted watermill, the oil pressure tooth type cutting table is suspended in the bed frame, and no support structure is arranged on the lower side, so that more power heads and cutter unfolding heads can be mounted, ten machining stations are formed, the overall machining of complicated valve products can be finished in the equipment, the efficiency is high, the precision is better, and the man-machine relationship influence islow.

Owner:ZHEJIANG SHUANGZHENG MACHINE TOOL CO LTD

Brake disc grinding process

InactiveCN107695799AQuick clearEfficient removalEdge grinding machinesPolishing machinesAngle grinderEngineering

The invention discloses a brake disc grinding process. The brake disc grinding process comprises the following steps that (1) coarse grinding is conducted, specifically, an automobile brake disc is horizontally fixed, then an angle grinder is used for grinding the surface of the brake disc, and the effect that the included angle between a grinding wheel of the angle grinder and the surface of thebrake disc is 15-30 degrees during grinding is ensured; and (2) fine grinding is conducted, specifically, No. 400-600 dry abrasive paper is used for grinding the surface of the brake disc, and the positions, where cannot be ground by the angle grinder, of the surface of the brake disc is ground by the dry abrasive paper for 18-25 times. The angle grinder is used for coarsely grinding the surface of the brake disc, burrs and oxide layers on the surface of the brake disc can be ground off, and the flatness and smoothness of the surface of the brake disc can be further improved through coarse grinding, fine grinding and polishing, so that the brake disc has better usability, through a ball brush and waterproof abrasive paper, burrs and oxide layers on the inner walls of ventilation ports canbe removed, and the effect that the inner walls of the ventilation ports are smooth after grinding can be ensured.

Owner:ANJI YUANMO MECHANICS TECH CO LTD

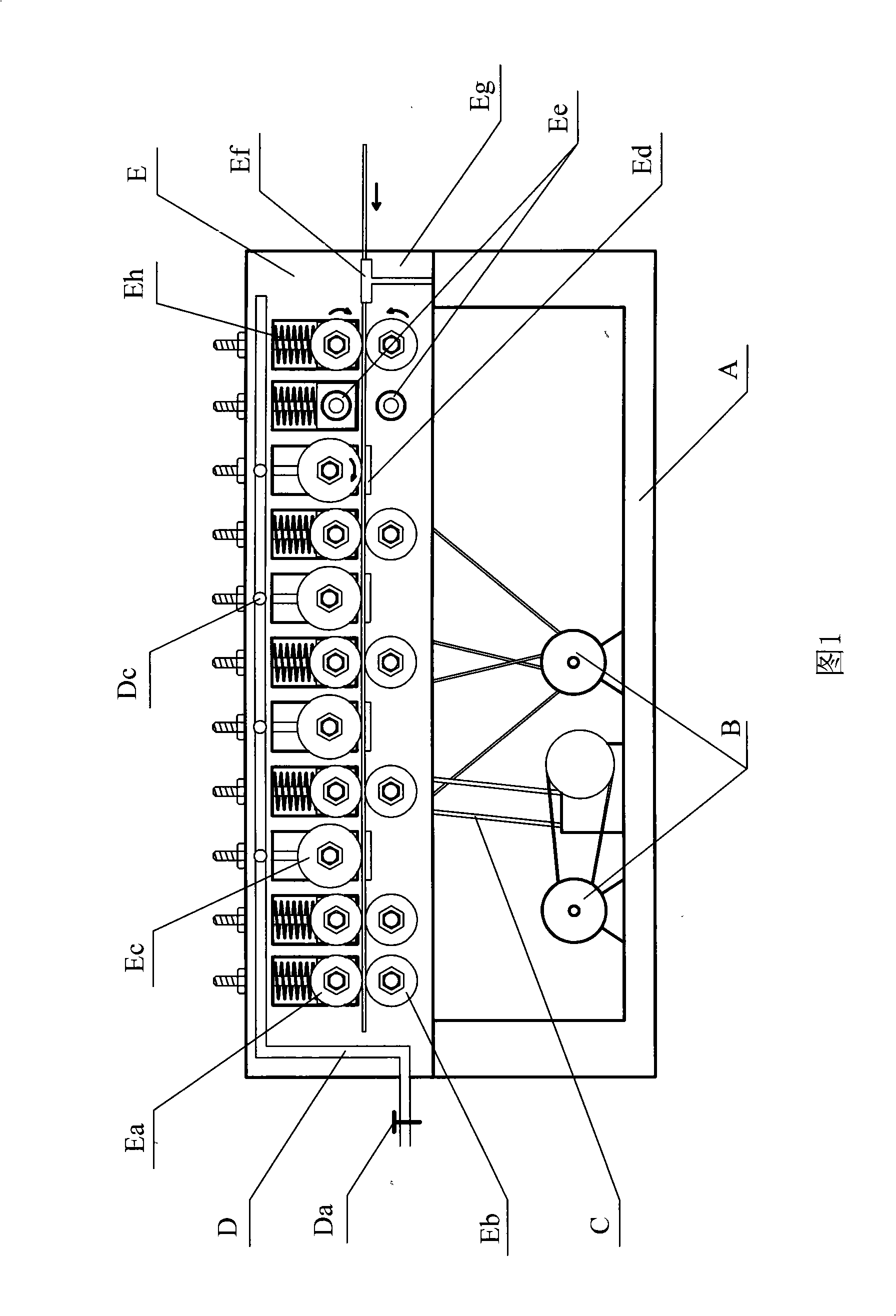

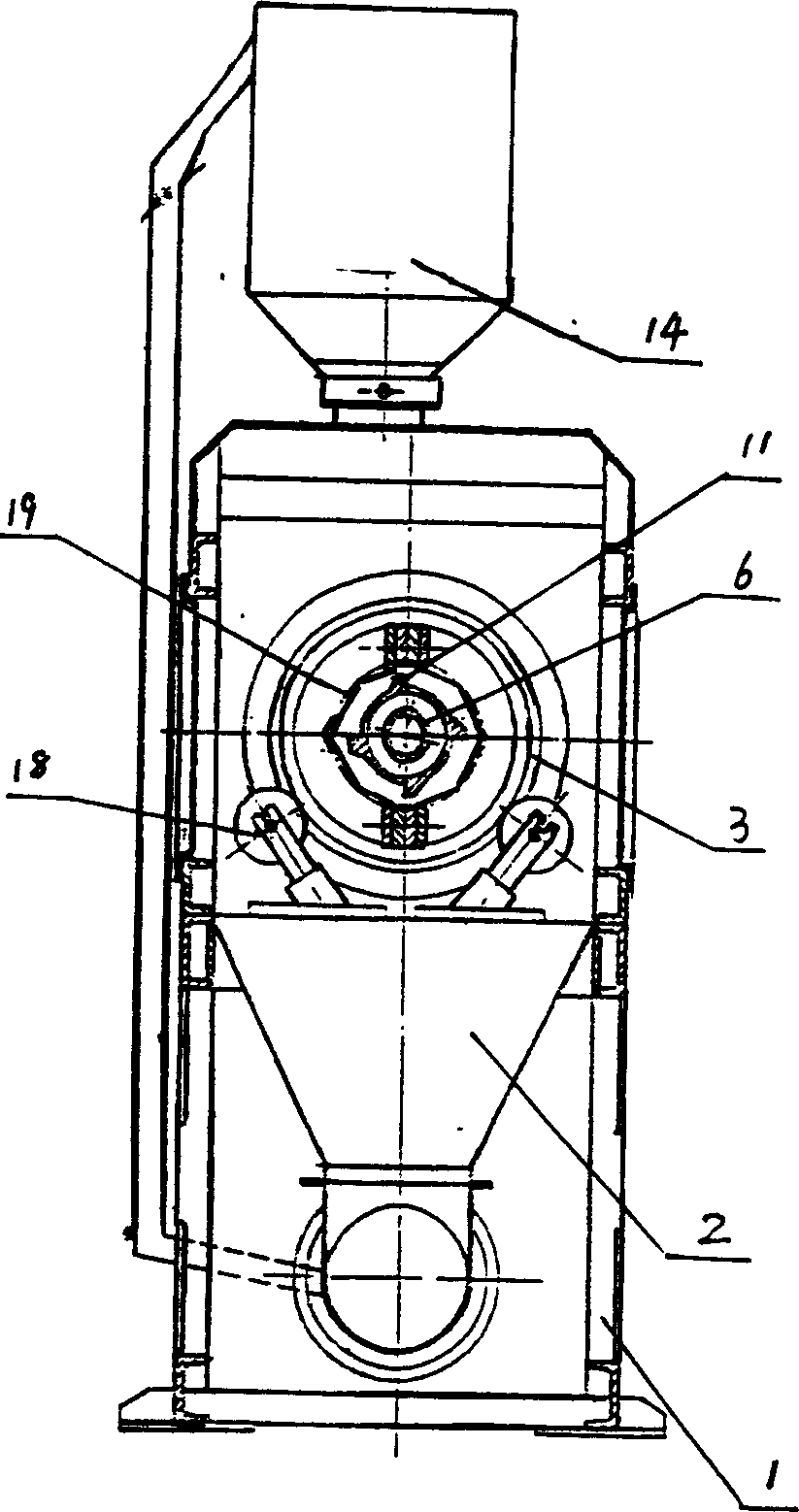

Rotary-sifting watermill polishing machine for rice

InactiveCN1836783ATumble fullImprove polishing effectGrain huskingGrain polishingDrive wheelReduction drive

The rice polisher with rotary sieve and water mill includes a frame, a bran collecting bin, a discharge port, a main shaft, a polishing roller, a screw conveyer, a rice sieve and a main driving belt wheel. It features the hollow main shaft with atomizing water pipe connected to water source inserted into its cavity and fixed on to the frame via bearing and other part; the rice sieve on the main shaft and with through hole to the cavity; the polishing roller with through hole for water to flow out; the main driving belt wheel connected to one end of the main shaft and the other belt wheel mounted to the other end of the main shaft and connected via a conveying belt to the reducer; the reducer meshed via a driving wheel to the driven gear on the rice sieve bracket; and the rice sieve bracket rotating in the same direction as and different speed from the main shaft. The rice polisher has the features of high rice polishing rate, high rice yield, low broken rice rate and low power consumption.

Owner:熊春辉

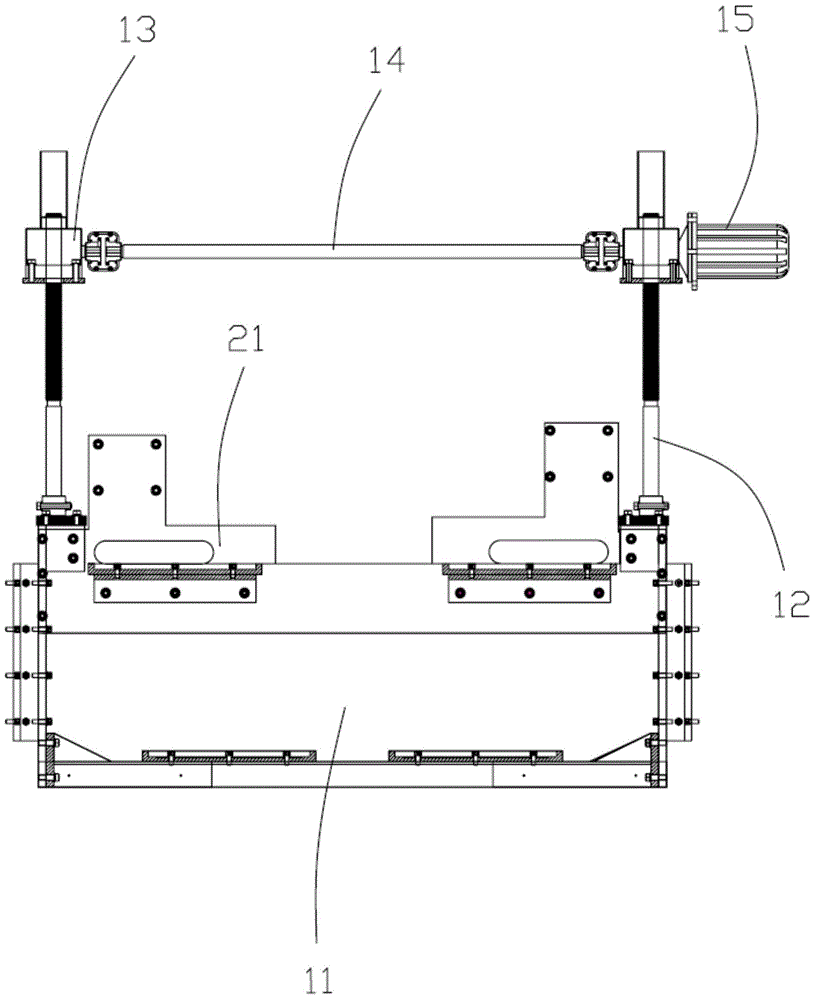

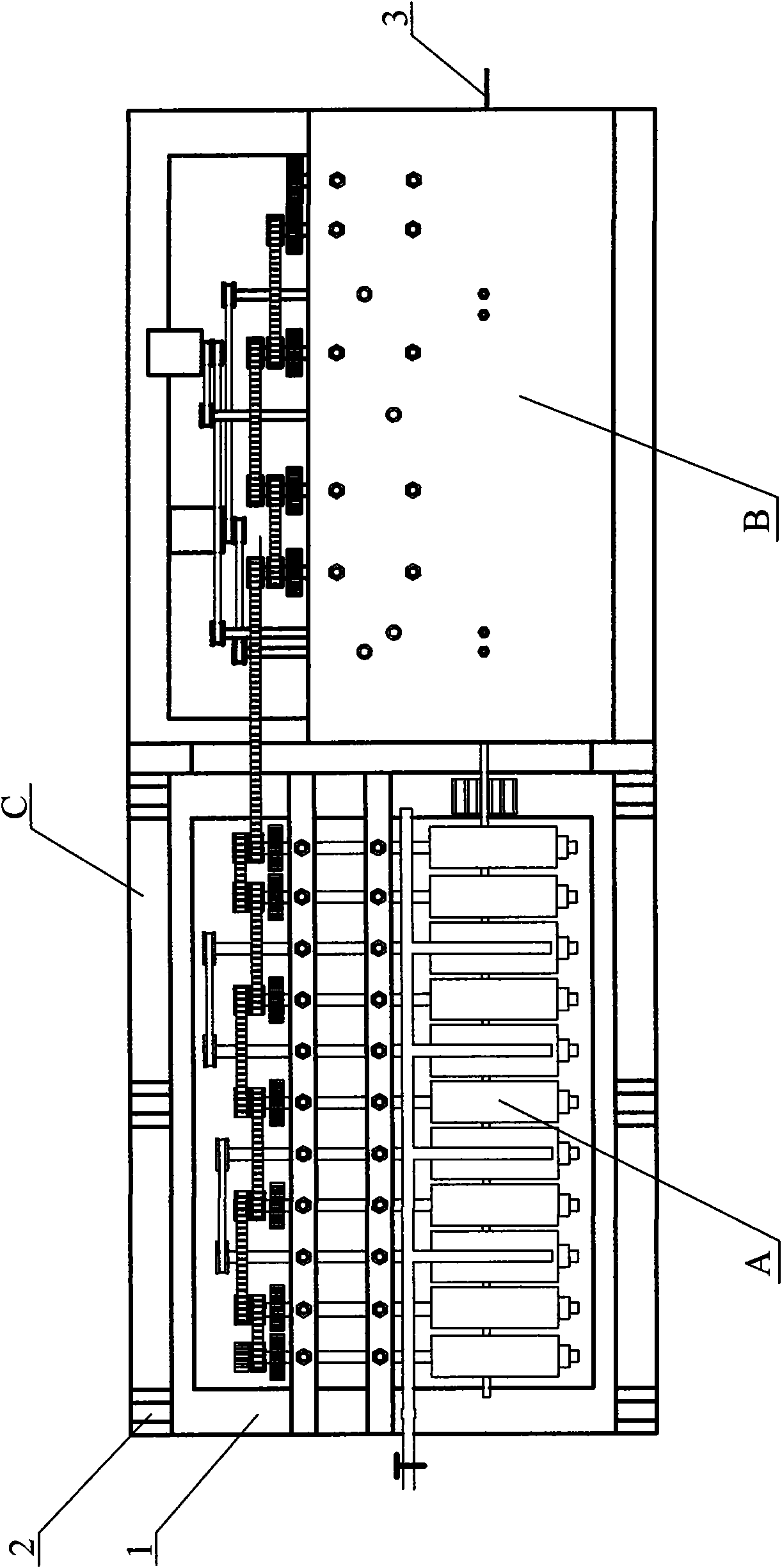

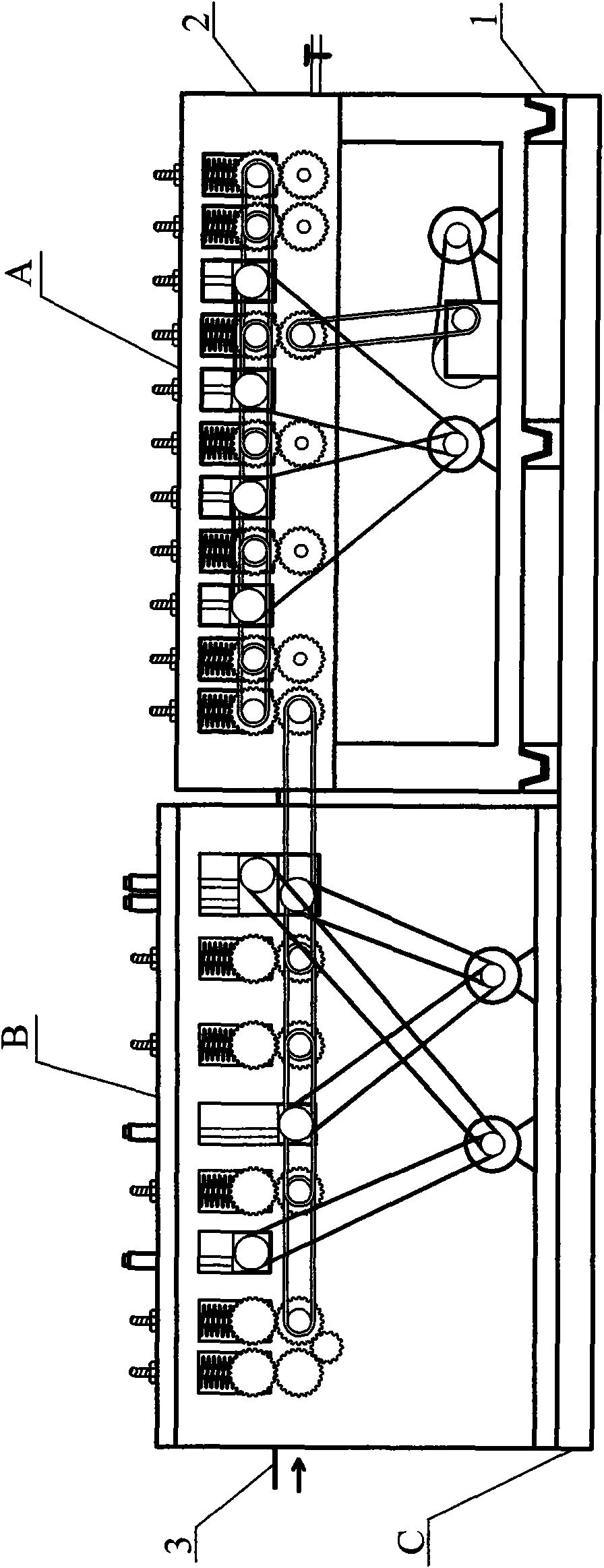

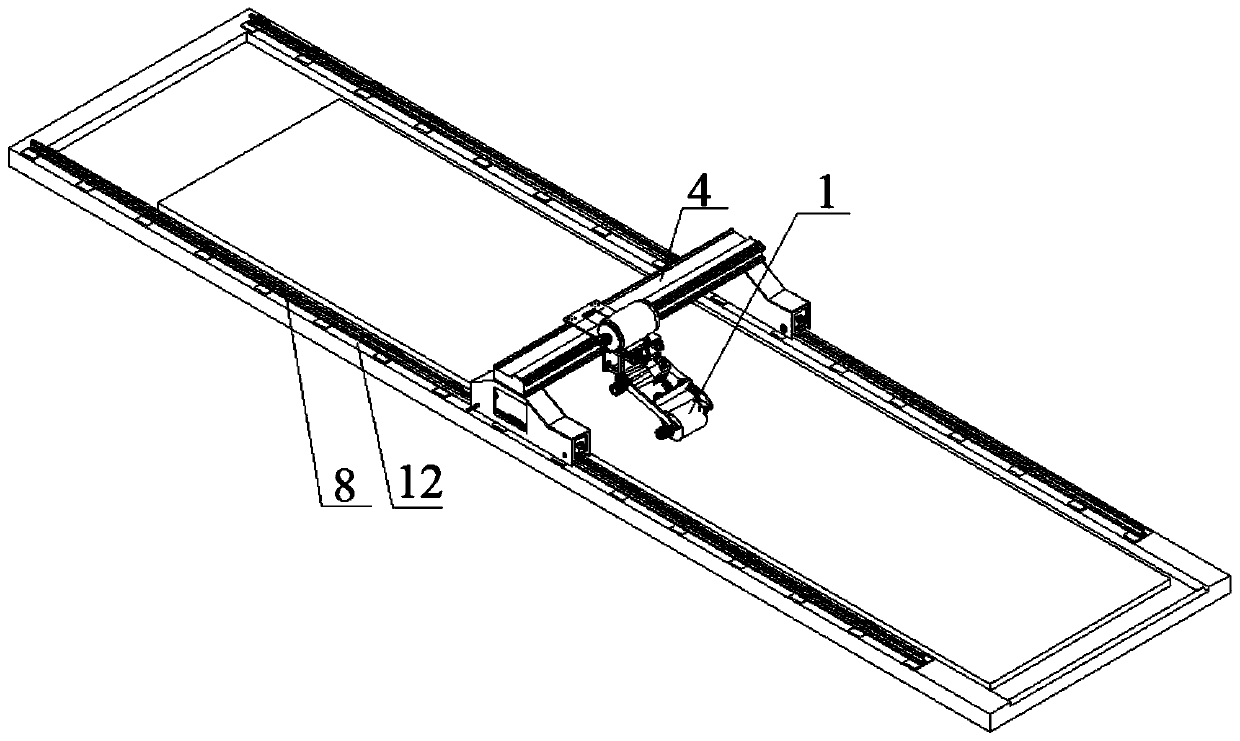

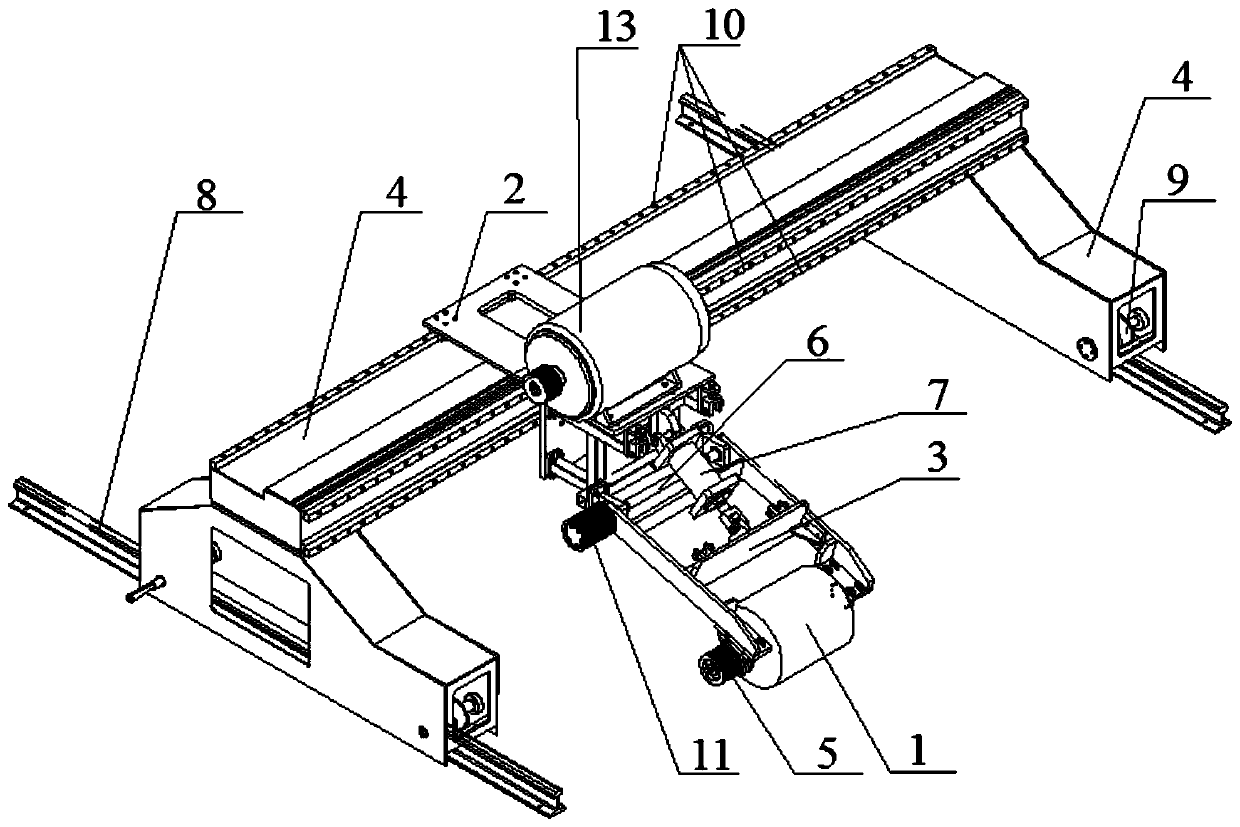

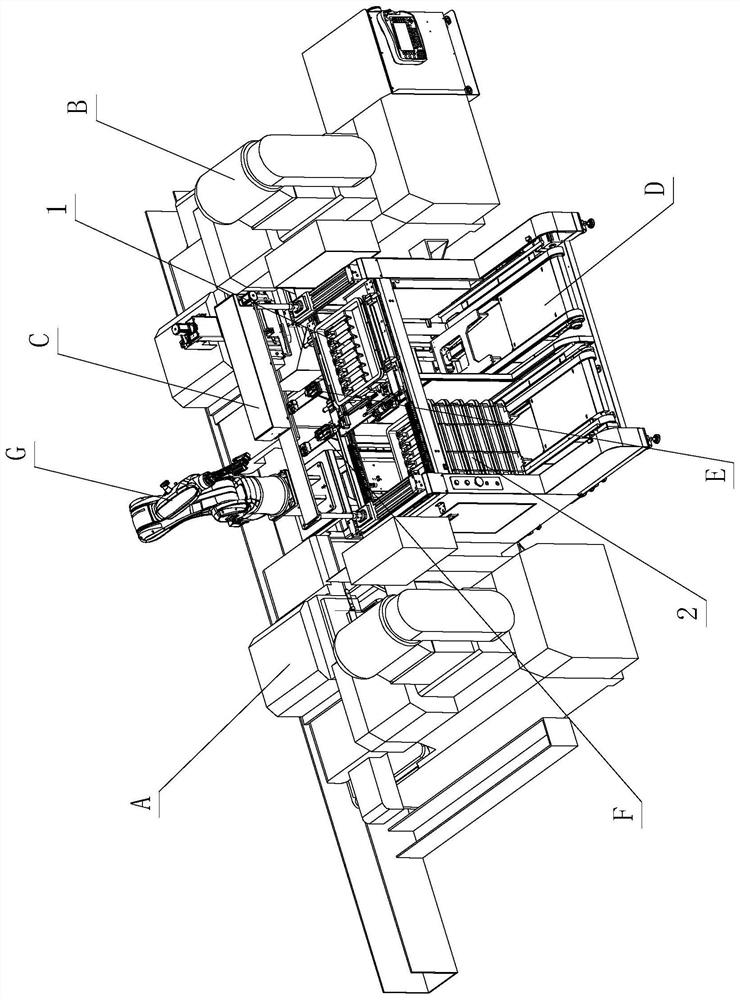

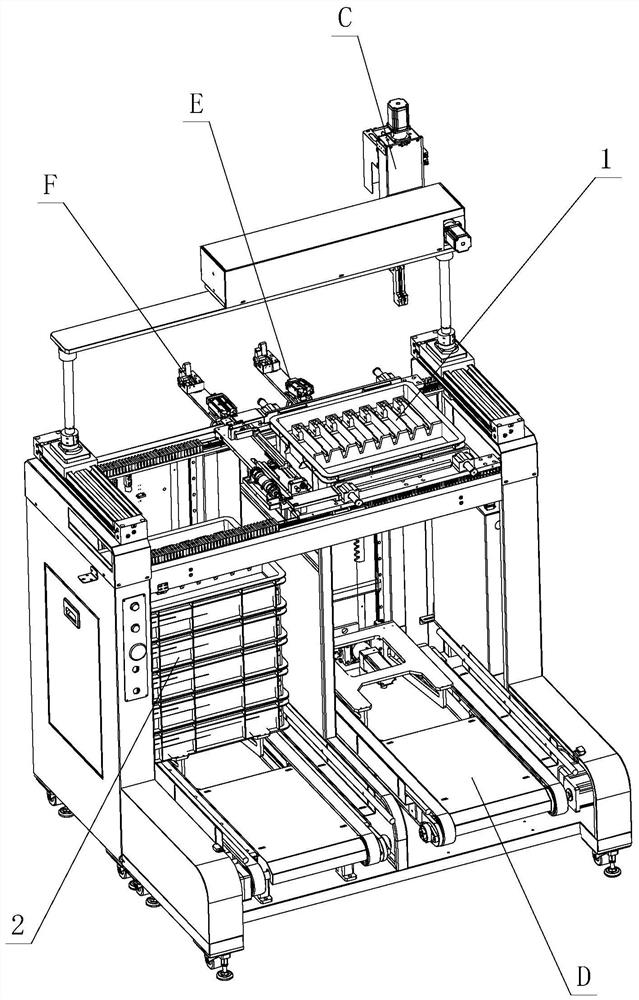

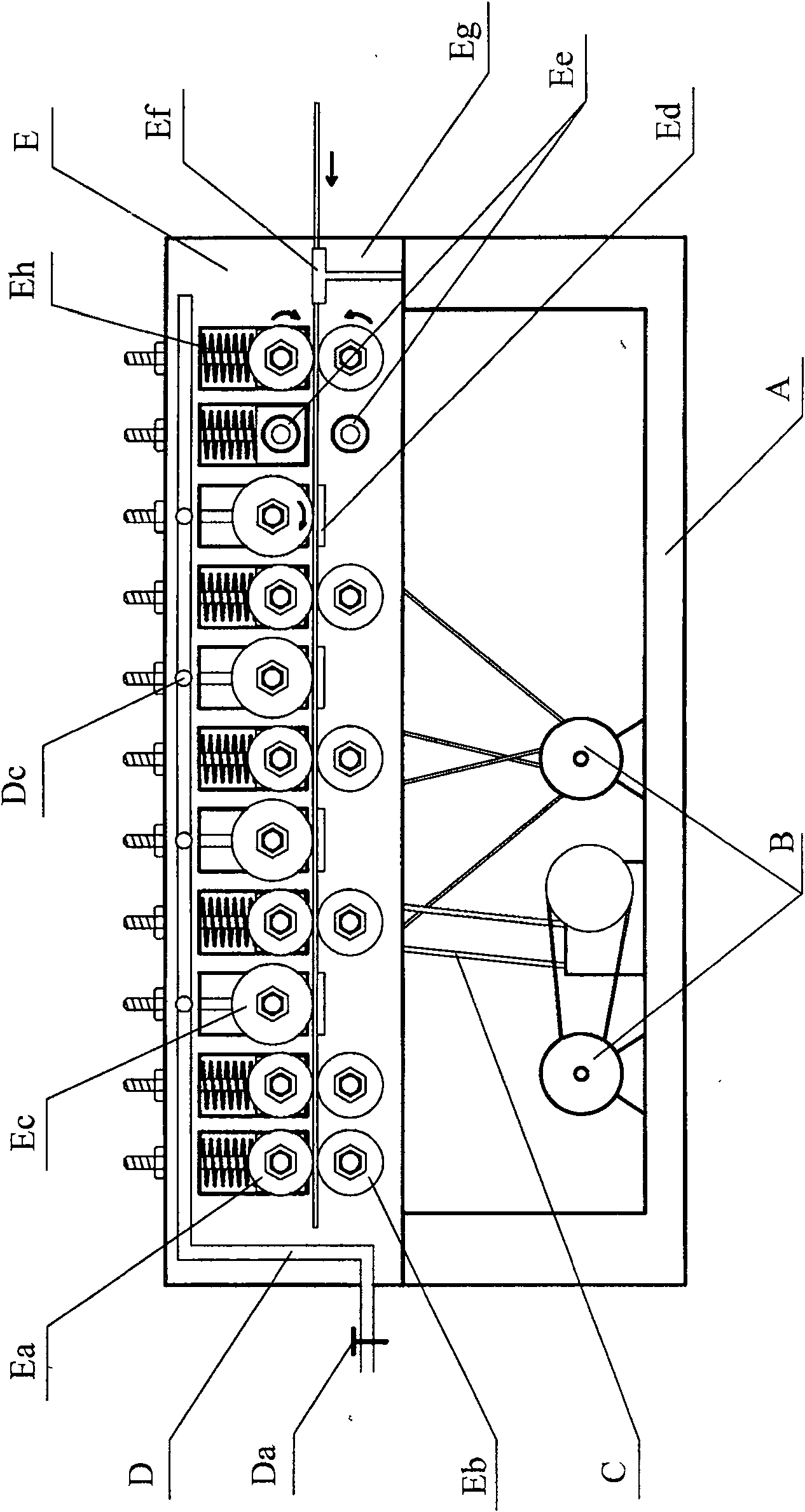

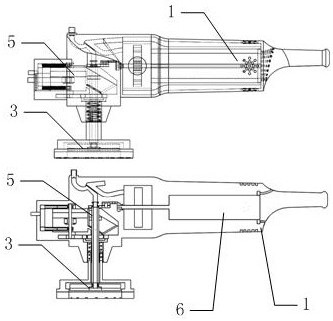

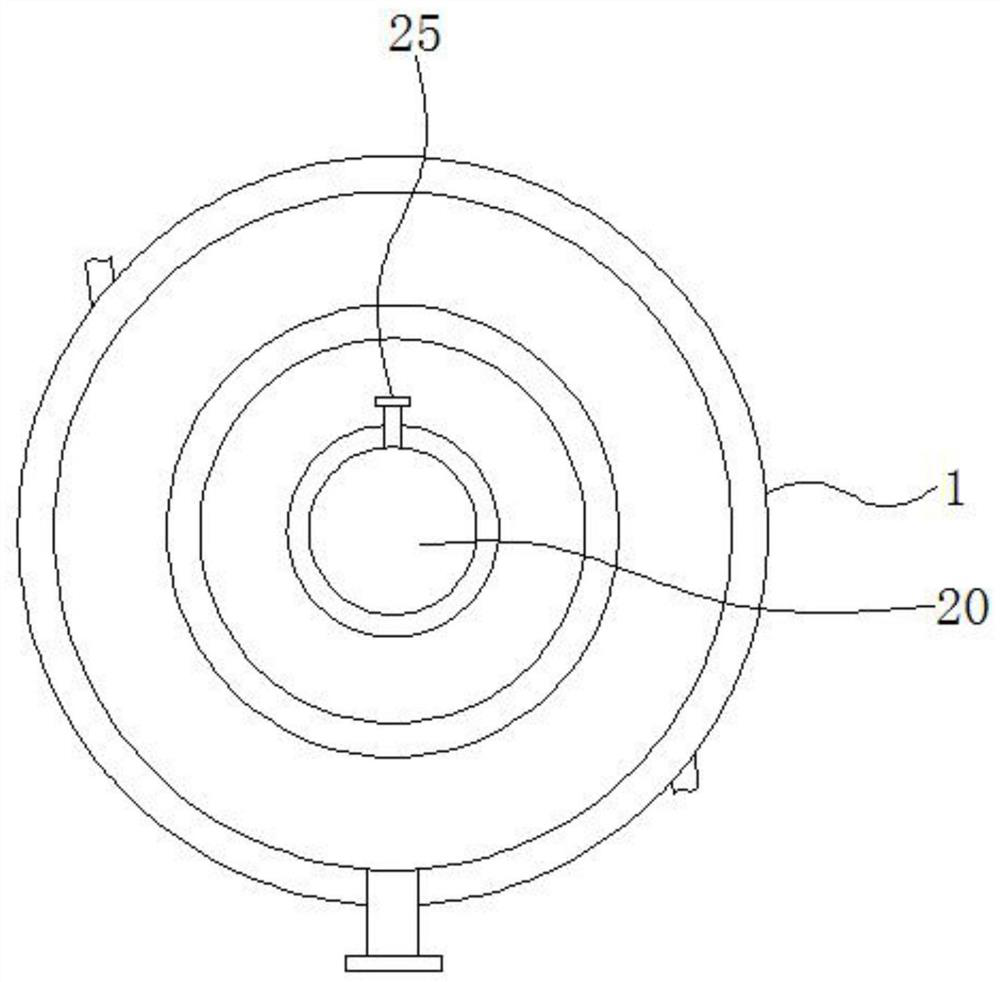

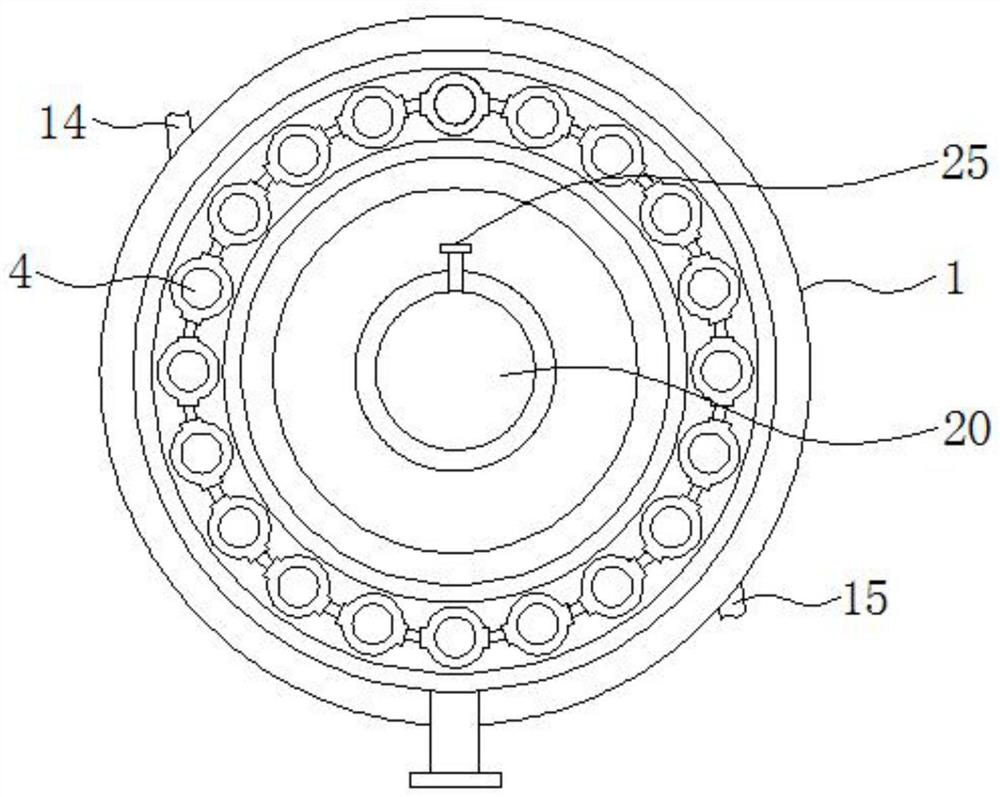

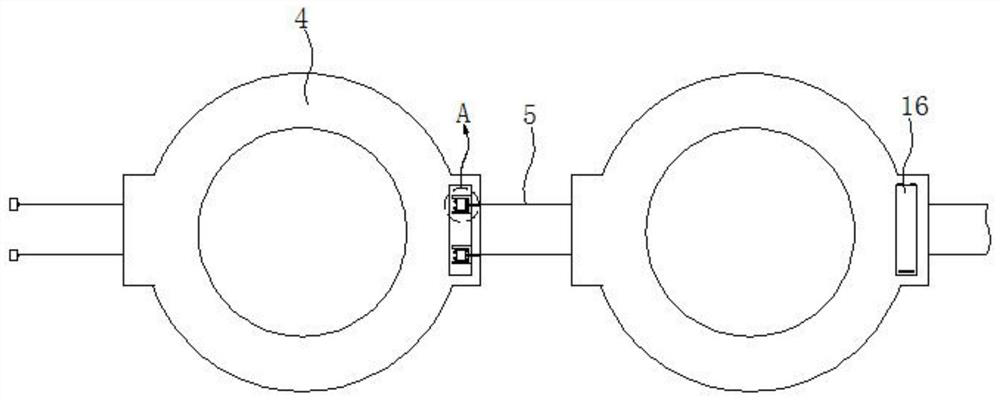

Material frame type feeding-discharging mechanism for tool water milling machining

ActiveCN111922795ASimple structureImprove loading and unloading efficiencyGrinding carriagesGripping headsProcess engineeringMachine

The invention provides a material frame type feeding-discharging mechanism for tool water milling machining. The material frame type feeding-discharging mechanism for tool water milling machining comprises a first water milling machine and a second water milling machine which are used for grinding two side faces of a tool and a material frame for placing the tool. A transferring device, an automatic feeding-discharging device, a transit device, an accurate locating device and a robot are arranged between the first water milling machine and the second water milling machine. The automatic feeding-discharging device comprises a feeding area and a discharging area for feeding and discharging of the material frame. The transit device and the accurate locating device are arranged on the automatic feeding-discharging device respectively. The transferring device moves among the automatic feeding-discharging device, the transit device and the accurate locating device, and the tool is picked andplaced when the transferring device moves. The robot moves among the transit device, the accurate locating device, the first water milling machine and the second water milling machine, and the tool is picked and placed when the robot moves. By means of the material frame type feeding-discharging mechanism for tool water milling machining, automated feeding and discharging by two water milling machines can be achieved; manual operation is reduced; the labor cost is lowered; automated production requirements are met; and in the meantime, scratching of finished products is also reduced, and thegood product rate is improved.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Grinding process for bamboo ware and bamboo strip

InactiveCN100586678CNot easy to deform and breakImprove processing utilizationVeneer manufactureGrinding machinesFiberWatermill

The invention relates to a grinding process for bamboo products, namely bamboo splints, and belongs to a bamboo splints processing method. Cut surface green bamboo chips are subjected to stewing, fiber forming, water milling, bleaching and drying to obtain the bamboo splints. The water milling treatment can effectively remove burrs and stains on the surfaces of the bamboo splints, so that the produced bamboo splints have smooth surfaces without the burrs and do not prick the hand; and the waste materials obtained after the water milling can be directly used for paper making, so that no pollution is caused and the environmental protection is ensured. The processed bamboo splints can be widely used in bamboo products such as bamboo mats, bamboo pillows, bamboo curtains, bamboo carpets, bamboo-splint woven handicraft articles and so on.

Owner:JIANGXI NANFENG ZHENYU IND GRP

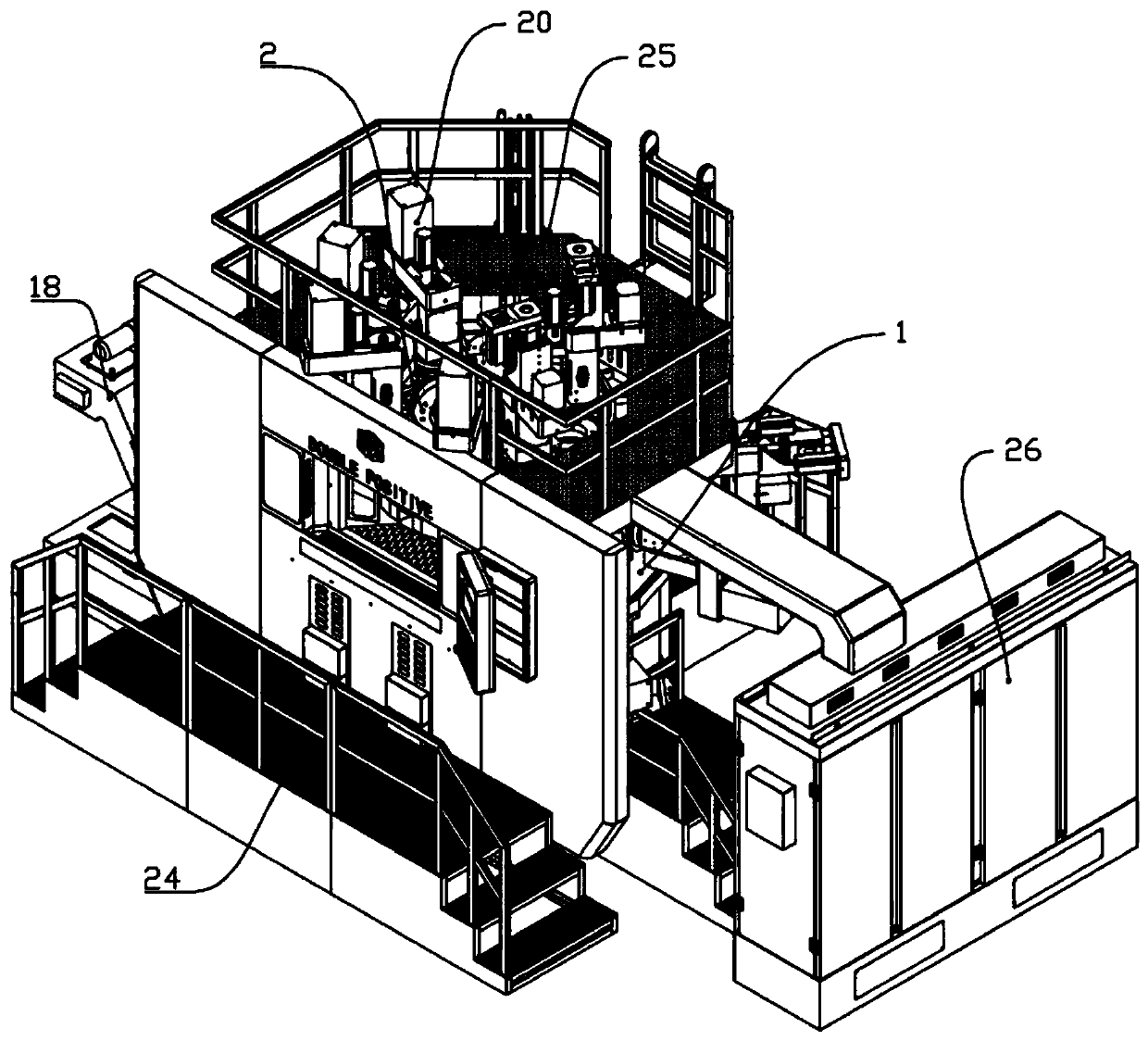

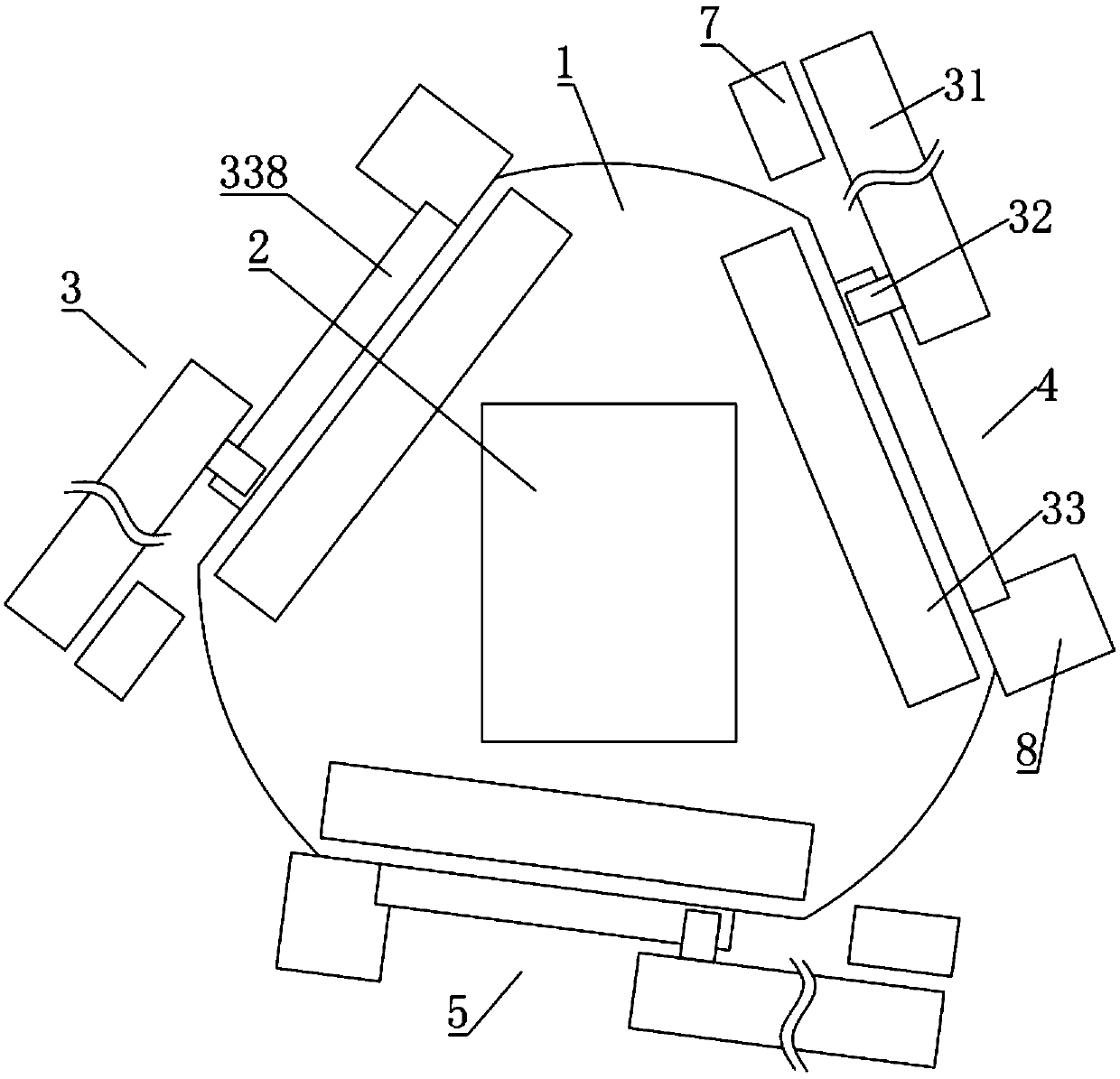

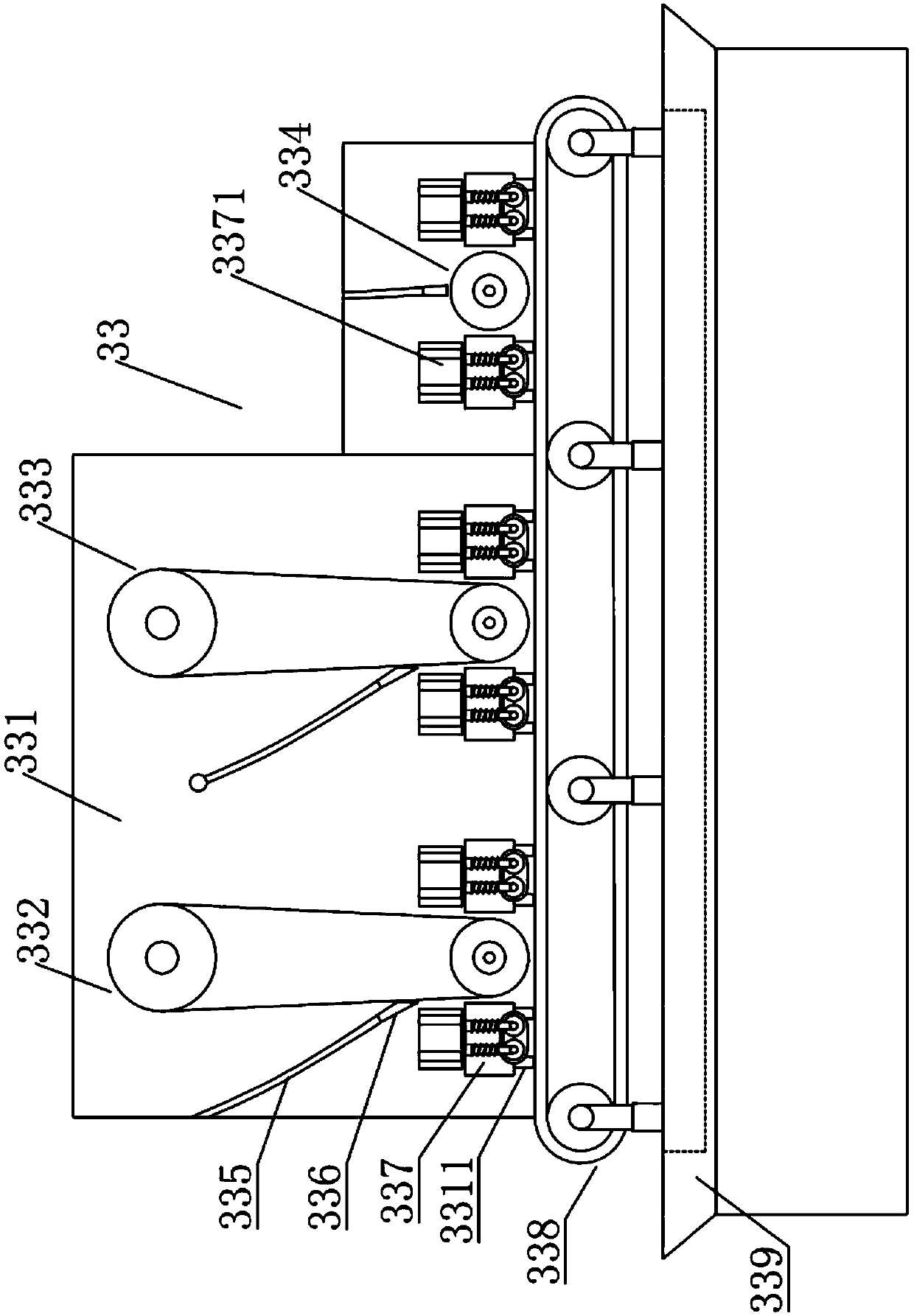

Three-head mechanical hand water belt sander

InactiveCN109531362AReasonable structural designQuality improvementBelt grinding machinesGrinding feed controlSanderEngineering

The invention discloses a three-head mechanical hand water belt sander, and belongs to the field of advanced manufacturing and automation. The belt sander comprises a machine table, an electric control cabinet unit, a first water belt sander unit, a second water belt sander unit and a third water belt sander unit, wherein the first water belt sander unit, the second water belt sander unit and thethird water belt sander unit are arranged on the circumference of the machine table in an annular array mode; and the first water belt sander unit, the second water belt sander machine unit and the third water belt sander unit comprise first linear modules, mechanical hand assemblies and water belt sander bodies. According to the three-head mechanical hand water belt sander, structural design isreasonable, three independent working water belt sander bodies are arranged on the circular machine table, grinding on to-be-ground elements can be conducted separately, the grinding is conducted through the rough grinding process, the fine grinding process and the deburring process, so that the quality of the to-be-ground elements is greatly improved, and the working efficiency is greatly improved due to that the three independent working units are arranged.

Owner:徐州优尚精密机械制造有限公司

Modified General Tso water mill

InactiveCN111375464AWind motor with solar radiationWind energy with water energyRainwater tankWater flow

The invention discloses a rain collection type modified General Tso water mill. By means of the modified General Tso water mill, through a combined device, automatic grinding is achieved by means of gathered rainwater, wind energy and solar energy, redundant water obtained after drive is guided underground so as to form the sponge ground, and the aim of developing and reutilizing rainwater is achieved. According to the technical scheme, rainwater on a roof is guided into a rain collection pond, the rain collection pond communicates into a rain collection water box, a base, an impeller, a rotating rod, a stone mill and the like which are used for supporting running of the water mill are sequentially arranged below the rain collection water box; rainwater in the rain collection water box directly impacts on the wooden impeller through a water guide pipe with a water flow adjusting valve, the rotating rod is driven to rotate, the stone mill is pushed to achieve grinding, rainwater impacting on the impeller continues to drive a downstream watercart, the water watercart rotates to a water return trough to drain water, rainwater is supplied back to the water collection box to be cyclically utilized, redundant rainwater is collected in a water accumulation pond, and the rainwater infiltrates through a seepage bent pipe to form the sponge ground. Other reserved power transmission rodscan push the water mill through other kinetic energy. An impeller and solar and kinetic energy device is erected above a base of a traditional General Tso water mill, and kinetic energy collected by impeller blades and solar energy collected by a solar photovoltaic plate can serve as power of the water mill through a power conversion device.

Owner:易小武 +2

Healthcare comb and its preparation method

InactiveCN1803060AImprove micro-ecological environmentPromotes nutrient absorptionMassage combsMassage beltsEcological environmentPrism

The invention discloses a health comb and making method, which comprises the following steps: utilizing the natural pearl shell as raw material; removing the pearl shell cuticles and prism layer through polishing method; cutting the disposed part into the comb shape through cutting method; proceeding once tooth punching and fine grinding and buffing. The polishing, cutting and tooth punching procedures adapt watermill, drip cutting and water punching separately as well as laser cutting or mechanic digital control cutter, which doesn't damage the natural active composition of mother-of-pearl within taurine, porphyrin, vitamin, amino acid and microelement due to high temperature. The invention can protect hair due to the touch of hair ornament and hair surface, which improves the micro ecological environment of hair surface to stimulate the blood circulation and delay the white hair generation.

Owner:张根芳

Coal ash based wood fiber artificial heat retaining panel and manufacturing method thereof

InactiveCN105569505AImprove toughnessIncrease profitSolid waste managementFireproof doorsFiberWood veneer

The invention discloses a coal ash based wood fiber artificial heat retaining panel and a manufacturing method thereof. The heat retaining panel comprises a raw material, a heat retaining material, and a wood panel. The raw material is formed by the materials in the following parts by weight: 100-120 parts of coal ash, 50-60 parts of wood fiber powders, 120-140 parts of water, 5-15 parts of tackifier, 3-10 parts of crack and permeation resistance agent, 5-10 parts of stabilizer, 20-40 parts of kaolinite, and 10-30 parts of lime putty powders. The heat retaining material is a heat insulation coating and an aerogel felt. The wood panel is a wood plate or a wood veneer. The steps of the manufacturing method comprise mixing and stirring, high-temperature sintering, water mill cutting, and sticking facing, etc. The coal ash is used as a base material to be processed into a door sheet, and the door sheet is added with the wood fiber powders, so as to improve tenacity of a coal ash sintered plate, and enhance plasticity and flintiness, and improve use ratio of coal ash. In a manufacturing process, the heat insulation coating and the material are added, effectively improving heat insulation performance of the door sheet. The manufactured coal ash plate effectively absorbs the heat insulation coating, so the heat insulation coating is fully used.

Owner:HEILONGJIANG HUAXIN FURNITURE

Water mill

ActiveCN111761440APlay a cooling effectImprove cooling effectGrinding drivesPortable grinding machinesThermodynamicsElectric machinery

The invention belongs to the technical field of water mills, and particularly relates to a water mill. The water mill comprises a shell, a grinding disc mechanism, an auxiliary handle, a motor, a fanand a second rotating shaft. The designed grinding disc mechanism is composed of an inner part and an outer part, and the speed between a friction disc and an annular friction plate is changed througha transmission adjusting mechanism; when relatively smooth stone is polished, the rotating speed of the annular friction plate is smaller than that of the friction disc, and it is expected that the effect of reducing sewage splashing is achieved through the low rotating speed; and when stone with large roughness is polished, due to the fact that the number of polished particles is relatively large, the situation that the particles are accumulated and scratch the surface of the stone, and normal polishing of the grinding disc mechanism is affected is avoided through the high-speed annular friction plate with the rotating speed equal to that of the friction disc.

Owner:杭州鼎好新材料有限公司

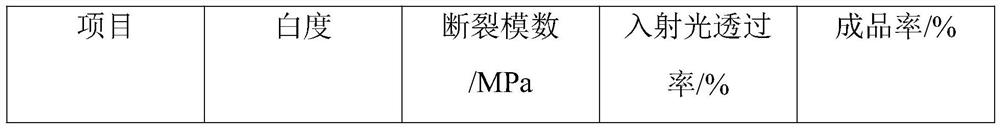

Light-transmitting brick and preparation method thereof

ActiveCN112851316AHigh light transmittanceHigh strengthCeramic materials productionPyrophylliteBrick

The invention provides a light-transmitting brick and a preparation method thereof, and relates to the field of ceramics. The light-transmitting brick is prepared from the following raw materials in percentage by mass: 5 to 8 percent of quartz, 10 to 30 percent of kaolin, 15 to 25 percent of feldspar, 6 to 8 percent of calcined talc, 1 to 5 percent of pyrophyllite, 15 to 25 percent of water milled nepheline, 5 to 10 percent of low-temperature sand and 30 to 45 percent of a calcium raw material, wherein the calcium raw material is bone meal or frit. The preparation method of the light-transmitting brick comprises the steps of carrying out ball milling on the raw materials to obtain a blank, and then carrying out compression molding on the blank to obtain a green brick; and carrying out pretreatment on the green brick, then feeding the green brick into a kiln to be sintered, and then obtaining a product through aftertreatment. The light-transmitting brick provided by the invention is high in light transmittance and high in strength.

Owner:清远市简一陶瓷有限公司 +2

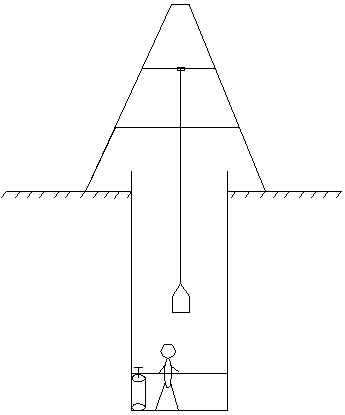

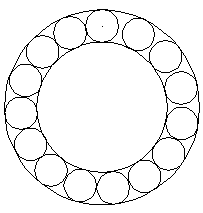

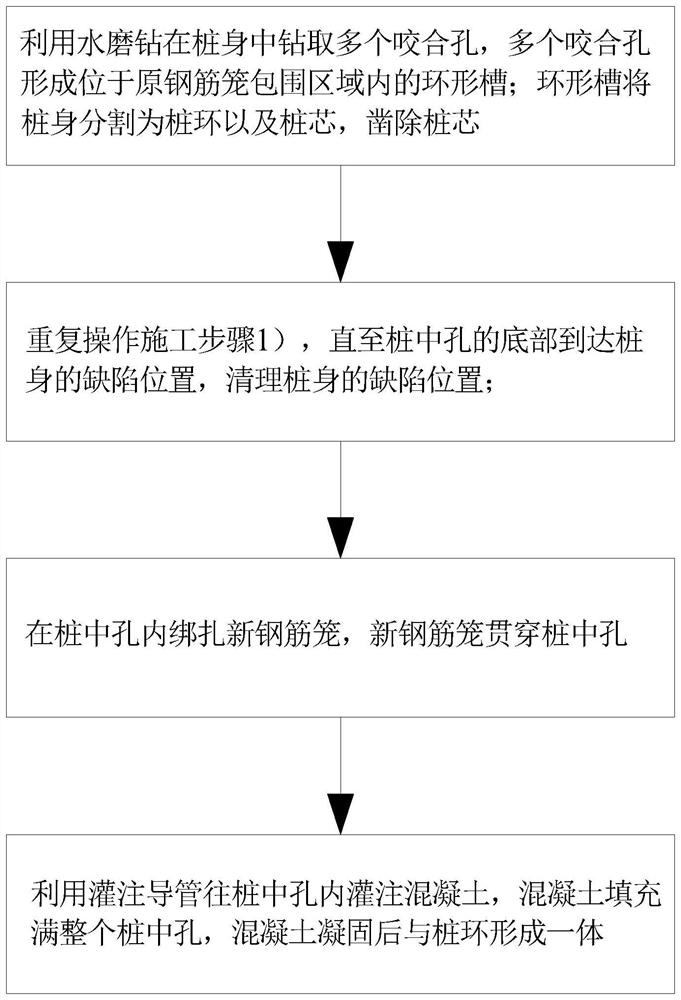

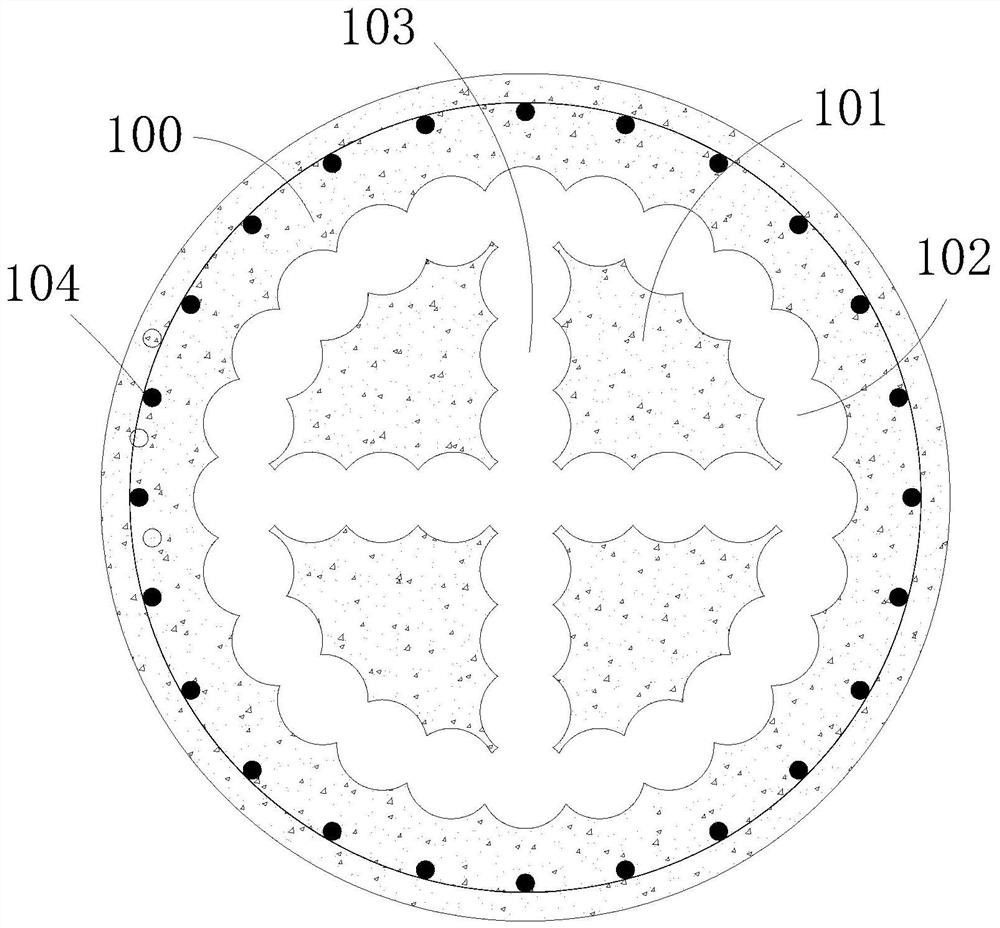

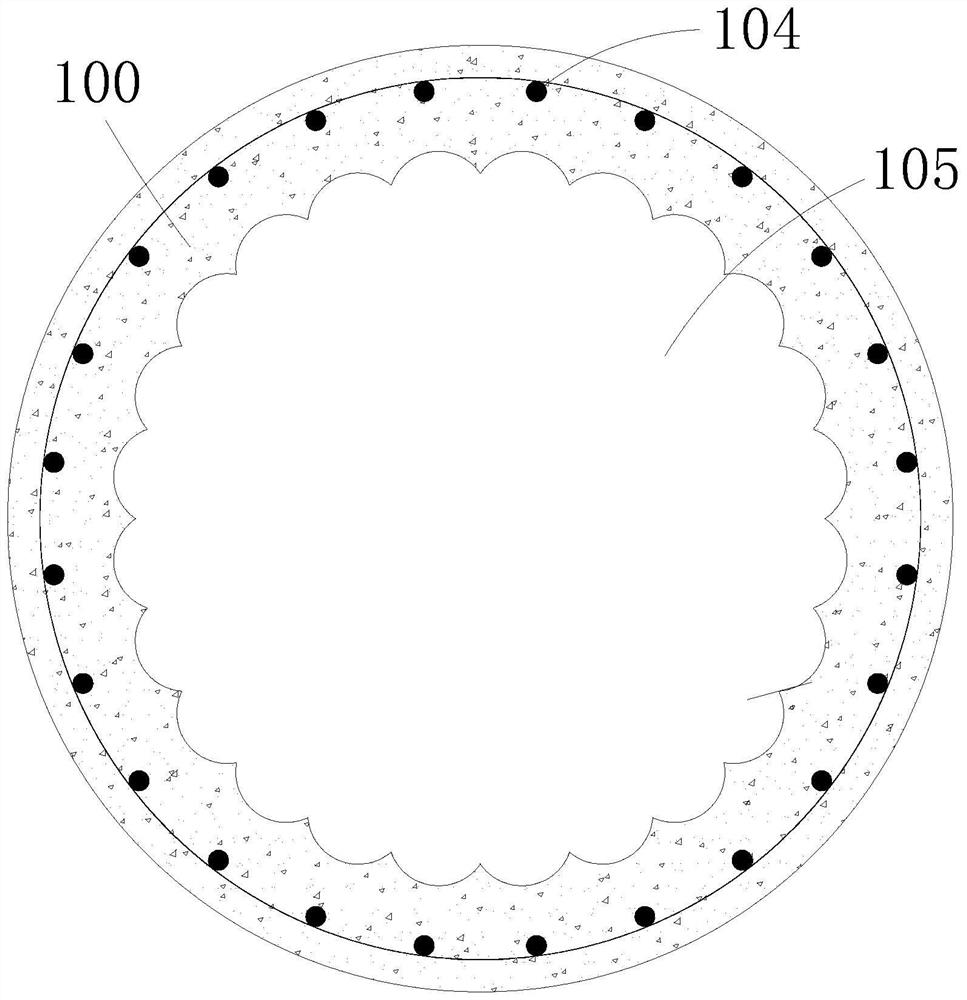

Water milling construction method for manual digging pile

PendingCN108589740AFlexible operationEasy maintenanceExcavationsBulkheads/pilesBridge engineeringRock core

The invention belongs to the technical field of bridge engineering construction, and relates to a water milling construction method for a manual digging pile of a bridge pile foundation engineering. The method comprises the following steps that 1 ) after the hole digging position and the diameter of a pile foundation are determined, drilling operation is continuously carried out along the circumference edge of the pile foundation hole through th water milling drill, the depth of each drilling hole is determined by the length of a drill cylinder, each drilling hole is sequentially tangent or intersected, and the water milling drill is transported out of a rock core after the drilling is finished; 2 ) the central part of the pile foundation hole is crushed and removed by using an air pick, the crushed rock slag is transported away, and the hole digging operation of a section of depth is completed; 3 ) the step 1 to the step 2 are repeated for a plurality of times, and the hole digging operation of the next section of depth is completed until the design depth of the pile foundation hole is reached. According to the method, the drilling process of the method is flexible in operation, the maintenance is simple and convenient, the construction is safe, and the pollution is small; and meanwhile, the vibration and the noise are small, and great advantages are achieved in the area construction which is not suitable for blasting.

Owner:JIANGSU PROVINGIAL TRANSPORTATION ENG GRP

Slurry grinding and conveying system

The invention relates to the technical field of plate recovering, in particular to a slurry grinding and conveying system. The slurry grinding and conveying system comprises a wet process ball mill, aslurry storing tank and an air compressor, the air compressor conveys ground waste in the wet process ball mill into the slurry storing tank through a pipe, and the wet process ball mill comprises abarrel and a bearing for bearing the barrel and maintaining the barrel to rotate; a waste treatment device comprises the wet process ball mill, the slurry storing tank and the air compressor, the waste is put into the wet process ball mill for water milling, high temperature is generated in the wet process ball mill, and a partial tobermorite crystal nucleus is better formed through silicon and calcium in the waste; meanwhile, the activity of the silicon and the calcium in the waste is improved, the later-period reacting is facilitated, the proportion of the waste in the formula is improved to5% from original 3%, and the performance of a plate is not influenced.

Owner:昆明华城兴建材有限公司

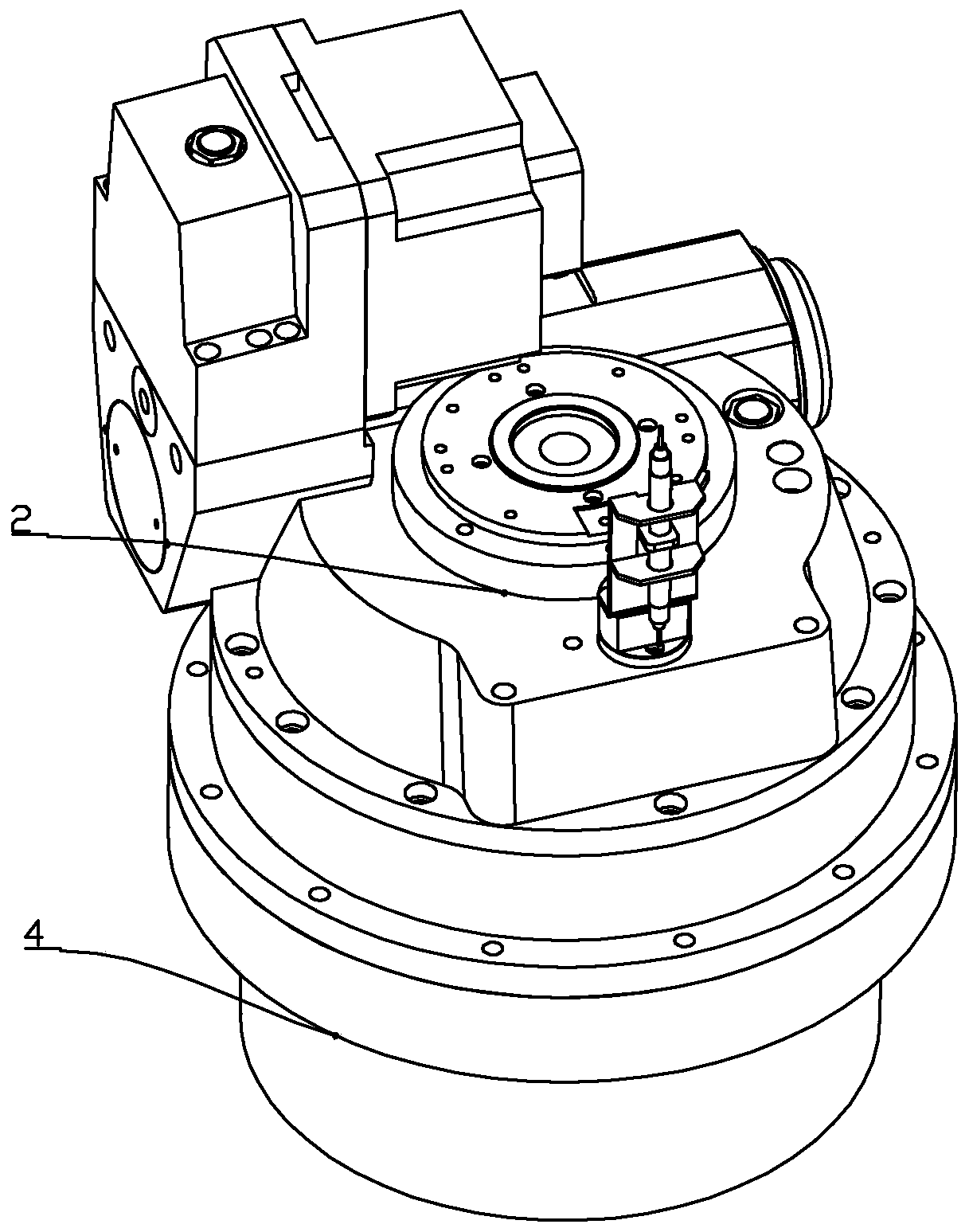

Water mill for stone machining and preparation method thereof

ActiveCN103056787AImprove grinding forceImprove polishing effectAbrasion apparatusGrinding devicesEpoxyCarbide silicon

The invention discloses a water mill for stone machining and a preparation method thereof. The water mill is prepared through black silicon carbide, silica, polyethylene glycol, epoxy resins, methyl ethyl ketone peroxide, cobalt iso-octoate and magnesium sulfate. The method comprises placing the polyethylene glycol and the epoxy resins in a reaction still to be heated and stirred evenly; putting the black silicon carbide, silica and the magnesium sulfate in a mixer to be stirred and mixed evenly; putting the evenly stirred mixtures in the mixer to be stirred evenly, adding methyl ethyl ketone peroxide and cobalt iso-octoate in the mixtures to be heated and stirred evenly to be discharged to obtain a mixed material; and putting the mixed material in a mould, and molding and drying the material naturally under the normal pressure and temperature to obtain the product water mill. The water mill prepared through the method has a higher grinding effect, surface smoothness and brightness than an ordinary grinding head, and ideal effects of users can be achieved without wool wheel polishing.

Owner:郑州新安华砂轮有限公司

Method for maintaining and treating defective cast-in-place pile

PendingCN114277790AEasy to handleEasy construction organizationBulkheads/pilesArchitectural engineeringRebar

The invention relates to the technical field of cast-in-place piles, and discloses a defective cast-in-place pile maintenance treatment method which comprises the following construction steps that (1) a defective cast-in-place pile is provided with a pile body, and an original reinforcement cage is arranged in the pile body; a water mill drill is used for drilling a plurality of meshing holes, and the meshing holes form an annular groove located in the surrounding area of the original reinforcement cage; the annular groove divides the pile body into a pile ring and a pile core, the pile core is chiseled away, and a pile middle hole is formed; (2) the construction step (1) is repeated till the bottom of the pile middle hole reaches the defect position of the pile body; 3) binding a new reinforcement cage in the hole in the pile; (4) concrete is poured into the pile center hole, and the concrete and the pile ring form a whole after being solidified; the defective cast-in-place pile maintenance treatment method has the advantages that defect position treatment construction organization is facilitated, the defect position treatment construction process is visual and controllable, construction is safe and reliable, and the comprehensive construction cost is low.

Owner:SHENZHEN GONGKAN GEOTECHN GRP +1

Manned rotary water mill

The invention provides a manned rotary water mill. The manned rotary water mill comprises: a U-shaped water tank; a first protection pad and a second protection pad which are arranged on the two sidesof the interior of the U-shaped water tank respectively; an inflatable boat connected to the interior of the U-shaped water tank in a sliding manner; and traction ropes, wherein one ends of the two traction ropes are fixed to one side of the inflatable boat. Each inflatable boat is installed, so the safety performance of tourists in the playing process is improved, and certain potential safety hazards caused by rollover of the inflatable boat due to the fact that the inflatable boat vibrates under the impact of water flow and children scream on the boat in the playing process of visits are avoided; and water in the U-shaped water tank is sprayed on the tourists through water spraying of water spraying nozzles, so interestingness of the tourists in the experience process is improved, participation of a large number of tourists can be attracted, and economic benefits of the project are improved.

Owner:安徽青云峡旅游发展有限公司

Micro water grinding head for edge grinding machine

InactiveCN101502941AReduce loadImprove edging efficiencyEdge grinding machinesGrinding machine componentsWater sourceBrackish water

The invention provides a brackish water edging head of an edge grinding machine which comprises a grinding wheel and a shaft that drives the grinding wheel to rotate. The grinding wheel is fixed on one end of the shaft which is characterized in that the shaft communicates communicate with a water feeder. A water conveyance channel which communicates with the water feeder is arranged in the shaft. The water conveyance channel runs through the end of the shaft for fixing the grinding wheel. When the edge grinding machine runs, an external water source slowly inputs cooling water into the water conveyance channel in the shaft by the water feeder. The cooling water flows out from the end of the shaft which is fixed with the grinding wheel and drops on the grinding wheel that rotates in high speed. Thus, the grinding wheel and work pieces are under the water lubrication and temperature lowering effects. Currents are slow, therefore, the cooling water dropping on the grinding wheel cannot produce flowing sewage. The brackish water edging head of the edge grinding machine overcomes both shortages of large water consumption and hard sewage processing of a traditional wet edge grinding machine and shortages of poor grinding quality, low grinding efficiency and fast grinding wheel loss of a traditional dry edge grinding machine.

Owner:佛山市一鼎科技有限公司

Flange surface grinding process

The invention discloses a flange surface grinding process, which includes the following steps: (1) Soaking: Soak the flange in a special solution for 25-35 minutes; (2) Rough grinding: Take out the soaked flange and wipe it with cotton cloth (3) Fine grinding: Rinse off the grinding debris attached to the surface of the flange after rough grinding with water, then dry the flange, and use 800# water grinding paper to grind the flange for sanding. The present invention makes the surface of the polished flange smooth and flat through reasonable setting of the steps of soaking, coarse grinding, fine grinding, water grinding and drying treatment, and each step is easy to operate and easy to implement.

Owner:ANJI YUANMO MECHANICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com