Water milling construction method for manual digging pile

A technology of manual hole-digging piles and construction methods, applied in the direction of drilling equipment and methods, excavation, sheet pile walls, etc., can solve problems such as major safety, hidden dangers, and house hazards, and achieve low vibration and noise, easy maintenance, and easy construction safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

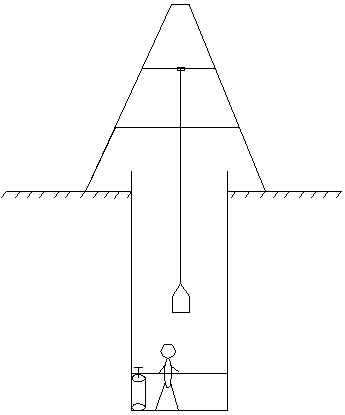

[0016] The construction process of the embodiment of the present invention (see figure 1 ):

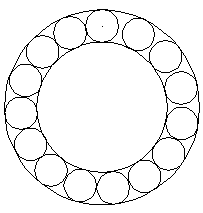

[0017] 1) After determining the location and diameter of the pile foundation hole, set the derrick at the wellhead of the pile foundation hole, install the lifting equipment, and carry out drilling operations continuously along the peripheral edge of the pile foundation hole with a water mill drill. According to the specifications of the drill pipe, each The depth of the drilled holes is 60cm, and the diameter is 16cm. Each drilled hole is tangent or intersected in turn (such as figure 2 ), after the drilling is completed, the core is transported out through the lifting equipment;

[0018] 2) Use a pick to break and remove the center of the pile foundation hole, and transport the broken rock slag out through the lifting equipment to complete a section of deep hole digging;

[0019] 3) Repeat step 1) to step 2) several times to complete the digging operation at the next depth until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com