Mirror processing method for stainless steel plate and polishing machine adopted in the same

A stainless steel plate and mirror surface processing technology, which is applied to machine tools, metal processing equipment, and grinding/polishing equipment suitable for grinding workpiece planes, and can solve problems such as difficulty in achieving 8K mirror surface effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

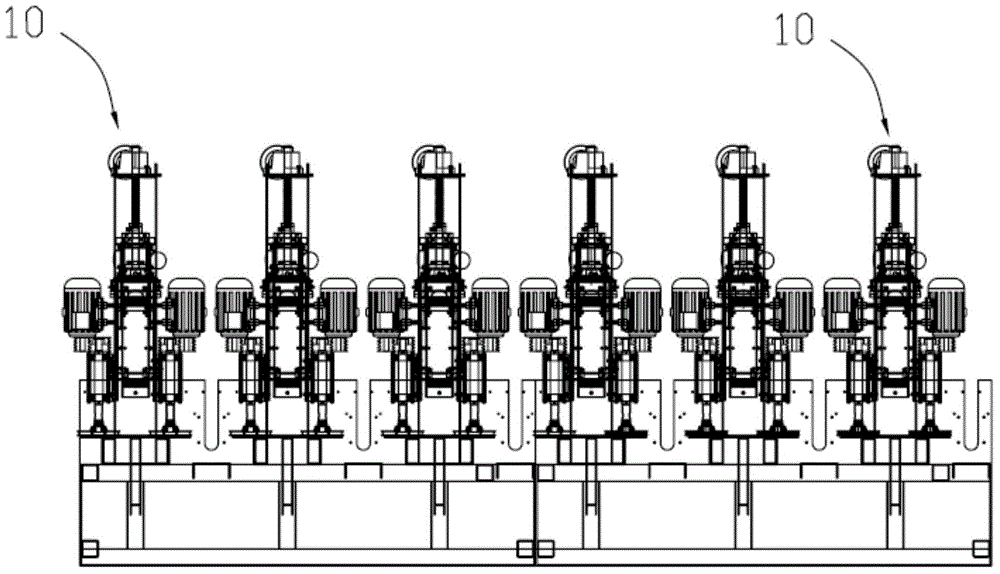

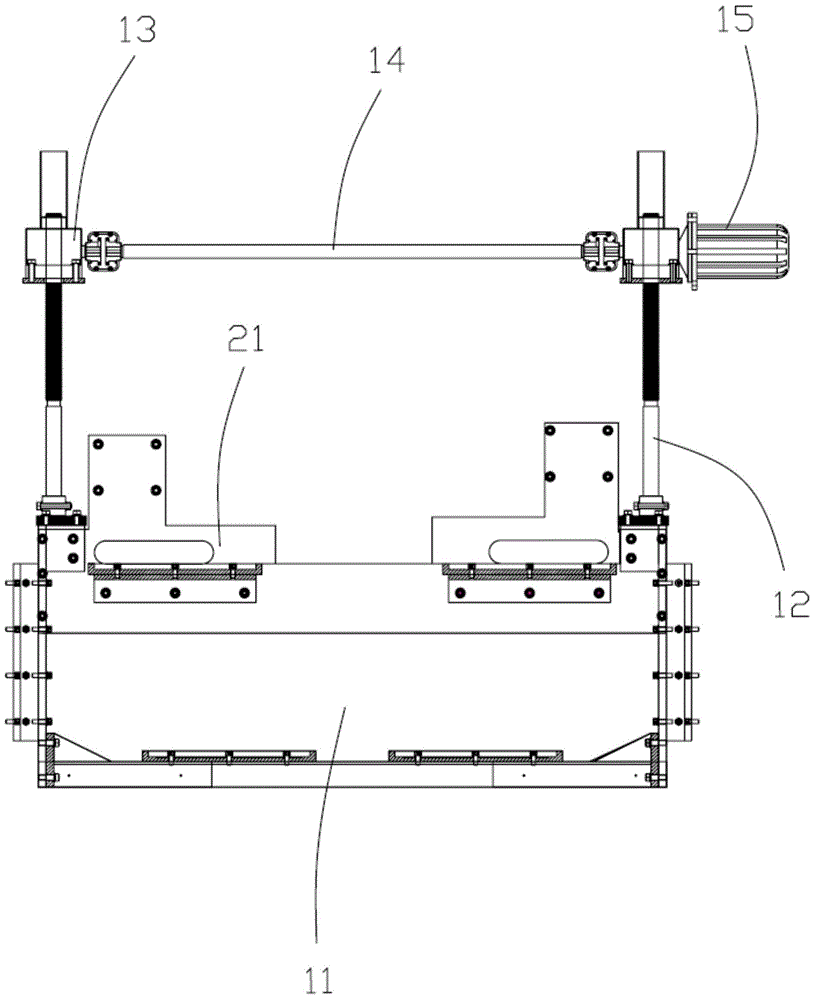

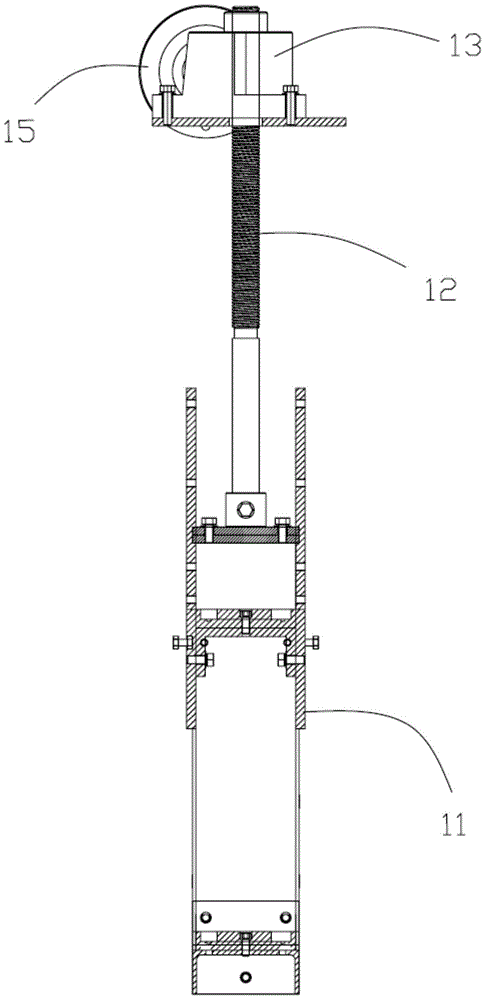

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. In the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the drawings and in combination with the embodiments.

[0024] The invention provides a method for processing a mirror surface of a stainless steel plate, which comprises the steps of rough grinding, polishing, cleaning, drying, and gluing and packaging. The raw material selected is stainless steel cold-rolled pickling plate, the surface is 2B or BA surface, without obvious quality problems (such as peeling, acid-base oxidation, scratches, scratche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com