MCD arc-surface-milling cutter

A cambered surface and tool technology, applied in milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of poor mirror effect and complicated process, so as to improve production efficiency, improve processing error, improve processing accuracy and high-gloss tool life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

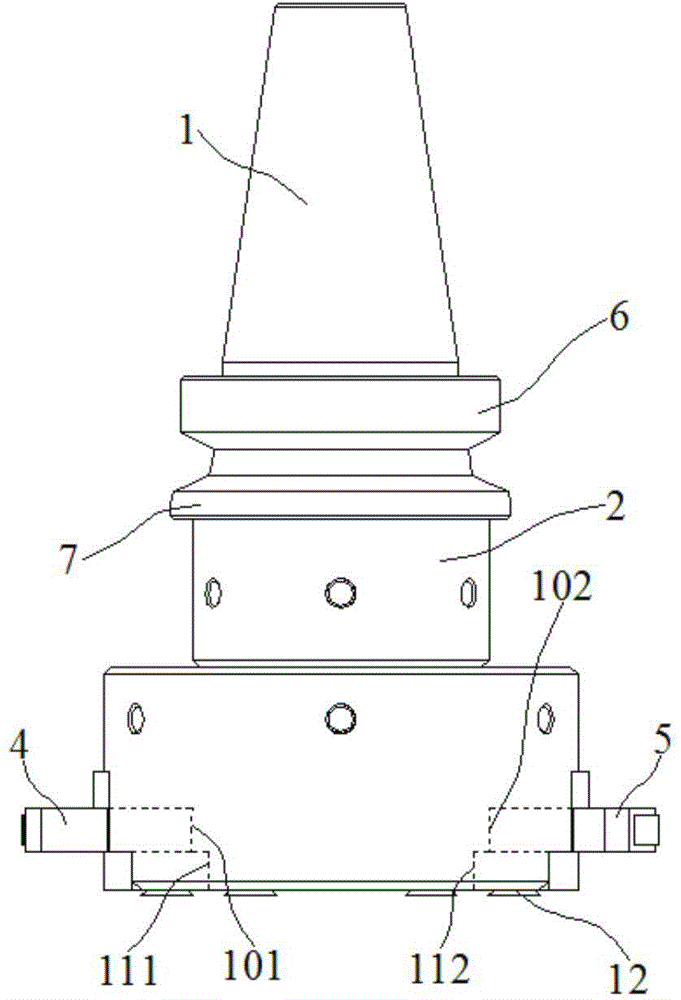

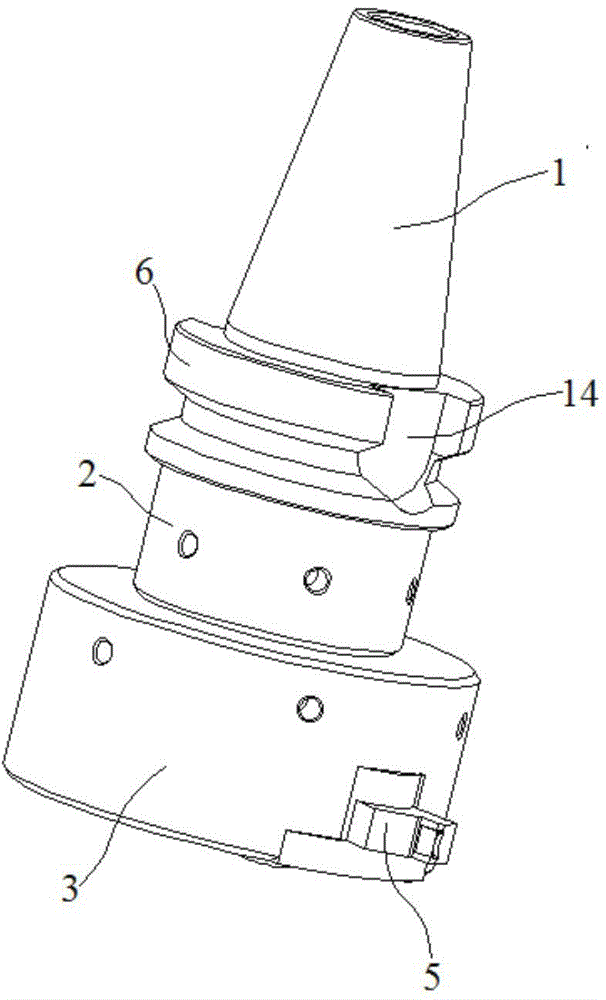

[0020] Embodiment 1: a kind of MCD arc milling cutter, comprises cutter shaft 1, connecting shaft 2, cutter head 3 and left and right diamond cutters 4,5, and the section of described cutter shaft 1 along its axis is a tapered surface, so The connecting shaft 2 is located between the cutter shaft 1 and the cutter head 3, the connection between the lower end of the connecting shaft 2 and the cutter shaft 1 is provided with a first flange 6 along the circumference, and the middle part of the connecting shaft 2 has a second flange 7. The left and right diamond knives 4 and 5 are all composed of a handle 8 and a diamond knives 9. The front portion of the protruding side diamond 9 has a diamond blade 91, and the connecting shaft 2 has 2 along the circumferential side. a positioning groove 14, and two positioning grooves 14 are symmetrically arranged on the side of the connecting shaft 2;

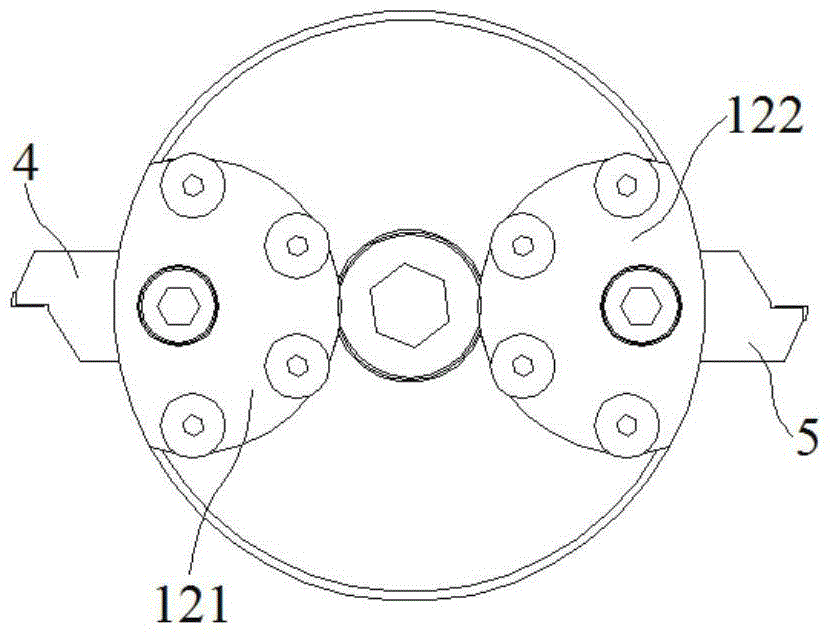

[0021] The cutter head 3 is provided with left and right mounting grooves 101, 102 and left a...

Embodiment 2

[0024] Embodiment 2: a kind of MCD arc milling cutter, comprises cutter shaft 1, connecting shaft 2, cutter head 3 and left and right diamond cutter 4,5, and the section of described cutter shaft 1 along its axis is a tapered surface, so The connecting shaft 2 is located between the cutter shaft 1 and the cutter head 3, the connection between the lower end of the connecting shaft 2 and the cutter shaft 1 is provided with a first flange 6 along the circumference, and the middle part of the connecting shaft 2 has a second flange 7. The left and right diamond cutters 4 and 5 are all composed of a handle 8 and a diamond cutter head 9. The diamond cutter head 9 on the protruding side has a diamond blade 91 at the front, and the connecting shaft 2 has 2 along the circumferential side. a positioning groove 14, and two positioning grooves 14 are symmetrically arranged on the side of the connecting shaft 2;

[0025] The cutter head 3 is provided with left and right mounting grooves 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com