Patents

Literature

92results about How to "Achieve mirror effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

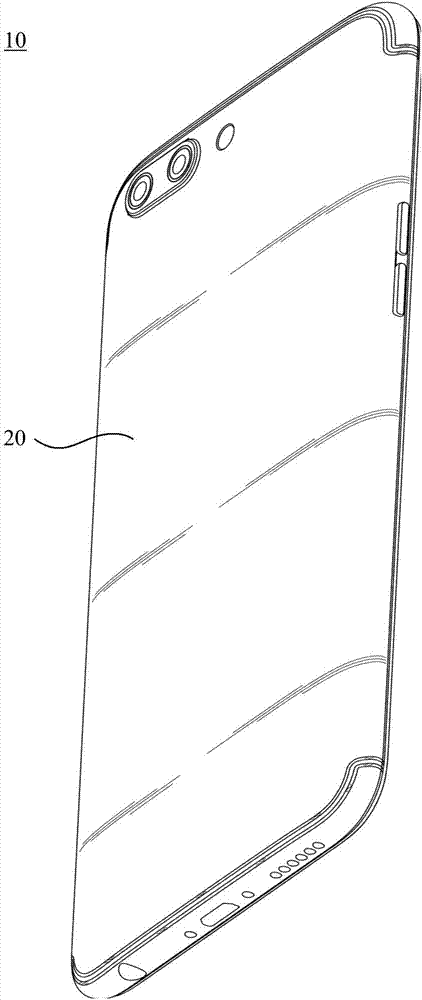

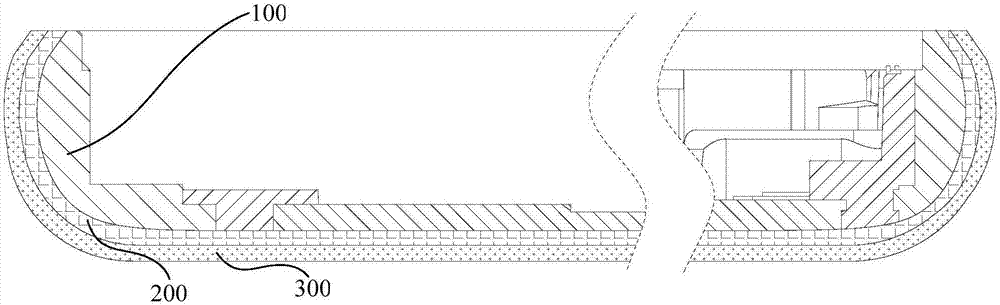

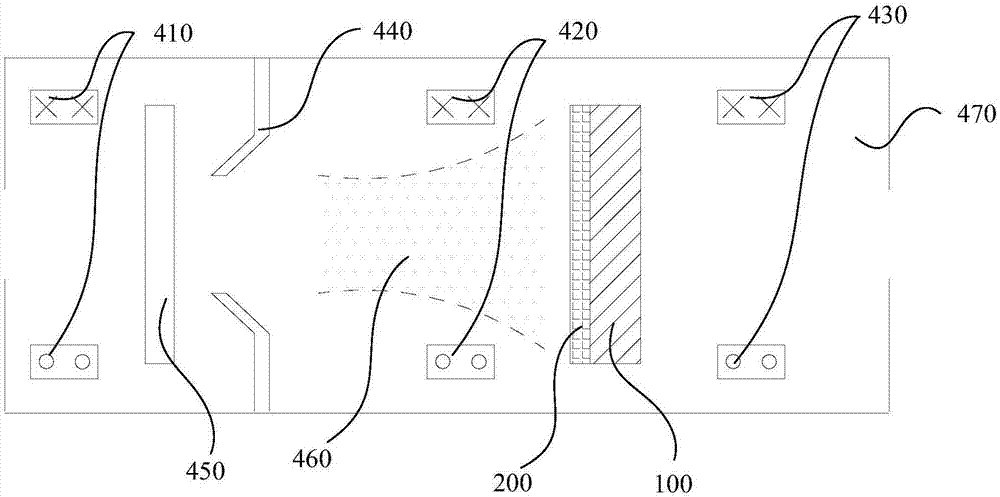

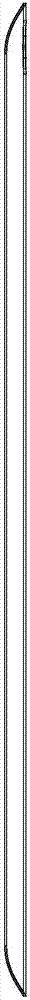

Terminal outer shell, electronic equipment and processing technology of terminal outer shell

InactiveCN107419267AReduce manufacturing costAchieve mirror effectSuperimposed coating processComputer terminalHardness

The invention relates to a terminal outer shell, electronic equipment containing the terminal outer shell and a processing technology of the terminal outer shell. The processing technology of the terminal outer shell comprises the following steps of obtaining an aluminum alloy shell body through a stamping or casting technology; conducting polishing treatment on the surface of the aluminum alloy shell body; generating a base plating layer on the surface of the aluminum alloy shell body through a water electroplating technology; generating a mirror surface plating layer on the surface of the base plating layer through a PVD vacuum coating technology; and machining accessory holes through a CNC technology. The terminal outer shell comprises the aluminum alloy shell body, the base plating layer and the mirror surface plating layer. The base plating layer is connected to the surface of the aluminum alloy shell body in a stacked manner, and the mirror surface plating layer is connected to the surface, far away from the aluminum alloy shell body, of the base plating layer in a stacked manner. The terminal outer shell has certain hardness; meanwhile, manufacturing cost is low; and in addition, the outer surface has the mirror surface effect.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

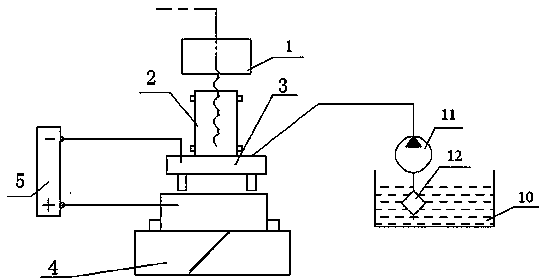

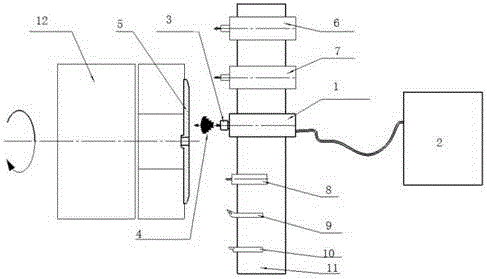

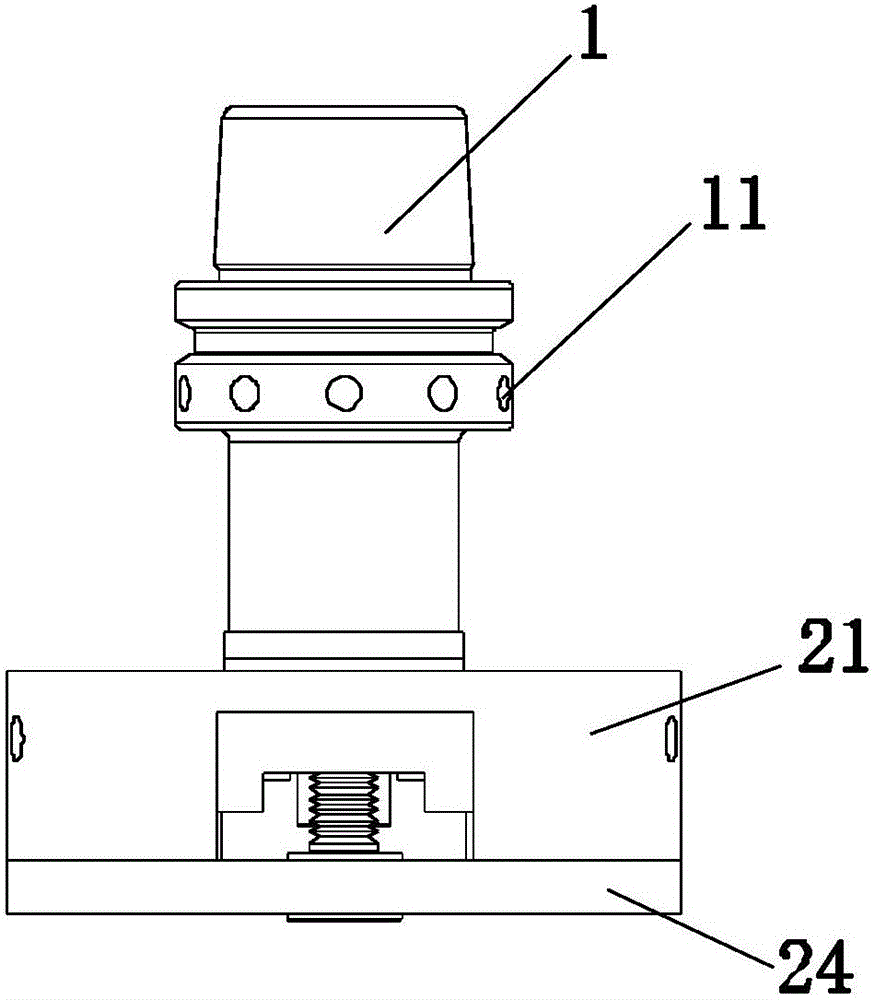

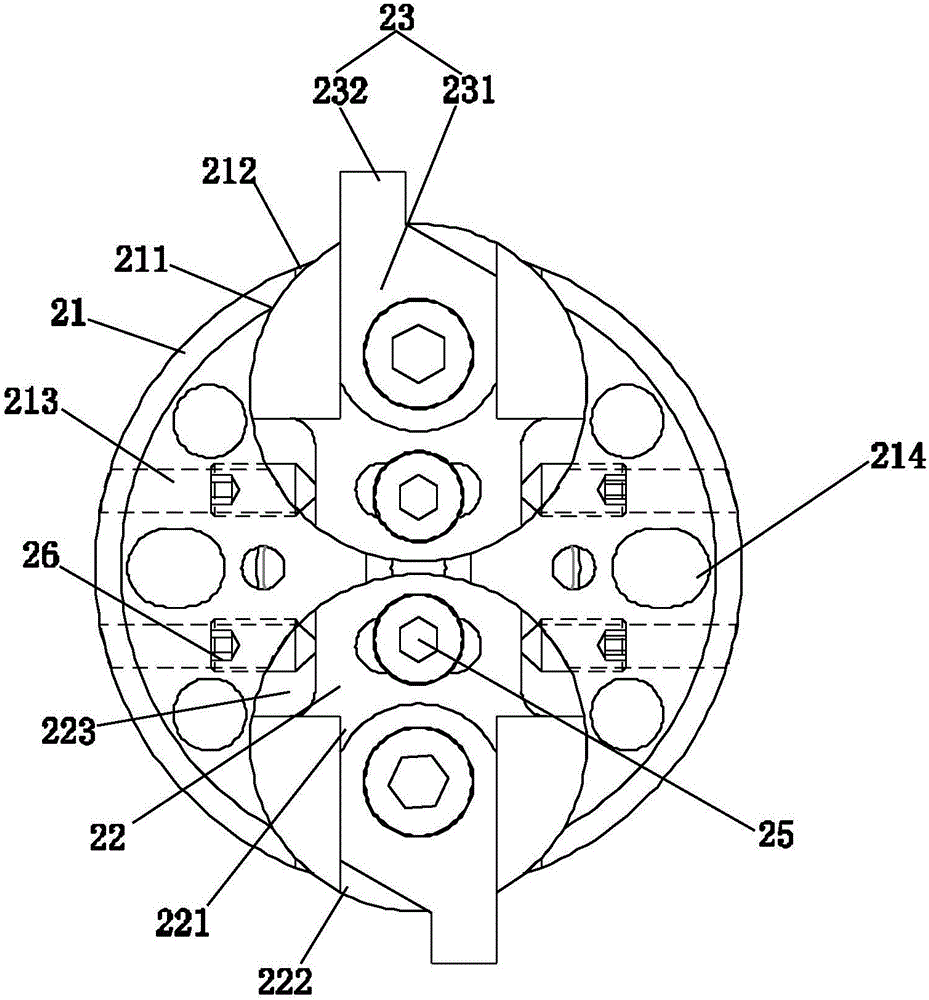

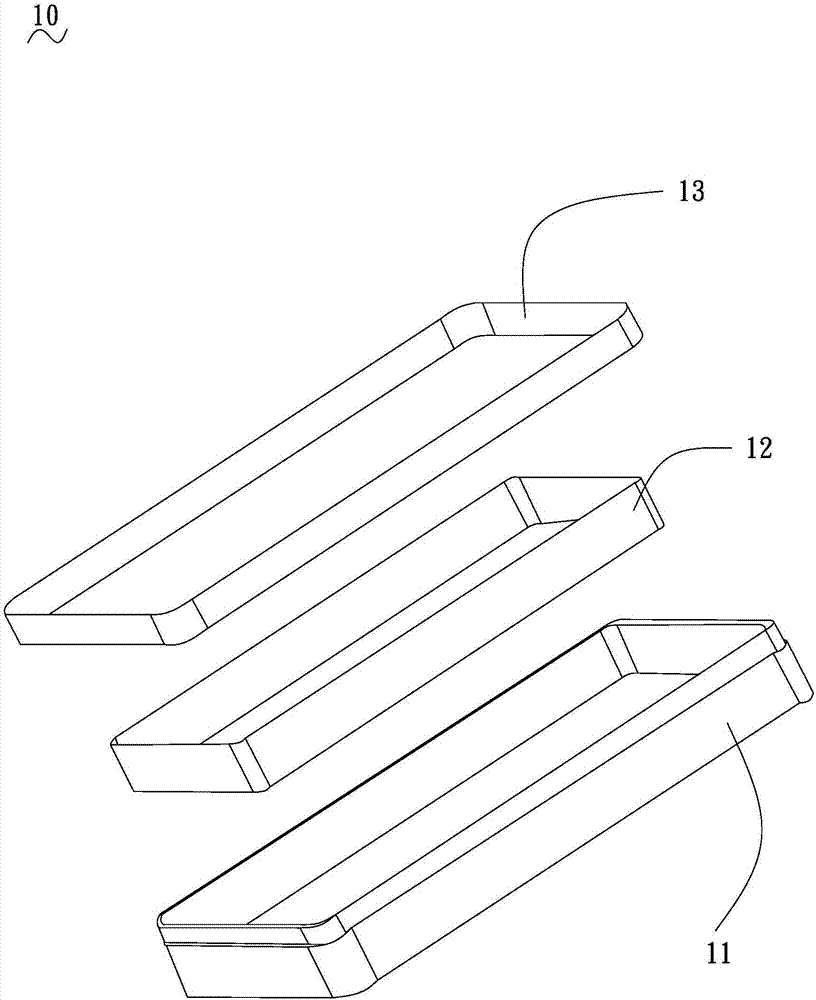

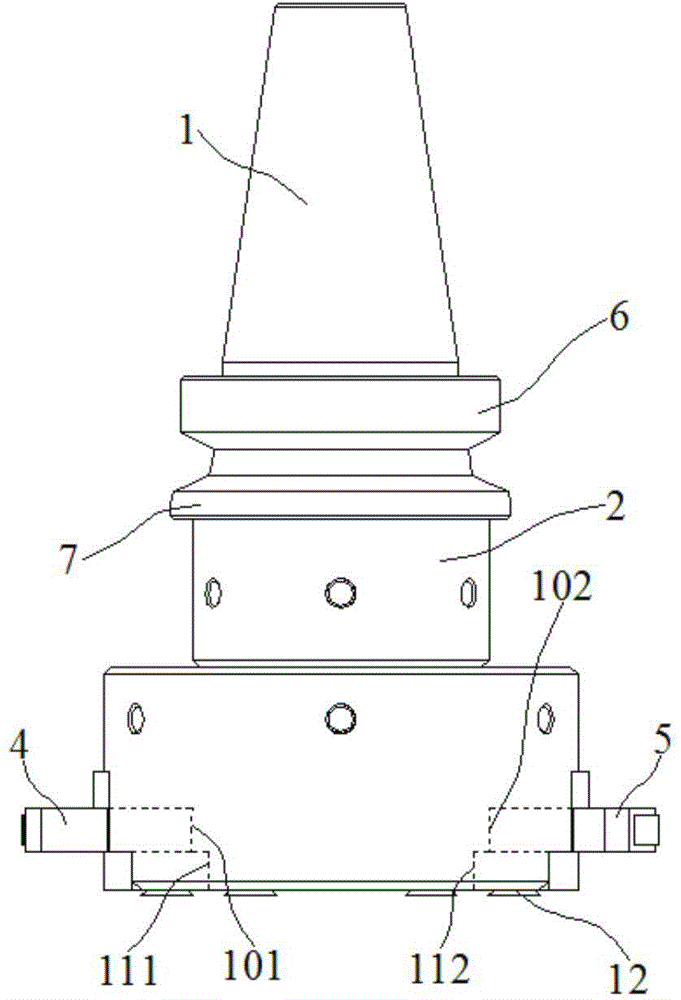

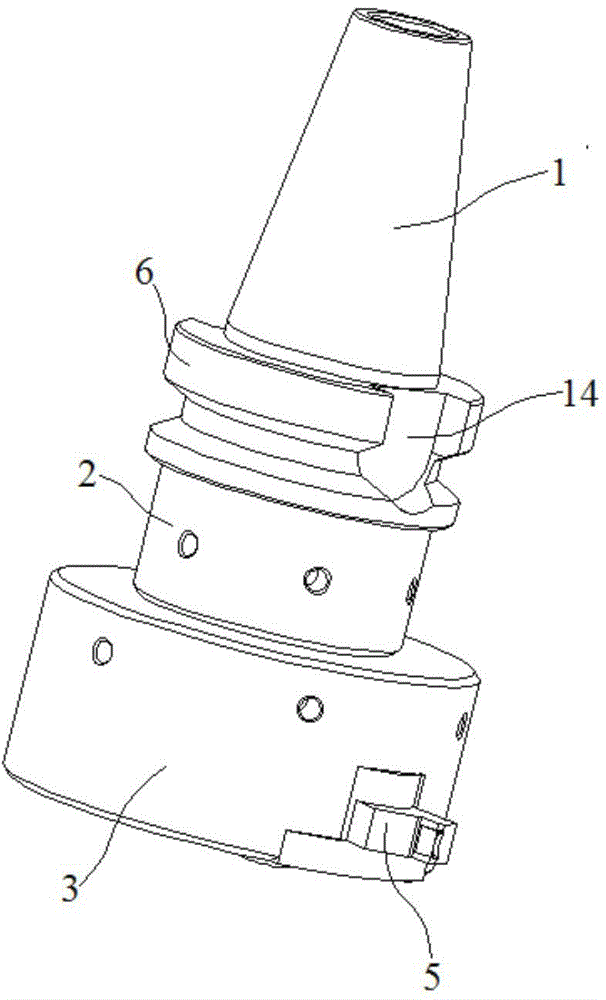

Electric spark milling and mechanical grinding combined machining device

The invention discloses an electric spark milling and mechanical grinding combined machining device. The combined machining device comprises a servo system (1), a milling machine chuck (2) connected with the servo system (1), a combined machining cutter (3) connected with the milling machine chuck (2), a rotary table (4) installed under the combined machining cutter (3) and a pulsed power supply (5) connected with the combined machining cutter (3). According to the combined machining device, discharge electrodes and material grinding rods are mounted on an electrode plate, mechanical grinding is carried out while electric discharge machining is conducted, no short out phenomena or arc discharge phenomena exist, electrode losses are even, quality of machining surfaces is good, compensation is easily achieved, machining efficiency is quite high, precision is high, the mirror surface effect can be achieved through machining, swarf removal is facilitated, and the combined machining device can be widely applied to machining insulators, semiconductors and other workpieces.

Owner:YANCHENG INST OF TECH

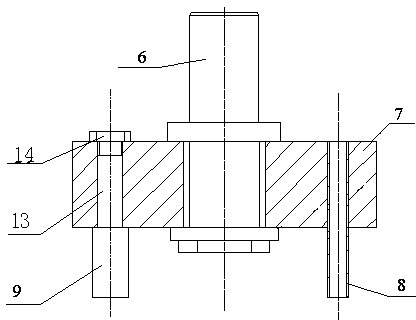

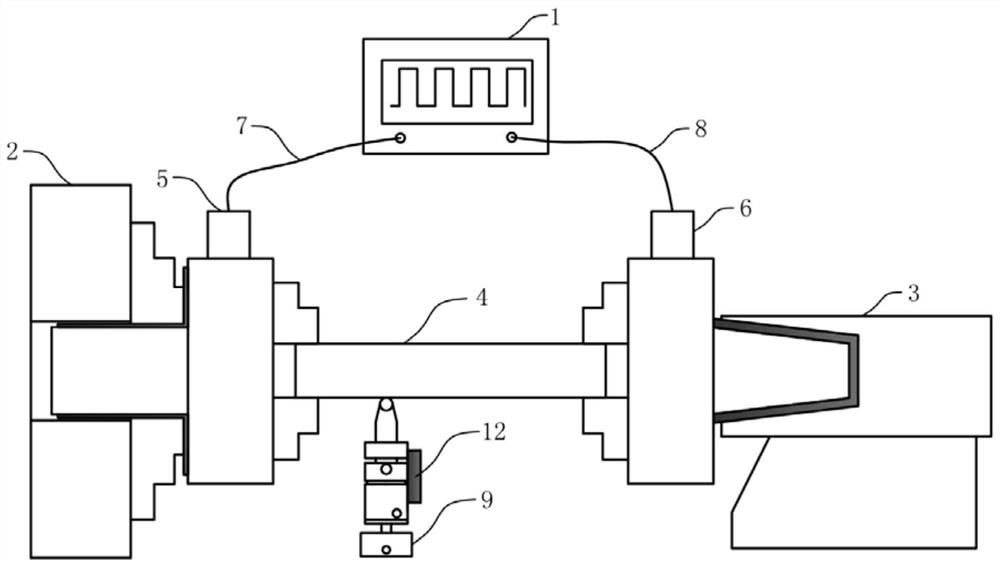

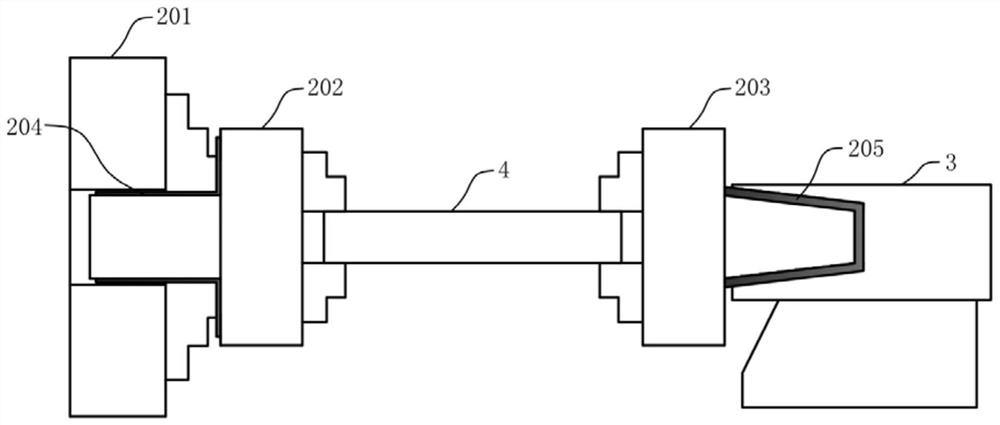

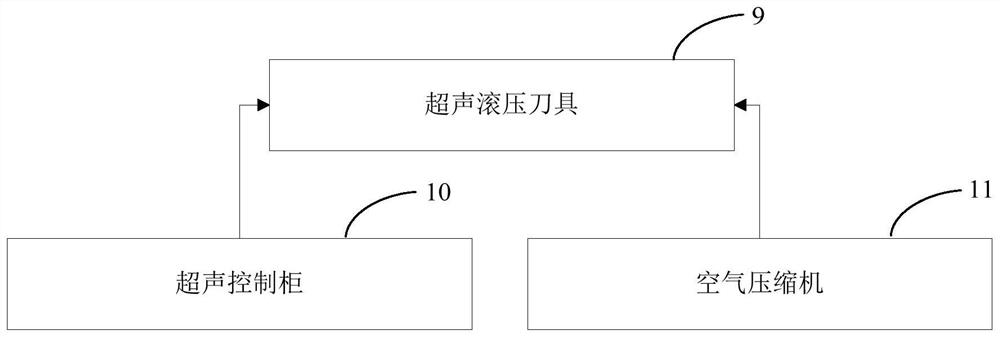

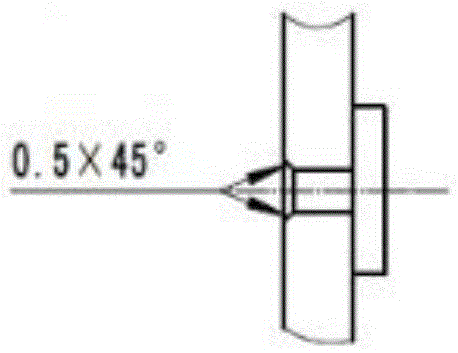

Pulse current assisted ultrasonic rolling surface strengthening device and method

The invention discloses a pulse current assisted ultrasonic rolling surface strengthening device and method. The device comprises a pulse power supply, a conductive part, a clamping mechanism and an ultrasonic rolling module, the clamping mechanism is used for clamping a workpiece, the clamping mechanism is driven by a lathe to rotate, the conductive part is in contact with the clamping mechanism, the pulse power supply is connected with the conductive part and used for applying pulse current to the workpiece, and the ultrasonic rolling module is used for conducting pulse current assisted ultrasonic rolling surface strengthening treatment on the surface of the workpiece. According to the pulse current assisted ultrasonic rolling surface strengthening device and the method, the electroplastic effect, the skin effect and the heat effect of pulse current are compounded with severe plastic deformation caused by ultrasonic rolling, so that the strengthened surface layer is thicker, the surface layer performance is better, the surface strengthening effect of the metal material can be improved, the surface appearance of the metal material is better, and the performance of the metal material is improved.

Owner:SOUTH CHINA UNIV OF TECH

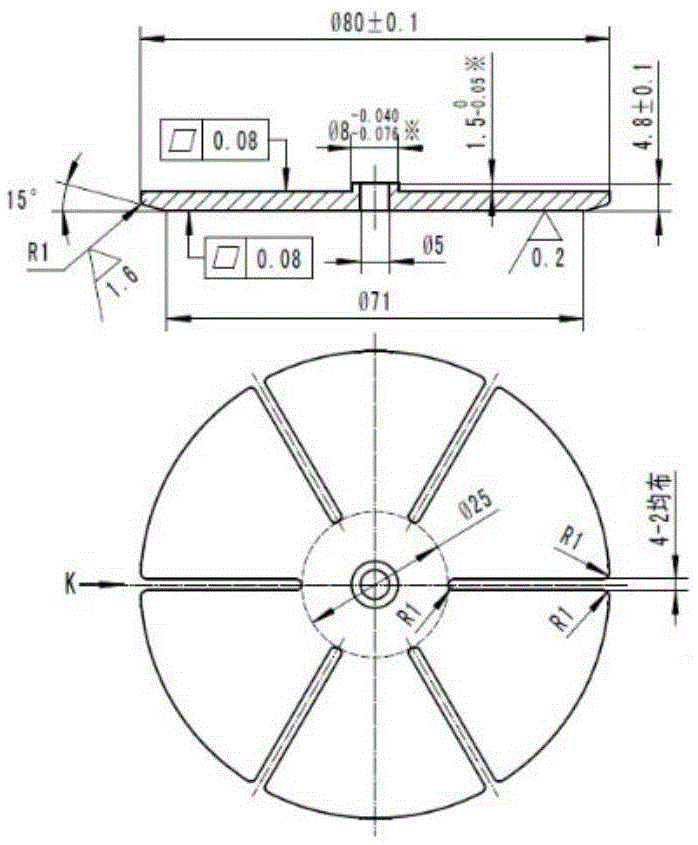

CuCr contact surface finishing equipment and method

The invention relates to CuCr contact surface finishing equipment and method. The equipment is a turning and milling composite machine tool additionally provided with a Hawking tool assembly directly installed on a machine tool row tool support plate of the turning and milling composite machine tool. The method comprises steps including blank preparation, turning I, turning II, Hawking finishing, milling of six grooves, cleaning and drying, turning III, appearance treatment, final inspection and vacuum packaging. Micro impact extrusion deformation is formed on contact surfaces under the combined action of high-frequency vibration impact energy and Hawking energy of Hawking metal machining equipment, so that the surface roughness of a CuCr contact material can be increased to Ra2.0 or below, the mirror effect can be realized, and the requirement of special use occasions of the CuCr contact material for working surface Ra2.0 or below is met.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Mirror face plastic printing ink for OPS (oriented polystyrene) thermoshrinkable film and preparation method thereof

InactiveCN102702859AMeet environmental protection requirementsAchieve mirror effectInksAcrylic resinPolystyrene

The invention relates to a mirror face plastic printing ink for an OPS (oriented polystyrene) thermoshrinkable film, which comprises 55-65 wt% of composite solvent, 10-18 wt% of composite resin, 20-26 wt% of pigment and 2-5 wt% of assistant, wherein the composite solvent is a mixture of ethanol, isopropanol, n-propyl acetate and propylene glycol monomethyl ether; the composite resin comprises a polyvinyl butyral resin as the main resin and an acrylic resin as the auxiliary resin; the pigment adopts ultrafine laminar aluminum silver slurry; and the assistant adopts a mixture of a setting agent and an organosilicon leveling agent. The environmental protection performance of the ink is controlled, and the non-toxic environmental-protection OPS thermoshrinkable film is matched to finally produce the recoverable novel skin packaging material which completely satisfies the requirement for environmental protection and is safe and non-toxic. By using the specific formula and production technique, the printed skin packaging has the mirror face effect, and can be used in high-grade packaging occasions with special requirements.

Owner:STARLIGHT NEW CHEM MATERIALS

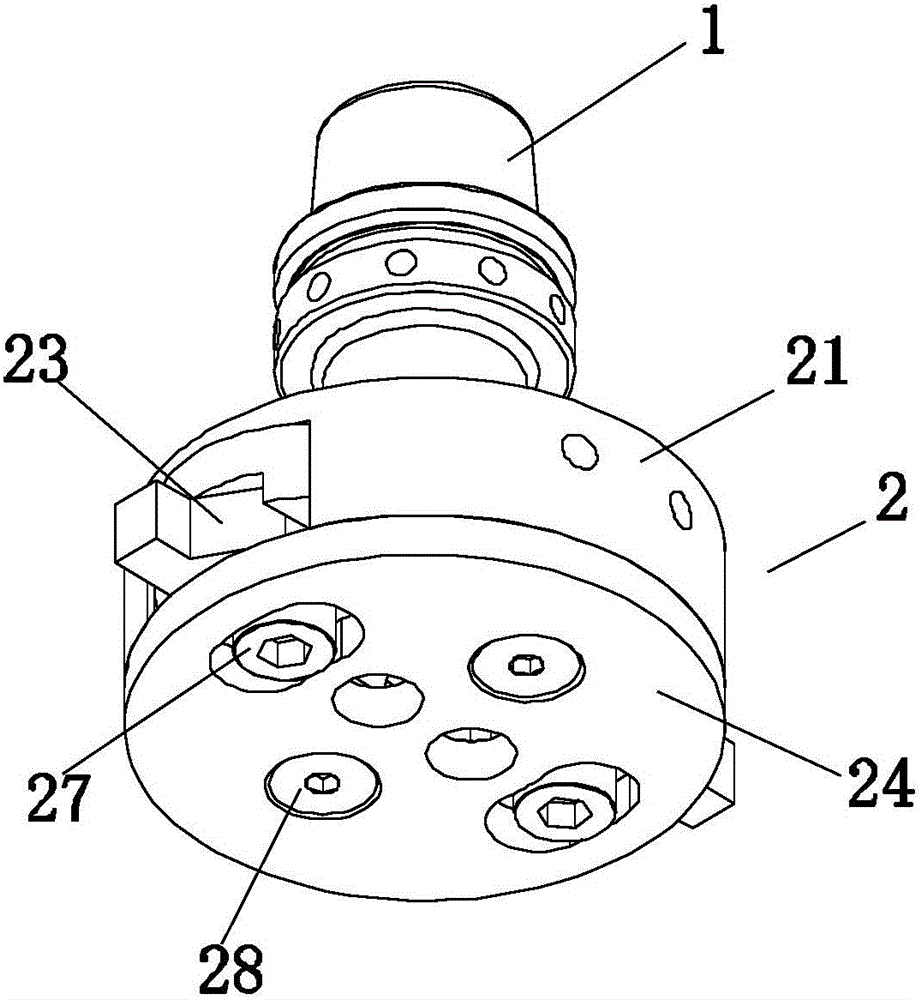

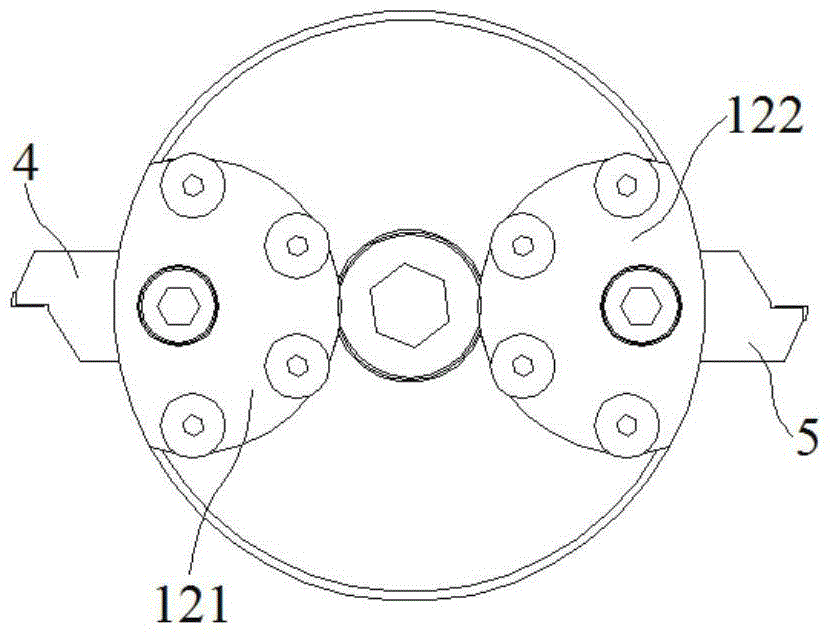

Highlight face milling cutterhead and highlight face milling cutter

ActiveCN105772820AImprove the knife patternGood highlight effectMilling cuttersMilling cutterEngineering

The invention discloses a highlight face milling cutterhead. The highlight face milling cutterhead comprises a face milling cutterhead body, two rotating plates, two milling cutters and a cover plate. Two circular grooves are symmetrically distributed in the end face of the face milling cutterhead body. Each rotating plate is installed in one circular groove and provided with a milling cutter installation groove. Each milling cutter comprises a milling cutter handle and a milling cutter head arranged at one end of the milling cutter handle. The milling cutter handles of the milling cutters are fixedly installed in the milling cutter installation grooves. The milling cutter head of each milling cutter sequentially penetrates a second notch and a first notch and extends outwards, wherein the second notch and the first notch correspond to the milling cutter head. The cover plate is fixedly connected with the end face of the face milling cutterhead body. The invention further discloses a highlight face milling cutter. By means of the highlight face milling cutterhead and the highlight face milling cutter, the highlight effect of products can be improved, the mirror surface effect that Ra is smaller than or equal to 25 nm is achieved, and cutter patterns are eliminated; and an upper chamfer and a lower chamfer can be machined at the same time, the machining efficiency is improved, the balance performance of the whole cutterhead can be effectively ensured, and the subsequent balancing difficulty is lowered.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

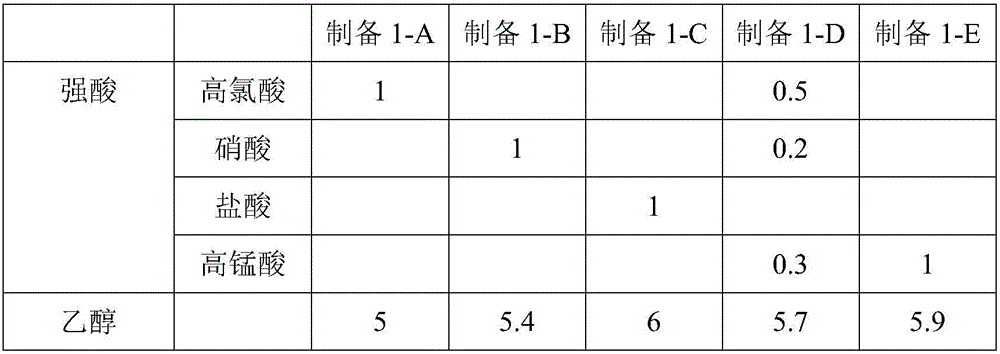

Electrochemical polishing technology for aluminum or stainless steel products

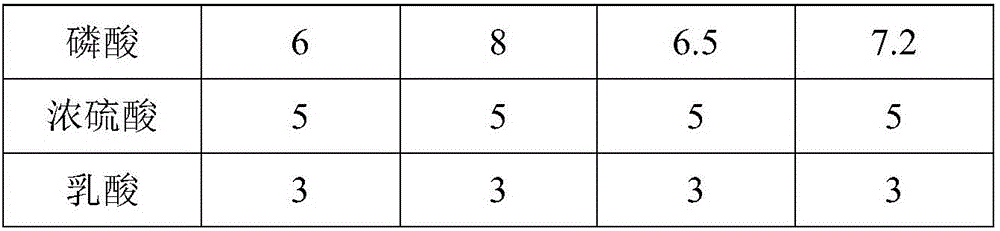

The invention relates to the field of electrochemical polishing and discloses an electrochemical polishing technology for aluminum or stainless steel products.The electrochemical polishing technology for aluminum or stainless steel products comprises the following steps that aluminum or stainless steel products to be polished are put into an organic solvent for ultrasonic cleaning and then blow-dried for use; an aluminum polishing solution is prepared, wherein strong acid is added into ethyl alcohol and mixed evenly, and the volume ratio of strong acid to ethyl alcohol is 1:(5-6); a stainless steel polishing solution is prepared, wherein phosphoric acid, concentrated sulfuric acid and lactic acid are mixed evenly, and the volume ratio of phosphoric acid to concentrated sulfuric acid to lactic acid is (6-8):5:3; the aluminum or stainless steel products serve as anode and cathode boards and are put into the corresponding polishing solutions, a direct current power source is connected, and polishing is carried out; the aluminum or stainless steel products are washed with clean water and blow-dried.The electrochemical polishing technology is easy and convenient to implement, free of potential safety hazards, efficient and environmentally friendly.

Owner:北京鼎臣世纪超导科技有限公司

Nano stone surface treating agent and preparation method thereof

InactiveCN104356827AImprove durabilityGood penetration and adhesionCoatingsMicrocrystalline waxAcrylic resin

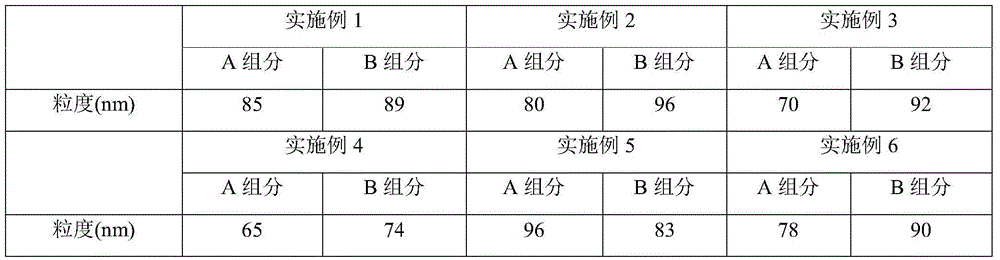

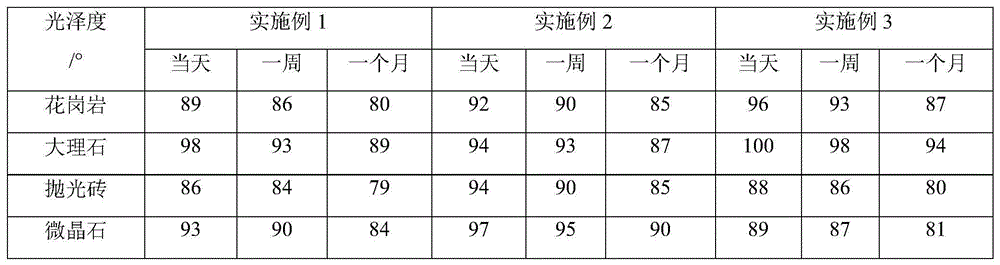

The invention discloses a nano stone surface treating agent which comprises a component A and a component B. The component A comprises the following raw materials in parts by weight: 1-2 parts of 5-10 wt% oxalate solution, 3-5 parts of 5-10 wt% fluosilicate solution, 6-9 parts of 30-50 wt% pure acrylic emulsion and 4-9 parts of water. The component B comprises the following raw materials: 3-5 parts of 15-20 wt% acrylic resin isopropanol solution, 1-2 parts of polyethylene wax or microcrystalline wax and 3-6 parts of solvent. The components A and B in the nano stone surface treating agent are both nano materials, and have favorable permeation and adhesion properties. The component A and component B are sequentially subjected to grinding treatment, so that the blend crystallizing layer formed by the component A and the specular layer formed by the component B form a firm and hard surface, thereby greatly enhancing the glossiness and being beneficial to enhancing the durability of the high glossiness of the stone surface.

Owner:HUAZHONG NORMAL UNIV

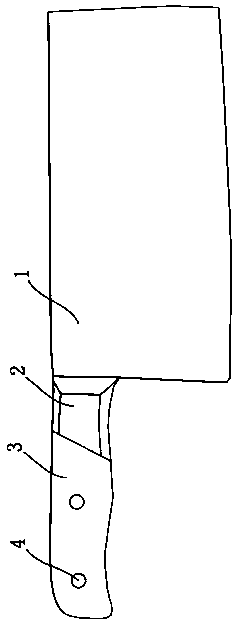

Mirror knife and manufacturing process thereof

InactiveCN109049010AChange performanceStrong anti-rust and anti-corrosion abilityMetal working apparatusMetal-working hand toolsEngineeringLaser cutting

The invention discloses a mirror knife and a manufacturing process thereof. The mirror knife comprises a mirror knife body. A knife handle connecting part is integrally arranged on one side of the mirror knife body and is composed of an inserting groove and an inserting piece. The inserting piece is inserted into a wooden knife handle, and the front end of the wooden knife handle is connected in the inserting groove in an inserted manner. Raw material annealing is adopted by the process to eliminate internal stress in steel, laser cutting forming, vacuum heat treatment and cryogenic treatmentare carried out, hardness reaches 60 HRC or above, and then structure refining, internal stress reducing, knife sharpening forming, edging, surface reinforcement, finished product assembling and otherprocedures are carried out. The high-end technology is adopted for enabling some specific metal objects to permeate into the surface of the knife, a multi-element compact surface film is formed by the metal objects and C, Cr, V and other elements in a base material, the hardness of the compact surface film reaches HV2000 or above, the anti-rust and anti-corrosion capacity is extremely high, and therefore the functions of thorough rust prevention and extreme scratching resistance are achieved, and the mirror effect is achieved; and thus, the usability and ornamental value of the knife are changed, and the effect that the use value and the artistic value of the knife are overlapped is achieved.

Owner:范永

Preparation method for environmental-protection and odorless anti-scratch polyurethane wood matt black top coat

InactiveCN104710928AAnti-scratch hasHigh hardnessPolyurea/polyurethane coatingsPigment pastesKetoneSolvent

The present invention relates to a preparation method for an environmental-protection and odorless anti-scratch polyurethane wood matt black top coat, which comprises double components A and B according to a weight ratio of 1:0.5, wherein the component A comprises a odorless anti-scratch alkyd resin, matting powder, a dispersant, a carbon black color paste, a modified leveling agent, a defoamer, an anti-sedimentation agent and a solvent, and the component B comprises TDI, a HDI trimer or a benzene-free curing agent adopting the adduct as the main component. According to the present invention, the prepared matt black top coat of the present invention does not contain aromatic hydrocarbons, aldehydes, ketones and heavy metals, and the odorless effects is achieved after the paint film is dried for 48 h; the matt black top coat has characteristics of no precipitate during storage, high solid while low viscosity, good leveling property, thick film formed in one time, no sagging, soft handfeeling, plump, delicate, solemn, rigid, soft, and full mirror-like decorative effect, and elegant and comfortable feeling, is adapted to the modern aesthetics, is popular in markets and customers, and is widely applied on the surface of wood ware, metal, plastics and other products so as to provide the protection decoration effect.

Owner:UNION FOSHAN CHEM +1

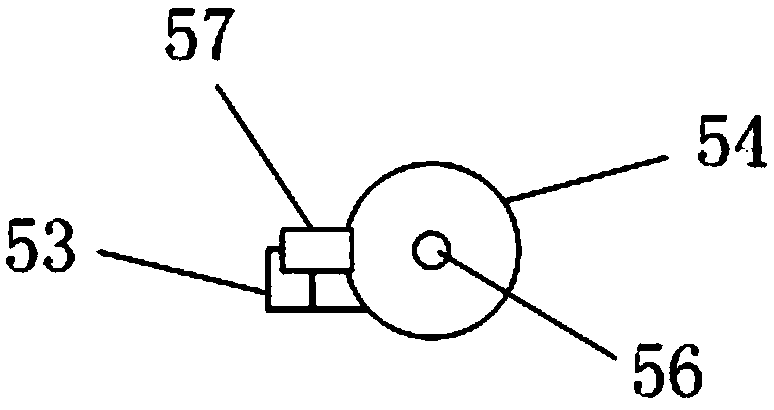

Mirror finishing technology for shell of beard clipper

ActiveCN105773433AShorten the timeReduce metal lossAbrasion apparatusLapping machinesMicrometerRazor Blade

The invention relates to the technical field of polishing, in particular to a mirror finishing technology for a shell of a beard clipper. The mirror finishing technology comprises following steps of (1) cleaning, wherein a metal layer to be machined is soaked into an alkaline solution to be subject to ultrasonic cleaning for 10 min to 30 min, and then is cleaned through clean water; (2), water sandblasting polishing, wherein quartz sand polishing liquid is used for carrying out water sandblasting polishing treatment on the metal layer to be machined, and then cleanwater is used for cleaning the metal layer, the quartz sand polishing liquid comprises quartz sand, and the granularity of the quartz sand ranges from 1000 meshes to 5000 meshes; and (3), grinding and finishing polish, wherein finishing polish liquid is used for carrying out polishing pad grinding and finishing polish on the metal layer to be machined, and the finishing polish liquid comprises abrasive ingredients. The mirror finishing technology is short in time, small in metal loss and low in error rate; and time of the whole working procedure is controlled within one hour, through secondary physical polishing, the metal layer to be machined reaches the mirror finishing effect, and the roughness is below 0.8 micrometer.

Owner:GUANGDONG ROMAN TECH CO LTD

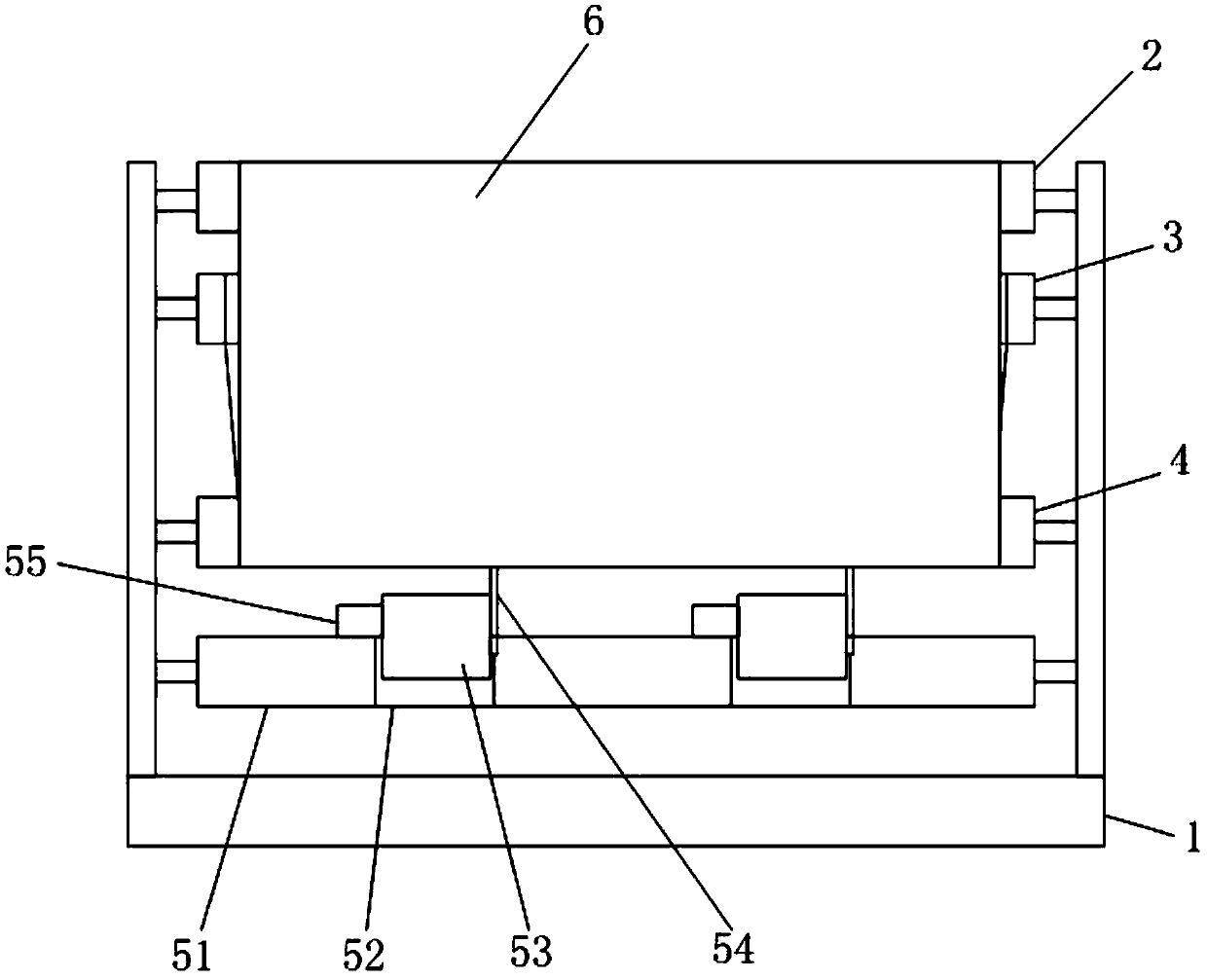

Preparation method of 3D ceramic backboard

ActiveCN106994732AImprove finished product qualitySolve the sweeping problemPolishing machinesCeramic shaping plants3d shapesPolymer science

The invention relates to a preparation method of a 3D ceramic backboard. The preparation method includes the following steps that ceramic powder is contained into a rubber die, the rubber die is sleeved with a plastic sleeve, and vacuumizing and preheating are carried out; the rubber die is placed into an isostatic pressing cylinder device to be pressed, and the rubber die is taken out after isostatic pressing is carried out; edge burrs are removed, and rubber discharging sintering is carried out; and a sweeping and polishing device is started to conduct polishing, and the 3D ceramic backboard is obtained. By means of the preparation method of the 3D ceramic backboard, a blank in a 3D shape can be directly molded, the powder using rate is improved by about 50%, meanwhile, the molding process is simple, and operation is easy; and the sweeping and polishing device is arranged, the one-face polishing function is used, a pure pig hair brush, a grinding rubber strip brush and the like are loaded on an upper die to be matched with drilling gypsum and polishing liquid to conduct the coarse sweeping process, the refined sweeping process and the like on the inwards-concave face and the peripheral side faces of the 3D ceramic backboard, the process route is simple and rapid, the effect is better, and the mirror surface effect is achieved.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

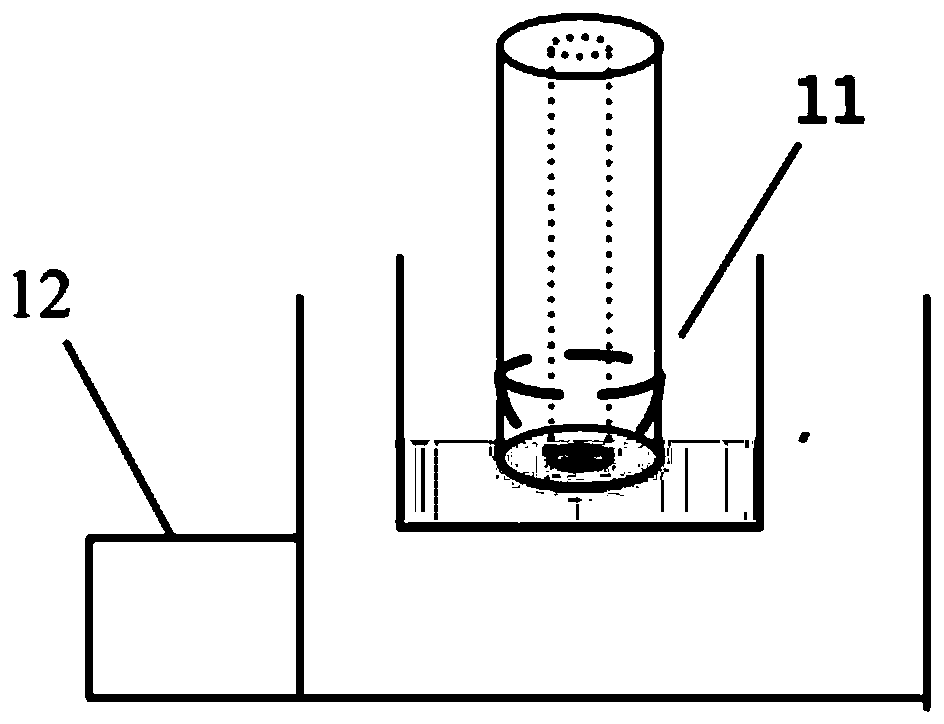

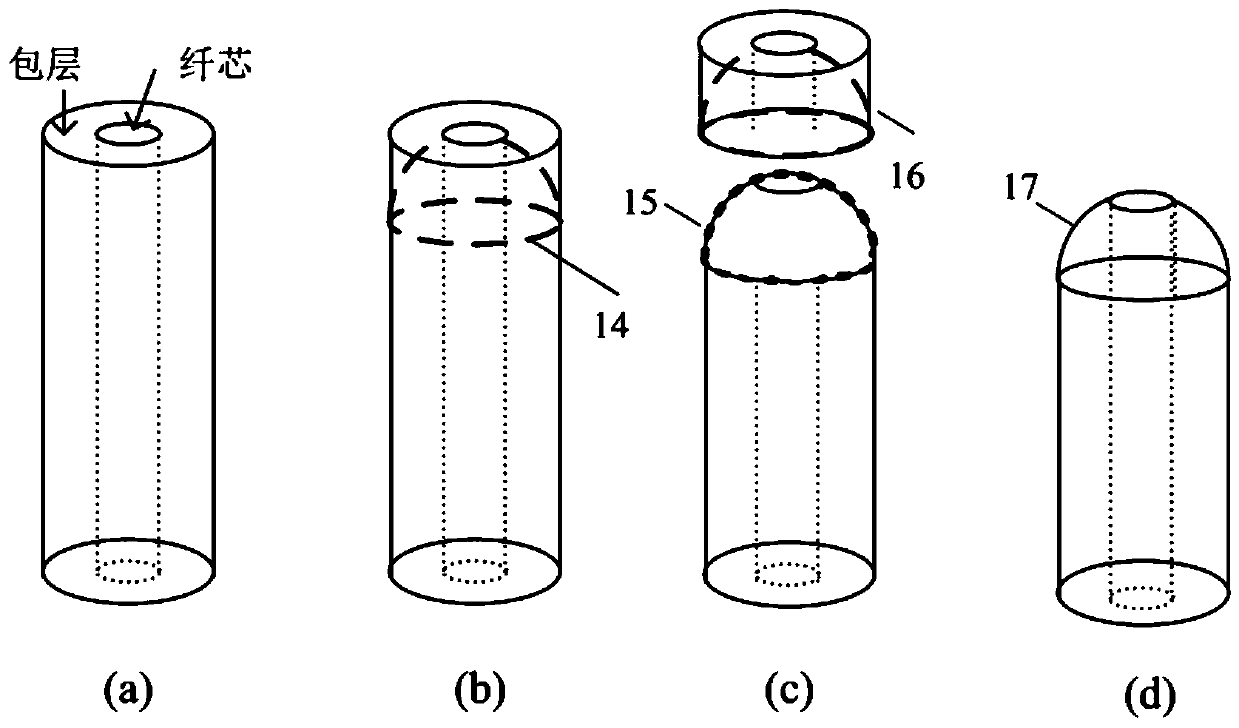

Femtosecond laser processing method of optical fiber lens

InactiveCN110405354AImprove machining accuracyGood symmetryCladded optical fibreOptical waveguide light guideThermal ablationCorrosion

The invention discloses a femtosecond laser processing method of an optical fiber lens. The femtosecond laser processing method comprises the following steps that a focused femtosecond laser is utilized for conducting scanning on an optical fiber according to the profile of a to-be-prepared lens, and a laser focus point irradiation area is subjected to material modification or etching removal; theend face of the treated optical fiber is partially soaked in a hydrofluoric acid solution, and through selective corrosion removal of materials in the modification area, the optical fiber outside theprofile of the lens is separated to form an optical fiber lens prototype; the corrosion time is controlled, so that the surface of the obtained optical fiber lens prototype tends to be smooth, and then the optical fiber lens is formed. According to the processing method, the processing working procedures are simple, the shape of the optical fiber lens is flexible, no heating effect exists duringprocessing, convex-face optical fiber lenses and concave-face optical fiber lenses in various shapes can be prepared on the end face of the optical fiber, the problems of stress damage and thermal ablation deformation occurring to existing preparing methods are solved, and the femtosecond laser processing method an be applied to optical fiber sensing, optical fiber laser devices and other fields requiring optical fiber coupling.

Owner:XI AN JIAOTONG UNIV +1

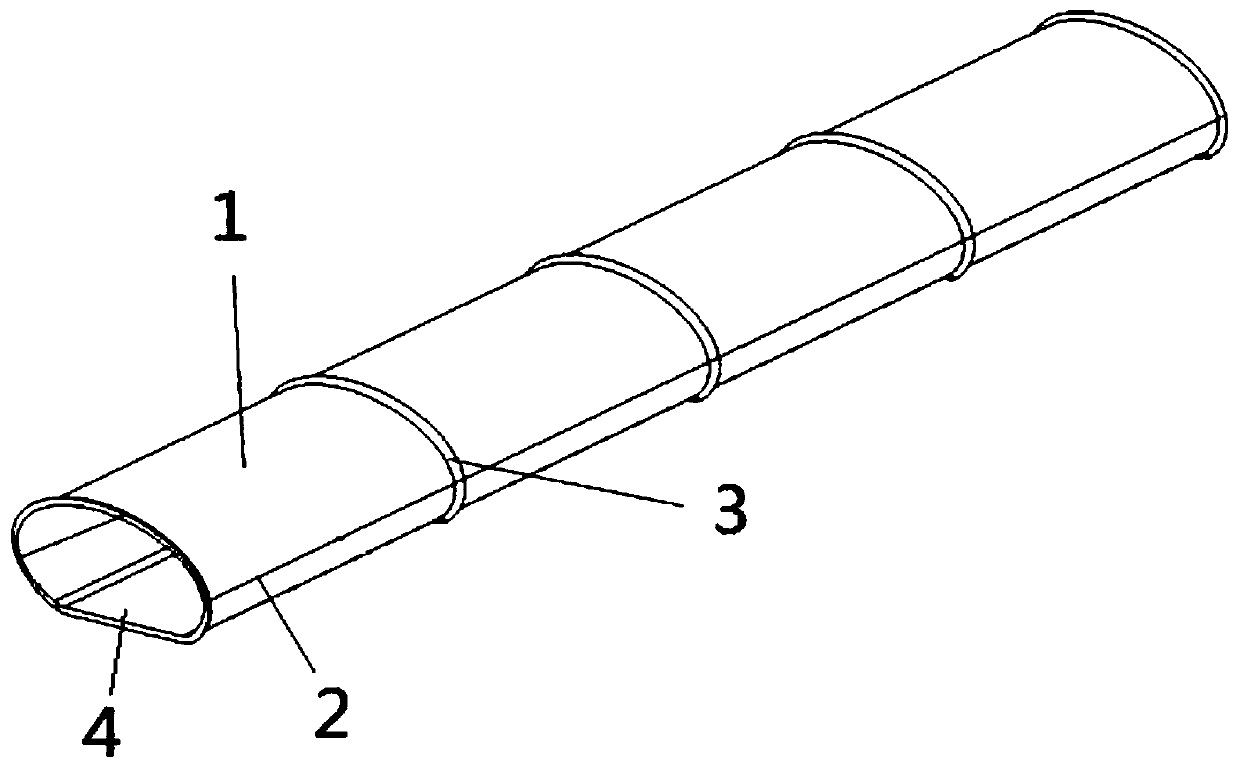

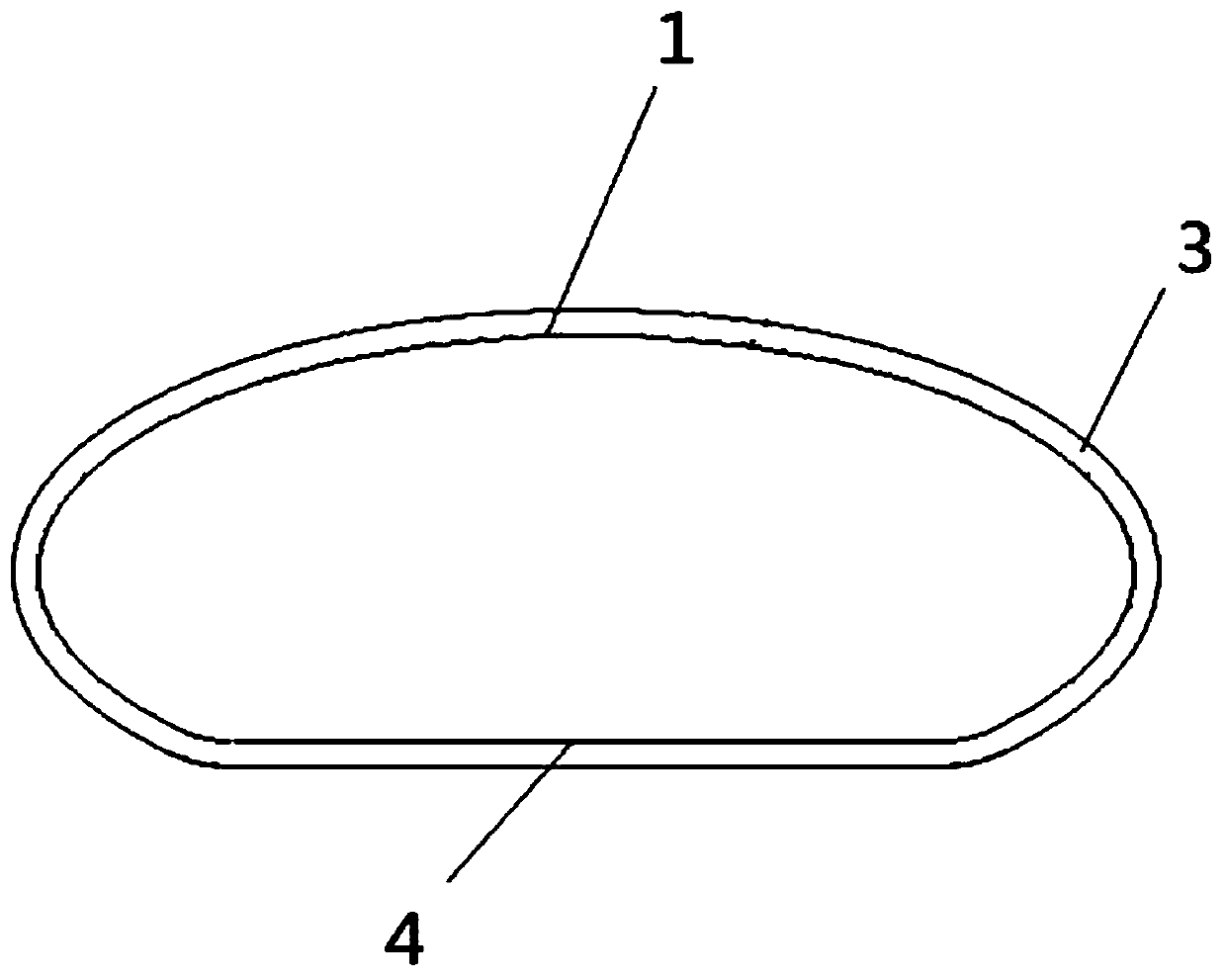

Cooling section flat tube for platinum channel in substrate glass production process and preparation method of cooling section flat tube

The invention discloses a cooling section flat tube for a platinum channel in a substrate glass production process and a preparation method of the cooling section flat tube. The cooling section flat tube comprises N sections of flat tube assemblies; every two adjacent flat tube assemblies are connected through flanging welding, and flangings are used for forming reinforcing ribs; each flat tube assembly comprises a flat tube top plate and a flat tube bottom plate, wherein each flat tube top plate is in an arch shape, and each flat tube bottom plate is a flat plate; two side edges of each flattube bottom plate are bent upwards for being welded to the corresponding flat tube top plate; and each flat tube top plate and the corresponding flat tube bottom plate are connected through butt welding, wherein N is an integer larger than or equal to 3, and the cooling section flat tube is made of platinum-rhodium alloy. Collapse and deformation of the tops of the flat tube can be prevented in production and use processes.

Owner:IRICO DISPLAY DEVICES

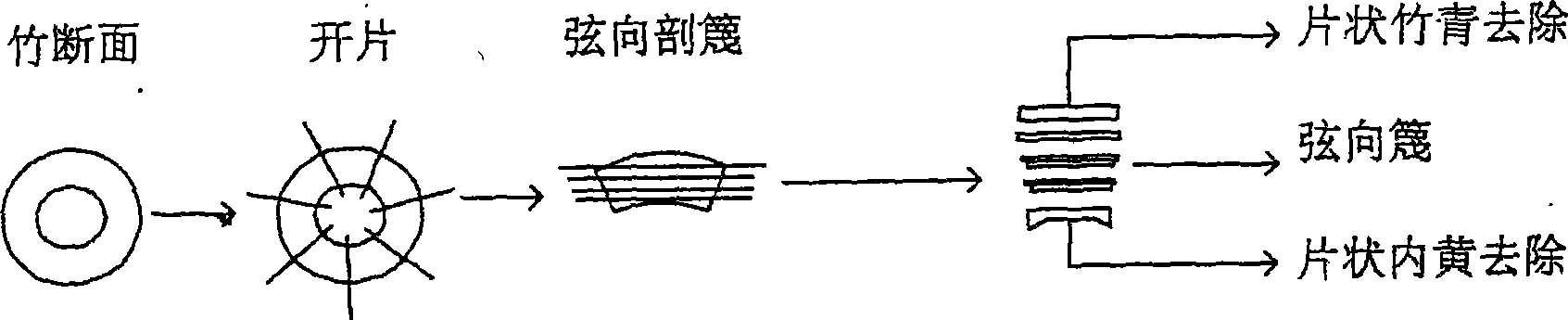

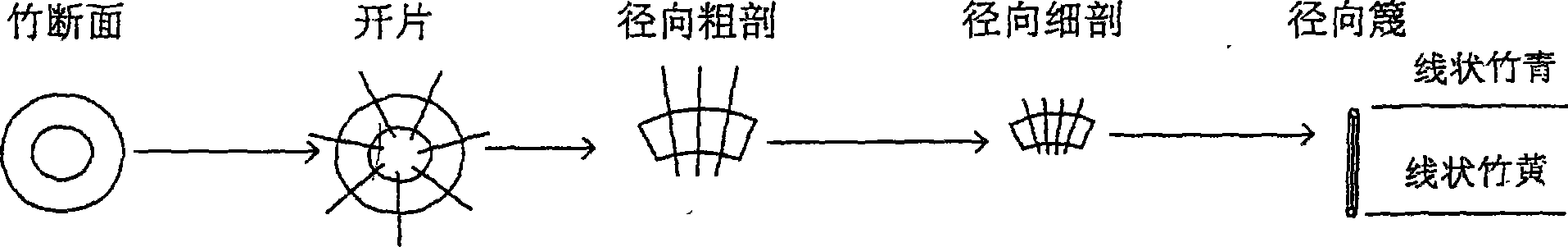

Radial bamboo-wood composite mirror surface formwork and its production method

InactiveCN101545317AGood value for moneyIncrease profitForming/stuttering elementsInter layerEngineering

The present invention discloses a radial bamboo-wood laminated mirror surface formwork and a production method of the formwork. The radial bamboo-wood laminated mirror surface formwork is produced by bamboo-wood lamination and hot pressing, with thin bamboo strips laid in radial direction as intermediate layers. The producing procedures include: dip glue film paper, apply glue on wood boards, prepare glued radial thin bamboo strips, lay wood board and thin bamboo strips, and then hot press. The wood-bamboo laminated board has higher strength than bamboo laminated boards, and the surface is more smooth than the surface of plywood boards; the utilization rate of bamboo is increased from 55% to 90%, and the cost is reduced by 40% or more; the novel formwork produced with radial thin bamboo strips has higher cost-performance ratio than conventional bamboo laminated boards.

Owner:周开梅 +1

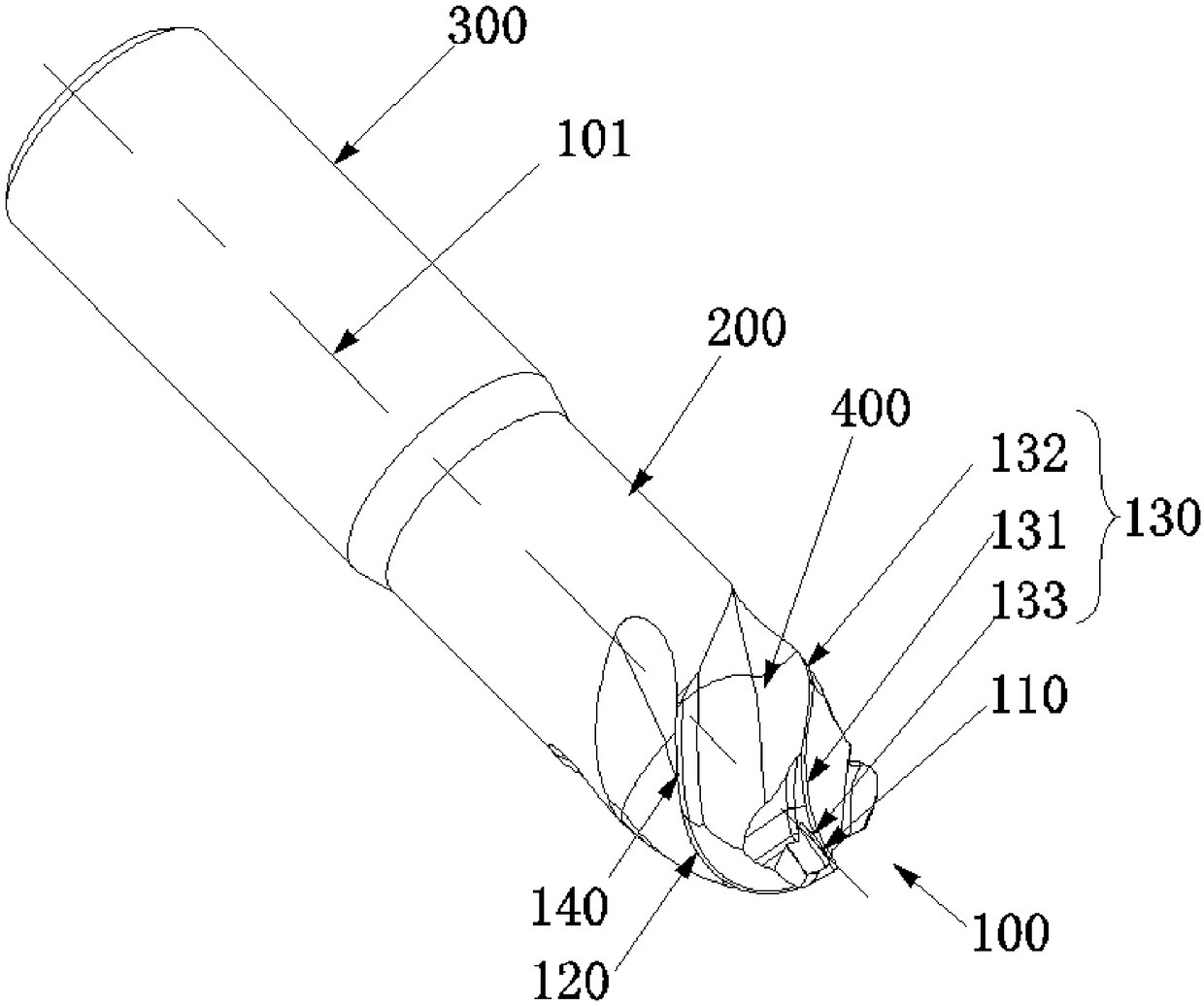

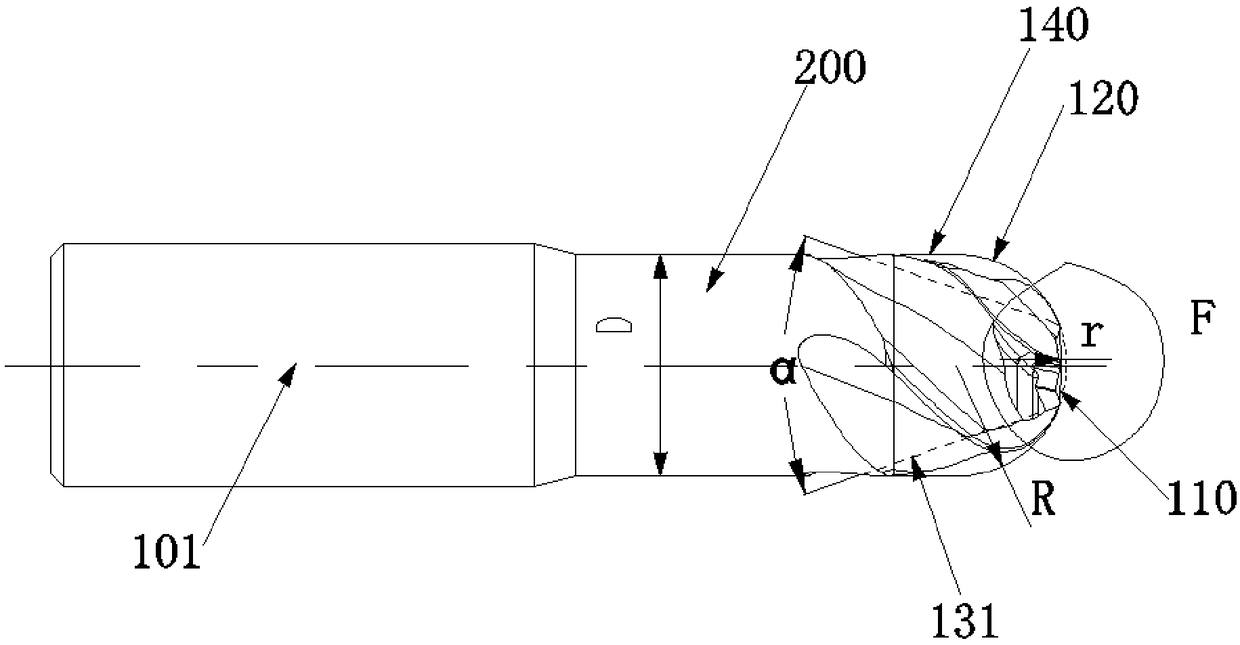

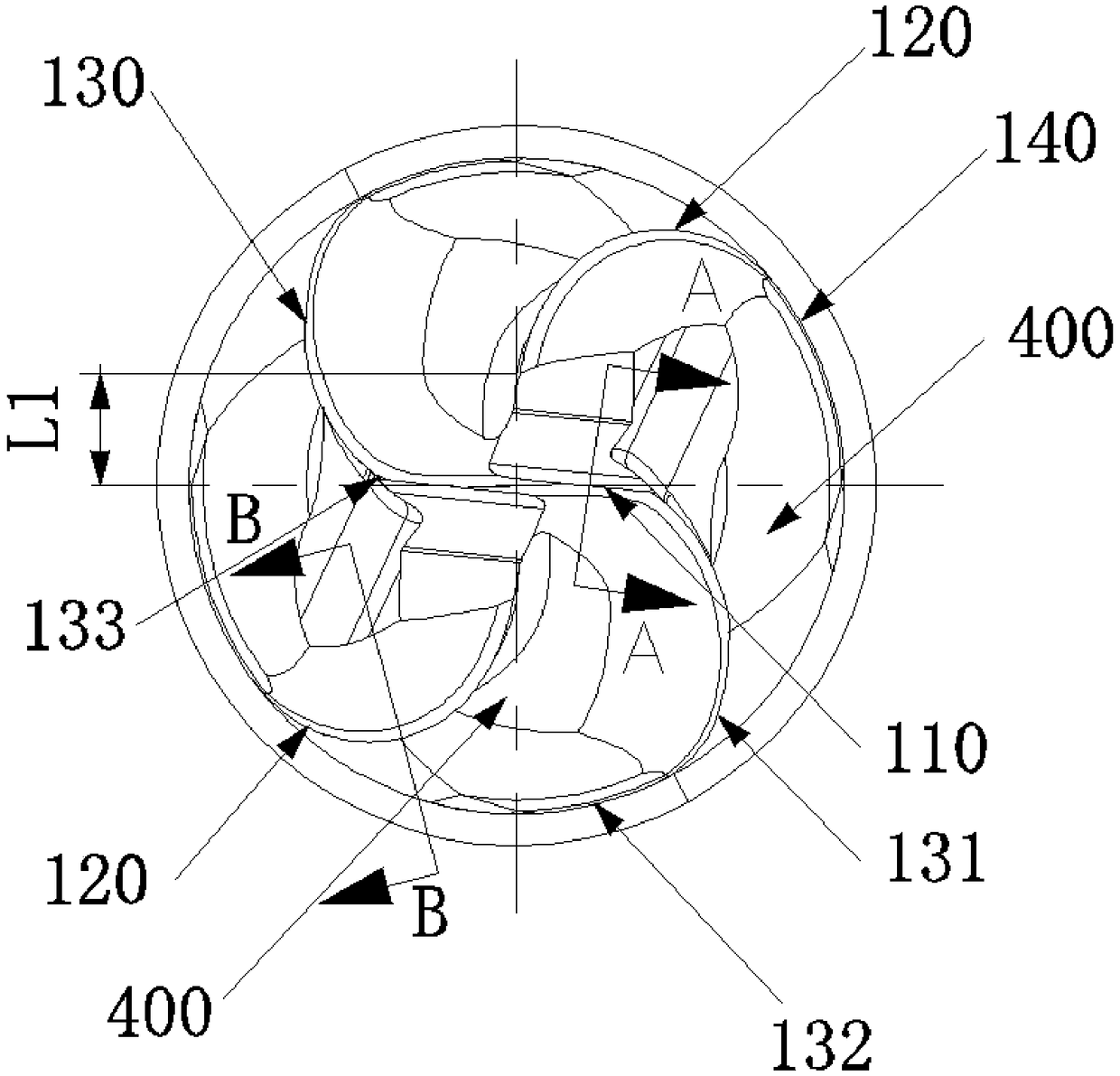

Multifunctional ball endmill

ActiveCN109262038ALow radial loadImprove cutting efficiencyMilling cuttersMilling cutting insertsEngineeringMilling cutter

The invention discloses a multifunctional ball endmill which includes a cutting portion, an assembly and disassembly portion and a connecting portion for the cutting portion, the assembly and disassembly portion. The cutting portion includes an inner ball cutting edge and at least one pair of outer ball cutting edges. The inner ball cutting edge and a central shaft are cross and are rotatably symmetric with respect to the central shaft, two outer ball cutting edges in each pair of outer ball cutting edges are rotatably symmetric with respect to the central shaft, a radial spacing is reserved between the outer ball cutting edges and the central shaft, a spherical surface formed by the inner ball cutting edge rotating with respect to the central shaft and a spherical surface formed by the outer ball cutting edge rotating with respect to the central shaft are cross, the spherical surface radius of the inner ball cutting edge is r, and the spherical surface radius of the outer ball cuttingedge is R, meeting: 5R<=r<=15R. The spherical surface radius of the inner ball cutting edge is far greater than that of the outer ball cutting edge, and when performing cavity large feeding cutting or flat surface copy milling, the endmill has a low radial load and high cutting efficiency.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

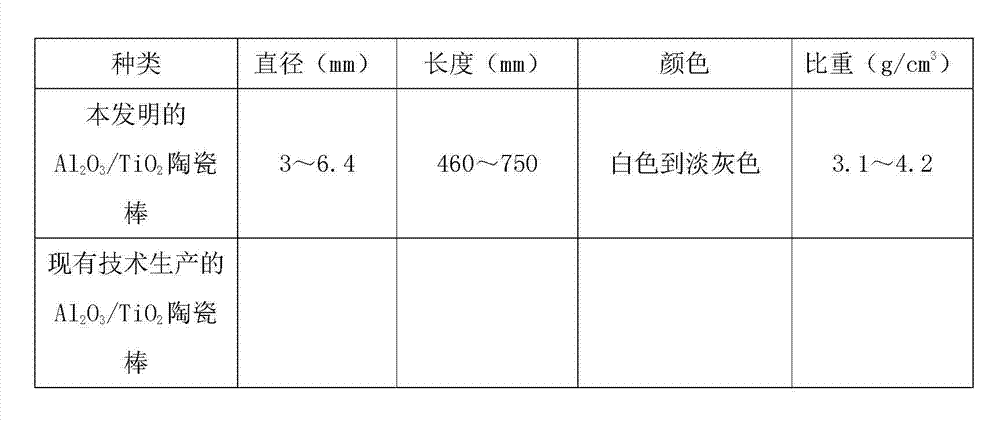

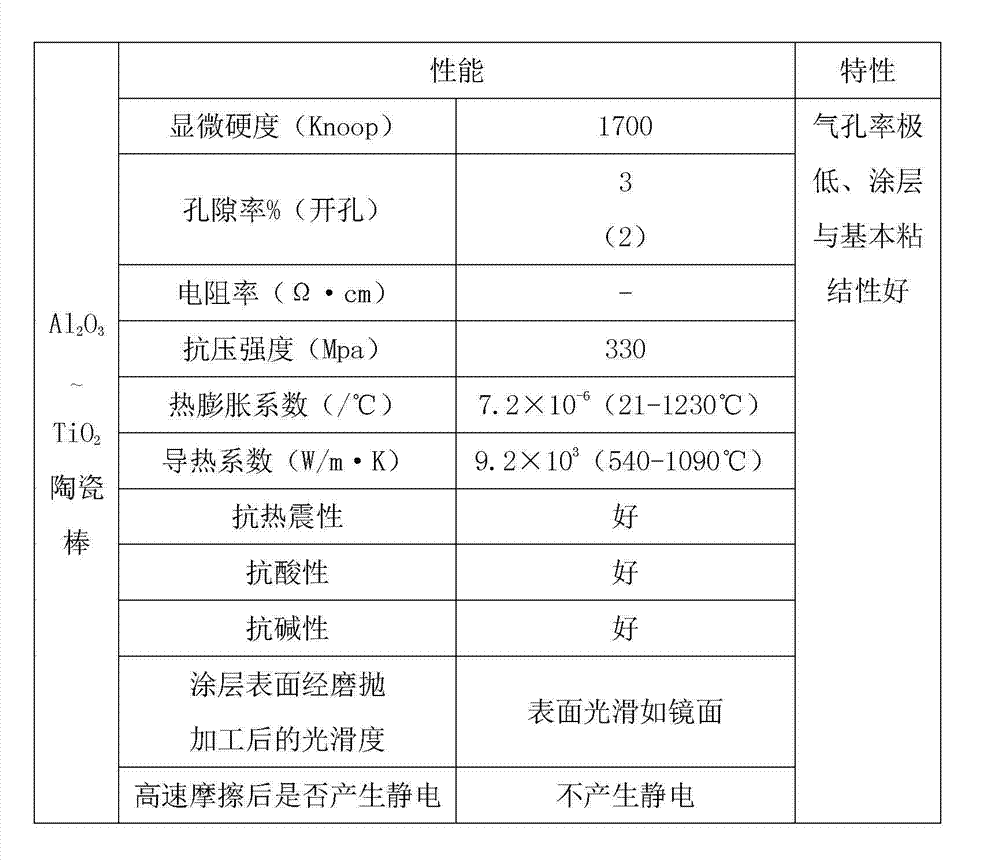

Preparation method of Al2O3/TiO3 ceramic stick for flame spraying

The invention discloses a preparation method of an Al2O3 / TiO3 ceramic stick for flame spraying. The preparation method comprises the following steps of: weighing ceramic raw materials, and batching; processing via ball milling; then blending in a dry way, so as to obtain mixed powder; adding modification styrene-acrylic emulsion and the like in the powder; mixing the materials; preparing and pugging; transferring the plastic clay block into a vacuum extruder to be extruded and formed; heating to degum through a horizontal burning way; and finally roasting at a certain temperature, thus obtaining the Al2O3 / TiO3 ceramic stick. The preparation method disclosed by the invention is simple in technology, high in product percent of pass, and greatly reduces producing coat. The prepared ceramic stick has a better coating performance; and the coated ceramic coating has a better mechanical property, and synchronously has a better heat insulation property, an insulating property, a corrosion resistance property, an antistatic property and high smoothness of a spray coating layer, and no static generated in friction at high speed, and the like, and has a good application prospect in cotton spinning and chemical fiber industries.

Owner:HEFEI RUIYONG CERAMIC MATERIAL TECH

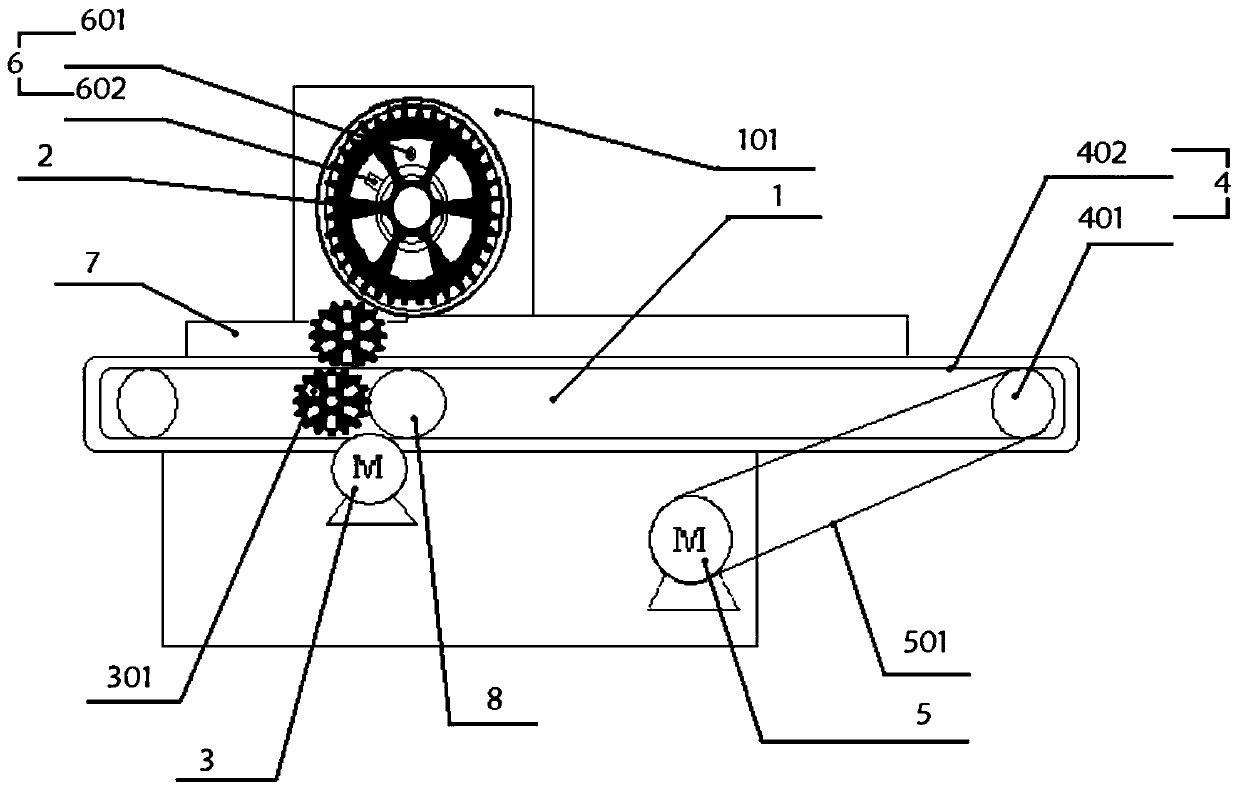

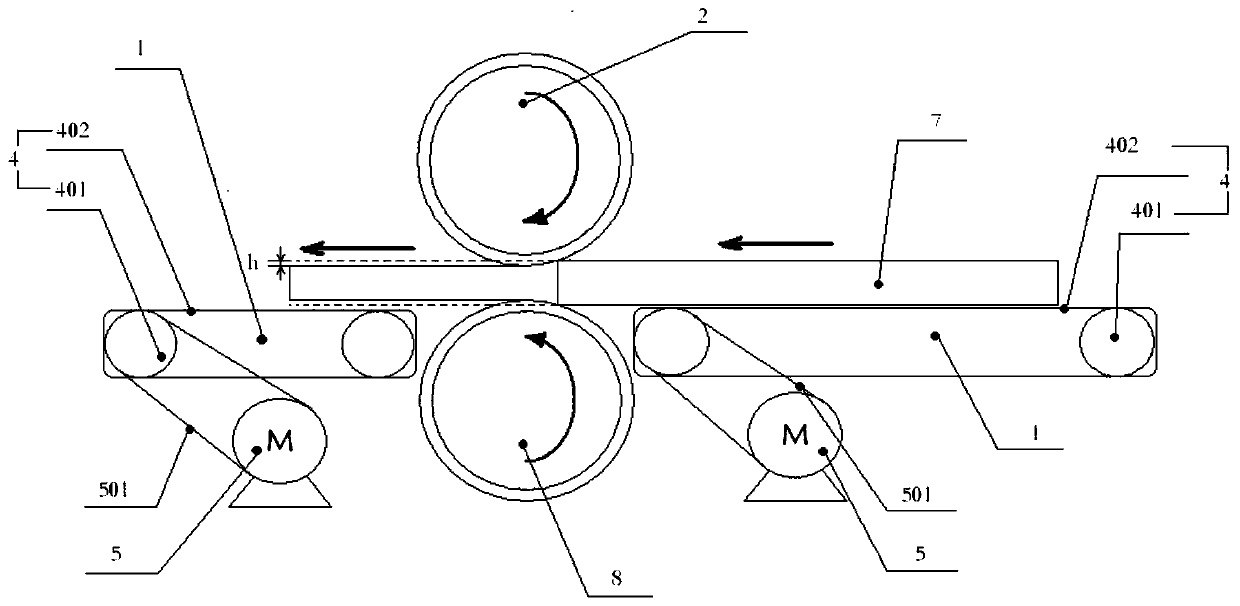

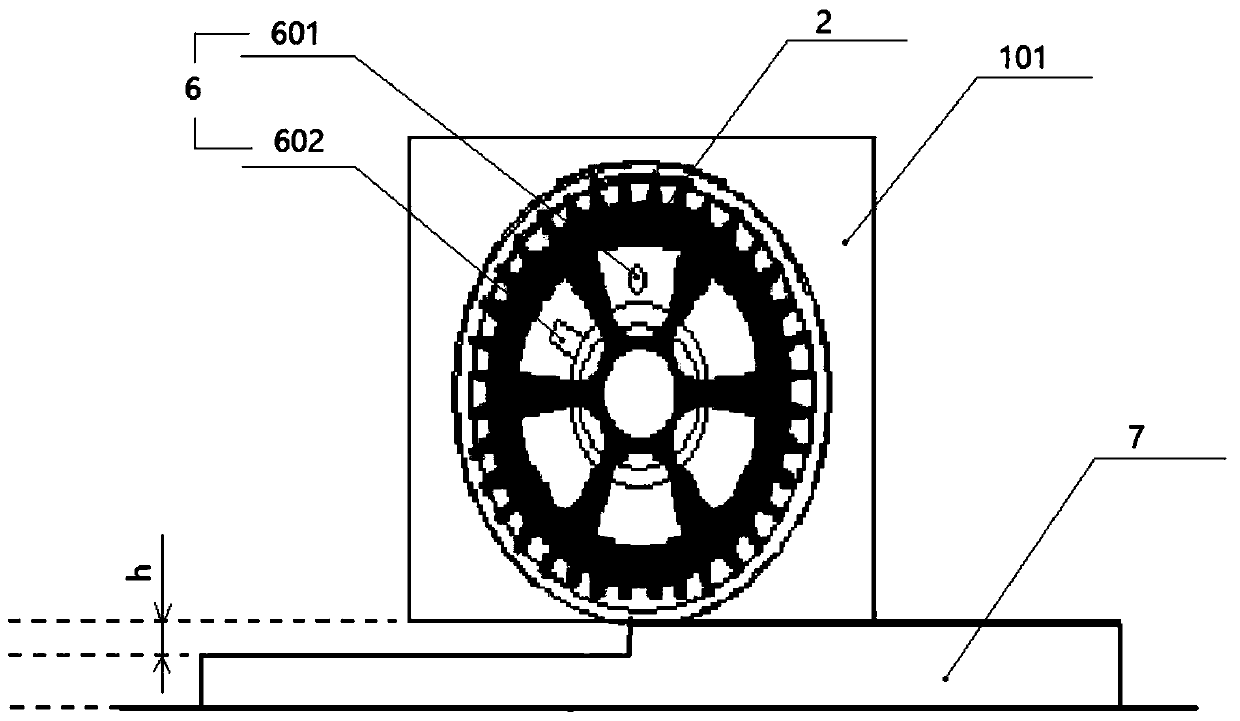

Wood surface treatment device and method

PendingCN110497497AEasy to rollEasy to paintWood compressionWood charring/burningTemperature controlMotor drive

The invention discloses a wood surface treatment device and method and belongs to the field of wood surface treatment. The device comprises a horizontal support, a metal compression roller, a first motor, a transfer assembly, a second motor and a heating assembly, wherein an adjustable-height cabinet is arranged in the position, close to the end, of the horizontal support in the length direction;the two ends of the metal compression roller are horizontally and rotationally connected with the side wall of the cabinet in the length direction through bearings, and the hardness of the surface ofthe metal compression roller is 40 greater than the Rockwell hardness; the first motor drives the metal compression roller to rotate horizontally; the transfer assembly comprises a plurality of transfer rollers arranged on the horizontal support in the length direction, a conveying belt winding across the multiple transfer rollers, and a positioning roller arranged under the metal compression roller; the second motor is used for driving the transfer rollers to rotate horizontally; and the heating assembly comprises a temperature sensor and a temperature controller which are in series connection in sequence, the temperature sensor is arranged on the metal compression roller, one end of the heating assembly is connected with a power supply through a heating electric wire, and the other end of the heating assembly is connected with the metal compression roller through a heating electric wire. According to the wood surface treatment device, a mirror light effect can be achieved on a wood surface, and the device is fast, efficient and convenient to use.

Owner:简木(广东)定制家居有限公司

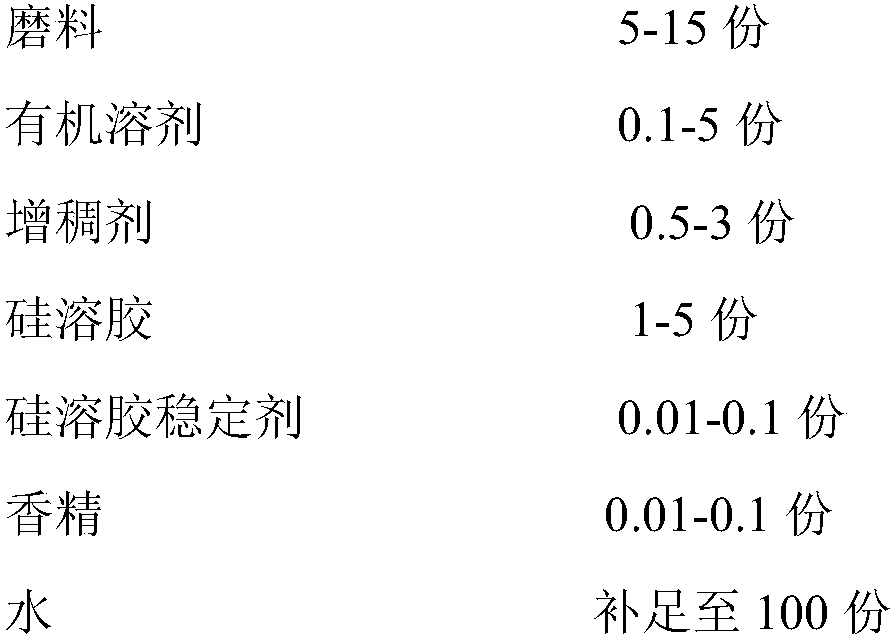

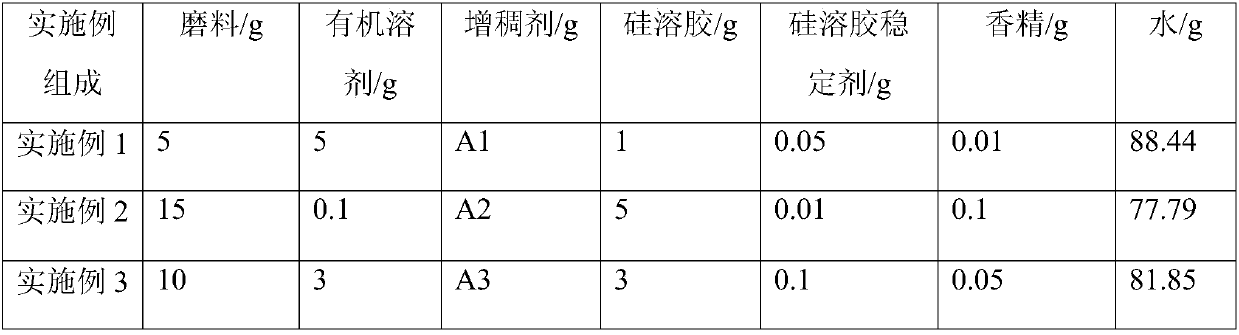

Brass polish cream having stable viscosity

The invention relates to the technical field of metal surface cleaning, and concretely relates to a brass polish cream having a stable viscosity. The brass polish cream comprises an abrasive, an organic solvent, a thickener, silica sol, a silica sol stabilizer, an essence and water. The brass polish cream having a stable viscosity is prepared through a special preparation process, and can be usedto clean surfaces of hotels, guesthouses and other large brass ornaments to achieve the mirror effect.

Owner:合肥普庆新材料科技有限公司

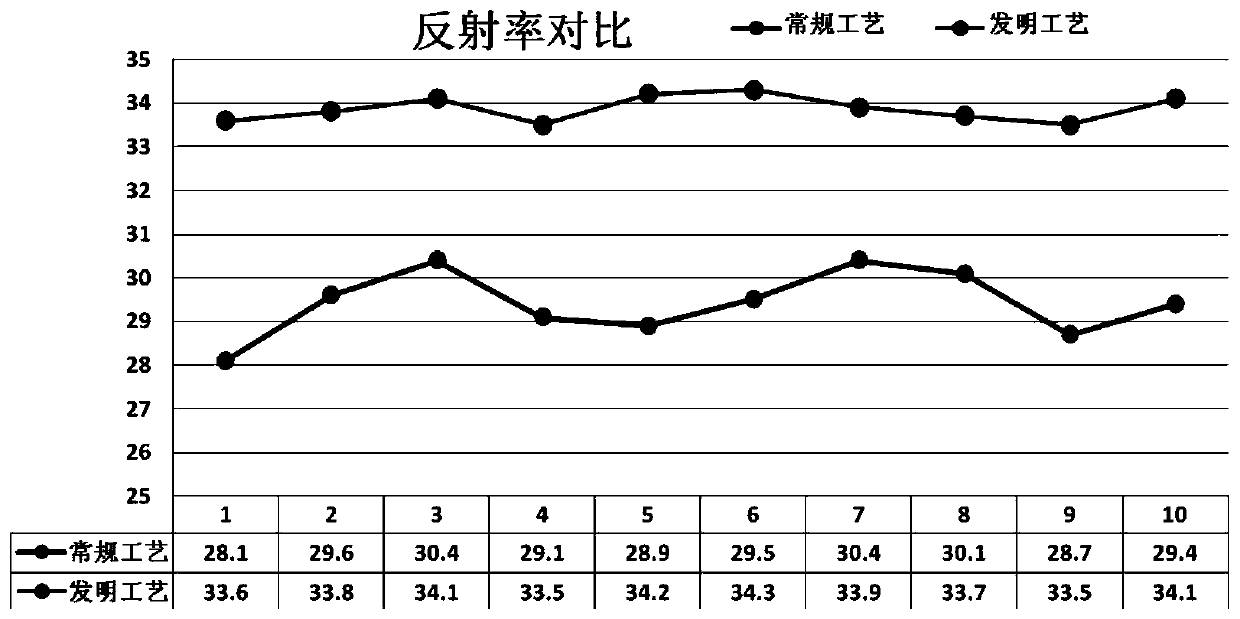

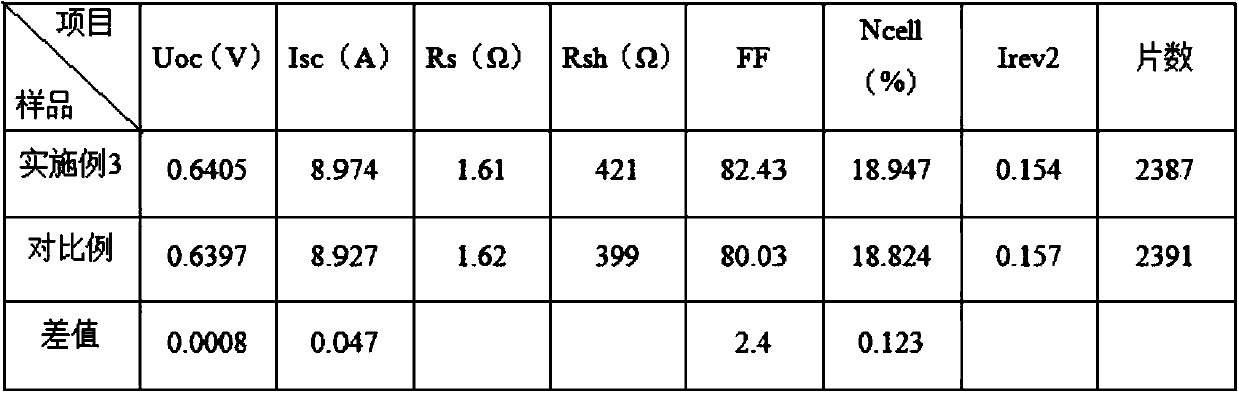

Back polishing process of solar cell sheet

ActiveCN109830564AImprove protectionNot corrodedFinal product manufacturePhotovoltaic energy generationScreen printingElectron hole

The invention discloses a back polishing process of a solar cell sheet. The back polishing process comprises the following steps of: preprocessing an unpolished silicon wafer; polishing the back sideof the silicon wafer; performing screen printing and drying. A silicon nitride film is grown by PECVD in the back polishing process to achieve good protection for a non-polished surface. The silicon wafer is successively polished by an alkali solution and an acid solution, which greatly improves the polishing quality of the silicon wafer. Thus, a good immersion polishing effect is achieved and theprobability of damaging the silicon wafer is reduced. An etching solution can corrode the textured surface on the back side of the cell and form a flat mirror structure to achieve a uniform polishingeffect and improve the reflectance and absorption rate of the silicon wafer. The silicon wafer of the back-polished silicon cell has a flat and bright back surface. The photons incident into the backsurface of the silicon wafer can be reflected only in one direction, thereby increasing the energy of the reflected light, exciting more electron-hole pairs, increasing the current of the cell sheet,and improve the efficiency of the cell sheet.

Owner:中建材浚鑫(桐城)科技有限公司

Manufacture method of mirror anode suitable for dyeing

InactiveCN107761149AAchieve mirror effectDon't worry about uneven color fadingAnodisationColor toneAnodic oxidation

The invention provides a manufacture method of a mirror anode suitable for dyeing. The method is characterized in that a product manufactured through the method can realize a mirror effect on the surface of an aluminum material, and is high in compatibility for dyeing and dye, suitable for dyeing of different color tones from light color to deep color, and compatible with most of anodic oxidationdyeing materials on the market, and properly gives consideration to the anti-corrosion property and decoration property of anodic oxidation. The method comprises the following steps: preliminary grinding mirror treatment of aluminum material anodes, pretreatment of anodes, aluminum anodic oxidation, hole micro sealing, post precise grinding of anode, activation of oxidation film, dyeing of oxidation film, and post hole seating treatment of anodes. The manufacture method has the innovation points that mirror grinding treatment is firstly performed on the surface of an oxidation film after anodic oxidation, so that the mirror effect is achieved, then activation and dyeing are performed, the manufacture method is different from the conventional method in which dyeing is firstly performed andthen grinding is performed, the phenomenon of uneven polishing and fading is not required to be worried, most of colors can be achieved according to actual requirements, and the mirror anode has all other advantages of an anode.

Owner:CHANGHONG PRECISION TOOL DONGGUAN CO LTD

Nano water-based environment-friendly material

InactiveCN104559349ASuitable for spraying mirror surface processing operationsAchieve mirror effectCoatingsWater basedSulfate

The invention discloses a nano water-based environment-friendly material, which is prepared from the following raw materials in percentage by weight: 40%-50% of basic material A, 30%-40% of a basic material B and 20%-30% of an additive, wherein the basic material A is prepared from the following raw materials in percentage by weight: 15%-30% of ammonium hydroxide, 20%-35% of dichloromethane and 40%-60% of water; the basic material B is prepared from the following raw materials in percentage by weight: 20%-35% of hydrazine sulfate, 10%-25% of dichloromethane and 50%-60% of water; the additive is prepared from an additive A, B or C; the additive A is prepared from the following raw materials in percentage by weight: 20%-40% of silver nitrate, 10%-15% of silver sulfate and 50%-70% of water; the additive B is prepared from the following raw materials in percentage by weight: 30%-40% of stannous chloride, 20%-30% of hydrochloric acid and 40%-50% of water; and the additive C is prepared from the following raw materials in percentage by weight: 30%-50% of sodium lauryl sulfate and 50%-70% of anhydrous sodium sulfate. The nano water-based environment-friendly material can be effectively suitable for processing work of spraying mirror surfaces.

Owner:东莞市博友纳米材料有限公司

Aluminum profile surface multi-section polishing system and polishing process

InactiveCN114102372AAchieve mirror effectImprove polishing efficiencyGrinding drivesBelt grinding machinesPolishingEngineering

The aluminum profile surface multi-section polishing system comprises a main box body and is characterized in that a polishing mechanism is arranged in the main box body, a lifting mechanism is arranged on the upper side of the polishing mechanism, and a conveying mechanism is arranged on the lower side of the polishing mechanism; by rotating four sections of abrasive belts with different granularities, the small-granularity abrasive belt can be automatically and timely replaced to polish the surface of an aluminum profile after the surface of the aluminum profile is polished once, so that the surface of the aluminum profile can achieve a better mirror surface effect, the step of replacing a grinding tool of a common polishing machine is replaced, the polishing efficiency of the polishing machine is improved, and the production cost is reduced. The production cost is reduced, meanwhile, the labor capacity of operators is relieved, and the device is simple in structure, convenient and fast to operate and easy to popularize in a large range.

Owner:王达

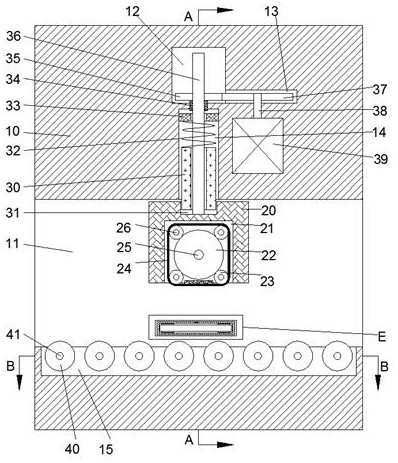

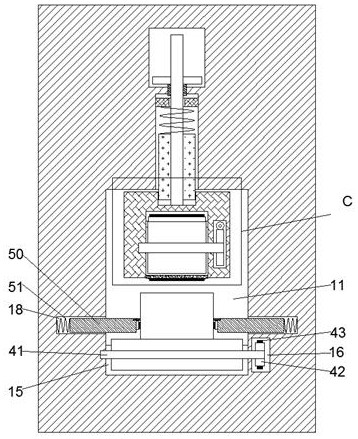

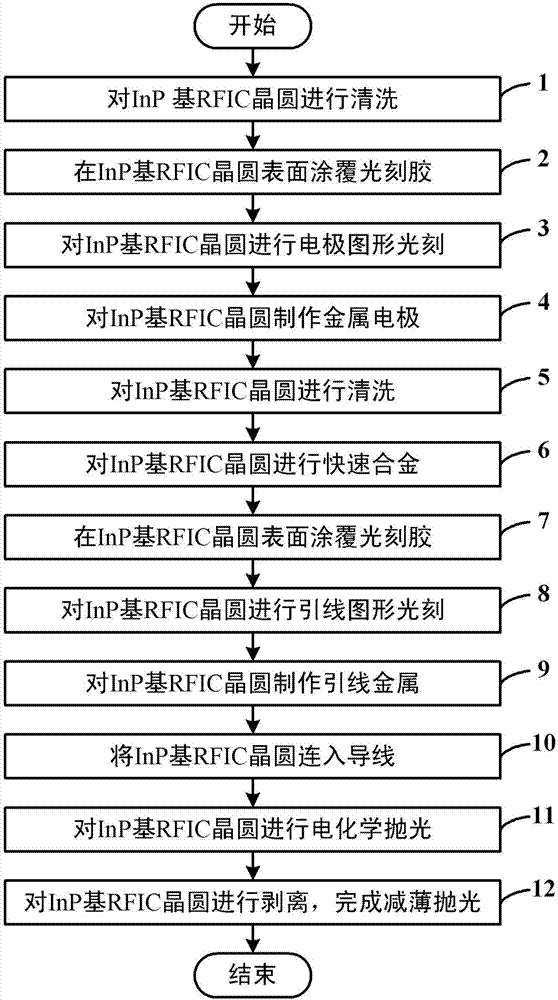

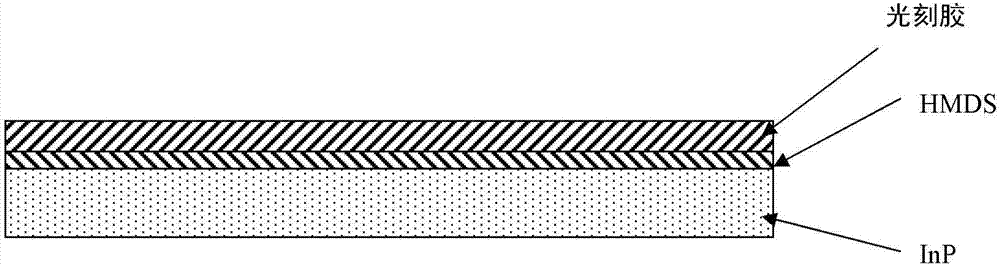

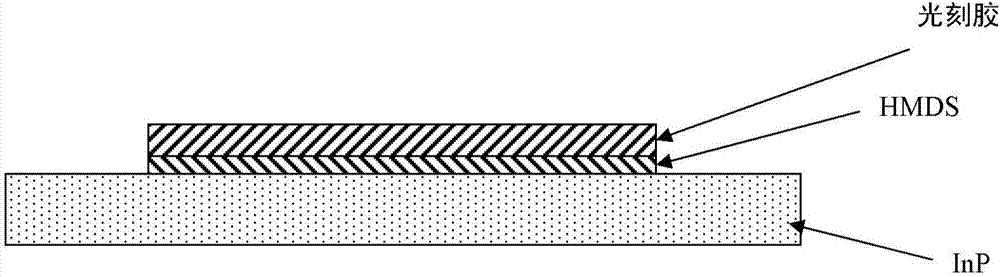

Method for electrochemically thinning and polishing InP-based RFIC (Radio Frequency Integrated Circuit) wafers

ActiveCN103500707AAchieve mirror effectAvoid damageSemiconductor/solid-state device manufacturingRFICPreventing injury

The invention discloses a method for electrochemically thinning and polishing InP-based RFIC wafers, which includes the following steps: an InP-based RFIC wafer is cleaned; photoresist is applied on the surface of the InP-based RFIC wafer; electrode pattern photolithography is performed on the InP-based RFIC wafer; metal electrodes are produced on the InP-based RFIC wafer; the InP-based RFIC wafer is cleaned; the InP-based RFIC wafer is rapidly alloyed; photoresist is applied on the surface of the InP-based RFIC wafer; lead pattern photolithography is performed on the InP-based RFIC wafer; lead metal is produced on the InP-based RFIC wafer; the InP-based RFIC wafer is connected with wires; the InP-based RFIC wafer is electrochemically polished; the InP-based RFIC wafer is stripped off, and thereby thinning and polishing are finished. The method effectively prevents injuries caused by mechanical thinning, realizes stress release in the process of thinning and polishing and the mirror effect of the polished surface of a substrate, and provides a new solution for the problem of a thinning and polishing process for ultrathin InP.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Semitransparent mahogany calcined umber smell cleaning type polyurethane woodenware paint and preparation method thereof

InactiveCN104726003AAnti-scratch hasHigh hardnessPolyurea/polyurethane coatingsPigment pastesBenzeneKetone

The invention relates to a semitransparent mahogany calcined umber smell cleaning type polyurethane woodenware paint and a preparation method thereof. The paint comprises a component A and a component B according to a weight ratio of 1:0.5; the component A is composed of smell cleaning type alkyd resin, extinction powder, a dispersant, an imitation mahogany color paste, a leveling agent, an antifoaming agent, an anti-settling agent and a solvent; and the component B is a non-benzene curing agent based on TDI and HDI trimer or adduct. The semitransparent mahogany calcined umber smell cleaning type polyurethane woodenware paint prepared in the invention does not contain aromatic hydrocarbons, aldehyde, ketone or heavy metals, and can reach a smell cleaning effect 48h after a film is formed by coating the paint; the paint has the advantages of no settlement, good levelability, good handle, high scratch resistance and no ghosting in the storage process; and the paint can be coated on woodenware to realize clear and intensive wood grains and make furniture elegant, noble, natural and comfortable, adapts to modern aesthetics, is popular in the market and is loved by users. The paint can be widely used to realize surface decoration protection of woodenwares, metals and plastics.

Owner:UNION FOSHAN CHEM +1

MCD arc-surface-milling cutter

InactiveCN104907619APrevent movementAchieve mirror effectMilling cuttersDiamond cuttingMilling cutter

The invention discloses an MCD arc-surface-milling cutter. The MCD arc-surface-milling cutter comprises a cutter shaft, a connecting shaft, a cutter disc, a left diamond cutter and a right diamond cutter, wherein the section of the cutter shaft along the axis is a cone-shaped surface; the connecting shaft is located between the cutter shaft and the cutter disc, a first flange is arranged at the joint between the lower end of the connecting shaft and the cutter shaft along the circumferential direction, and a second flange is arranged in the middle of the connecting shaft; the left diamond cutter and the right diamond cutter consist of cutter handles and diamond cutter heads; diamond cutting edges are arranged at the front parts of the diamond cutter heads protruding out of the side surface; a left mounting groove, a right mounting groove, a left fixing groove and a right fixing groove are circumferentially formed in the cutter disc, the left mounting groove and the right mounting groove are formed right above the left fixing groove and the right fixing groove, respectively, the left diamond cutter and the right diamond cutter are embedded into the left mounting groove and the right mounting groove, respectively, and a left fixed block and a right fixed block are mounted in the left fixing groove and the right fixing groove through fixing bolts and clamp the left diamond cutter and the right diamond cutter; two positioning grooves are symmetrically formed in the side surface of the connecting shaft along the circumferential direction. According to the MCD arc-surface-milling cutter, a cut surface is relatively smooth and flat, a vertical line is eliminated, and problems that the cutter heads play or jump in a high-speed rotation process, the machining error is produced, and the machining precision is low are prevented.

Owner:KUNSHAN KERSEN SCI & TECH

Preparation method of non-benzene low-odor/odor-free scratch-resistant polyurethane woodware matte black finishing paint

InactiveCN104710923AAnti-scratch hasHigh hardnessPolyurea/polyurethane coatingsPigment pastesKetoneSolvent

The invention relates to a preparation method of a non-benzene low-odor / odor-free type scratch-resistant polyurethane woodware matte black finishing paint composed of a component A and a component B with the weight ratio of the component A to the component B of 1:0.5; the component A is composed of a non-benzene low-odor / odor-free type scratch-resistant alkyd resin, an extinction powder, a dispersing agent, a carbon black color paste, a modified levelling agent, a defoamer, an anti-settling agent and a solvent; the component B is a non-benzene curing agent with a TDI trimer, an HDI trimer or an addition product as a main component. The prepared matte black finishing paint does not contain aromatic hydrocarbon, aldehyde ketone or heavy metals, and a paint film has no odor after 48 hours after spraying; the prepared matte black finishing paint is not precipitated when stored, is high in solid content, low in viscosity, good in levelling performance, capable of forming a thick film at one step without sagging, soft in hand feeling, full and exquisite, solemn, hard and soft, and capable of generating a mirror-surface-like full decorative effect, brings elegance and comfort for people, and conforms to the modern aesthetic view so as to be popular to the market and consumers; and the matte black finishing paint is widely applied to the surfaces of woodware, metals, plastics and other products for protection and decoration.

Owner:UNION FOSHAN CHEM +1

Wet CMP mirror polishing solution for stainless steel mobile phone middle frame and preparation method of wet CMP mirror polishing solution

InactiveCN111234708AGood suspensionGood dispersionPolishing compositions with abrasivesOrganic acidPolishing

The invention discloses a wet CMP mirror polishing solution for a stainless steel mobile phone middle frame and a preparation method of the wet CMP mirror polishing solution. The wet CMP mirror polishing solution is composed of a component A and a component B,the component A is prepared from the following components in parts by weight: 5 to 30 parts of an organic acid, 3 to 40 parts of a wax, 4 to20 parts of an emulsifier and 30 to 100 parts of deionized water; the component B is prepared from the following components in parts by weight: 4-60 parts of an abrasive, 5-10 parts of a suspending agent, 1-5 parts of a corrosion inhibitor, 1-5 parts of a preservative, 1-10 parts of a defoaming agent and 20-100 parts of deionized water. The prepared polishing solution is good in dispersity and suspension property, and the phenomena of precipitation, layering and cakingoccured after long-time storage are avoided; the lubricating property is good, and scratches and microcracks on the stainlesssteel surface are greatly reduced; all the components are water-soluble, so that the cleaning is easy, and the adhesion of impurities and dirt is avoided; the light emitting effect is good, and the polished stainless steel surface achieves the mirror surface effect; cost is low, maintenance is convenient, and recycling can be achieved.

Owner:HENAN UNION ABRASIVES

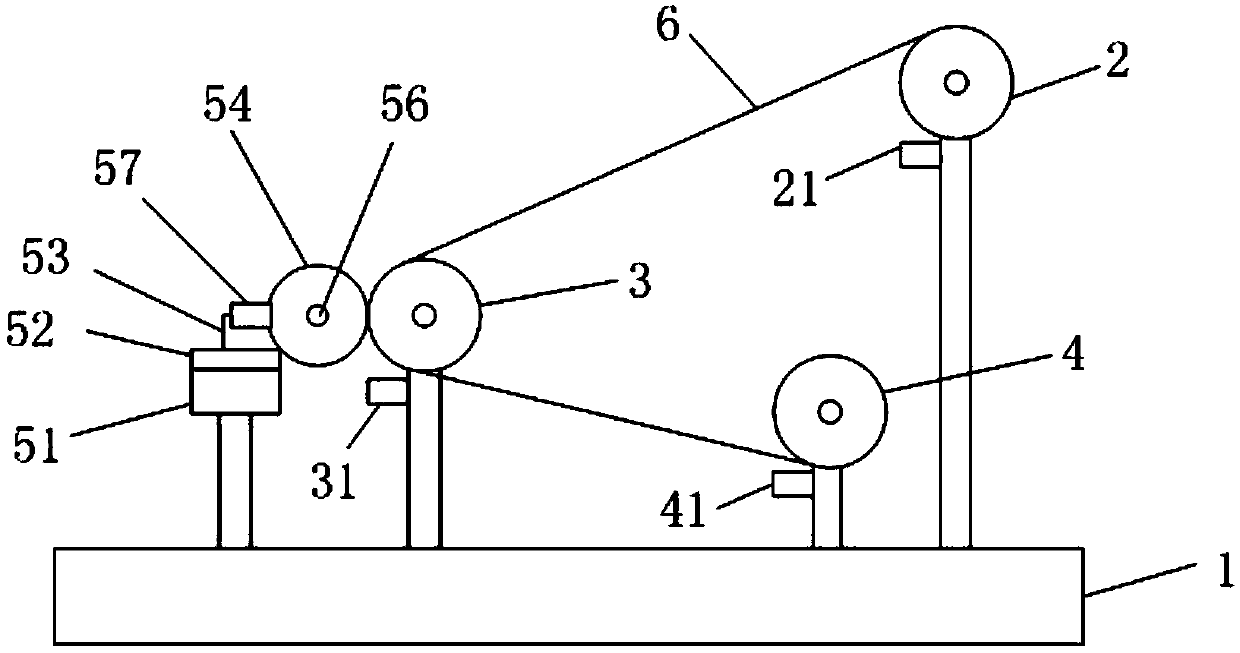

Aluminum foil cutting equipment and cutting method

InactiveCN109664353AReduce frictionFlat cutting surfaceMetal working apparatusEngineeringRaw material

The invention discloses aluminum foil cutting equipment. The aluminum foil cutting equipment comprises a rack, a first rolling shaft, a second rolling shaft, a third rolling shaft and a cutting device; the cutting device comprises a sliding rail, a slider, a fixing seat, a circular knife and a first driving device, wherein the sliding rail is arranged on the rack; the slider is slidably connectedto the sliding rail; the fixing seat is arranged on the slider; the circular knife is connected to the fixing seat; the first driving device is used for driving the circular knife to rotate; the sliding rail is arranged at one side of the second rolling shaft; the edge of the circular knife makes contact with an aluminum foil positioned on the second rolling shaft; the second rolling shaft is connected with a second driving device; the linear speed of the circular knife is the same as that of the aluminum foil on the second rolling shaft; the first rolling shaft is provided with an aluminum foil raw material; the aluminum foil sequentially passes through the second rolling shaft and the third rolling shaft from the first rolling shaft; and the third rolling shaft is used for re-rolling thealuminum foil which is cut. Correspondingly, the invention further discloses an aluminum foil cutting method. The aluminum foil cutting equipment disclosed by the invention is simple in structure, the cut surface of the aluminum foil is smooth, and a good cutting effect is achieved.

Owner:佛山市中技烯米新材料有限公司

Waterless grinding mirror polishing process

The invention discloses a waterless grinding mirror polishing process which comprises the following steps: A, customizing and producing a dragging type automatic polishing machine meeting the polishing operation distance of a client product according to the boundary dimension of the product; B, selecting 24 to 960 polishing rods according to the capacity of a client, the distance between the polishing rods ranging from 60 mm to 400 mm, and then customizing proper technological processes (rough polishing, medium polishing and fine polishing) according to the quality standard of mirror polishingof the surface of a client product. According to the invention, a dragging type automatic polishing machine is combined with a grinding carrier of walnut grains, corncobs, wool balls, aluminum oxide,cerium oxide, silicon carbide and diamond and polishing oil; no water is used for enabling the surfaces of zinc alloy, aluminum alloy, stainless steel, titanium alloy and precious metal to achieve the mirror surface effect, meanwhile, the manufacturing process is simple, the production efficiency is high, no water is used, environmental protection is achieved, the quality is stable, full-closed noise is low, the mirror surface polishing production efficiency can be improved, and applicability is wide.

Owner:谭长福 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com