Brass polish cream having stable viscosity

A technique for rubbing copper paste and viscosity, which is applied in the field of rubbing copper paste to achieve the effect of simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

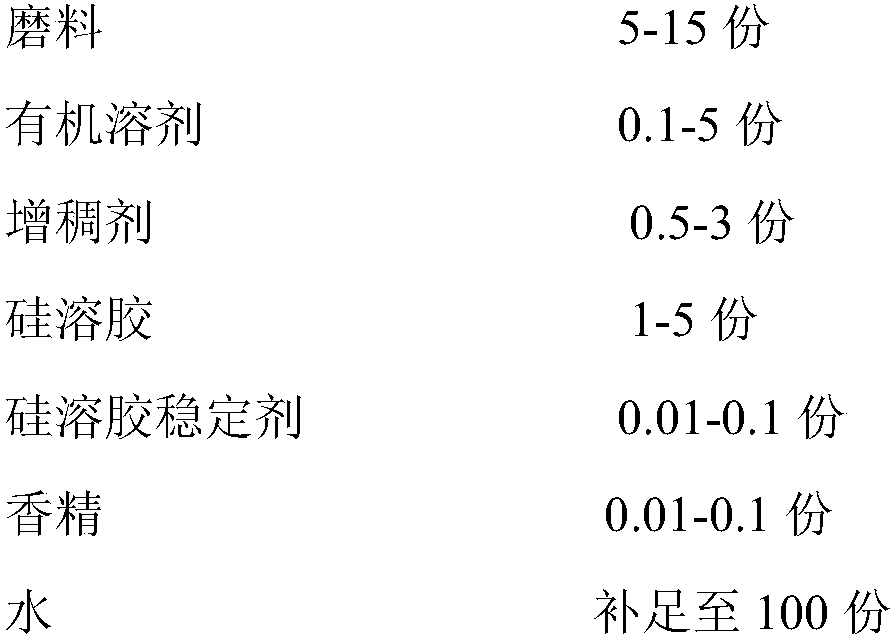

Method used

Image

Examples

preparation example Construction

[0020] Preparation of thickener solution A:

[0021]

Total amount / g

Component (a)

Dosage / g

50% component (b)

Dosage / g

Thickener A1

0.5

0.25

0.125

Thickener A2

2

Methylcellulose

1.8

0.1

Thickener A3

3

2.7

1.5

[0022] Preparation method: first add the measured thickener component (a) and 50% component (b) into water, heat to 60°C, and stir at 800-1000rpm for 10-20min to obtain a stable and uniform thickener. Solvent solution A is set aside.

[0023]

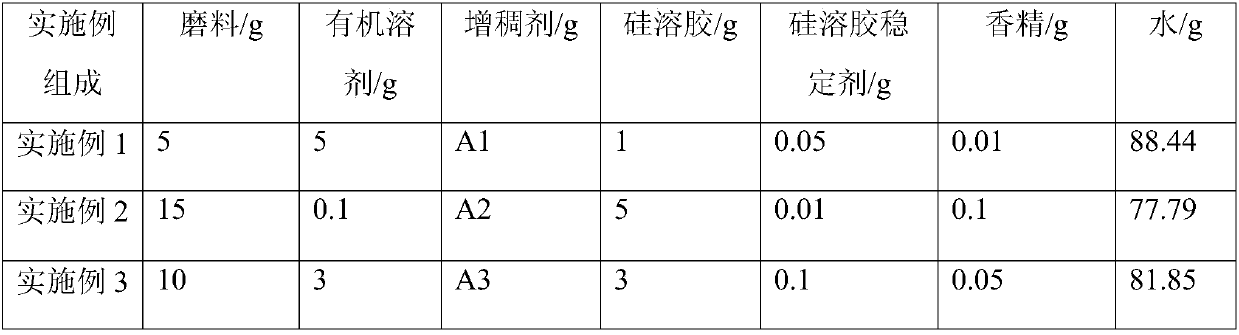

Embodiment

[0024] Embodiment preparation method:

[0025] (1) Under stirring at 800-1000rpm, add abrasive, silica sol, silica sol stabilizer, organic solvent and essence to thickener solution A in turn, stir at room temperature to obtain mixture B. Every time you add a raw material, you must ensure that it is evenly mixed before adding another raw material.

[0026] (3) Under the condition of stirring at 800-1000rpm, add the remaining 50% component (b) thickener solution to the mixture B to fine-tune the viscosity, and obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com