Wood surface treatment device and method

A wood surface and treatment device technology, applied in wood compression, wood processing equipment, charcoal burning/combustion, etc., can solve the problems of high cost, time-consuming and laborious sanding process of wooden furniture, and high technical requirements for skilled workers, so as to achieve improvement Hardness and flatness, improve smoothness, and facilitate the effect of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

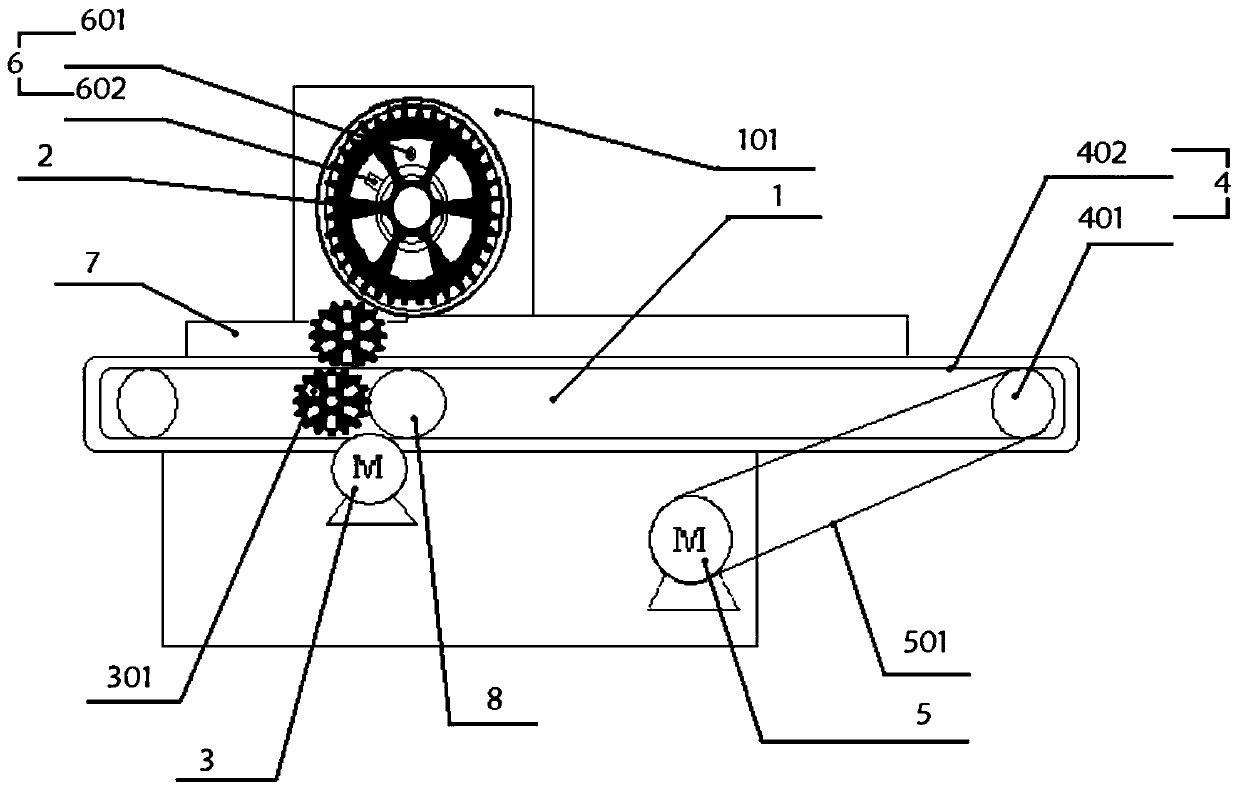

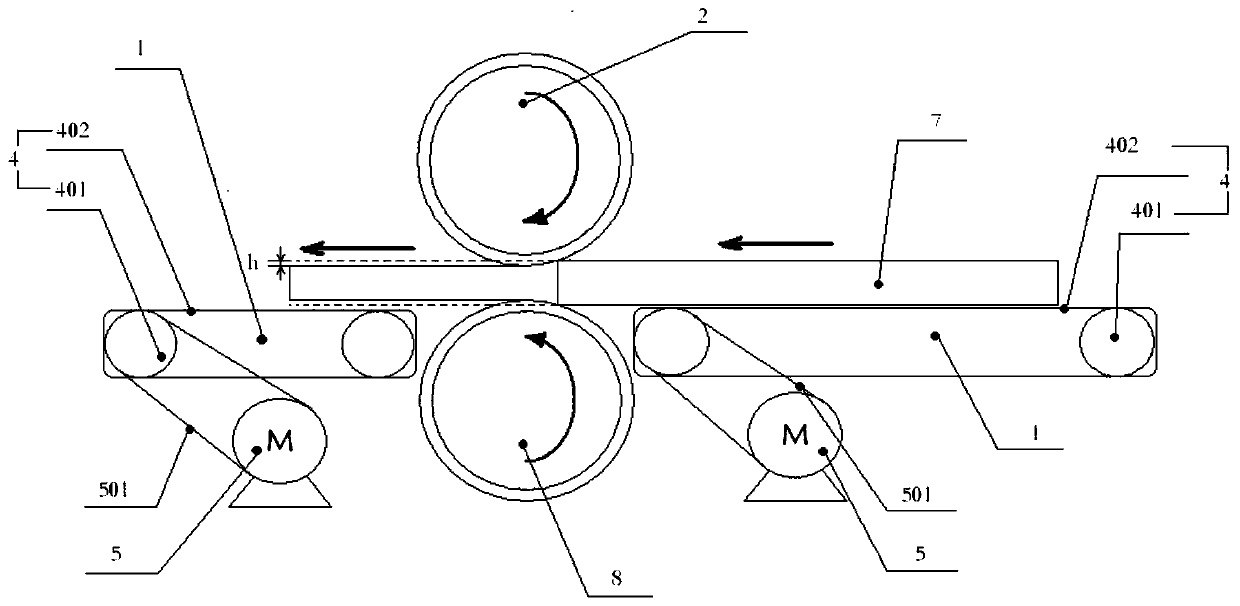

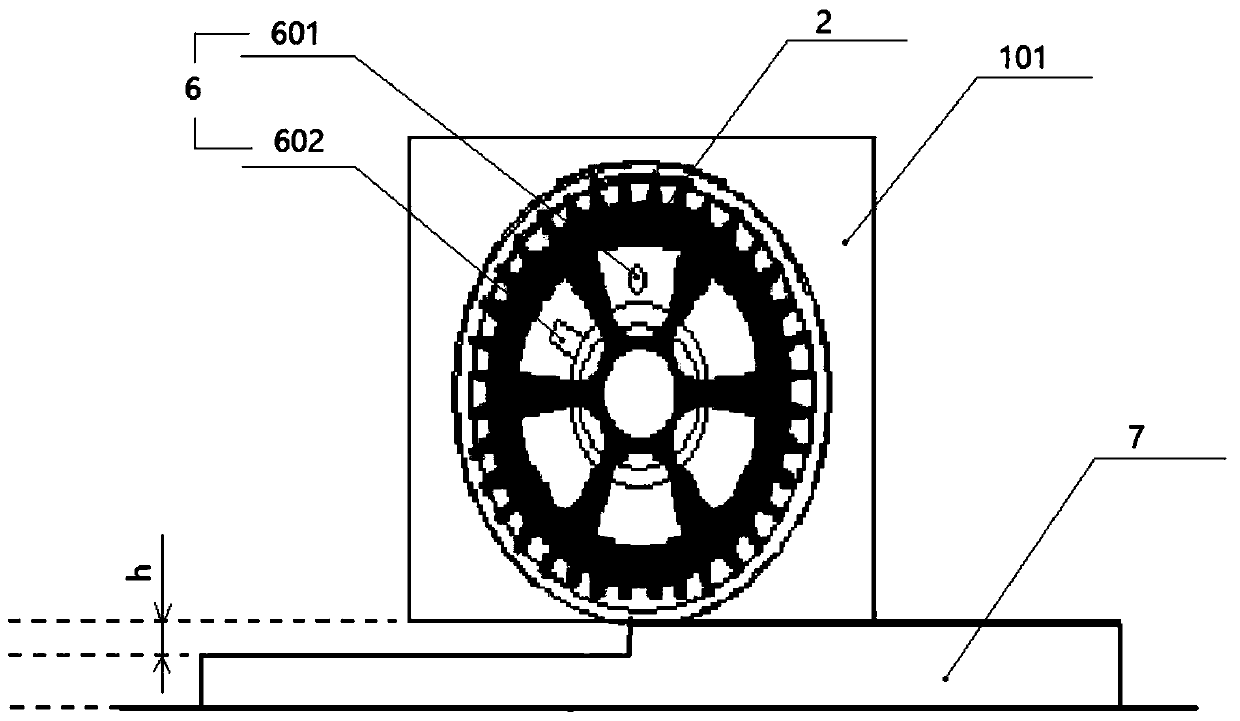

[0051] In the first aspect, the embodiment of the present invention provides a wood surface treatment device, such as the attached figure 1 As shown, the device includes: a horizontal support 1, and a height-adjustable chassis 101 is arranged near the end along the length direction.

[0052] Both ends of the metal pressure roller 2 are horizontally connected to the side wall in the length direction of the cabinet 101 through bearings, and the surface hardness of the metal pressure roller 2 is greater than 40 on the Rockwell scale.

[0053] The first motor 3 is arranged at one end of the metal pressing roller 2 and is connected with the metal pressing roller 2 through a differential gear 301 to drive the metal pressing roller 2 to rotate horizontally.

[0054] The conveying asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com