Electrochemical polishing technology for aluminum or stainless steel products

A stainless steel, electrochemical technology, applied in the field of electrochemical polishing, can solve problems such as difficult to find electrolytic polishing parameters, many parameters of electrolytic polishing, complex composition of polishing liquid, etc., to achieve no safety hazard, consistent color and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0022] Preparation Example 1 Electrochemically polished aluminum product

[0023] The process of electrochemically polishing aluminum products of the present invention comprises the following steps:

[0024] (1) Cleaning: Put the aluminum products to be polished into acetone and ethanol in turn, clean them with ultrasonic waves for 7 minutes, and dry them for later use;

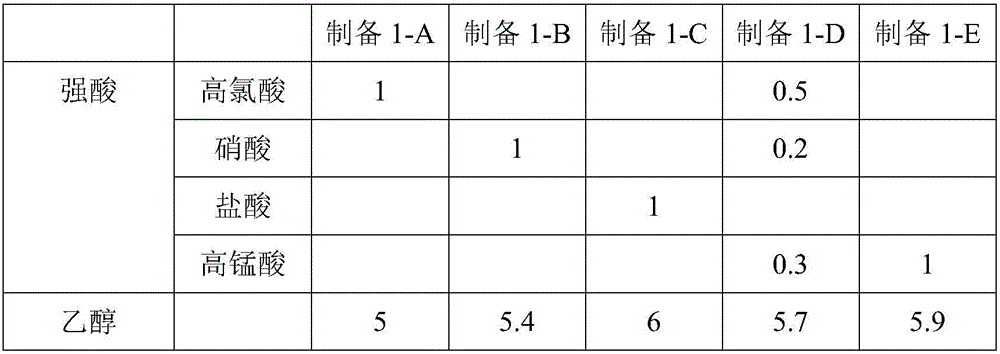

[0025] (2) Prepare polishing solution: add strong acid in ethanol, mix well, the volume ratio of strong acid and ethanol is shown in Table 1;

[0026] (3) Electrolytic polishing: take the cleaned aluminum product as the anode, and the cathode plate is a stainless steel plate or lead plate, put it in the polishing solution, connect the DC power supply, control the voltage at 8-15V, and put it in a water bath environment of 5-20°C Polishing for 8-9 minutes, the area of the stainless steel plate or lead plate is 4 times the maximum cross-sectional area of the aluminum product;

[0027] (4) Rinse and dry: R...

preparation Embodiment 2

[0034] Preparation Example 2 Electrochemically Polished Stainless Steel Products

[0035] A process for electrochemically polishing stainless steel products, comprising the following steps:

[0036] (1) Cleaning: Put the stainless steel products to be polished into acetone and ethanol in turn, clean them with ultrasonic waves for 7 minutes, and dry them for later use;

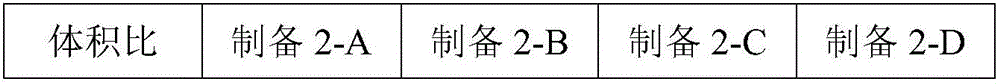

[0037] (2) prepare polishing liquid: phosphoric acid is mixed with concentrated sulfuric acid and lactic acid, and the volume ratio of mixed acid is as shown in table 3;

[0038] (3) Electrolytic polishing: take the cleaned stainless steel product as the anode, and the cathode plate as the lead plate or stainless steel plate, put it in the polishing solution, connect the DC power supply, control the current at 0.5A, and polish it in a water bath environment at 40-100°C 30-32min, the area of the stainless steel plate or lead plate is 4 times the maximum cross-sectional area of the stainless steel product; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com