Method for improving corrosion resistance of neodymium-iron-boron waste recycled magnet

A technology of waste recycling and NdFeB, applied in the direction of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of magnet main phase grain shedding, electrochemical corrosion, magnet corrosion, etc., to achieve uniform distribution, Effect of improving corrosion resistance and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

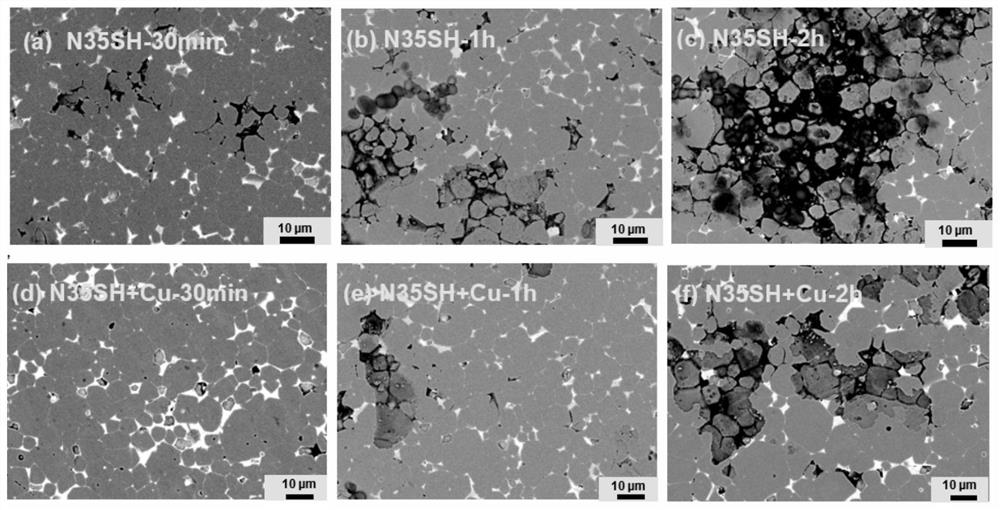

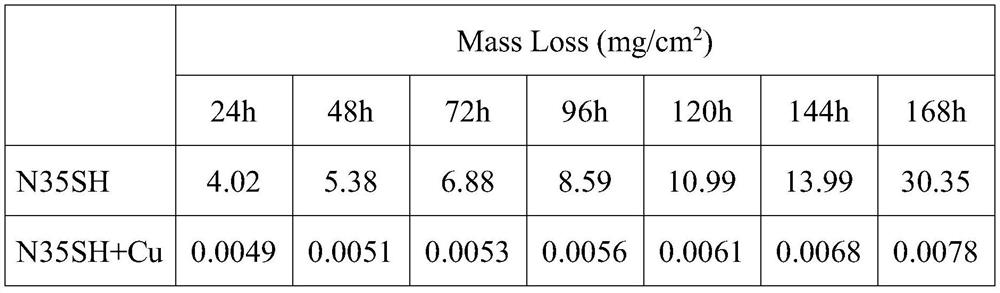

[0022] Step 1), with N35SH brand (H cj : 19~20kOe, (BH) max : 34~35MGOe, B r : 11 ~ 12kGs) NdFeB magnet as the main alloy, take the NdFeB magnet with a mass ratio of 99.7%, and carry out hydrogen cracking treatment at 590°C and 0.6MPa hydrogen pressure. After dehydrogenation, the mass ratio 0.3% copper powder with an average particle size of 1 μm was subjected to jet milling at a speed of 5000 rpm to prepare mixed magnetic powder with an average particle size of 3 μm.

[0023] Step 2), the mixed powder is subjected to compression molding orientation under a 2T orientation magnetic field, and then cold isostatic pressing under a pressure of 200MPa to obtain a green body of a magnet;

[0024] Step 3), sintering the obtained magnet green body at 1040°C for 2h, then heat-treating at 850°C for 3h in the next step, and then heat-treating in the second step at 550°C for 4h, to obtain a NdFeB grain boundary reconstructed magnet;

[0025] The weight loss data of the obtained grain b...

Embodiment 2

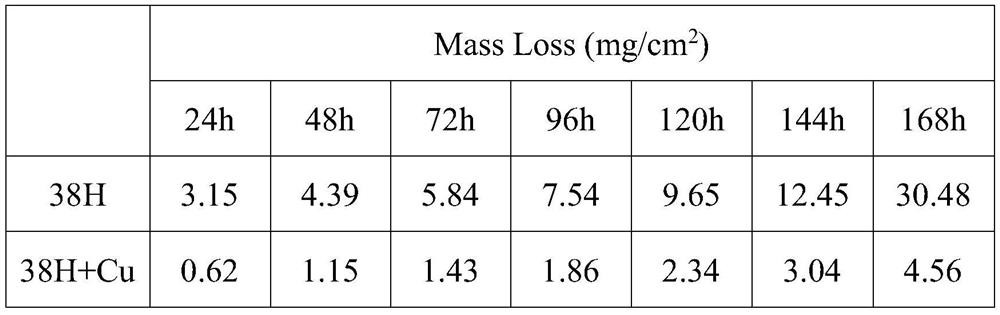

[0035] Step 1), with 38H grade (H cj : 15~18kOe, (BH) max : 35~38MGOe, B r: 12 ~ 13kGs) NdFeB magnets as the main alloy, take NdFeB magnets with a mass ratio of 99.8%, and carry out hydrogen cracking treatment at 590 ° C and 0.6 MPa hydrogen pressure. After dehydrogenation, the mass ratio 0.2% of copper powder with an average particle size of 1 μm is subjected to jet milling, and the jet mill speed is 5000 rpm to prepare mixed magnetic powder with an average particle size of 3 μm;

[0036] Step 2), the mixed powder is subjected to compression molding orientation under a 2T orientation magnetic field, and then cold isostatic pressing under a pressure of 200MPa to obtain a green body of a magnet;

[0037] Step 3), sintering the obtained magnet green body at 1040°C for 2h, then heat-treating at 850°C for 3h in the next step, and then heat-treating in the second step at 550°C for 4h, to obtain a NdFeB grain boundary reconstructed magnet;

[0038] The weight loss data obtained b...

Embodiment 3

[0047] Step 1), with N40 brand (H cj : 10~15kOe, (BH) max : 38~40MGOe, B r : 12~13kGs) NdFeB magnets as the main alloy, take the NdFeB magnets with a mass ratio of 99.9%, and carry out hydrogen cracking treatment at 590°C and 0.6MPa hydrogen pressure. After dehydrogenation, the mass ratio 0.1% of copper powder with an average particle size of 1 μm is subjected to jet milling at a speed of 5000 rpm to prepare mixed magnetic powder with an average particle size of 3 μm;

[0048] Step 2), the mixed powder is subjected to compression molding orientation under a 2T orientation magnetic field, and then cold isostatic pressing under a pressure of 200MPa to obtain a green body of a magnet;

[0049] Step 3), sintering the obtained magnet green body at 1040°C for 2h, then heat-treating at 850°C for 3h in the next step, and then heat-treating in the second step at 550°C for 4h, to obtain a NdFeB grain boundary reconstructed magnet;

[0050] The weight loss data obtained by exposing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com