Wet CMP mirror polishing solution for stainless steel mobile phone middle frame and preparation method of wet CMP mirror polishing solution

A technology of mirror polishing and mobile phone middle frame, which is applied in the field of mirror polishing liquid, which can solve the problems that it is difficult to achieve mirror effect on stainless steel surface, damage the health of operators, metal dust pollution and other problems, achieve excellent polishing performance, save manpower and cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

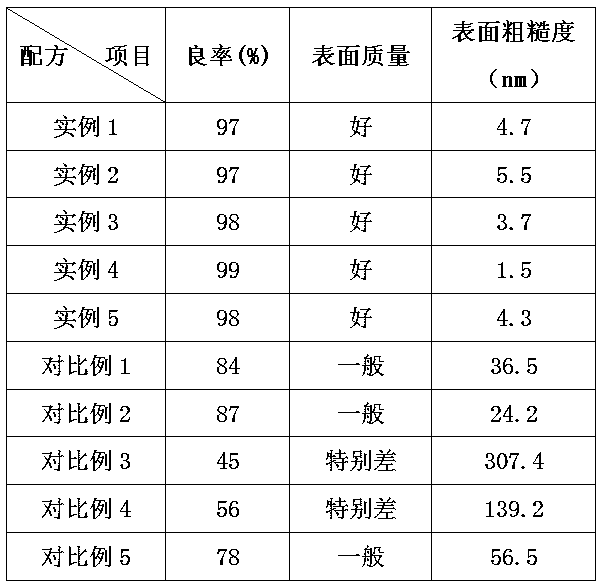

Examples

Embodiment 1

[0028] The formula of the present embodiment polishing liquid is:

[0029] Component A: 5 parts of oleic acid, 10 parts of paraffin, 1 part of triethanolamine, 10 parts of OP-10, 80 parts of water;

[0030] Component B: 10 parts of α-alumina, 2 parts of PAAS, 3 parts of benzotriazole, 3 parts of potassium sorbate, 4 parts of silicone oil, and 90 parts of water.

[0031] The preparation method of the polishing liquid of the present embodiment is as follows:

[0032] (1) Preparation method of component A: Mix the weighed oleic acid, paraffin, triethanolamine, and OP-10 together, heat to 110°C to completely melt, and keep stirring. Weigh 90°C hot water, slowly add it to the mixed liquid, keep the liquid temperature at 70°C-90°C, the mixed liquid will change from oily to watery, and the transition time will take about 20-60 minutes;

[0033] (2) Preparation method of component B: Weigh 90 parts of deionized water, add PAAS, benzotriazole, potassium sorbate, silicone oil in seque...

Embodiment 2

[0036] The formula of the present embodiment polishing liquid is:

[0037] Component A: 3 parts of stearic acid, 5 parts of oleic acid, 10 parts of paraffin wax, 5 parts of palm wax, 1 part of triethanolamine, 10 parts of OP-10, 70 parts of water;

[0038] Component B: 10 parts of α-alumina, 2 parts of sodium hexametaphosphate, 3 parts of benzotriazole, 10 parts of sodium sorbate, 2 parts of tributyl phosphate, and 80 parts of water.

[0039] The preparation method of the polishing liquid of the present embodiment is as follows:

[0040] (1) Preparation method of component A: Mix the weighed stearic acid, oleic acid, paraffin wax, palm wax, triethanolamine, and OP-10 together, heat to 110°C to completely melt, and keep stirring. Weigh hot water at 90°C, slowly add it to the melted mixed liquid, keep the temperature of the liquid at 70°C-90°C, the mixed liquid will change from oily to watery, and the transition time will take about 20-60 minutes;

[0041] (2) Preparation meth...

Embodiment 3

[0044] The formula of the present embodiment polishing liquid is:

[0045] Component A: 10 parts of oleic acid, 5 parts of paraffin, 10 parts of beeswax, 2 parts of triethanolamine, 3 parts of Span 80, 10 parts of Tween 20, 100 parts of water;

[0046] Component B: 20 parts of α-alumina, 2 parts of sodium hexametaphosphate, 3 parts of barium petroleum sulfonate, 5 parts of sodium benzoate, 2 parts of silicone oil, and 90 parts of water.

[0047] The preparation method of the polishing liquid of the present embodiment is as follows:

[0048] (1) Preparation method of component A: Mix the weighed oleic acid, paraffin, beeswax, triethanolamine, Span 80, and Tween 20 together, heat to 90°C to completely melt, weigh 80°C hot water, slowly add to melt In the mixed liquid, keep the temperature of the liquid at 70°C-85°C and keep stirring until the mixed liquid changes from oily to watery, and the transition time takes about 20-50min.

[0049](2) Preparation method of group B: Wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com