Pulse current assisted ultrasonic rolling surface strengthening device and method

A technology of ultrasonic rolling and pulse current, which is applied in the field of surface treatment of metal materials, can solve the problems of not being able to reach deeper into the material, difficult to strengthen the surface layer, and high hardness of the surface layer, and achieve low cost, superior comprehensive performance, and simple device structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

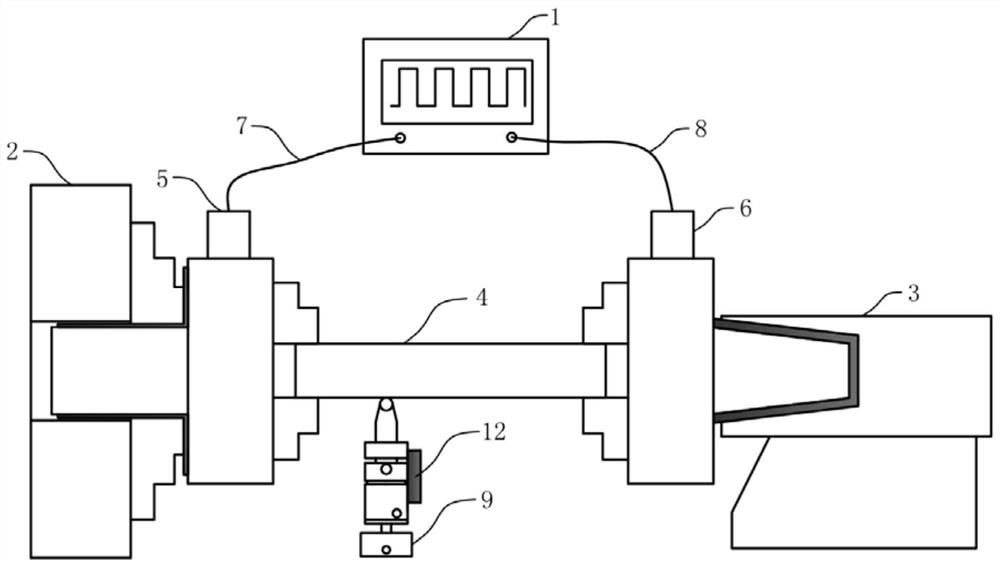

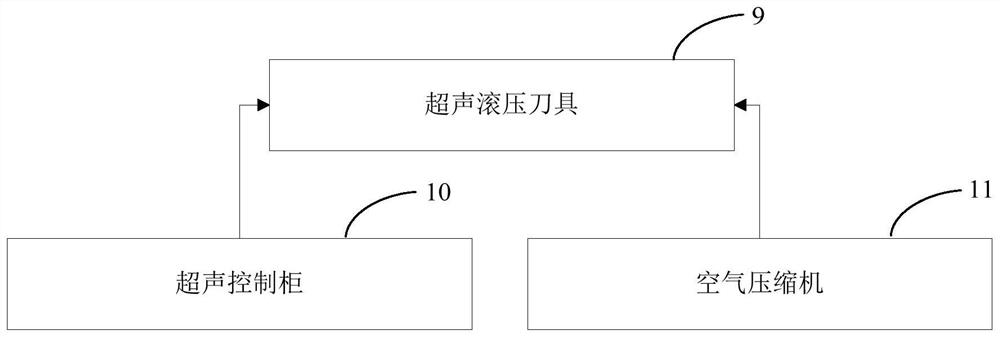

[0044] Such as figure 1 As shown, this embodiment provides a pulse current assisted ultrasonic rolling surface strengthening device, which is implemented on a lathe, including a pulse power supply 1, conductive parts, clamping mechanism 2 and ultrasonic rolling module, only shown in the figure The lathe tailstock 3 of the lathe is shown, and other parts of the lathe are not shown.

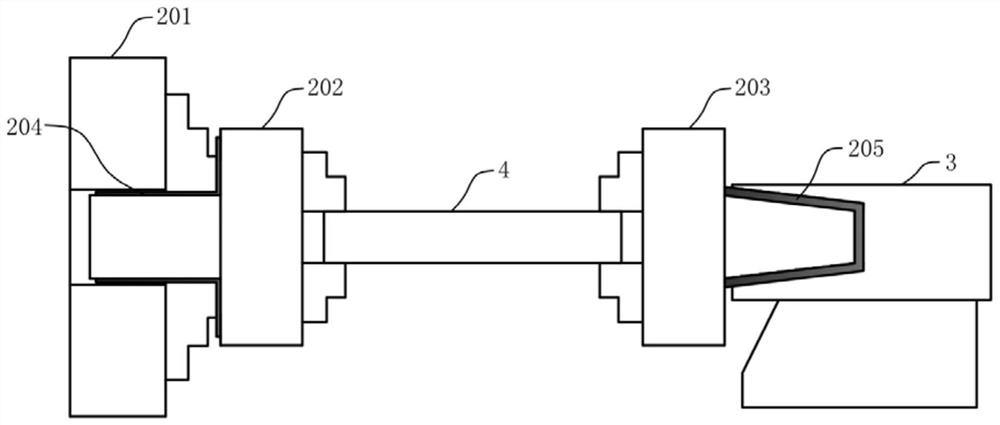

[0045] The clamping mechanism 2 is used to clamp the workpiece 4, and the clamping mechanism 2 is driven to rotate by the lathe, wherein the workpiece 4 is a metal material, such as figure 1 and figure 2 As shown, the clamping mechanism 2 includes a first chuck 201, a second chuck 202 and a third chuck 203, the second chuck 202 is a cylindrical shank chuck, the third chuck 203 is a conical shank chuck, and the first chuck 202 is a cylindrical handle chuck. Chuck 201 can be the chuck that lathe itself has, and first chuck 201 is connected with lathe main shaft, and second chuck 202 is installed o...

Embodiment 2

[0068] The main features of this embodiment are: using an AC pulse welding machine, or using a pulse welding machine with the function of outputting AC pulse current, or using an AC welding machine, and using AC pulses or AC current to process workpieces. All the other are with embodiment 1.

Embodiment 3

[0070] The main features of this embodiment are: use a DC pulse welding machine, or use a pulse welding machine with the function of outputting DC pulse current, or use a DC welding machine, and use DC pulse current or DC current to process the workpiece. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com