A preparation method of anti-cracking low-smoke halogen-free optical cable flame-retardant sheath material

A flame-retardant sheath and anti-cracking technology, which is applied in the field of optical cable sheathing, can solve the problems of poor cracking resistance and achieve the effects of improving interface bonding force, improving high-temperature cracking resistance, and good cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

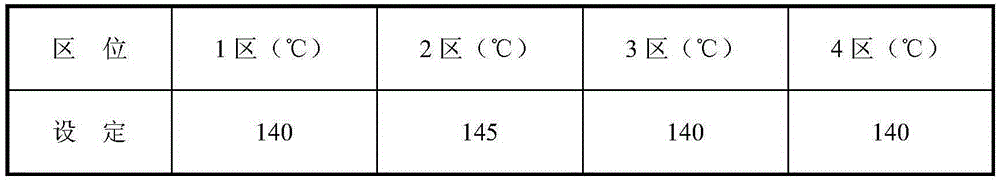

Embodiment 1

[0041] Dry the flame retardant (35kg aluminum hydroxide H-WF-1, 3kg zinc borate ZB-2335 and 1.2kg organic montmorillonite DK-4) until the moisture content is lower than 5%, and the dried flame retardant Mix it with a coupling agent (1kg monoalkoxy titanate TC-2), and stir at a temperature of 80°C at a stirring speed of 200rpm for 8 minutes to obtain a mixture a; Fuel filler (6kg active calcium carbonate), lubricant (1.2kgPE wax and 0.3kg stearic acid) and antioxidant (0.5kg antioxidant 1010 and 0.5kg antioxidant 168), after adding, the temperature is 80℃ Under the condition of 220rpm stirring for 10min, mixture b was obtained; base material (30kgHDPE5000S, 10kgEVA7470M and 5kgPOE polyolefin elastic 8201), anti-ultraviolet agent (3.3kg polyethylene carbon black masterbatch ), compatibilizer (2kg compatibilizer MC-218) and additives (1kg silicone masterbatch PW1050), after adding, stir at a speed of 250rpm for 2min to obtain mixture c, first send mixture c into twin-screw The e...

Embodiment 2

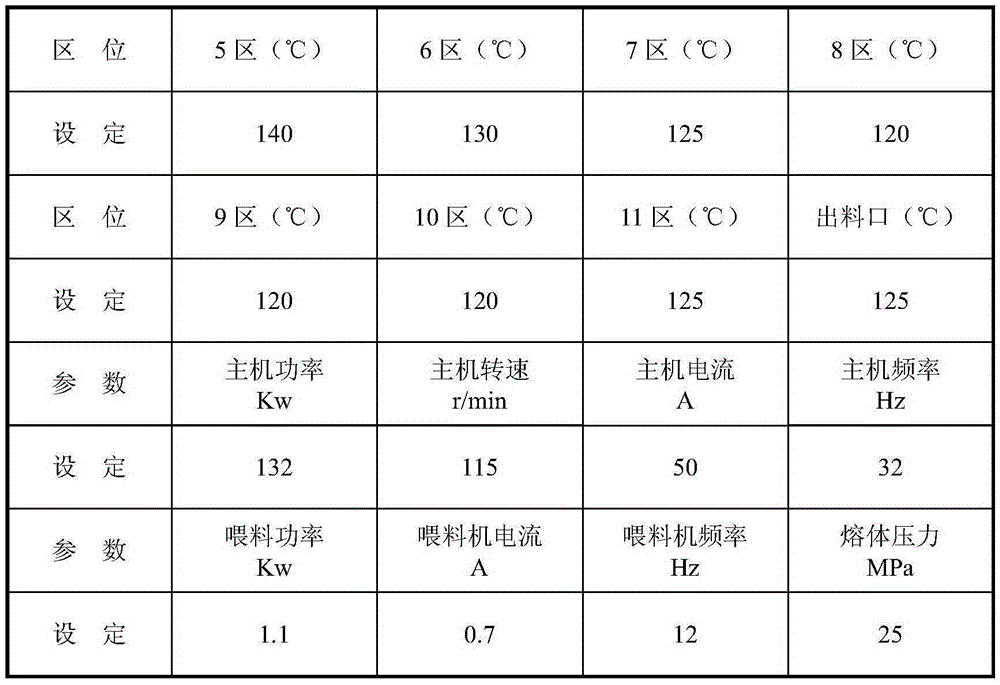

[0043]Dry the flame retardant (35kg aluminum hydroxide H-WF-1, 3kg zinc borate ZB-2335 and 1.2kg organic montmorillonite DK-4) until the moisture content is lower than 5%, and the dried flame retardant Mix it with a coupling agent (0.5kg monoalkoxy titanate TC-2), and stir for 9 minutes at a stirring speed of 250rpm at a temperature of 85°C to obtain a mixture a; Flame retardant filler (4kg active calcium carbonate), lubricant (1.2kgPE wax and 0.3kg stearic acid) and antioxidant (0.5kg antioxidant 1010 and 0.5kg antioxidant 168), after adding, the temperature is 85 Under the condition of ℃, stir at a stirring speed of 250rpm for 11min to obtain mixture b; add base material (30kgHDPE5000S, 10kgEVA7470M and 5kgPOE polyolefin elastic 8201), anti-ultraviolet agent (1kg polyethylene carbon black masterbatch ), compatibilizer (1kg compatibilizer MC-218) and additives (0.5kg silicone masterbatch PW1050), after adding, stir at a stirring speed of 270rpm for 3min to obtain mixture c, f...

Embodiment 3

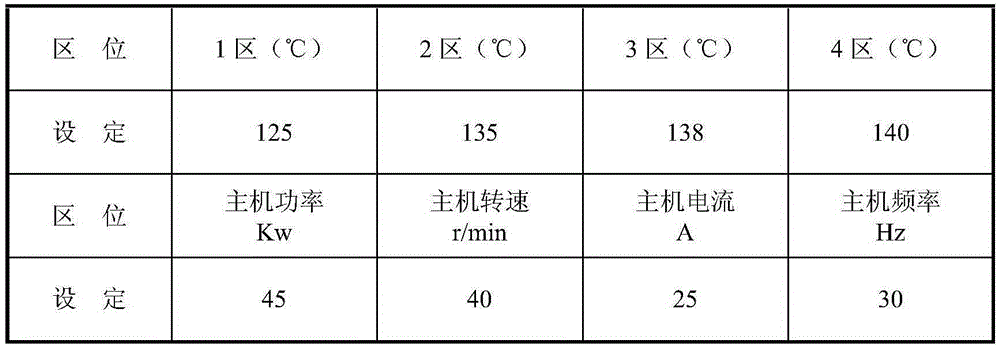

[0045] Dry the flame retardant (35kg aluminum hydroxide H-WF-1, 3kg zinc borate ZB-2335 and 1.2kg organic montmorillonite DK-4) until the moisture content is lower than 5%, and the dried flame retardant Mix it with a coupling agent (1.5g monoalkoxy titanate TC-2), and stir at a stirring speed of 300rpm for 10min at a temperature of 90°C to obtain a mixture a; Flame retardant filler (8kg active calcium carbonate), lubricant (1.2kgPE wax and 0.3kg stearic acid) and antioxidant (0.5kg antioxidant 1010 and 0.5kg antioxidant 168), after adding, the temperature is 90 Under the condition of ℃, stir at a stirring speed of 280rpm for 12min to obtain mixture b; add base material (30kgHDPE5000S, 10kgEVA7470M and 5kgPOE polyolefin elastic 8201), anti-ultraviolet agent (5kg polyethylene carbon black masterbatch ), compatibilizer (3kg compatibilizer MC-218) and additives (1.5kg silicone masterbatch PW1050), after adding, stir at a stirring speed of 320rpm for 3min to obtain mixture c, first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com