High temperature steam pipe forging process for supercritical unit

A technology for high-temperature steam pipelines and supercritical units, which is applied in the field of forging, can solve the problems of inability to crush as-cast dendrites, weak oblique tee, and difficulty in punching holes, so as to eliminate internal structure defects and homogenize internal structures. , the effect of increasing the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

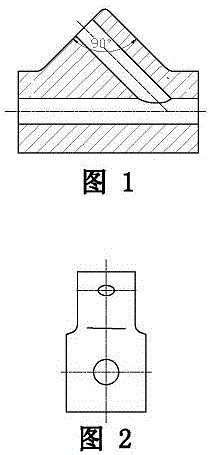

[0031] Such as figure 1 , figure 2 Shown is the finished forging for the oblique tee of the main steam pipe of the nuclear power ultra-supercritical generating set. The weight of the forging of the oblique tee is 50 tons, and the shape is a structure with edges and facets. Main pipe hole and branch pipe hole. The branch pipe hole is located on the V-shaped outer flange platform on the body, the wall thickness of the main pipe hole is at least twice the diameter of the hole, the depth-to-diameter ratio of the main pipe hole is at least 8, and the angle between the centerline of the main pipe hole and the branch pipe hole is 45°. The length of the main pipe hole is 3200mm, and the length of the branch pipe is 2000mm.

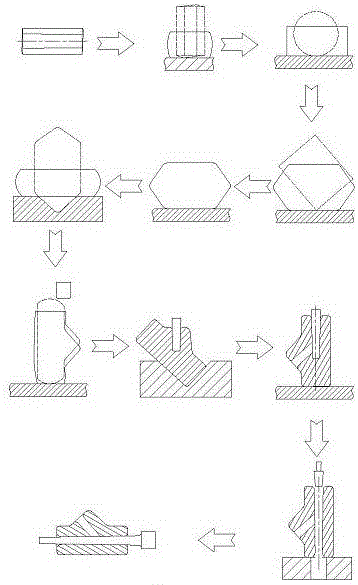

[0032] image 3 A flow chart of the process steps of a specific embodiment of the present invention is shown (the solid line in the figure is the outline of the forging, and the dotted line is the outline of the forging before forging). The octagonal prism-sh...

Embodiment 2

[0041] The structure of another forging product used for the inclined tee of the main steam pipe of thermal power ultra-supercritical generating units is still as follows figure 1 , figure 2 As shown, the finished product weight of the oblique tee forging is 45 tons, and the shape has edges and facets. There are intersecting main pipe holes and branch pipe holes on the pipe body, and the angle between the centerlines of the main pipe hole and the branch pipe holes is 45°. , the length of the main pipe hole is 3000mm, and the length of the branch pipe is 1800mm.

[0042] still with image 3 The flow chart of the process steps shown (the solid line in the figure is the outline of the forging, and the dotted line is the outline of the forging before forging) is forged. An octagonal prism-shaped steel ingot is selected. The material of the steel ingot is martensitic heat-resistant steel P92. The weight of the steel ingot is 57.5 tons. The weight of the steel ingot is about 1.28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com