Method for electrochemically thinning and polishing InP-based RFIC (Radio Frequency Integrated Circuit) wafers

A thinning, polishing, electrochemical technology, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve problems such as damage stress, achieve the effect of stress release, avoid damage, and achieve mirror effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

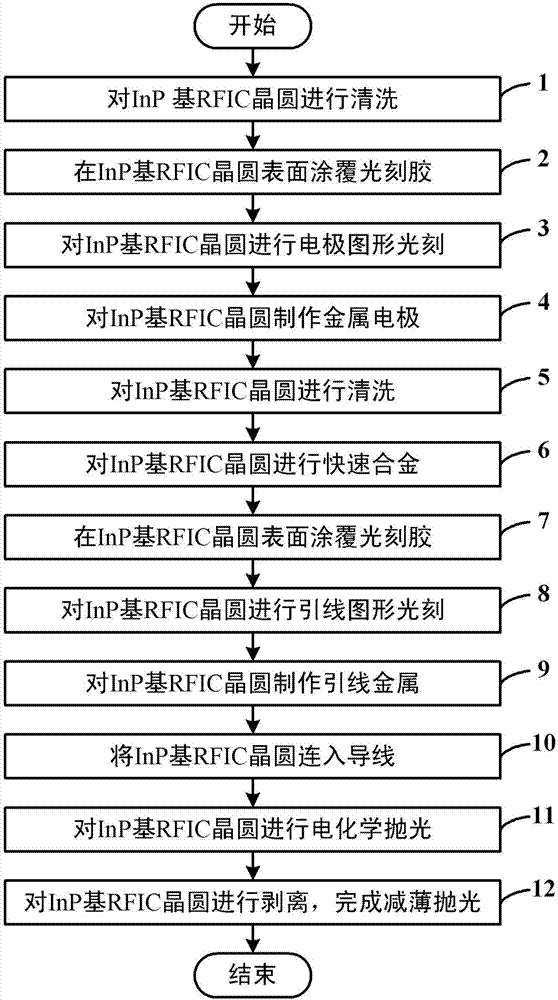

[0034] Such as figure 1 Shown, the method that the InP base RFIC wafer provided by the present invention is carried out electrochemically thins and polishes, comprises the following steps:

[0035] Step 1: cleaning the InP-based RFIC wafer;

[0036] In this step, the InP-based RFIC wafer is immersed in deionized water for ultrasonic cleaning for 20 minutes, and then taken out with hot N 2 blow dry;

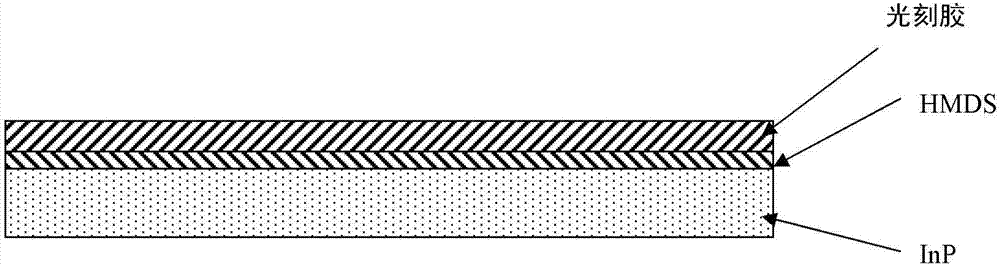

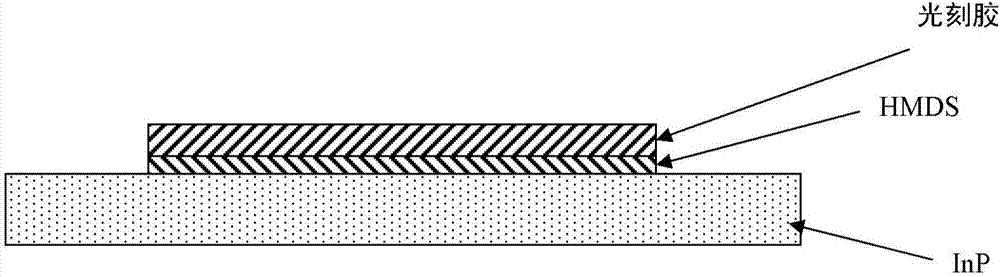

[0037] Step 2: Coating photoresist on the surface of the InP-based RFIC wafer;

[0038] In this step, first spray HMDS on the surface of the InP-based RFIC wafer, bake it in a vacuum oven at 180°C for 10 minutes, then apply S9920 photoresist with a thickness of 3 μm, and then bake it on a hot plate at 100°C for 100 seconds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com