Nano stone surface treating agent and preparation method thereof

A surface treatment agent and stone technology, applied in the direction of coating, etc., can solve the problems of poor film strength and inability to effectively maintain the mirror surface for a long time, and achieve the effects of improving gloss, facilitating industrial production, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

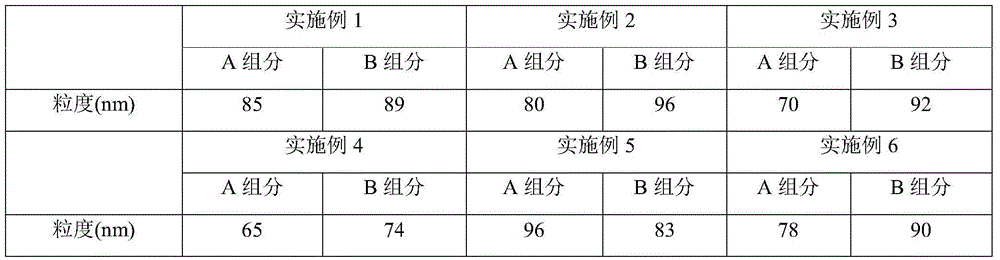

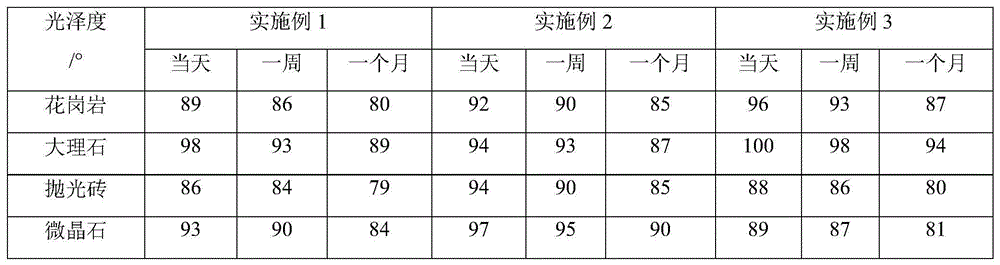

Examples

Embodiment 1

[0026] A nano-stone surface treatment agent, which is composed of A component and B component, and the A component includes the following raw materials: 5g 5wt% sodium oxalate solution, 15g 5wt% sodium fluorosilicate solution, 30g 30wt% AcronalDS-6266ap pure acrylic emulsion and 20g water; The B component includes the following raw materials: 15g 15wt% BR-116 acrylic resin isopropanol solution, 5g microcrystalline wax (weight average molecular weight Mw=500), 15g isopropyl alcohol.

[0027] The preparation method of above-mentioned nanometer stone material surface treatment agent, comprises the steps:

[0028] (1) Preparation of component A: Mix 5g of 5wt% sodium oxalate solution and 15g of 5wt% sodium fluorosilicate solution and heat up to 40°C, add 30g of 30wt% AcronalDS-6266ap pure acrylic emulsion and 20g of water and stir for 30min , to obtain 70g of component A;

[0029] (2) Preparation of component B: warm up 15g of 15wt% BR-116 acrylic resin isopropanol solution to 6...

Embodiment 2

[0032] A nano-stone surface treatment agent, which is composed of A component and B component, and the A component includes the following raw materials: 10g 10wt% sodium oxalate solution, 25g 10wt% sodium fluorosilicate solution, 45g 50wt% BA-201 pure acrylic emulsion and 45g water; The B component includes the following raw materials: 25g 20wt% DM-810 acrylic resin isopropanol solution, 10g microcrystalline wax (weight average molecular weight Mw=1000), 30g ethyl acetate ester.

[0033] The preparation method of above-mentioned nanometer stone material surface treatment agent, comprises the steps:

[0034] (1) Preparation of component A: Mix 10g of 10wt% sodium oxalate solution and 25g of 10wt% sodium fluorosilicate solution and heat up to 50°C, add 45g of 50wt% BA-201 pure acrylic emulsion and 45g of water and stir for 15 minutes , to obtain 125g of component A;

[0035] (2) Preparation of component B: heat up 25g of 20wt% DM-810 acrylic resin isopropanol solution to 80°C,...

Embodiment 3

[0038] A nano-stone surface treatment agent, which is composed of A component and B component, and the A component includes the following raw materials: 10g 10wt% potassium oxalate solution, 5g 10wt% magnesium fluorosilicate solution, 10g 10wt% Sodium fluorosilicate solution, 10g 10wt% aluminum fluorosilicate solution, 45g 50wt% AcronalDS-6266ap pure acrylic emulsion and 45g water; the B component includes the following raw materials: 25g 20wt% DM-810 acrylic resin isopropanol Solution, 10g polyethylene wax (weight average molecular weight Mw=2000), 10g ethyl acetate, 10g isopropanol, 10g butyl acetate.

[0039] The preparation method of above-mentioned nanometer stone material surface treatment agent, comprises the steps:

[0040](1) Preparation of component A: Mix 10g 10wt% potassium oxalate solution, 5g 10wt% magnesium fluorosilicate solution, 10g 10wt% sodium fluorosilicate solution, 10g 10wt% aluminum fluorosilicate solution and heat up to 50°C , add 45g of 50wt% Acronal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com