Light-transmitting brick and preparation method thereof

A technology of light-transmitting bricks and raw materials, applied in the field of ceramics, can solve the problems of unsatisfactory transparency, visual changes, low firing rate of finished products, and lack of light transmission, etc., to achieve strong plasticity, high yield, and light transmittance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

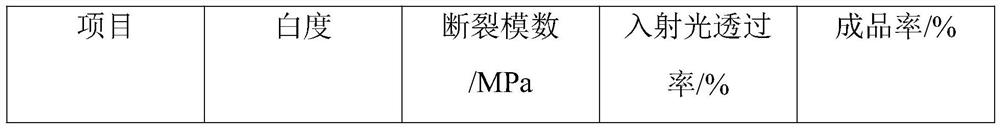

Examples

preparation example Construction

[0058] The preparation method of the light-transmitting brick comprises:

[0059] The raw material is ball milled to obtain a blank, and then the blank is pressed to obtain an adobe;

[0060] The adobe is sent to a kiln for firing after pretreatment, and then the product is obtained through posttreatment.

[0061] Preferably, before carrying out described ball milling, also include:

[0062] Stir-frying after mixing the raw materials, and then rapidly cooling;

[0063] The frying temperature is 200-400°C, and the rapid cooling refers to reducing the frying material to 20-25°C within 1-2 minutes;

[0064] Preferably, the particle size of the blank is less than or equal to 250 mesh.

[0065] The purpose of frying and rapid cooling is to enhance the plasticity of raw materials and reduce the deformation rate of later high-temperature firing.

[0066] Optionally, the frying temperature may be any value between 200°C, 250°C, 300°C, 350°C, 400°C and 200-400°C.

[0067] Preferab...

Embodiment 1

[0079] Prepare ingredients:

[0080] 5kg of quartz, 10kg of kaolin, 25kg of feldspar, 6kg of burnt talc, 4kg of pyrophyllite, 15kg of terrazzo nepheline, 5kg of low-temperature sand, 25kg of frit and 5kg of bone meal.

[0081] Wherein, the mass ratio of potassium feldspar and albite in feldspar is 1:1.

[0082] It should be noted that the chemical composition of the frit used in this embodiment includes: 58% silicon dioxide, 15% aluminum oxide, 0.2% iron oxide, 25% calcium oxide, 0.9% magnesium oxide, and 0.1% potassium oxide. %, sodium oxide 0.1% and a small amount of impurities.

[0083] Add water to the above raw materials, pass through a 250-mesh sieve to obtain a blank, and then press the blank under the condition of 100MPa to obtain a brick; grind the brick, inkjet and glaze, then send it to a kiln for firing, and then polish it to obtain a product; The firing includes the first firing, the second firing and the third firing; the temperature of the first firing is 300°...

Embodiment 2

[0086] Prepare ingredients:

[0087] 6kg of quartz, 12kg of kaolin, 21kg of feldspar, 7kg of burnt talc, 1kg of pyrophyllite, 17kg of terrazzo nepheline, 7kg of low-temperature sand, 28kg of frit and 1kg of bone meal.

[0088] Wherein, the mass ratio of potassium feldspar and albite in feldspar is 1:2.

[0089] It should be noted that the chemical composition of the medium-temperature frit used in this example includes: 59.44% silicon dioxide, 14.23% aluminum oxide, 0.45% iron oxide, 23.56% calcium oxide, 1.07% magnesium oxide, potassium oxide 0.46%, sodium oxide 0.31% and a small amount of impurities.

[0090] After mixing the raw materials, fry them at 200°C, and then lower the fried materials to 20°C within 1 minute. Add water to the above-mentioned fried raw materials, pass through a 250-mesh sieve after ball milling to obtain a blank, and then press the blank under the condition of 150MPa to obtain a brick; after the brick is ground, inkjet and glazed, it is sent into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com