Micro water grinding head for edge grinding machine

An edger and water mill technology, which is applied to the parts of grinding machine tools, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problems of low edge grinding efficiency, large heat generation of grinding wheels, and large consumption of grinding wheels, etc. Achieve the effect of high edging efficiency, good edging quality and slow grinding wheel wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

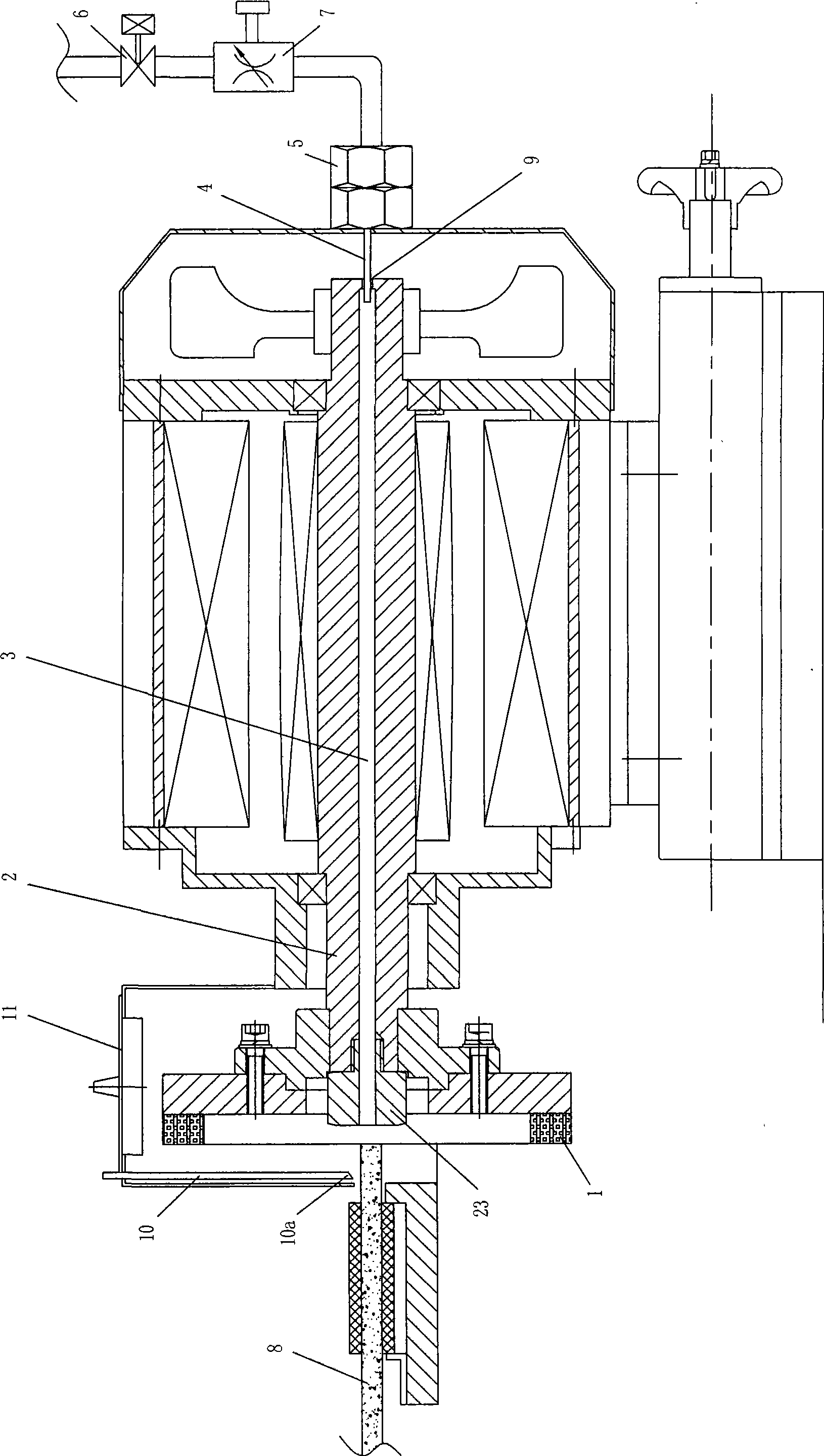

[0010] see figure 1 The micro-water edging head of the edging machine includes a grinding wheel 1 and a rotating shaft 2 that drives the grinding wheel 1 to rotate, and the grinding wheel 1 is fixed on one end of the rotating shaft 2 . As the best implementation mode, the rotating shaft 2 of this embodiment is the motor shaft, which makes the overall structure the simplest and most compact. The rotating shaft 2 is connected with a water supplier 4 . A water delivery channel 3 connected to the water supply is opened in the rotating shaft 2, and the water delivery channel 3 runs through to one end of the fixed grinding wheel of the rotating shaft. The water supply device of this embodiment is a water delivery pipe 4 inserted into the water delivery channel 3, and the water delivery pipe 4 is inserted from the end face of the rotating shaft 2 without a fixed grinding wheel. The water pipe 4 is fixed on the motor housing by a nut 5 . In order to facilitate the control of the wa...

Embodiment 2

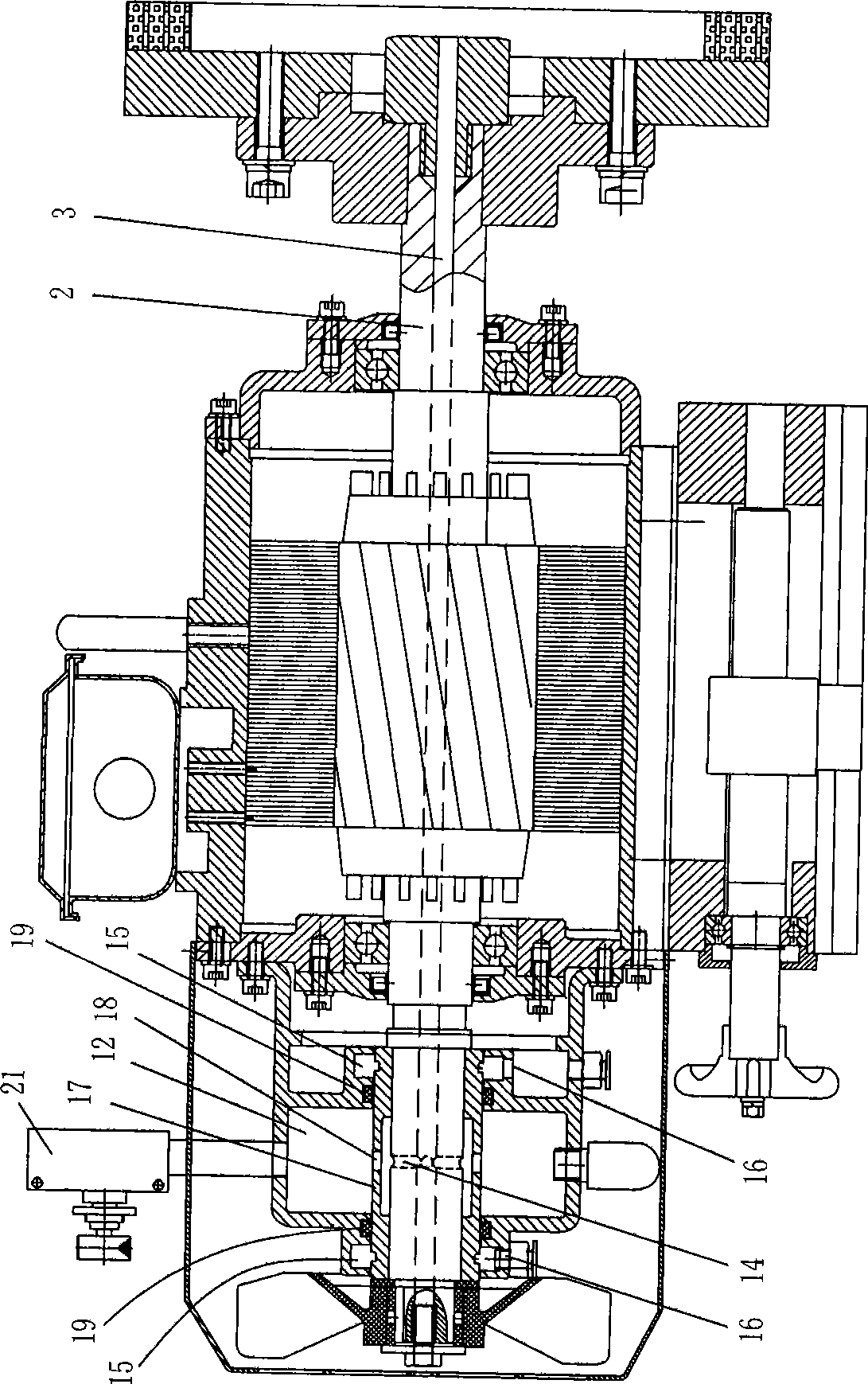

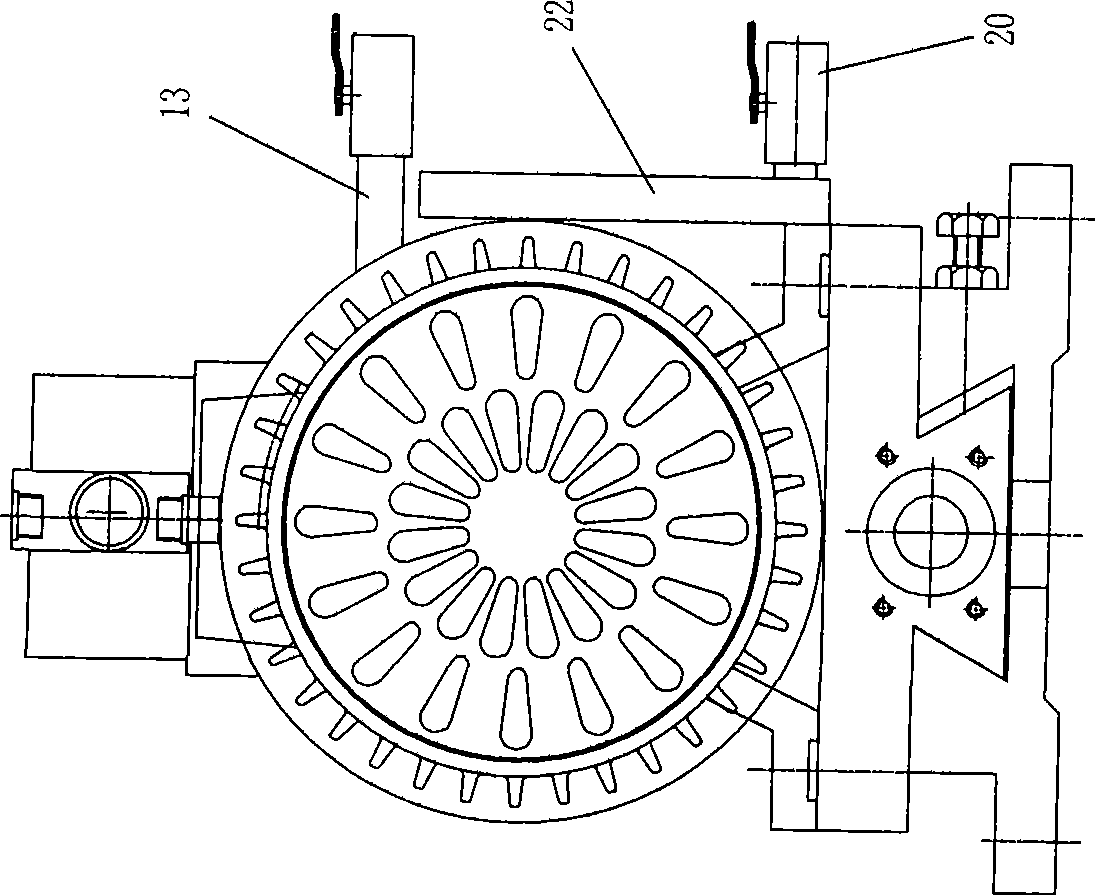

[0012] see figure 2 , image 3 , The difference between this embodiment and Embodiment 1 lies in the structure of the water supply device to which the rotating shaft 2 is connected. The water supplier in this embodiment is a fixed water storage chamber 12 that is rotatably coupled with the rotating shaft 2 , and the water storage chamber is connected with a water inlet pipe 13 . A radial through hole 14 is opened in the rotating shaft, and the through hole 14 communicates the water delivery channel 3 with the water storage chamber 12 . The cooling water delivered by the external water source first enters the water storage chamber 12 from the water inlet pipe 13, then enters the water delivery channel 3 from the water storage chamber 12, and finally flows out from the end surface of the rotating shaft.

[0013] In order to prevent the water in the water storage chamber 12 from leaking out so as to affect the safe operation of other parts (such as motors) in the edging machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com