Grinding process for bamboo ware and bamboo strip

A technology of bamboo products and bamboo strips, which is applied in the direction of manufacturing tools, grinding/polishing equipment, grinding machines, etc., can solve the problems of unfavorable environmental protection, easy breakage and deformation, waste of resources, etc., to improve processing utilization, not easy to break and deform, and save energy The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

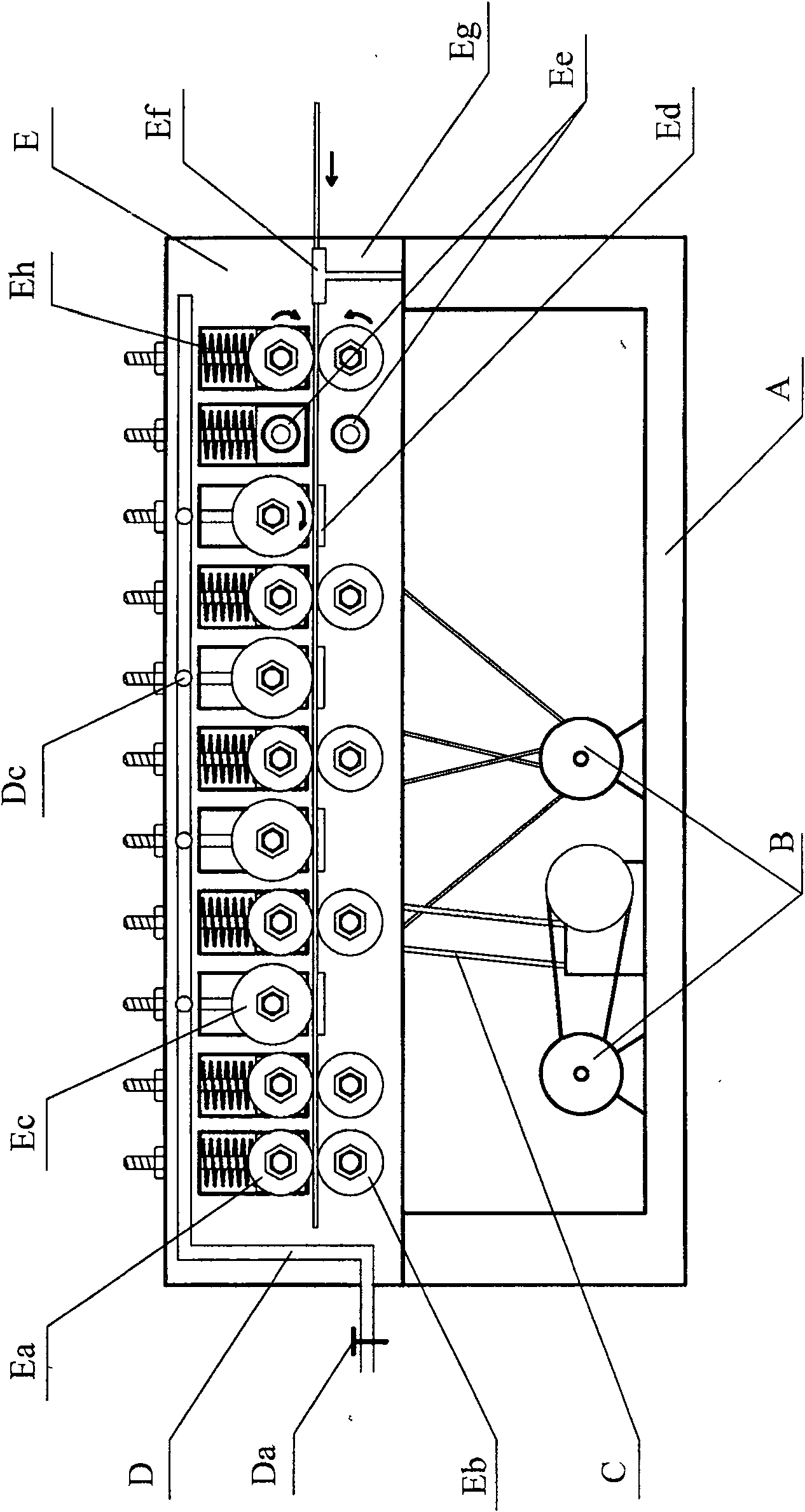

Image

Examples

Embodiment 1

[0020] A kind of grinding technique of bamboo product bamboo strip, the processing method that it adopts comprises following several steps successively:

[0021] (1) Fragmentation is carried out after bamboo is cut off as required, and bamboo chips are obtained after removing bamboo joints;

[0022] (2) the bamboo slices are further subdivided, and the bamboo green bamboo slices are separated from the bamboo yellow bamboo slices;

[0023] (3) Put the green bamboo slices obtained into water and cook for 20 minutes, the cooking temperature is 100°C;

[0024] (4) pick up the cooked bamboo slices and put them into a cold water pool to clean with clear water until cooling;

[0025] (5) drawing the cooled bamboo chips to obtain bamboo strips;

[0026] (6) bamboo strips are put into a water mill for water milling, the bamboo strip epidermis is worn off, and cleaned;

[0027] (7) get the bamboo strips after the water mill cleaning, and carry out bleaching process;

[0028] (8) Put...

Embodiment 2

[0032] A kind of grinding technique of bamboo product bamboo strip, the processing method that it adopts comprises following several steps successively:

[0033] (1) Fragmentation is carried out after bamboo is cut off as required, and bamboo chips are obtained after removing bamboo joints;

[0034] (2) the bamboo slices are further subdivided, and the bamboo green bamboo slices are separated from the bamboo yellow bamboo slices;

[0035] (3) Put the green bamboo slices obtained into water and cook for 15 minutes, and the cooking temperature is 110°C;

[0036] (4) pick up the cooked bamboo slices and put them into a cold water pool to clean with clear water until cooling;

[0037] (5) drawing the cooled bamboo chips to obtain bamboo strips;

[0038] (6) bamboo strips are put into a water mill for water milling, the bamboo strip epidermis is worn off, and cleaned;

[0039] (7) get the bamboo strips after the water mill cleaning, and carry out bleaching process;

[0040] (8)...

Embodiment 3

[0043] A kind of grinding technique of bamboo product bamboo strip, the processing method that it adopts comprises following several steps successively:

[0044] (1) Fragmentation is carried out after bamboo is cut off as required, and bamboo chips are obtained after removing bamboo joints;

[0045] (2) the bamboo slices are further subdivided, and the bamboo green bamboo slices are separated from the bamboo yellow bamboo slices;

[0046] (3) Put the obtained green bamboo slices into water and cook for 30 minutes, and the cooking temperature is 80°C;

[0047] (4) pick up the cooked bamboo slices and put them into a cold water pool to clean with clear water until cooling;

[0048] (5) drawing the cooled bamboo chips to obtain bamboo strips;

[0049] (6) bamboo strips are put into a water mill for water milling, the bamboo strip epidermis is worn off, and cleaned;

[0050] (7) get the bamboo strips after the water mill cleaning, and carry out bleaching process;

[0051] (8) Pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com