Capacitive acceleration detector intermediate movable electrode

A technology of acceleration and geophones, which is applied in the field of capacitive acceleration geophones, can solve the problems of affecting the strength of support beams, easily forming stress concentration, and poor consistency of capacitance, so as to achieve good capacitance consistency, not easy to deform and break, and not Easy stress concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

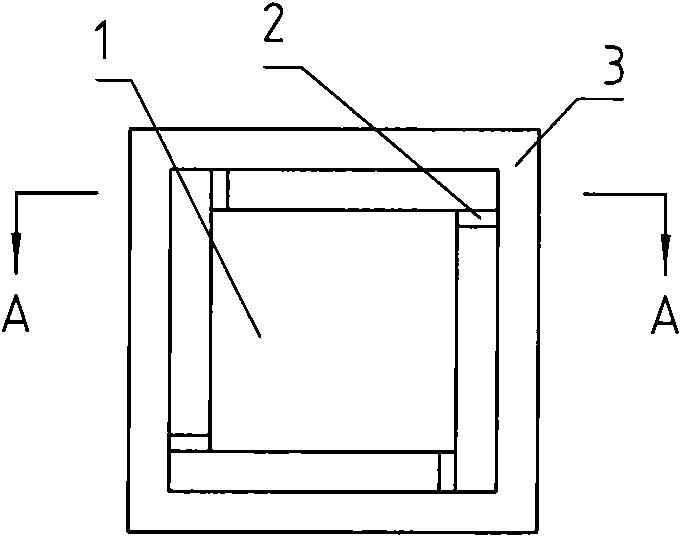

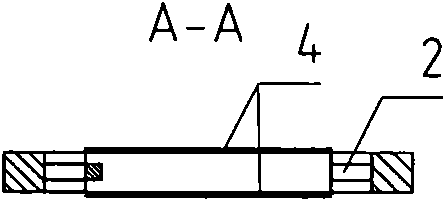

[0025] Such as figure 1 , figure 2 The movable electrode in the middle of the capacitive acceleration detector is provided with a mass block 1, and a support beam 2 is uniformly distributed on the mass block 1, and the support beam 2 is connected to the inner side of the frame 3. 2 is a straight support beam. The support beam 2 is located at the corner of the mass block 1 and is perpendicular to the mass block 1 and the frame 3. The manufacturing process is simple and the cost is low. It is not easy to form stress concentration during the manufacturing process, and it is not easy to cause deformation and fracture. Good consistency, low noise, stable performance, and low waveform distortion.

Embodiment 2

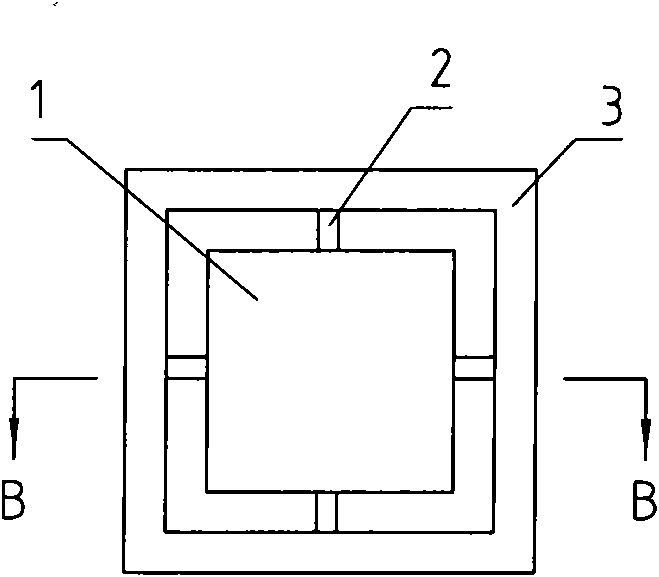

[0027] Such as image 3 , Figure 4 The movable electrode in the middle of the capacitive acceleration detector is provided with a mass block 1, and a support beam 2 is uniformly distributed on the mass block 1, and the support beam 2 is connected to the inner side of the frame 3. 2 is a straight support beam, the support beam 2 is located in the middle of the side of the mass block 1, perpendicular to the inner side of the mass block 1 and the frame 3, the manufacturing process is simple, the cost is low, and it is not easy to form stress concentration during the manufacturing process, and it is not easy to cause deformation and fracture. Capacitance consistency is good, noise is small, performance is stable, and waveform distortion is small.

Embodiment 3

[0029] Such as Figure 5 , Figure 6 The movable electrode in the middle of the capacitive acceleration detector is provided with a mass block 1, and a support beam 2 is uniformly distributed on the mass block 1, and the support beam 2 is connected to the inner side of the frame 3. 2 is a straight support beam. The support beam 2 is located on the sharp corner of the mass block 1 and the inner corner of the frame 3. The manufacturing process is simple and the cost is low. It is not easy to form stress concentration during the manufacturing process, and it is not easy to cause deformation and fracture. The capacitance consistency is good. Low noise, stable performance, and small waveform distortion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com