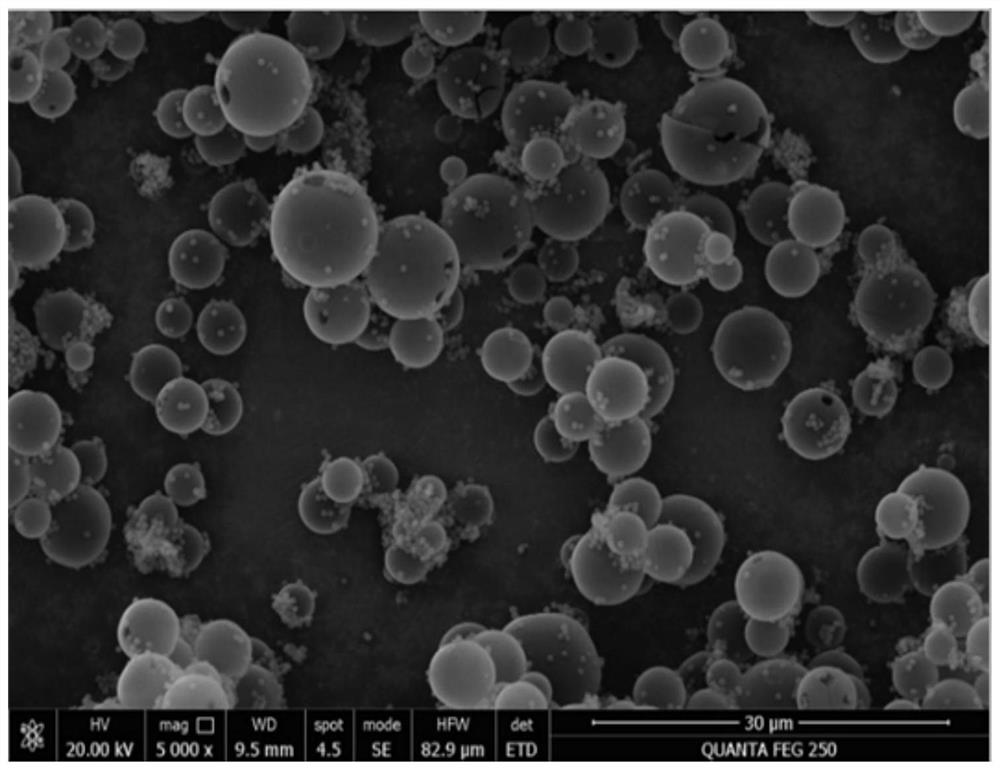

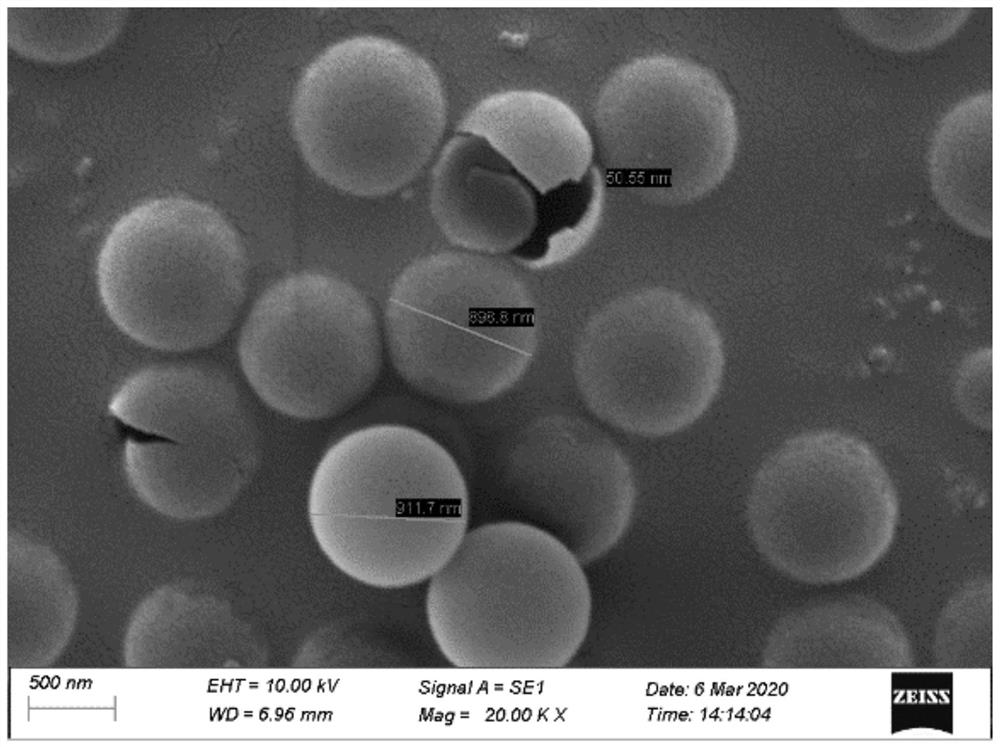

Preparation method of low-dielectric hollow silicon dioxide microspheres

A hollow silica, low dielectric technology, applied in the field of non-metallic materials, can solve the problems of many influencing factors, complicated structure control, difficult to obtain particle size, etc., to reduce energy consumption, not easily deformed and cracked, and the surface dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1.1, 1.5g polyvinylpyrrolidone, 45g ethanol, 5g distilled water, 15g styrene, 0.29g initiator azobisisobutyronitrile were dissolved for 10min and then loaded into a 250mL three-necked flask (including nitrogen inlet, stirring paddle inlet and condensation mouth), stirred at room temperature to form a homogeneous solution;

[0042] Step 1.2, deoxidize the homogeneous solution by bubbling nitrogen gas at room temperature for 30 minutes, then heat to 70°C and continue stirring for 24 hours to obtain a polystyrene sphere dispersion;

[0043] In step 1.3, add 10 g of methyltrimethoxysilane to 50 ml of water and mix evenly, then add hydrochloric acid after heating up to 35°C, adjust the pH to 3, and continue stirring for 3 hours to obtain the hydrolyzed solution of the organosilane precursor;

[0044] Step 1.4, add 2g of cetyltrimethylammonium bromide (CTAB) and 3ml of ammonia water to the polystyrene sphere dispersion obtained in step 1.2, stir for 6min, add the organos...

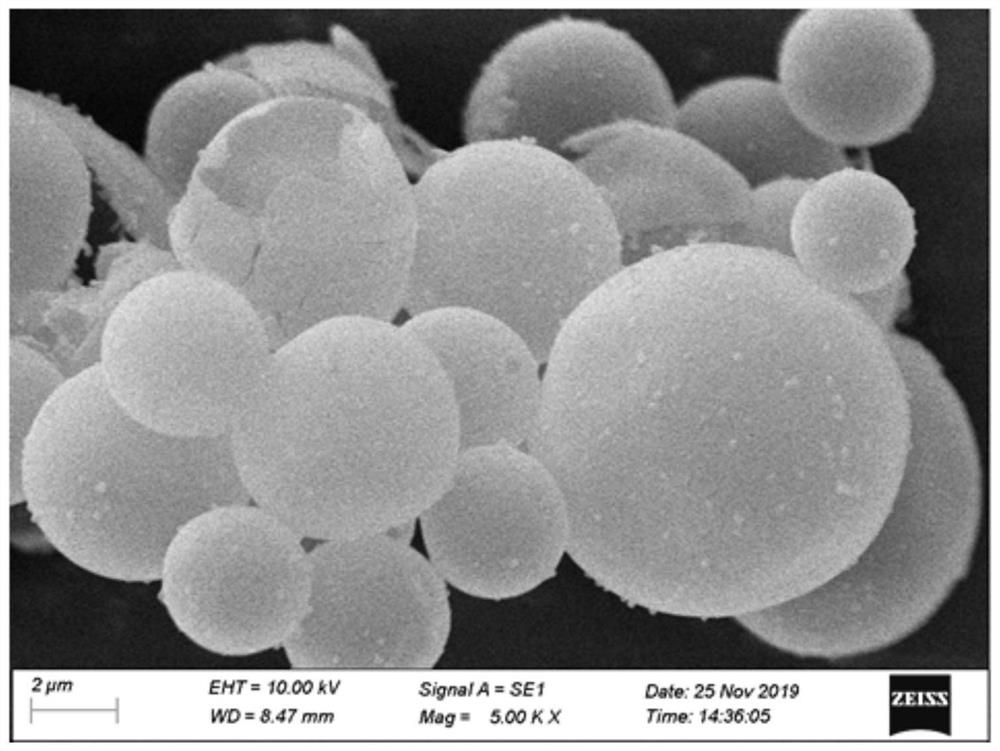

Embodiment 2

[0048] Step 2.1, after ultrasonically dissolving 1.5g polyvinylpyrrolidone, 45g ethanol, 5g distilled water, 15g styrene, 0.29g initiator azobisisobutyronitrile and cationic comonomer acryloxyethyltrimethylammonium chloride for 10min Pack into a 250 mL three-necked flask (including nitrogen inlet, stirring paddle inlet and condensation outlet), and stir at room temperature to form a homogeneous solution;

[0049] Step 2.2, deoxidize the homogeneous solution by bubbling nitrogen gas at room temperature for 30 minutes, then heat to 70°C and continue stirring for 24 hours to obtain a positively charged polystyrene sphere dispersion;

[0050] In step 2.3, add 5 g of methyltrimethoxysilane to 50 ml of water and mix evenly. After heating up to 35° C., add hydrochloric acid, adjust the pH to 3, and continue stirring for 3 hours to obtain the hydrolyzed solution of the organosilane precursor;

[0051] Step 2.4, add 3ml of ammonia water to the polystyrene sphere dispersion obtained in ...

Embodiment 3

[0055] Step 3.1, 1.5g polyvinylpyrrolidone, 45g ethanol, 5g distilled water, 15g styrene, 0.29g initiator azobisisobutyronitrile and cationic comonomer acryloxyethyltrimethylammonium chloride were ultrasonically dissolved for 10min Pack into a 250 mL three-necked flask (including nitrogen inlet, stirring paddle inlet and condensation outlet), and stir at room temperature to form a homogeneous solution;

[0056] Step 3.2, deoxidize the homogeneous solution by bubbling nitrogen gas at room temperature for 30 minutes, then heat to 70°C and continue stirring for 24 hours to obtain a positively charged polystyrene sphere dispersion;

[0057] In step 3.3, add 8 g of methyltrimethoxysilane to 50 ml of water and mix evenly, then add hydrochloric acid after heating up to 35° C., adjust the pH to 3, and continue stirring for 3 hours to obtain the hydrolyzed liquid of the organosilane precursor;

[0058] Step 3.4, add 3ml of ammonia water to the polystyrene sphere dispersion obtained in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com