Production process and device for large-length copper-based amorphous alloy contact line for high speed railway

A copper-based amorphous alloy, high-speed railway technology, used in metal/alloy conductors, circuits, conductors, etc. It can reduce the single shear band structure, realize cooling and continuous production, and improve the solidification structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

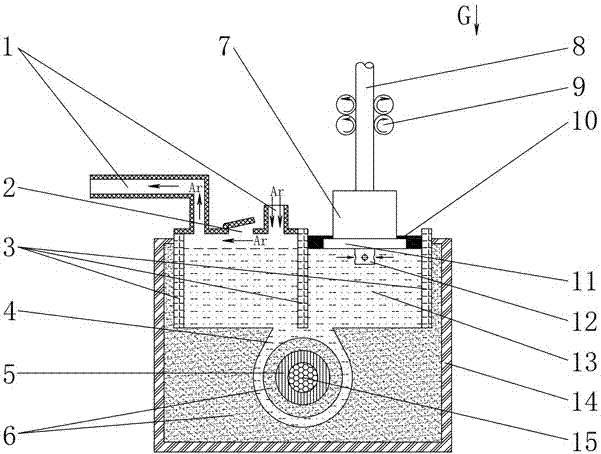

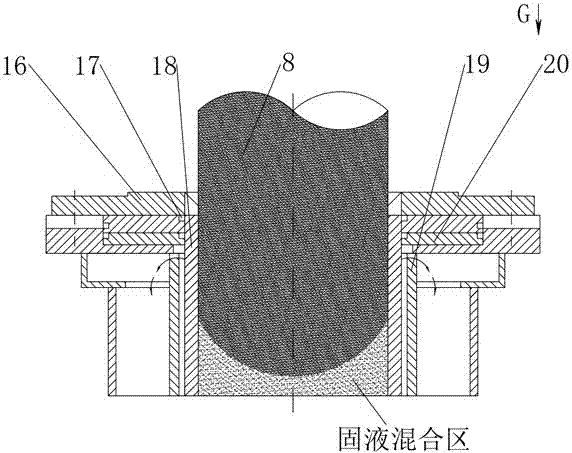

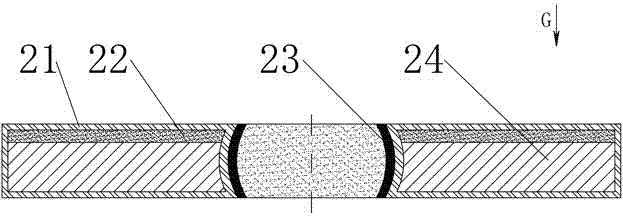

[0067] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0068] The production process of the large-length copper-based amorphous alloy contact wire for high-speed railways in this embodiment includes the following process steps:

[0069] Step 1: Melting in a non-vacuum semi-closed single-melting ditch double-body electromagnetic melting furnace protected by an Ar gas atmosphere.

[0070] Put standard cathode copper, pure silver, Cu-Zr master alloy and Al-Zr master alloy respectively into the smelting furnace in order of proportion to smelt the copper alloy.

[0071] The Ar gas atmosphere protects the non-vacuum semi-closed single-melting ditch double-body induction furnace smelting device such as figure 1 As shown, it includes the first furnace body (smelting area), the second furnace body (upward casting area), double-body furnace liner and partition wall 3, melting ditch 4, water cooling jacket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com