Flower-shaped milling cutter for wood door production

A flower-shaped and milling cutter technology, which is applied in wood processing equipment, rotary cutting tools, manufacturing tools, etc., can solve the problems of low work efficiency and processing accuracy, cannot meet new process requirements, and cannot achieve mass production, etc., and achieves a simple structure , Avoid heat accumulation, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

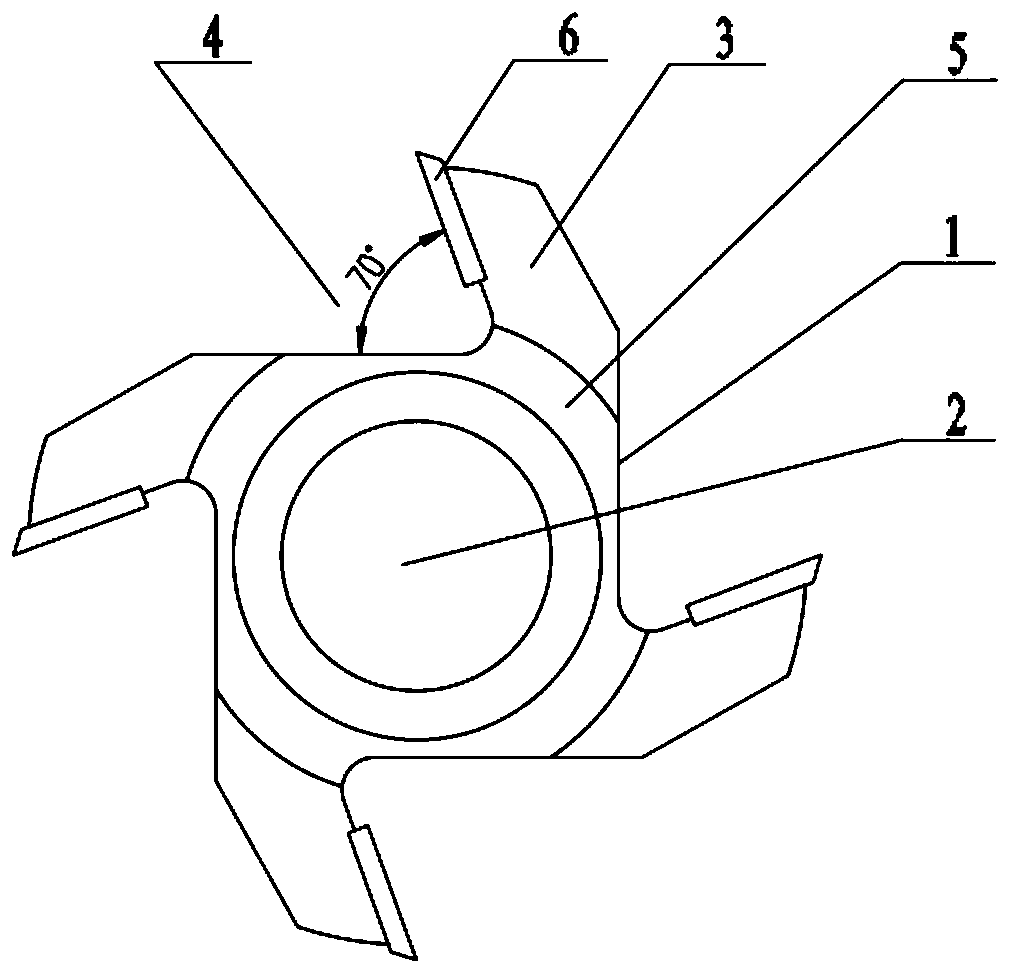

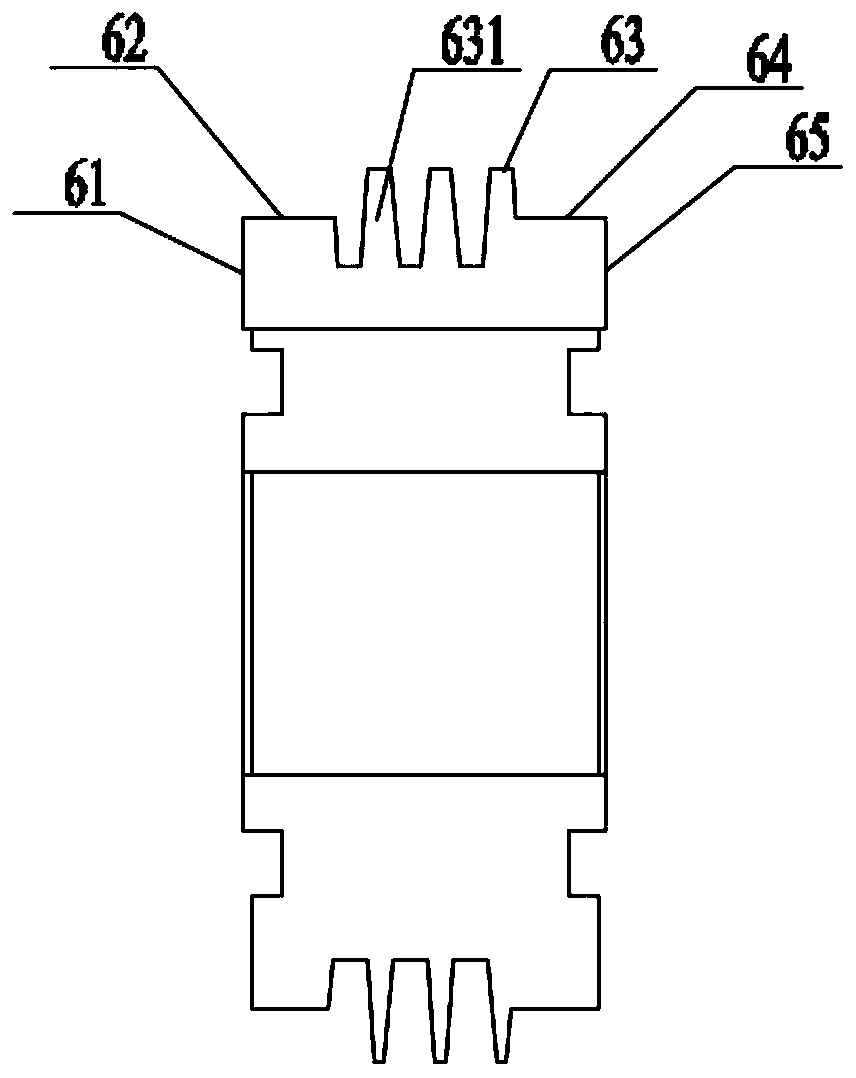

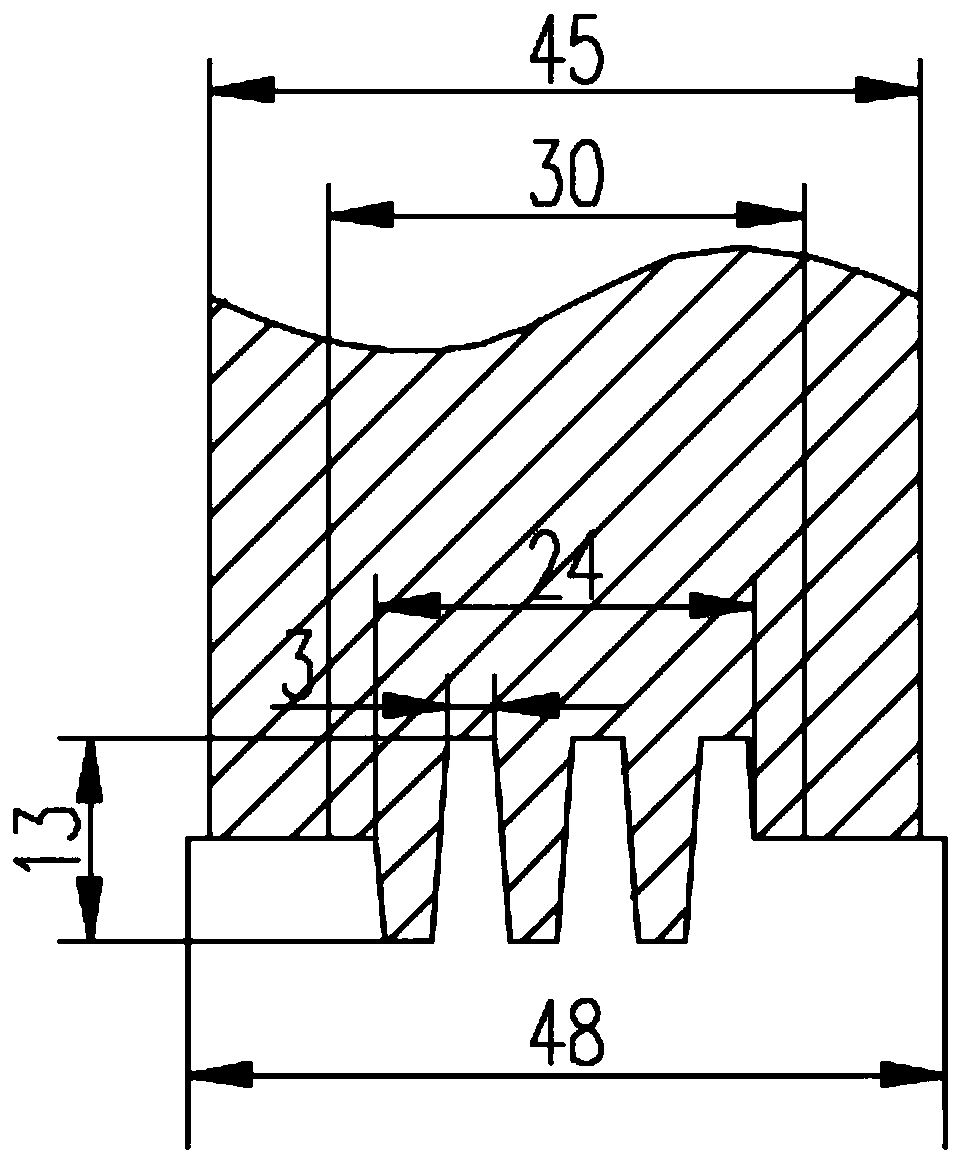

[0026] Such as Figure 1 to Figure 3 As shown, a flower-shaped milling cutter for wooden door production according to the present invention includes a cutter body 1, which is in a windmill-like shape. The center of the cutter body 1 is provided with a central installation through hole 2. A plurality of cutter heads 3 are evenly arranged, and a heat dissipation and chip removal cavity 4 is arranged between adjacent cutter heads 3, and an annular groove 5 is arranged between the cutter head 3 and the central installation through hole 2; the end of the cutter head 3 is provided with There is a blade 6, and the blade 6 includes a first vertical end blade 61 arranged in sequence from left to right, a first horizontal blade 62, a sunken serrated blade 63, a second horizontal blade 64 and a second vertical end Blade 65, the sunken serrated blade 63 includes several trapezoidal raised blades 631 equidistantly arranged, the first horizontal blade 62 and the second horizontal blade 64 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com