Patents

Literature

73results about How to "Improve grinding force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Abrasive grain, abrasive articles, and methods of making and using the same

Owner:3M INNOVATIVE PROPERTIES CO

Abrasive grain, abrasive articles, and methods of making and using the same

InactiveUS6287353B1Easy accessImprove grinding efficiencyPigmenting treatmentOther chemical processesComposite materialCeramic materials

Owner:3M INNOVATIVE PROPERTIES CO

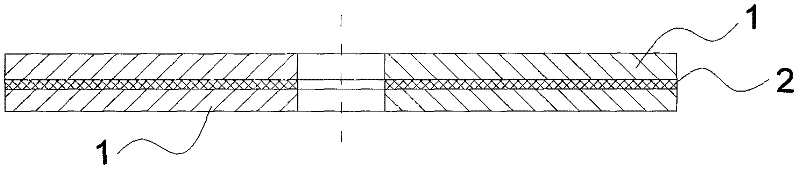

Resin grinding wheel and manufacturing method thereof

ActiveCN102363287AStrong grinding forceImprove grinding forceAbrasion apparatusGrinding devicesPyriteEngineering

The invention provides a resin grinding wheel and a manufacturing method thereof, which belong to the field of grinding tools and are used for solving the problem of the production of harmful sulfur dioxide by pyrite serving as a lubricating agent existing in the conventional resin grinding wheel. The resin grinding wheel comprises a grinding body and a reinforcing sheet which is arranged inside the grinding body for enhancing the revolving strength of the grinding body, wherein 90-105 parts by mass of corundum is taken as a grinding material the grinding body; 2-8 parts by mass of phenolic aldehyde resin liquid and 6-25 parts by mass of phenolic aldehyde resin powder are taken as bonding agents; and 1-10 parts by mass of cryolite and 1-5 parts by mass of polytetrafluoroethylene powder are taken as fillers. The invention further provides a manufacturing method of the resin grinding wheel. In the grinding wheel, the polytetrafluoroethylene powder instead of pyrite is taken as a lubricating agent, so that sulfur dioxide is not produced and other pollution is avoided in the using process.

Owner:NINGBO DAHUA GRINDING WHEEL

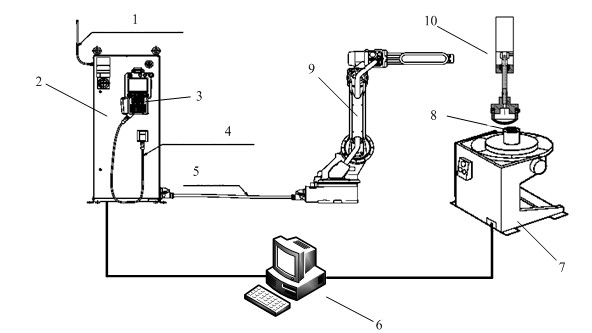

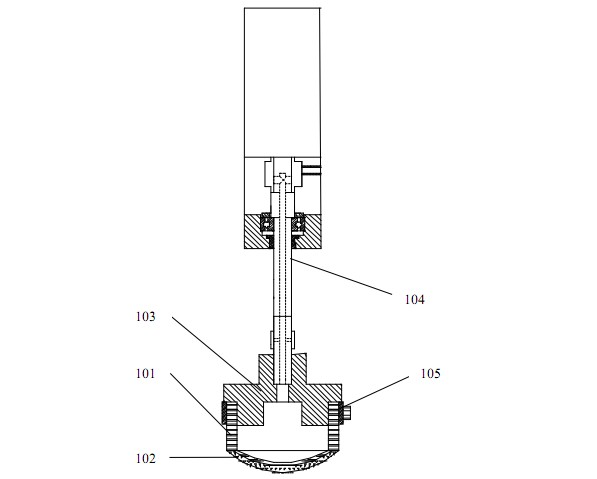

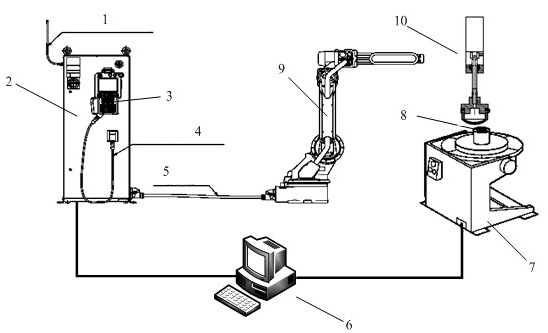

Pneumatic grinding wheel-based robot finish-machining system

InactiveCN102179746AImprove efficiency and effectivenessImprove efficiencyProgramme-controlled manipulatorGrinding machinesAutomatic controlEngineering

The invention discloses a pneumatic grinding wheel-based robot finish-machining system, which comprises a pneumatic grinding wheel finishing tool, wherein the pneumatic grinding wheel finishing tool is arranged above a workbench and in contact with a machined workpiece on the workbench; the pneumatic grinding wheel finishing tool is connected to a robot for controlling movement and rotation of the pneumatic grinding wheel finishing tool; the robot is connected with a robot control cabinet for controlling the motion of the robot, a computer control and processing module for automatically controlling the motion of the robot and a teaching programmer for manually controlling the motion of the robot are connected to the robot control cabinet, and the workbench is connected with the computer control and processing module for controlling the revolution number of the workbench; the pneumatic grinding wheel finishing tool comprises a first module, the first module comprises a rubber air bag and a grinding material stuck onto the rubber air bag, and the rubber air bag is arranged on an air bag retainer; and the air bag retainer is connected with a rotary main shaft, and the rotary main shaft is connected with a second module for supplying required rotary driving force and air bag pressure to the first module.

Owner:ZHEJIANG UNIV OF TECH

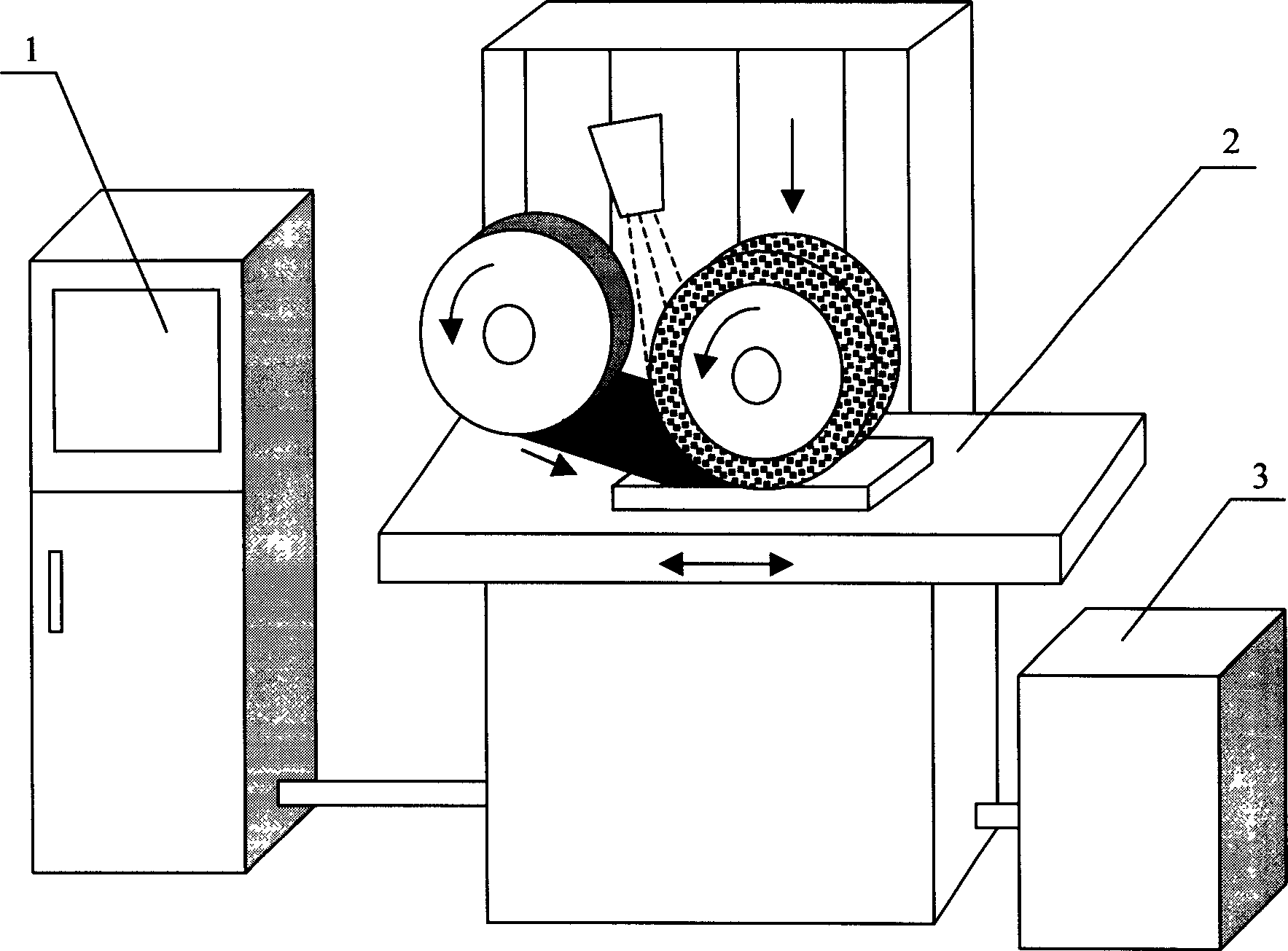

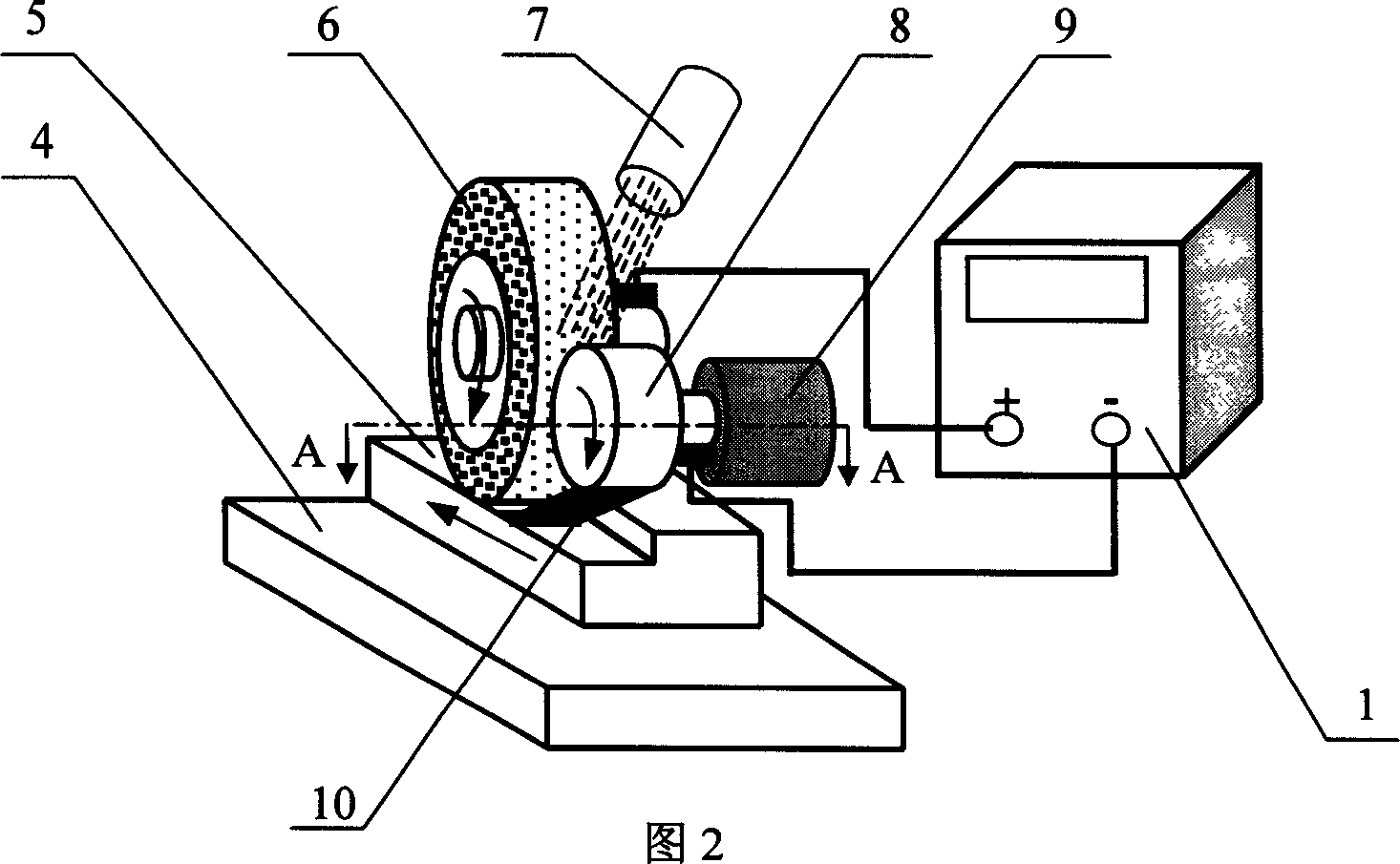

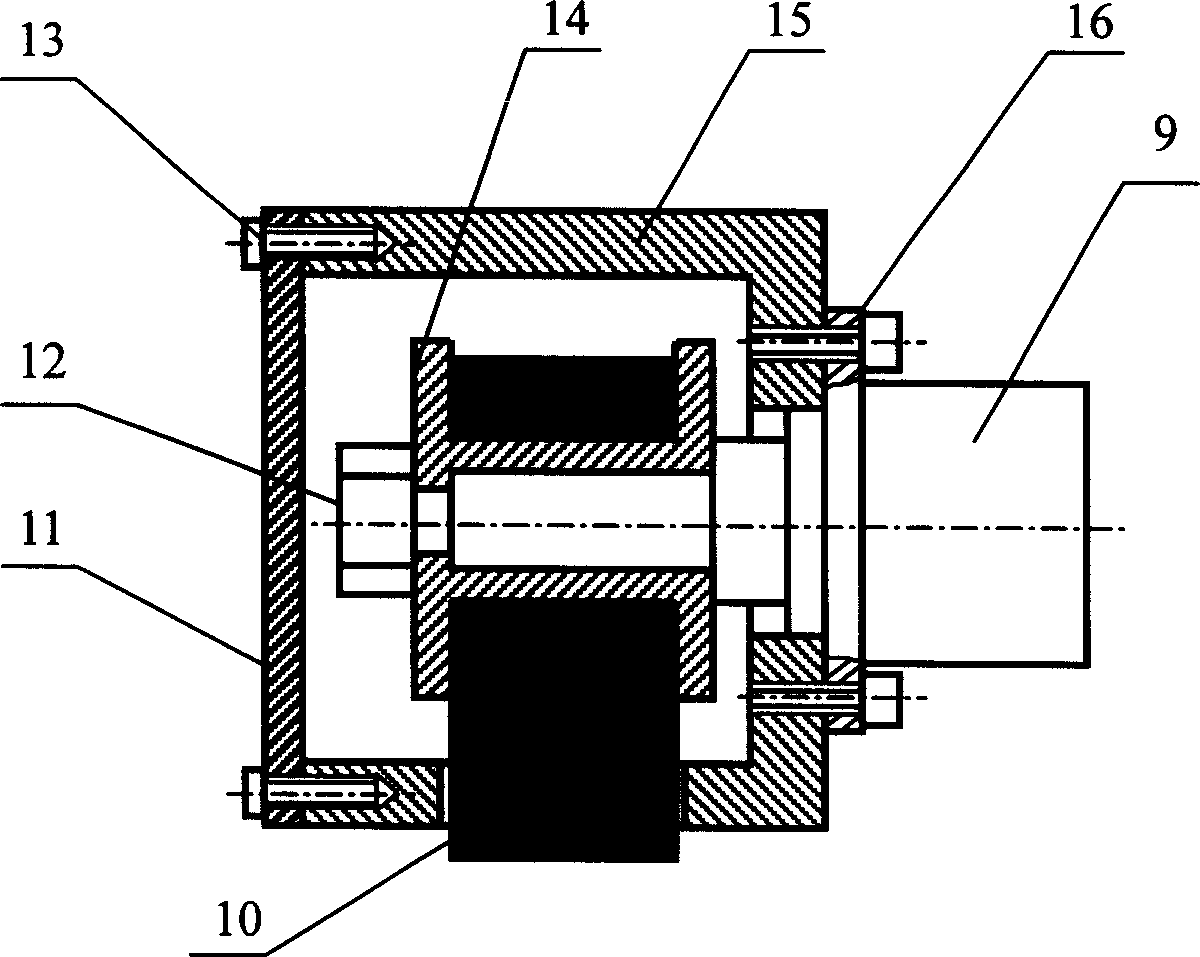

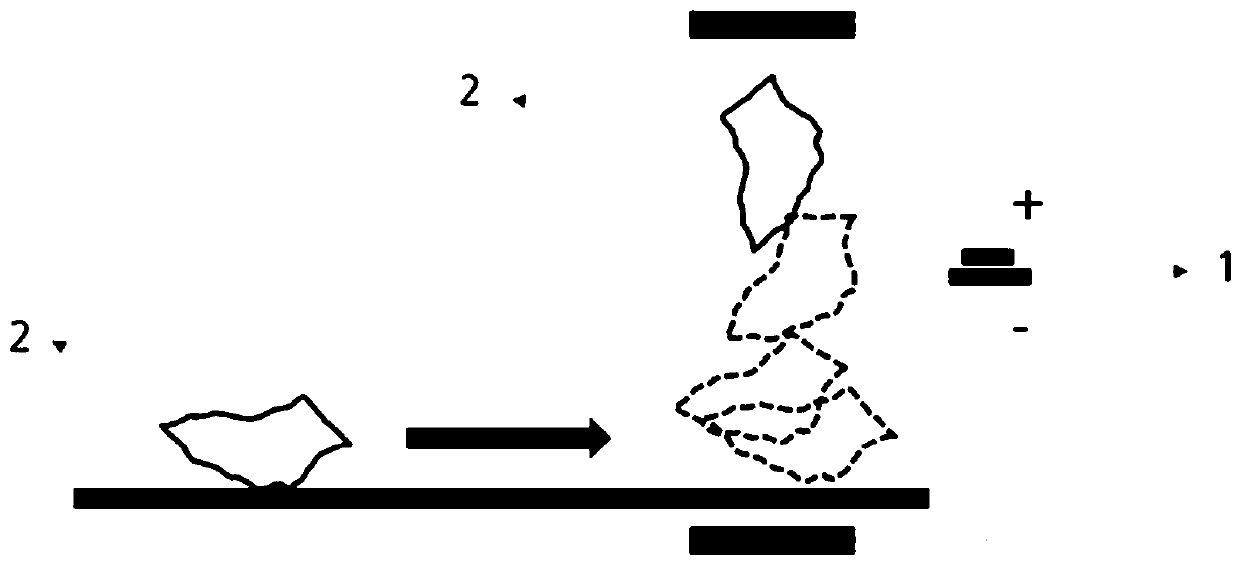

Electric spark mechanical composite grinding method and machine for non-conductive superhard material

ActiveCN1557606AImprove processing efficiencyLow costOther manufacturing equipments/toolsSuperhard materialControl system

The present invention is composite electric spark machine grinding method and machine apparatus for machining non-conductive super-hard material. During the machine, the rotary conducting grinding wheel is used as one electrode for electron spark grinding, electrode sheet feeding along the surface of the workpiece as the other electrode, and the spark discharge in the surface of workpiece between the conducting grinding wheel and the sheet electrode makes the surface of the workpiece of non-conductive super-hard material carbonized and denatured for being eliminated via mechanical grinding. The machine apparatus includes machining unit, pulse power source, control system and liquid supplying system. The sheet for machining is wound onto a barrel, which is driven by a DC motor for servo motion. The present invention has high machining efficiency on non-conductive super-hard material, high surface quality and low machining cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

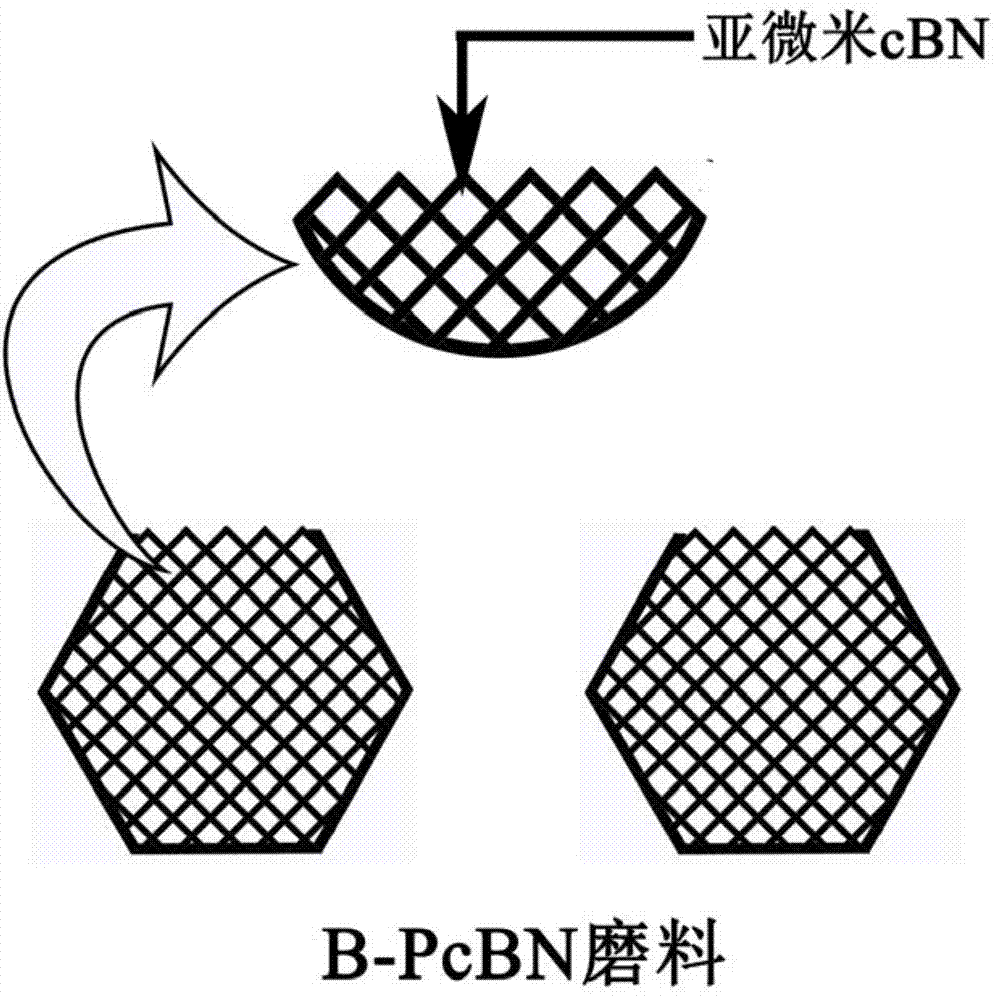

Binder-free polycrystalline cubic boron nitride abrasive and preparation method thereof

ActiveCN104774591ARestricted useLimited lifeNitrogen compoundsOther chemical processesHexagonal boron nitrideSingle crystal

The invention discloses a binder-free polycrystalline cubic boron nitride abrasive and a preparation method thereof. The preparation method of the abrasive comprises the following steps: 1, adding hexagonal boron nitride powder into a die, and carrying out molding preformation; 2, carrying out cold isostatic pressing treatment on the above preformed product under vacuum conditions; 3, adding the above obtained hexagonal boron nitride block into a tantalum cup in order to form an assembled block together with a pressure transmitting medium; and 4, carrying out high temperature high pressure synthesis treatment on the assembled block, carrying out furnace cooling, demolding, crushing, and grading to prepare the abrasive. The binder-free polycrystalline cubic boron nitride abrasive has the ultrafine crystal structure of submicron dimension cBN monocrystal, and the micro-fragmentation self-sharpening effect and the isotropy of the binder-free polycrystalline cubic boron nitride abrasive overcome passivation, cleavage, anisotropy and other defects of monocrystalline cBN abrasives; and the binder-free polycrystalline cubic boron nitride abrasive disclosed in the invention has high hardness and strength, is suitable for high precision processing of high hardness quenched steel, especially electrical, electronic and optical devices, has very high social values and economic benefit, and is suitable for popularization and application.

Owner:FUNIK ULTRAHARD MATERIAL

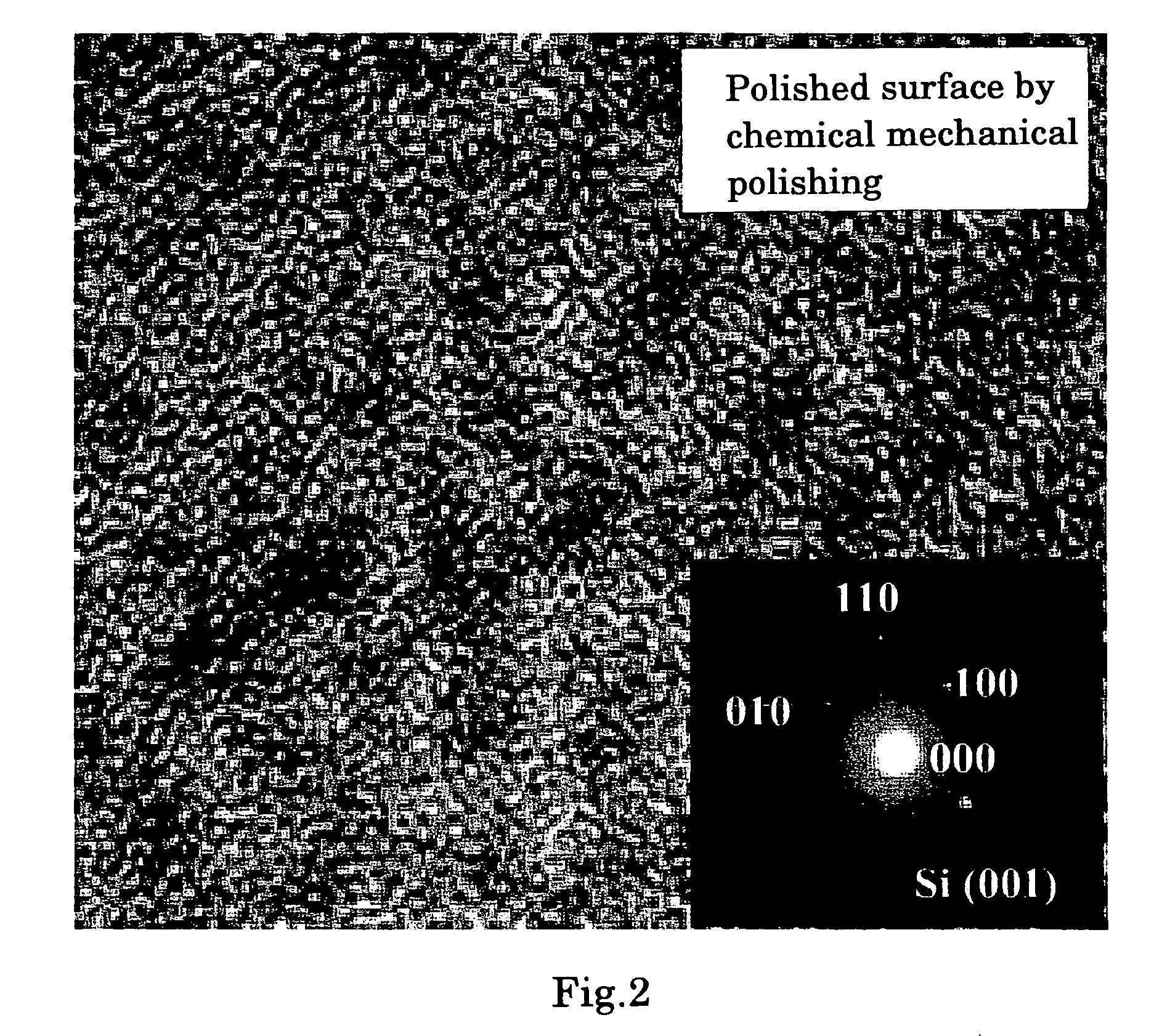

Production method of polishing powder for liquid crystal display device

InactiveCN101381586AHigh crystallinityAccelerated settlementPolishing compositionsNon-linear opticsComing outTunnel kiln

The invention relates to a method for producing polishing powder used for a liquid crystal display device. The method comprises the following steps: at the room temperature, 30 to 40 percent of fluorosilicic acid is added into rare earth chloride solution with REO of between 80 and 100 gram / litre and CeO2 / REO of more than or equal to 70 percent under the stirring; after five minutes, an additive A is added into the mixture, is heated to the temperature of between 70 and 80 DEG C, is kept at the temperature and is added with mixed precipitant solution till the reaction ends; the PH value of the mixture is 7; the mixture is stirred for 10 minutes, is kept stand for 3 to 5 hours and supernatant fluid of the mixture is removed through siphonage; under the stirring, cold water is added to nearly fill a groove fully; before the stirring is stopped, flocculant solution is added till appearing the flocculating effect; the mixture is kept stand, is deposited and the supernatant fluid of the mixture is removed through siphonage for three times; the mixture is washed, is heated up to 98 DEG C, is kept at the temperature for 10 minutes and is discharged to a stainless steel sieve with 120 meshes; the mixture is subjected to solid-liquid separation, vacuum extraction and filtering and dewatering by a centrifuge; a filter cake is transferred to a quartz material sagger; the charging thickness is less than or equal to 9 centimeters; the filter cake is transported to a muffle tunnel kiln at the temperature of 900 DEG C, is subjected to dehydration in a preheating section and decomposition and transformation at certain degree, is roasted for 3 to 4 hours at high temperature of 900 DEG C, is cooled to the temperature of less than 400 DEG C in a cooling section and comes out from the kiln; a roasted material is cooled to the room temperature and is subjected to stage treatment; and a quality part is the product.

Owner:SHANGHAI JIELONG RARE EARTCH FINE ABRASIVE MATERIAL

Diamond grinding material grinding tool

ActiveCN106799685AAvoid passivationImprove grinding forceAbrasion apparatusDiamond grindingFilling materials

The invention provides a diamond grinding material grinding tool. The diamond grinding material grinding tool is made of the following raw materials including diamond, auxiliary grinding materials, sodium chloride, filling materials and binding agents. The invention provides an addition agent which can enhance diamond exposure in the usage process of the diamond grinding material grinding tool. Sodium chloride is added to the formula of the diamond grinding material grinding tool, and therefore the exposure of diamond in the grinding process can be enhanced, the phenomenon of passivation of diamond in the grinding process is effectively avoided, and the grinding force of the diamond grinding tool is improved. A method is easy and convenient to operate and low in cost, and can effectively reduce the surface roughness of a processed product and improve the surface quality of the processed product.

Owner:LENS TECH CHANGSHA

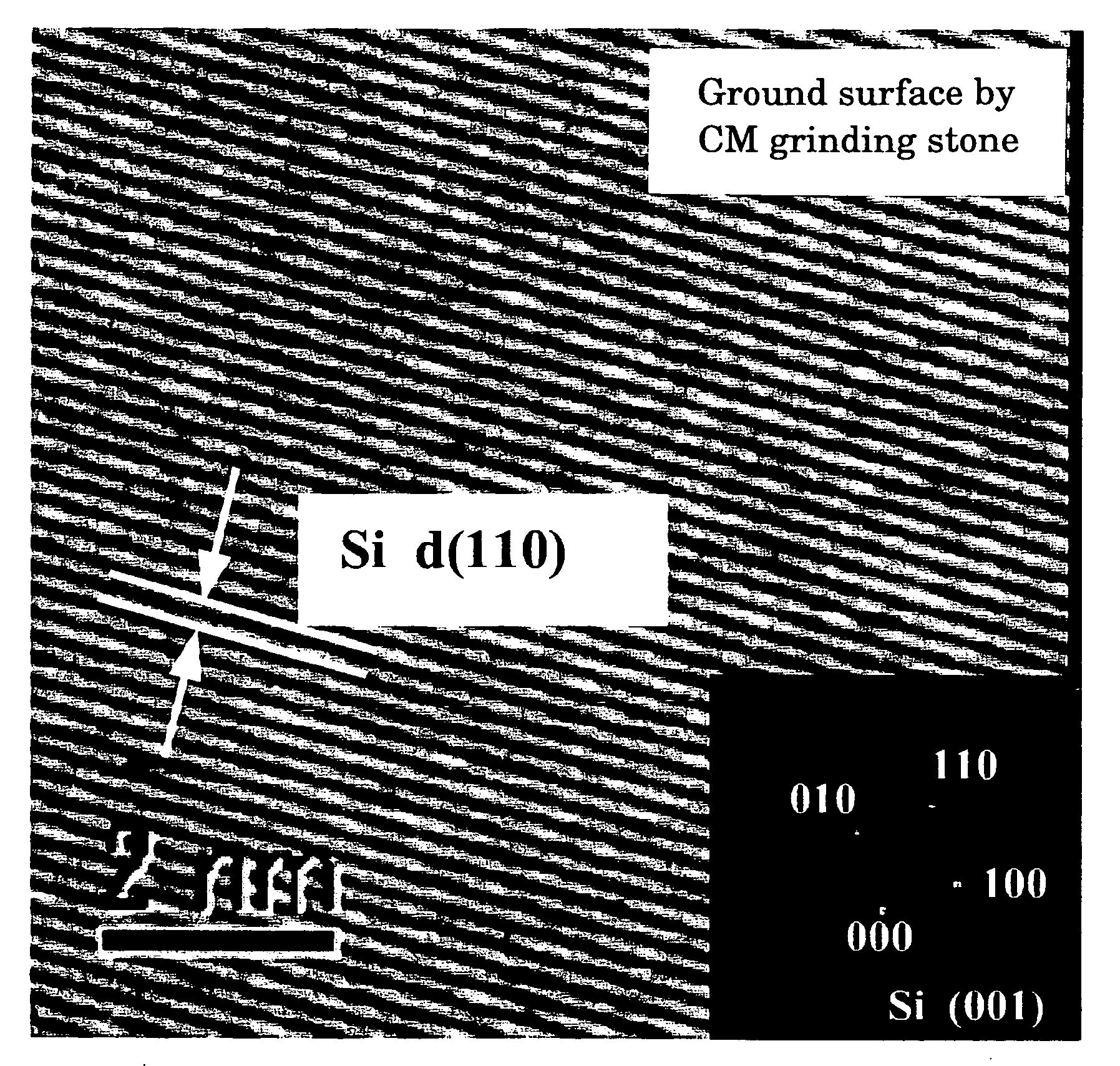

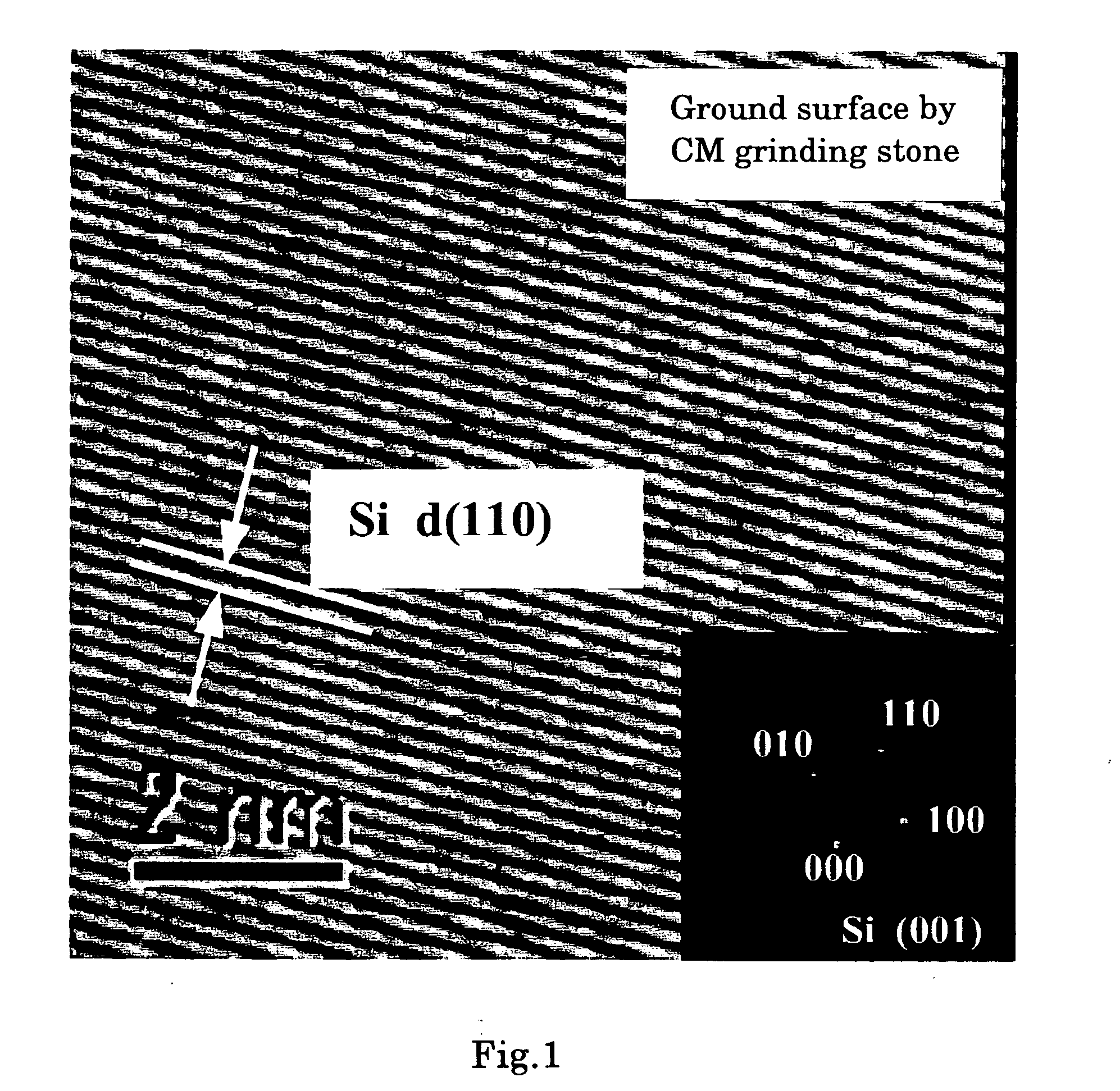

Synthetic grinding stone

ActiveUS20100037530A1Good grinding effectImprove grinding forcePigmenting treatmentOther chemical processesCerium oxideAdamite

Owner:TOKYO DIAMOND KOGU +1

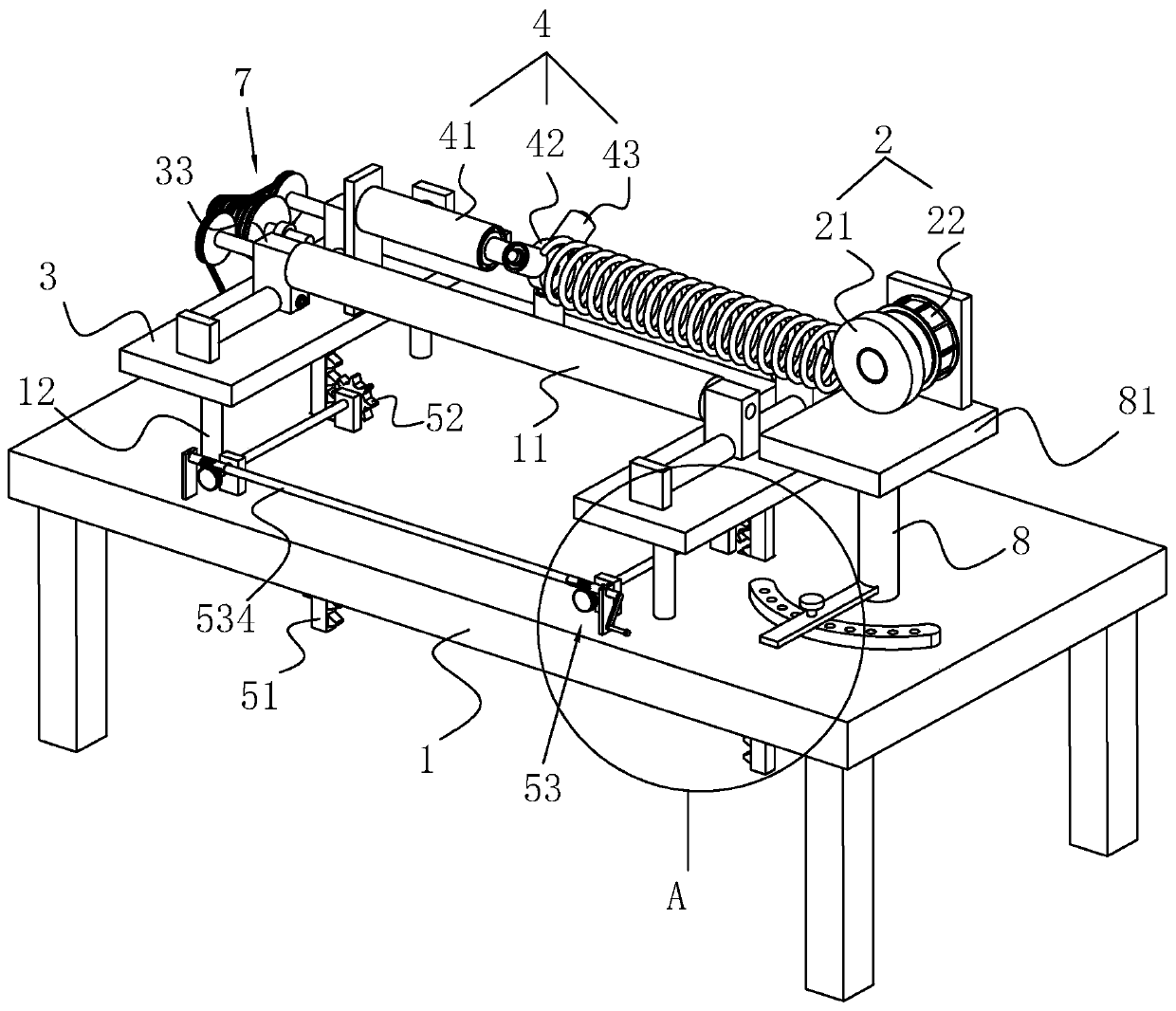

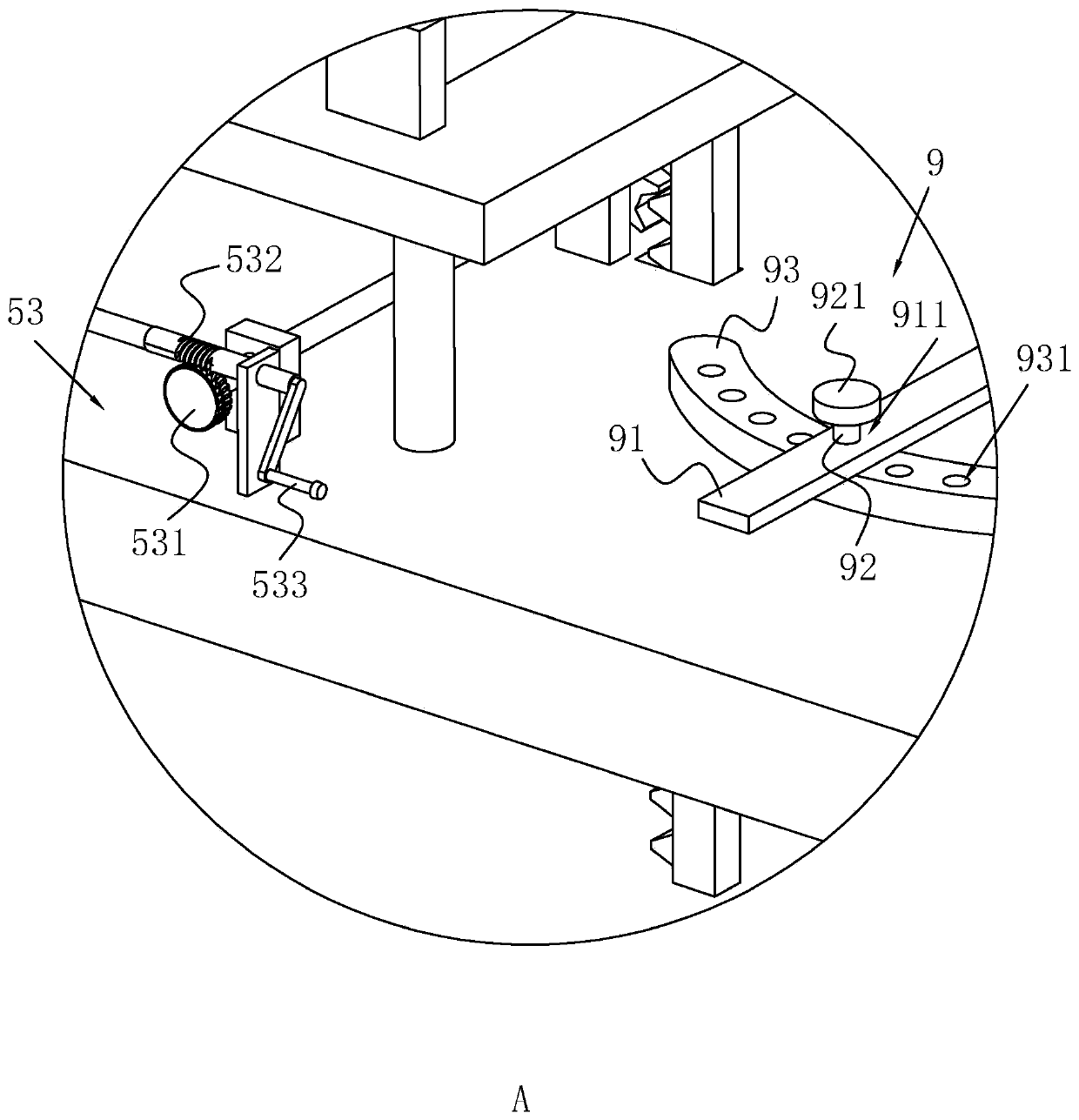

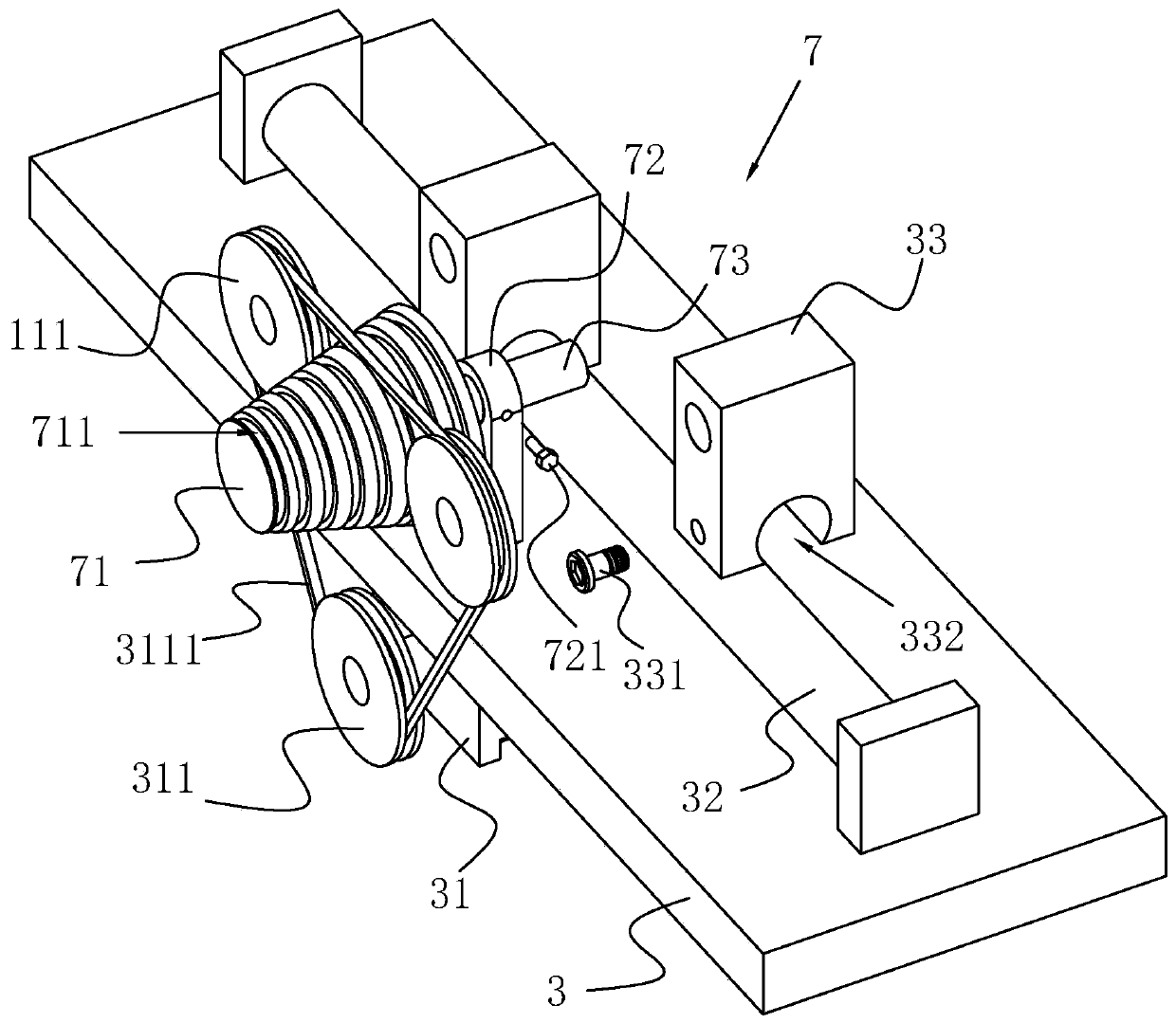

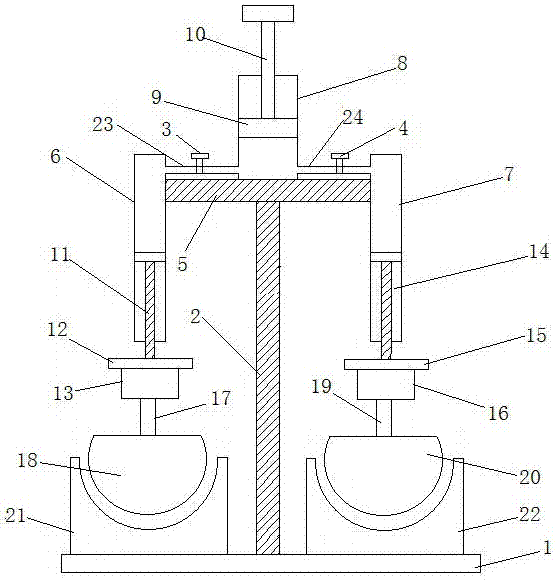

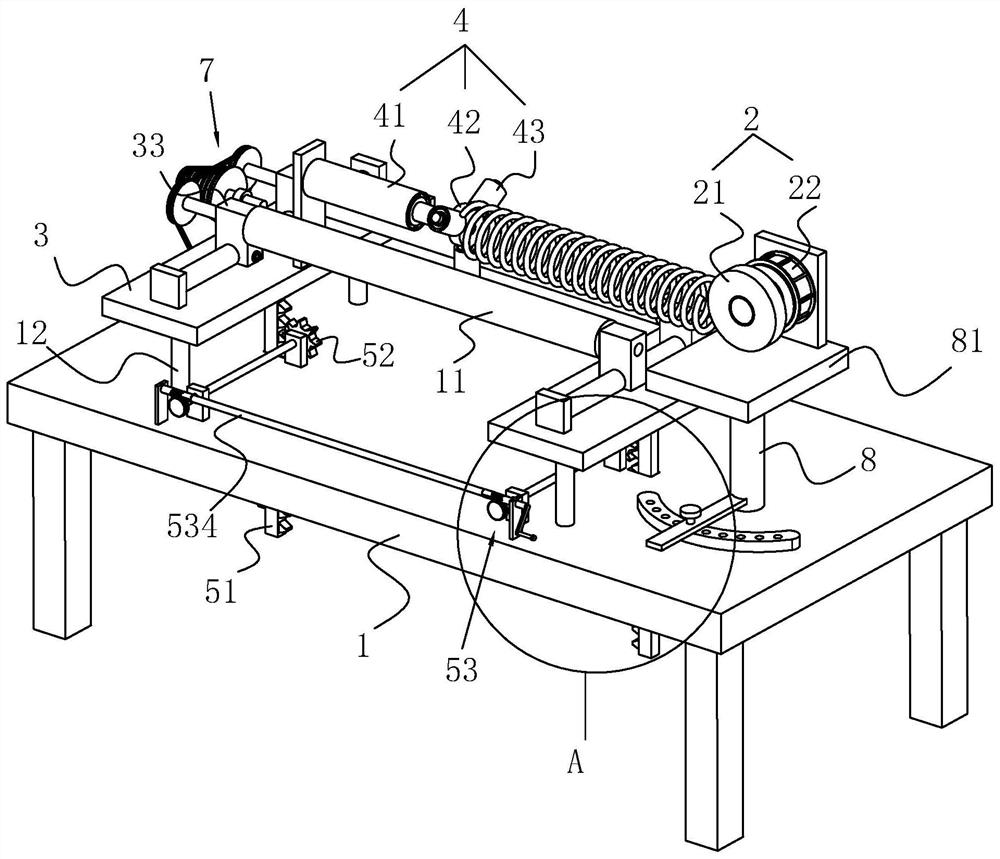

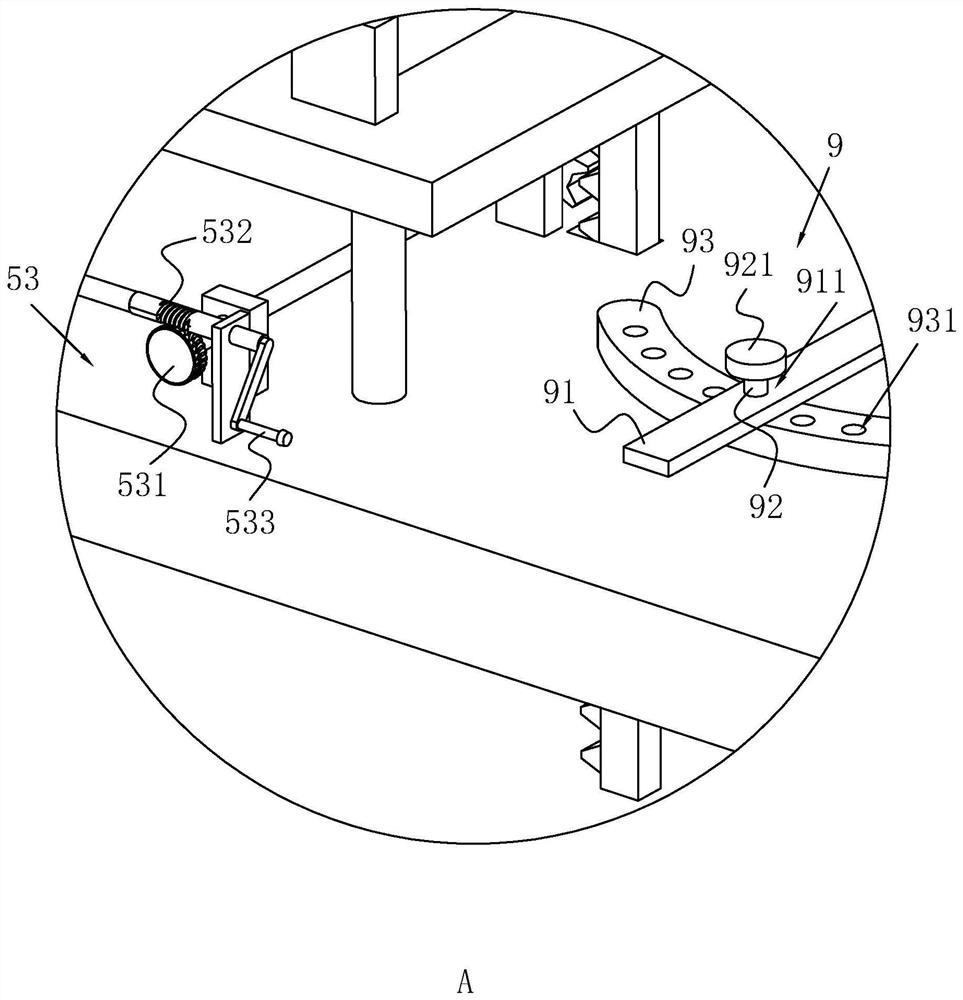

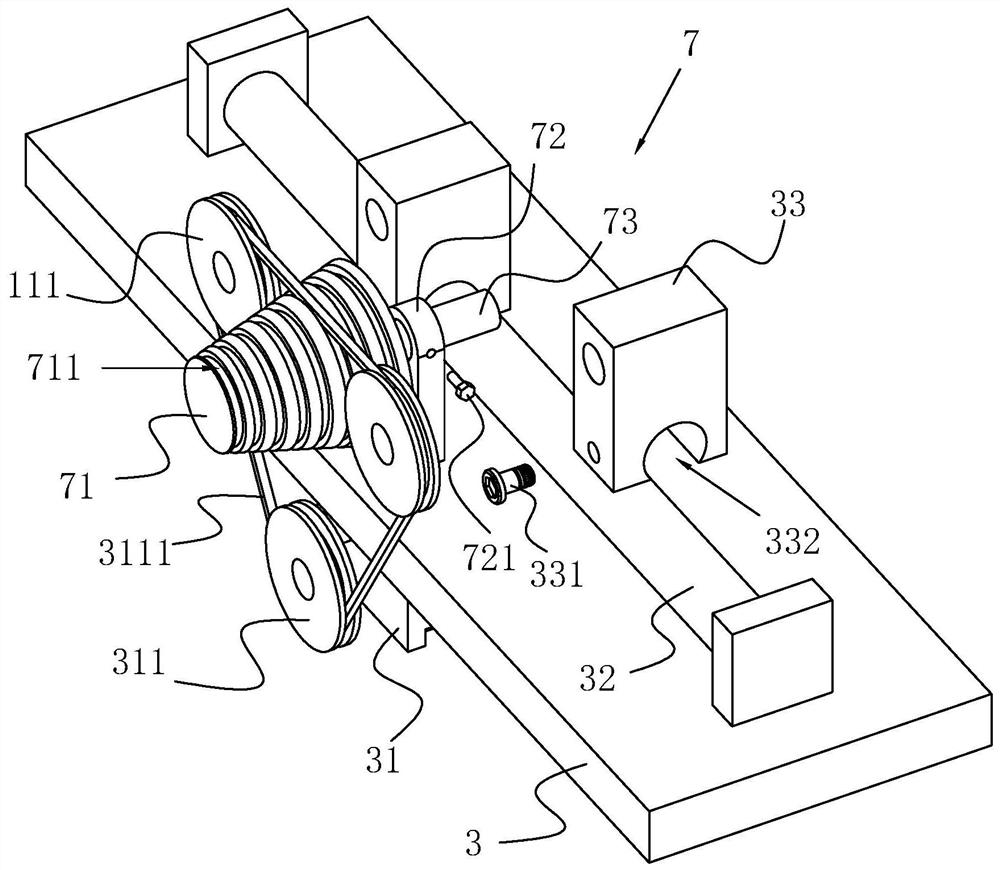

Spring end face grinding device and grinding method thereof

InactiveCN111037389ALower the altitudeImprove grinding performanceGrinding carriagesGrinding drivesElectric machineryEngineering

The invention relates to a spring end face grinding device and a grinding method thereof, and belongs to the technical field of spring grinding. The spring end face grinding device comprises a bottomplate, wherein a grinding assembly used for grinding a spring is arranged on the bottom plate, and the grinding assembly comprises a grinding wheel and a rotating motor; a mounting plate is arranged on the bottom plate, an abutting assembly used for abutting against one end, away from the grinding assembly, of the spring is arranged on the mounting plate, two rotating rollers are horizontally arranged on the mounting plate, and a driving source for driving the rotating rollers to rotate is arranged on the mounting plate; and a lifting assembly used for driving the mounting plate to ascend anddescend is arranged on the bottom plate. When a larger spring is polished, the mounting plate is driven to move downwards through the lifting assembly to reduce the height of the spring, and then theabutting assembly abuts against the spring; and the height of the spring is adjusted, so that the grinding position of the spring and the center of the grinding wheel are on the same horizontal line,the grinding effect of the grinding wheel on the spring is improved, radial jumping of the spring in the grinding process is reduced, and the grinding quality is effectively improved.

Owner:CHENGDU CHENHUI SPRING MFG

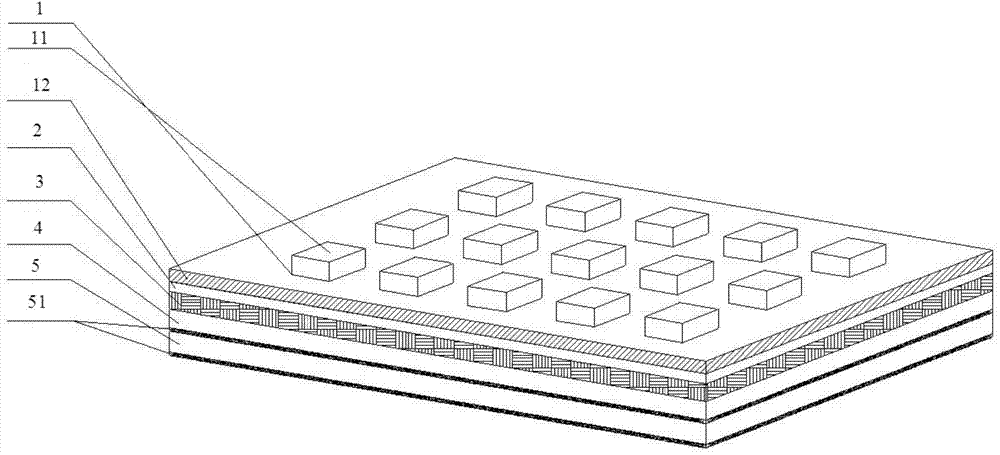

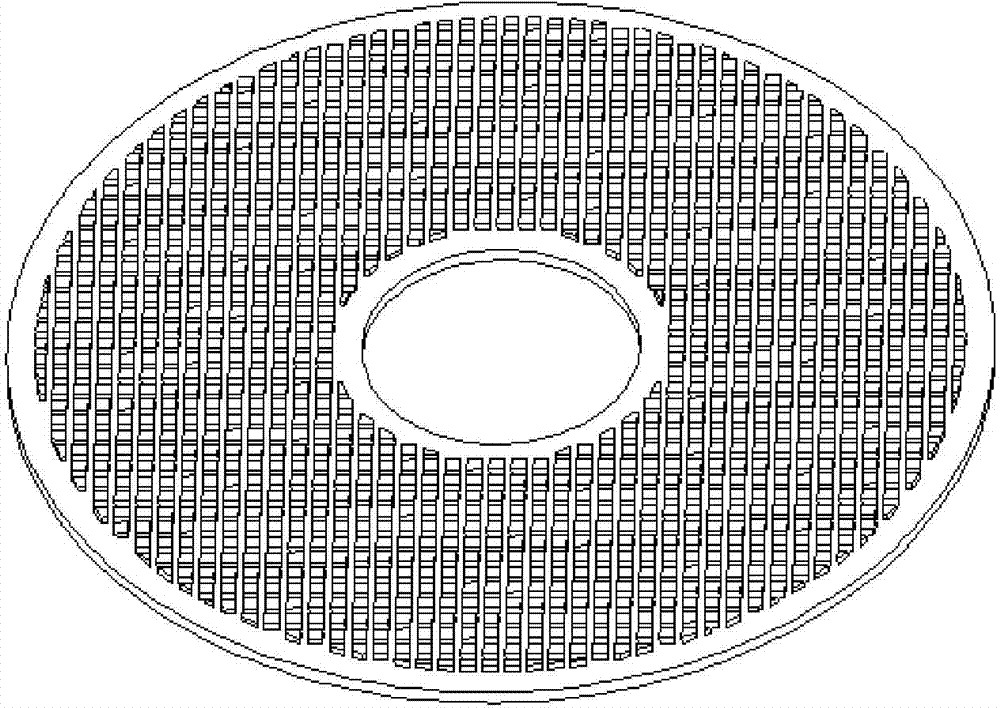

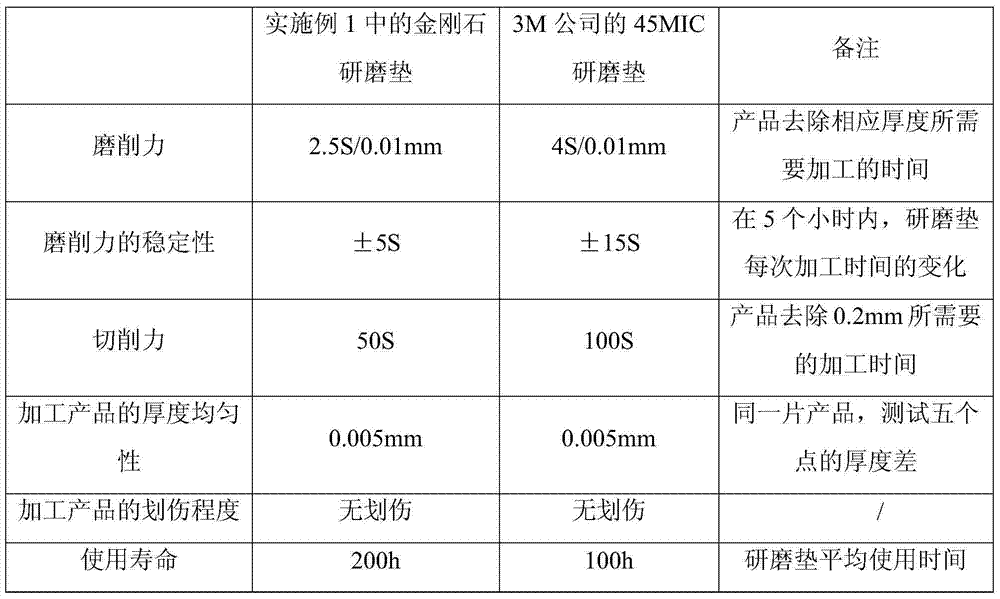

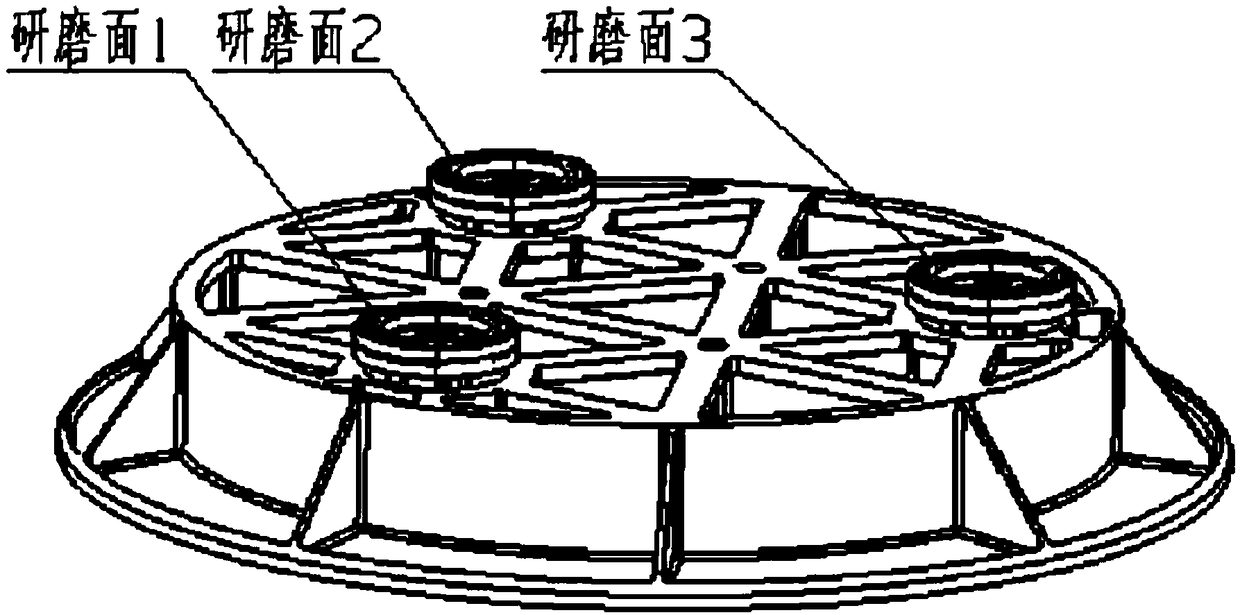

Diamond grinding pad for processing super-hard ceramics and preparation method for diamond grinding pad

ActiveCN104772693ASave raw materialsWide variety of sourcesGrinding devicesLapping toolsDiamond grindingBlock layer

The invention provides a diamond grinding pad for processing super-hard ceramics. The grinding pad comprises a diamond material layer, wherein the diamond material layer comprises a square grinding block layer and a tiling layer and is prepared from the following raw materials in percentage by mass of 25 to 50 percent of resin binder, 5 to 20 percent of diamond, 1 to 10 percent of molybdenum disulfide, 20 to 50 percent of wollastonite and 0.5 to 5 percent of fumed silica. All of performances of the diamond grinding pad provided by the invention in the grinding force, the grinding force stability, the cutting force and the service life are remarkably superior to the performances of a 45MIC grinding pad of 3M company.

Owner:LENS TECH CHANGSHA

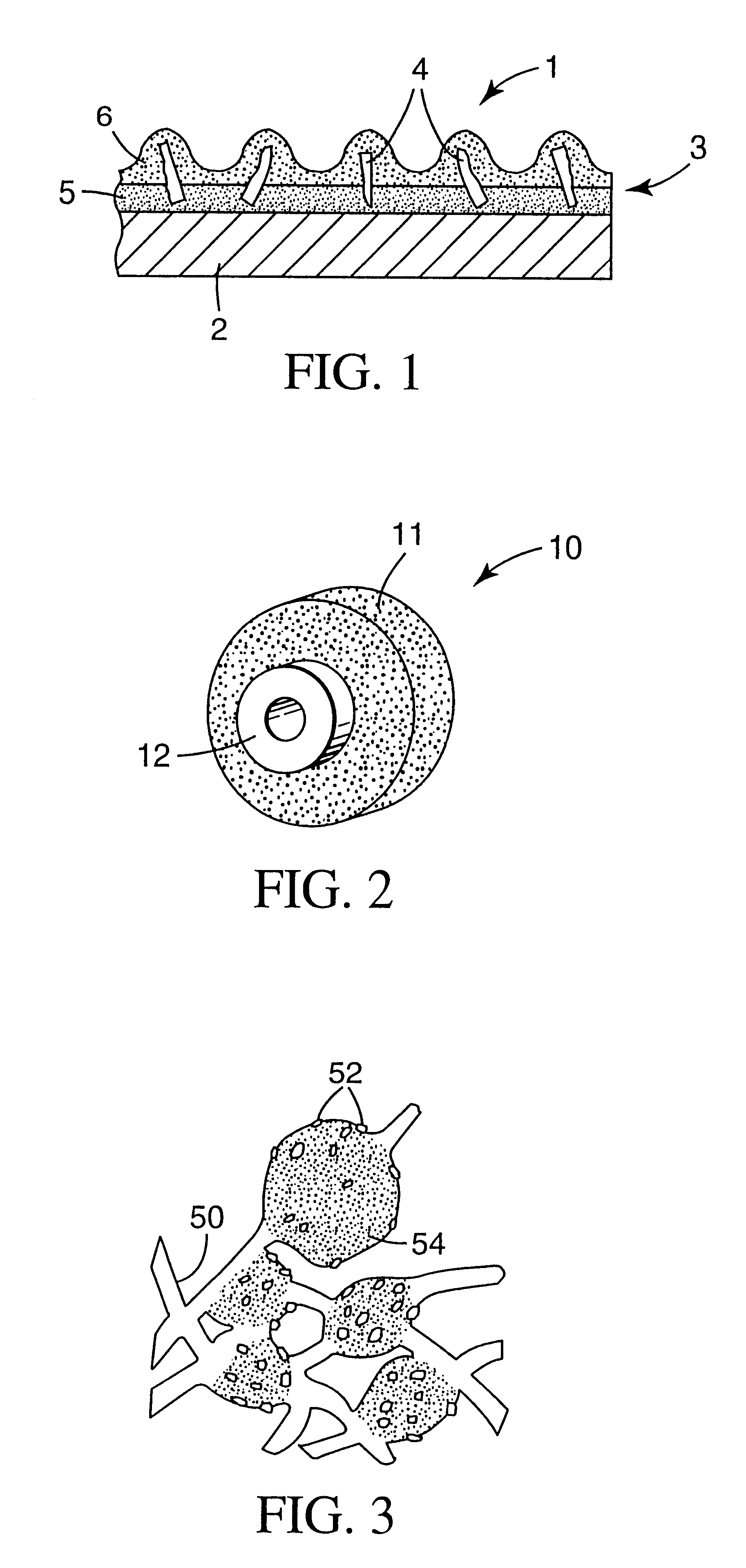

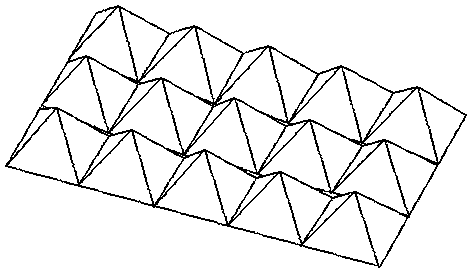

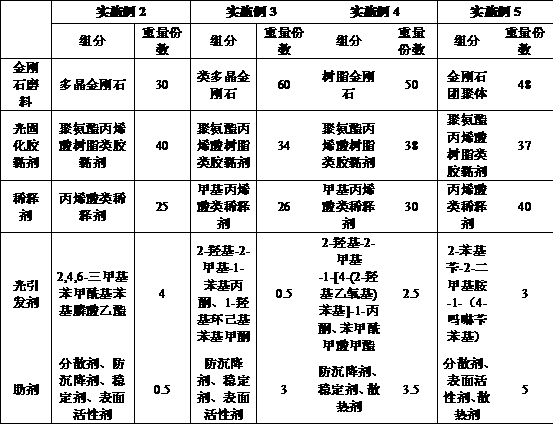

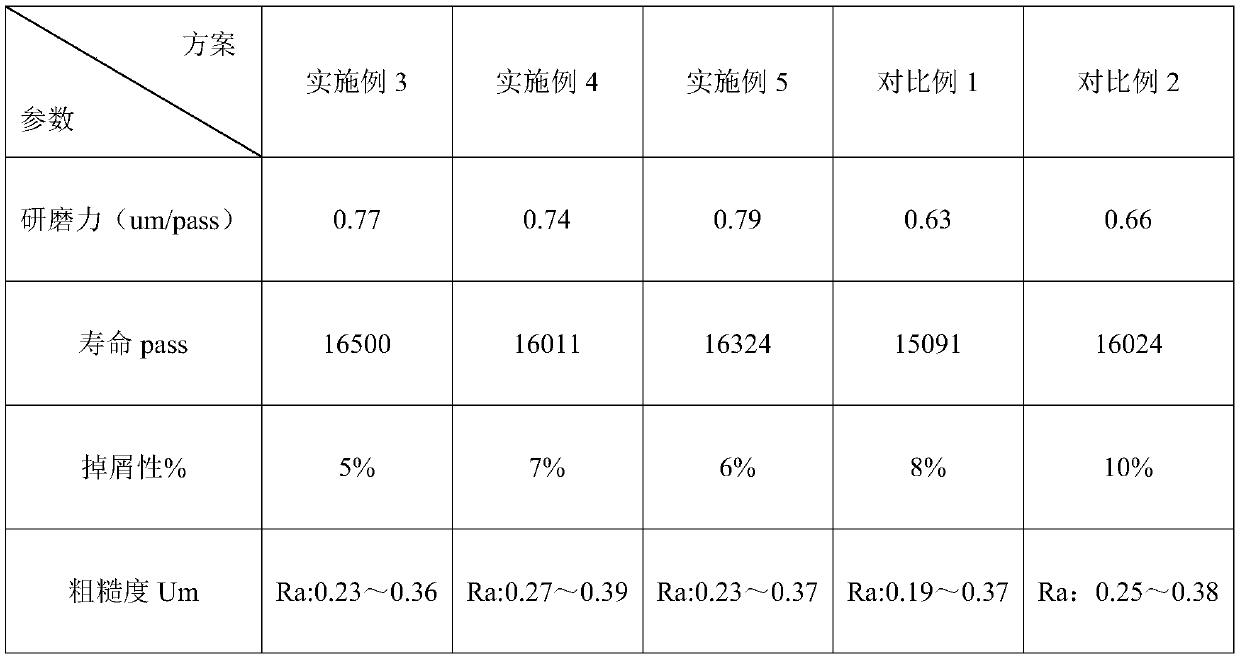

Pyramid-type solid grinding tool for grinding metallic middle frame of mobile phone and preparation method

InactiveCN108481217AEasy to processImprove sanding effectBonded abrasive wheelsGrinding devicesAdhesiveSolid structure

The invention discloses a pyramid-type solid grinding tool for polishing a metallic middle frame of a mobile phone. The pyramid-type solid grinding tool comprises a soft substrate disposed on a bottomlayer, wherein a plurality of pyramids projecting upwardly and formed by curing a diamond slurry are arranged on the soft substrate; the diamond slurry is prepared from, by weight, 30-60 parts of diamond abrasive, 30-60 parts of photocurable adhesive, 20-40 parts of diluent, 0.5-5 parts of photoinitiator and 1-5 parts of adjuvant. The present invention employs intaglio printing and photocuring techniques to coat diamond slurry onto a mold having a pyramid structure, after photocuring, to a soft substrate to obtain a soft base diamond abrasive tool having a pyramid-type stereo structure a softsubstrate diamond grinding tool having a pyramid-type solid structure is obtained by coating a mold having a pyramid structure with the diamond slurry, performing photocuring, and transferring the diamond slurry subjected to photocuring to the soft substrate with intaglio printing and photocuring techniques, and the grinding tool can be applied to polishing operation in a high-strength metallic middle frame of the mobile phone, and the processing cost can be reduced on the basis of bringing convenience for processing, improving product polishing effect and increasing processing yield.

Owner:河北思瑞恩新材料科技有限公司

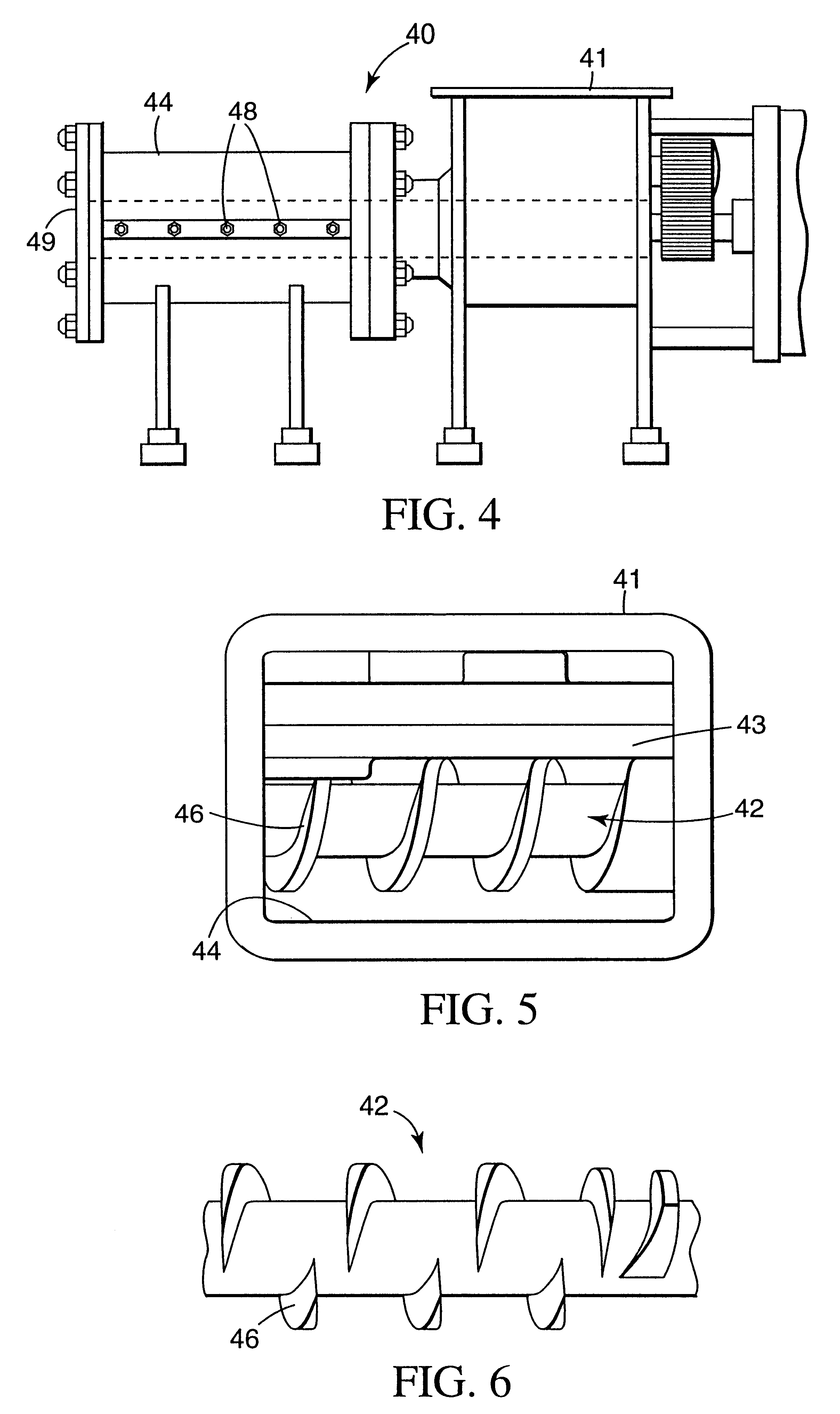

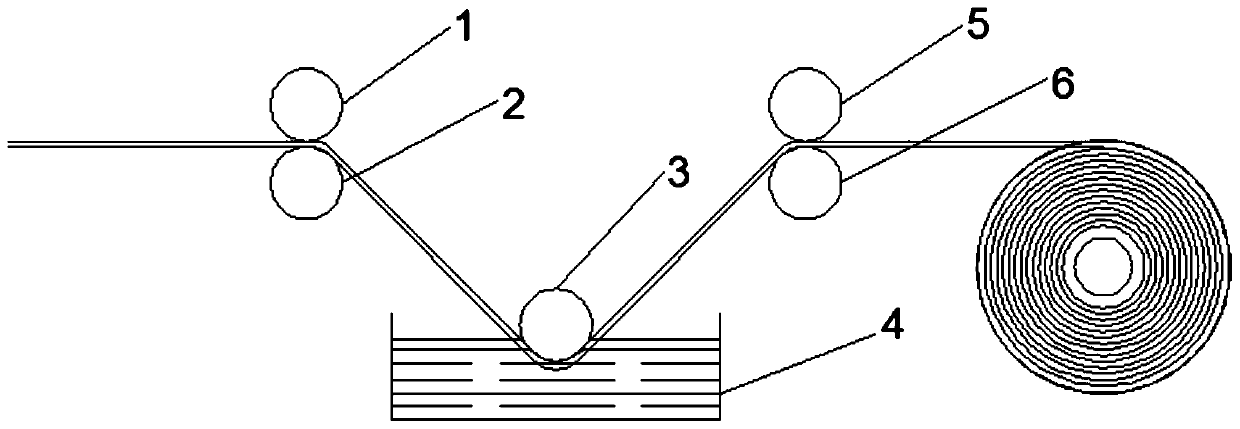

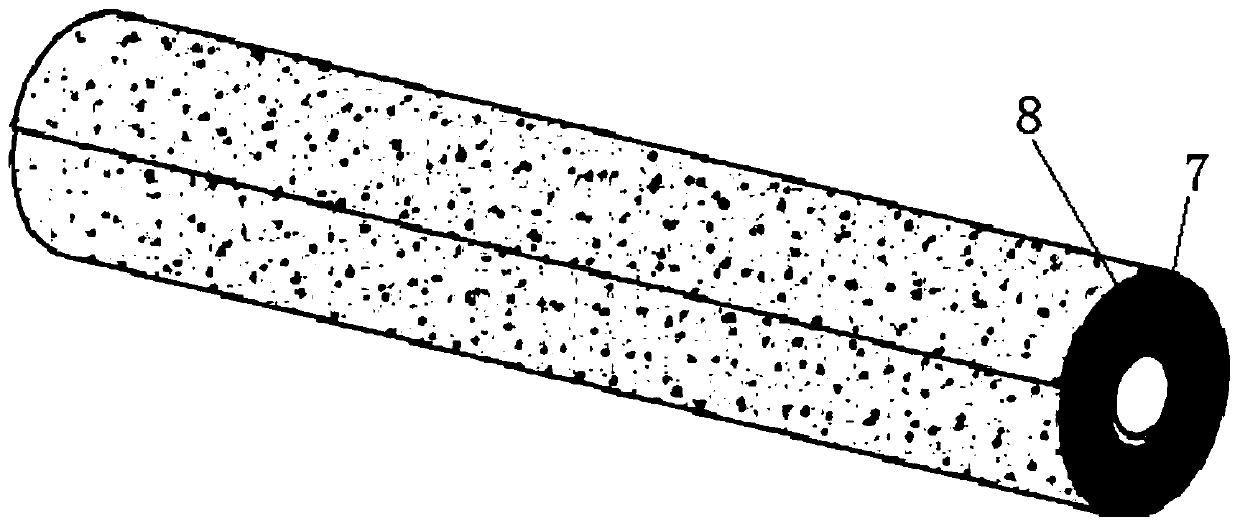

Non-woven fabric brush wheel as well as production system and method thereof

PendingCN110103155AHigh hardnessImprove gel uniformityFlexible-parts wheelsGrinding devicesHardnessMechanical engineering

The invention belongs to the field of PCB cutting, and discloses a non-woven fabric brush wheel as well as a production system and method thereof. The non-woven fabric brush wheel comprises an axis and a non-woven fabric layer which is wound on the axis and is formed by a plurality of layers of non-woven fabrics. The non-woven fabric brush wheel is characterized in that the non-woven fabric layeris formed by a non-woven fabric wound on the axis after being impregnated. The production system for the non-woven fabric brush wheel comprises a feeding unit for inputting the non-woven fabric, an impregnating unit for impregnating non-woven fabric and a rolling unit for rolling impregnated non-woven fabric into a compact non-woven fabric roll, and the feeding unit, the impregnating unit and therolling unit are sequentially arranged. The invention aims to provide the non-woven fabric brush wheel. The non-woven fabric brush wheel is high in hardness, is uniform in glue content, is good in grinding effect and is long in service life. The invention further discloses the production system and the production method for the non-woven fabric brush wheel.

Owner:广州捷骏电子科技有限公司

Grinding fluid for optical sapphire

InactiveCN108559407AImprove grinding efficiencyImprove suspensionPolishing compositions with abrasivesSodium silicateNonionic surfactant

The invention discloses a grinding fluid for optical sapphire, belonging to the technical field of grinding and polishing. The grinding fluid comprises the following raw materials by weight: 4-7 partsof fine boron nitride powder, 5-9 parts of fine quartz sand powder, 3-6 parts of stearic acid, 4-7 parts of ethylene glycol, 2-5 parts of sodium lignosulfonate, 5-9 parts of montmorillonite, 2-4 parts of sodium hydroxide, 5-10 parts of polyethylene glycol, 2-4 parts of a lubricant, 5-10 parts of a nonionic surfactant, 3-7 parts of sodium gluconate, 5-8 parts of sodium silicate and 30-40 parts ofwater. The grinding fluid of the invention has high polishing efficiency and high precision; workpieces treated with the grinding fluid are small in surface scratch loss and have smooth surfaces; andwhen the grinding fluid is used for grinding and polishing of optical sapphire, a sapphire sheet is allowed to have flatness of 0.1 nm, so good conditions are provided for subsequent precision polishing.

Owner:安徽全兆光学科技有限公司

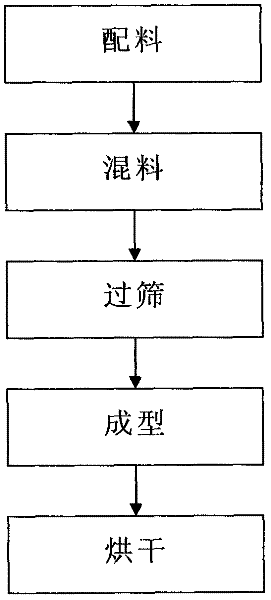

Method for preparing resin grinding wheel

The invention discloses a method for preparing a resin grinding wheel. The method comprises the following steps: (1) placing 70-85 parts by weight of white corundum into 10-15 parts by weight of acrylic emulsion to be soaked, evenly mixing 6-8 parts by weight of polytetrafluoroethylene powder, 1-2 parts by weight of boron nitride, 15-20 parts by weight of cryolite and 30-35 parts by weight of phenolic resin powder with the soaked white corundum, and enabling the mixture to pass through 20-25-mesh standard screens to obtain a grinding wheel mixture; (2) taking a glass fiber cloth, coating the two faces of the glass fiber cloth with phenolic resin, then placing the glass fiber cloth into a drying oven, and baking the glass fiber cloth at the temperature of 135-140 DEG C for 15-20min to obtain glass fiber pieces; (3) placing the glass fiber mixture into a forming mold, spreading the glass fiber mixture, completely embedding the glass fiber pieces into the grinding wheel mixture, and conducting compression forming to obtain a grinding wheel green body; (4) placing the grinding wheel green body into a sintering furnace to be sintered; (5) machining the sintered grinding wheel green body on a lathe and a grinding machine to obtain the finished resin grinding wheel. When resin grinding wheel prepared by the method is used, harmful gas caused by oxidation can not emit.

Owner:CHANGSHU JULI GRINDING WHEEL

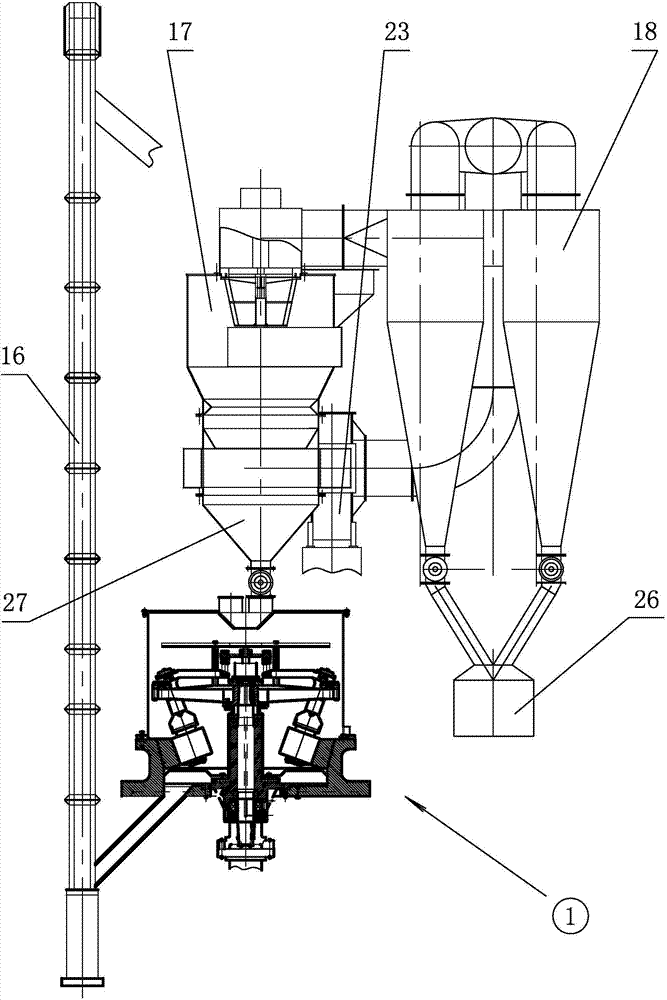

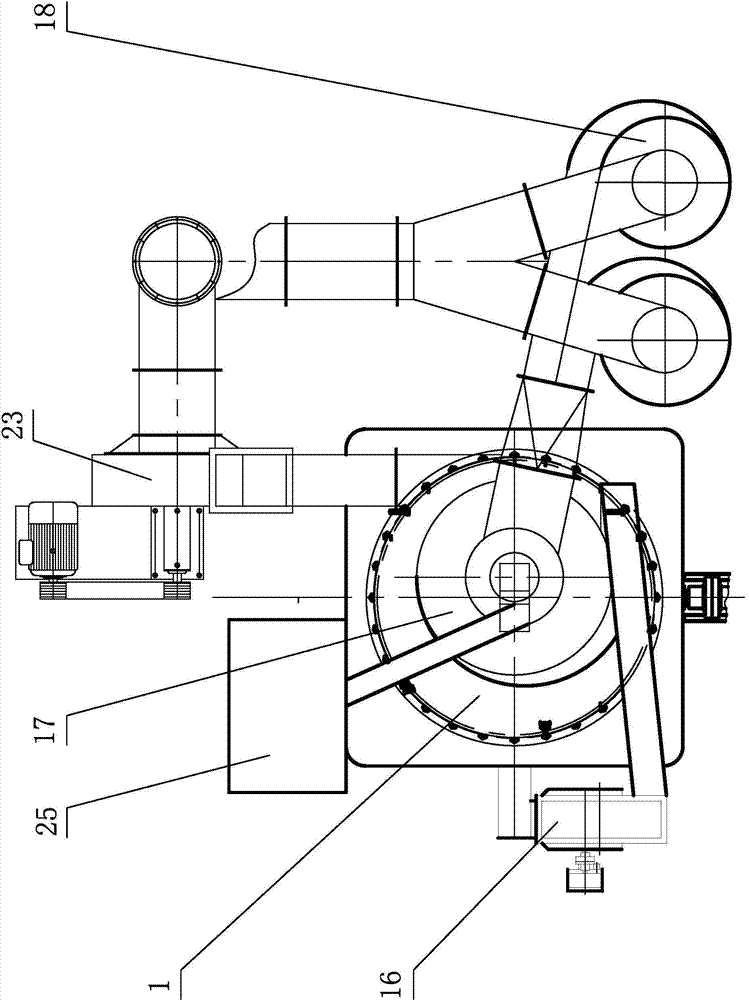

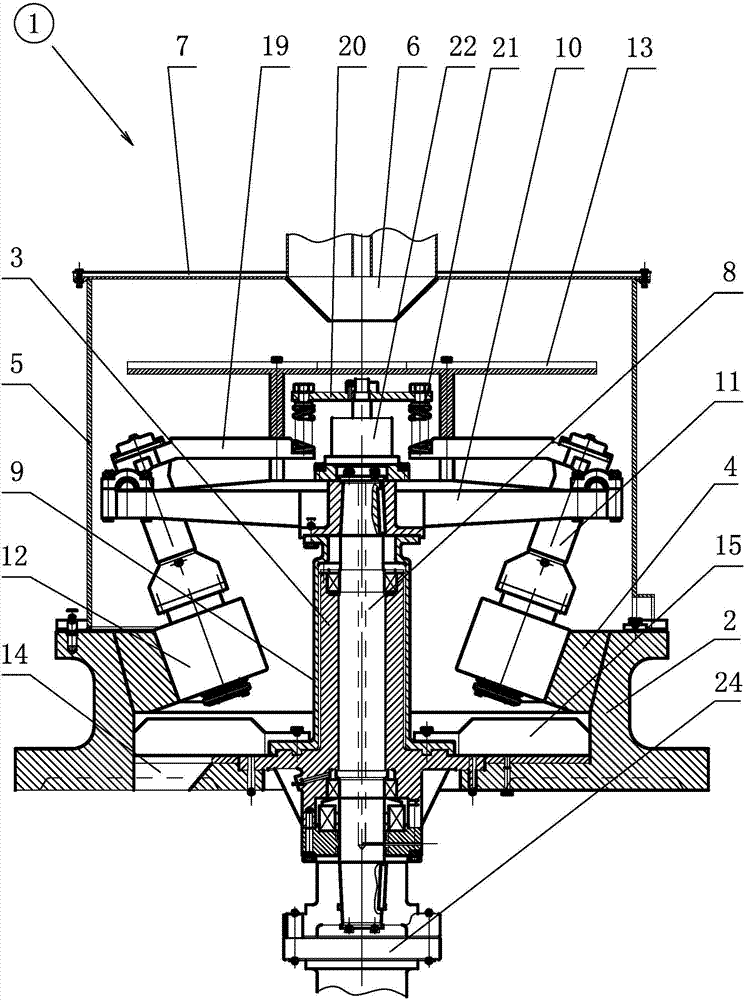

Oblique swing pressurization external circulation mill

The invention discloses an oblique swing pressurization external circulation mill. A central shaft frame is mounted at the bottom of a base of a milling main engine; milling rings are mounted at an upper part of the base; a cover barrel is mounted on the end surface of the base; a main engine feeding hole is formed in an upper cover of the cover barrel; a main engine discharging hole is formed in the bottom of the base near the central shaft frame and communicated with an external grading system through a pipeline; a lower part of a main-engine main shaft is arranged on the central shaft frame; a fixed roller frame connected with a material scraping frame is mounted at an upper end of the main-engine main shaft; the central shaft frame is sleeved with the material scraping frame; material scraping plates are mounted on the material scraping frame; milling roller devices are uniformly distributed around the circumference of the main-engine main shaft; each milling roller device comprises a milling roller sleeve, a milling roller and a milling roller shaft; the milling roller sleeves are obliquely hung on the fixed roller frame; the milling rollers obliquely lean on the milling rings; a material equalizing plate synchronously rotating and provided with a baffle edge is arranged above the fixed roller frame; a pressurization mechanism acting on the milling roller devices is arranged on the fixed roller frame. According to the mill, a finished product is separated by adopting external circulation, so that equipment is convenient to repair; a shovel blade mechanism is not arranged, so that the power consumption is reduced and the total power loss of the milling main engine is reduced.

Owner:吴斌

Coated abrasive tool and preparation method and application method thereof

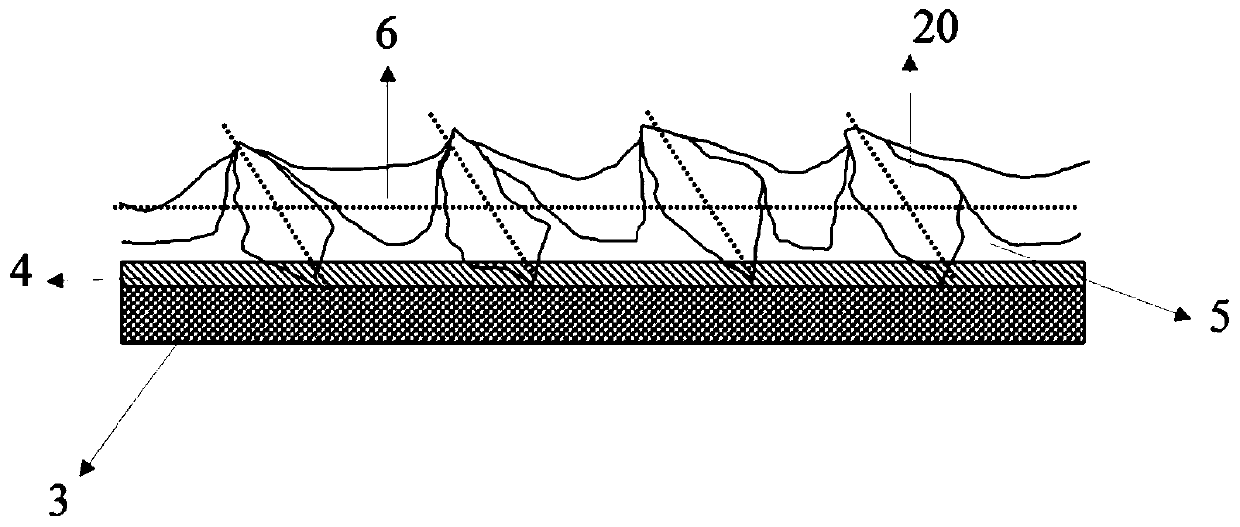

ActiveCN110052975AExtended service lifeImprove grinding forceNon-macromolecular adhesive additivesAbrasion apparatusAngle alphaContact angle

The invention relates to a coated abrasive tool and a preparation method and application method thereof. The coated abrasive tool comprises a base material and an abrasive material layer. The abrasivematerial layer comprises a primer layer, an abrasive material implanted into the primer layer and a composite glue layer coating the abrasive material and the primer layer. Abrasive particles with the sand implanting angle alpha being larger than or equal to 30 degrees and smaller than 90 degrees in the abrasive material implanted into the primer layer are 20%-50% of all abrasive particles. According to the coated abrasive tool, the sand implanting angle of part of abrasive material is adjusted, the contact angle of the abrasive material and a machined workpiece is optimized during grinding,and tests prove that the grinding efficiency of a product of the coated abrasive tool can be effectively improved by adjusting the sand implanting angle of the abrasive material.

Owner:白鸽磨料磨具有限公司

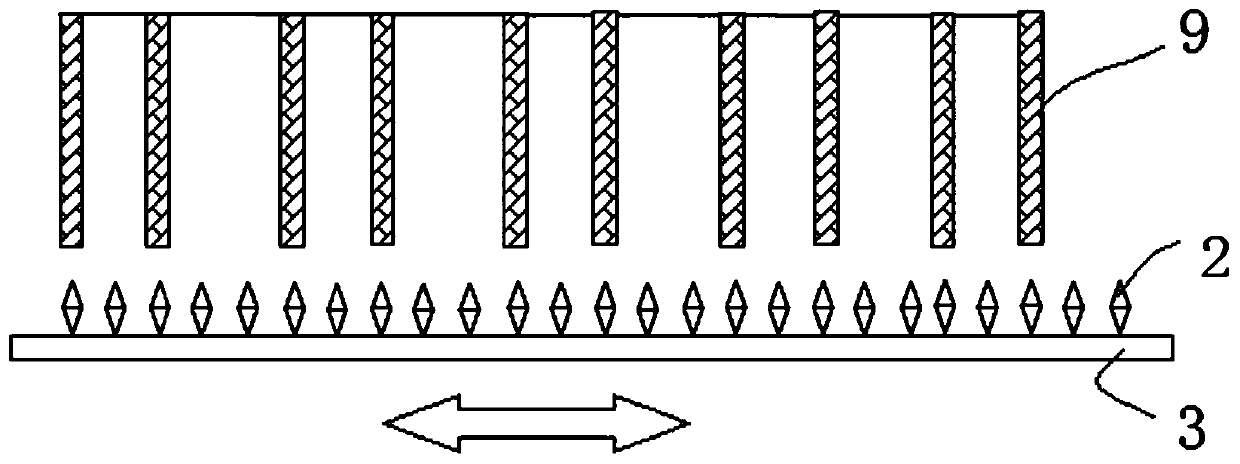

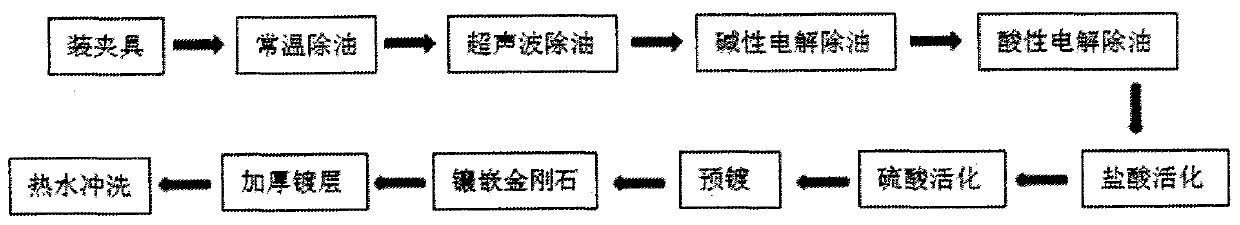

Method for manufacturing electroplating diamond grinding wheel

The invention discloses a method for manufacturing an electroplating diamond grinding wheel. The method comprises the steps of fixture assembly, normal-temperature degreasing, ultrasonic degreasing, alkaline electrolytic degreasing, acidic electrolytic degreasing, hydrochloric acid activation, sulfuric acid activation, pre-plating, diamond inlaying, coating thickening and hot water rinsing. The method disclosed by the invention improves a pre-treatment degreasing process and an activation process, and provides an optimum plating solution formula so as to improve the binding force between a coating and a matrix and increase the clamping force of the coating to a diamond, thus improving the grinding and cutting force and durability of the grinding wheel.

Owner:奚经龙

Improved dual-support oil wedge-shaped dynamic pressure spindle assembly for conical roller coreless grinding machine

InactiveCN103447945AHigh rotation accuracyGood surface roughnessGrinding machine componentsRevolution surface grinding machinesSingle supportPulp and paper industry

The invention discloses an improved dual-support oil wedge-shaped dynamic pressure spindle assembly for a conical roller coreless grinding machine. The dual-support oil wedge-shaped dynamic pressure assembly comprises a spindle, a sand wheel combination and tile sleeve combinations; the sand wheel combination is positioned in the middle of the spindle and comprises a sand wheel chuck, a spindle conical sleeve, a sand wheel chuck end cover and a sand wheel; the sand wheel is fixed on the sand wheel chuck by the spindle, the sand wheel chuck, the spindle conical sleeve and the sand wheel chuck end cover; the tile sleeve combinations are arranged at two ends of the spindle; each tile sleeve combination comprises a tile sleeve, a shaft tile, a tile sleeve end cover, a tile sleeve end cover and an end cover connection disc. Compared with the single-support oil wedge-shaped spindle assembly, the improved dual-support oil wedge-shaped dynamic pressure spindle assembly for the conical roller coreless grinding machine has the advantages of high machining and rotating precision and large grinding force.

Owner:栾谨泉

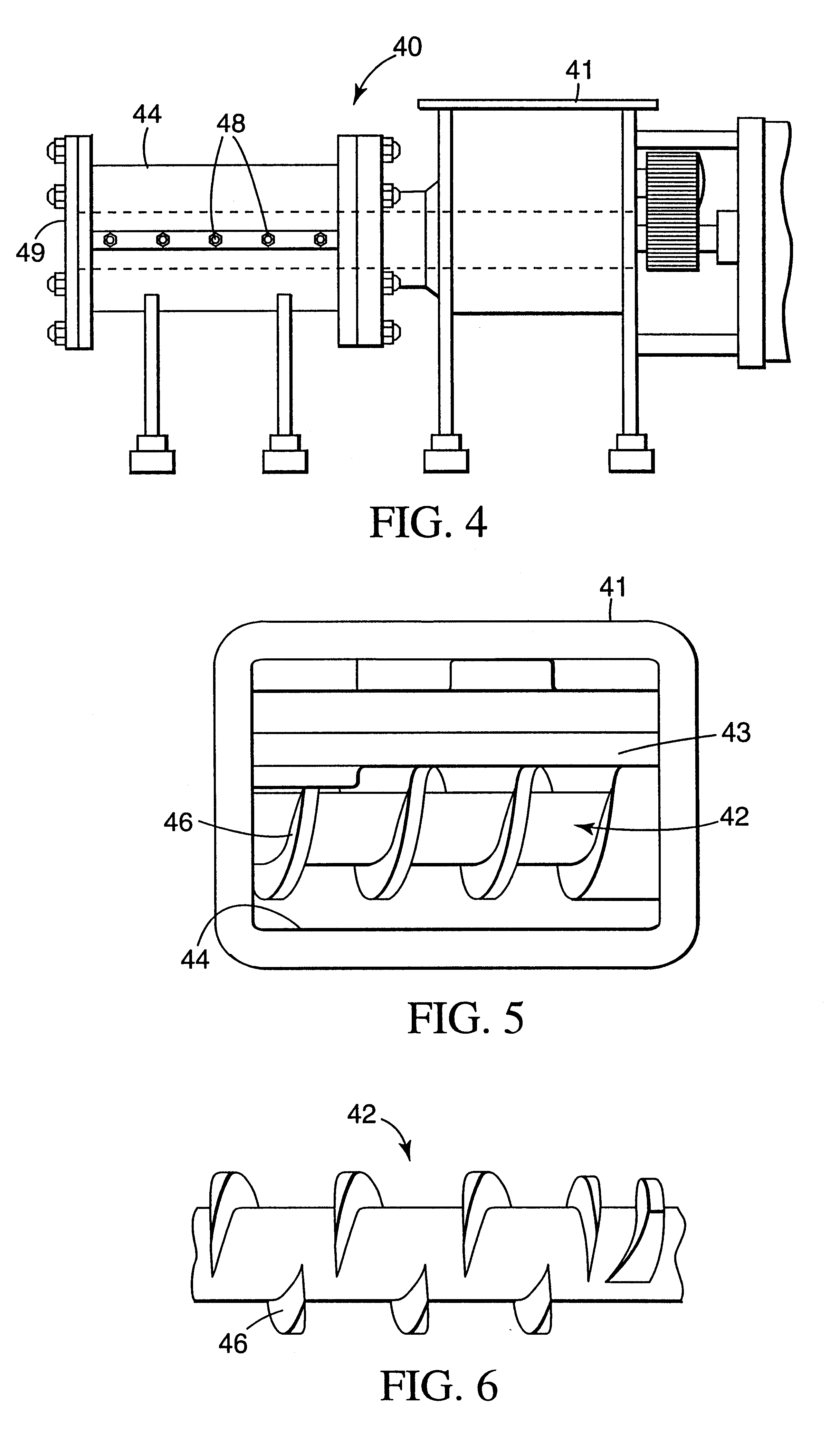

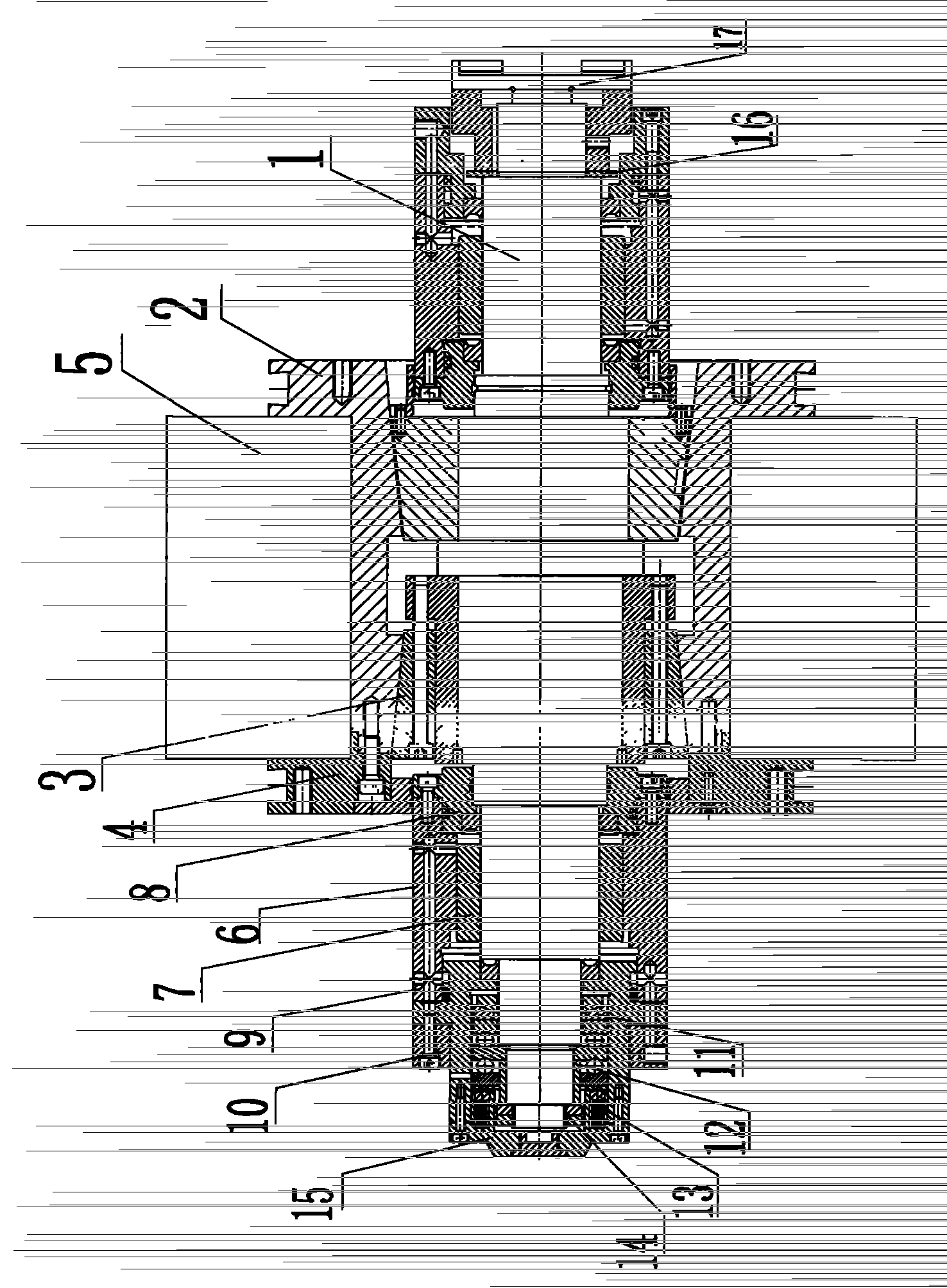

Forcing type efficient double grinding machine

The invention discloses a forcing type efficient double grinding machine. A left forcing cylinder is welded to the left end of a supporting plate. A right forcing cylinder is welded to the right end of the supporting plate. A left forcing cylinder shaft is mounted in the left forcing cylinder. A right forcing cylinder shaft is mounted in the right forcing cylinder. A left carrying plate is welded to the bottom end of the left forcing cylinder shaft. A right carrying plate is welded to the bottom end of the right forcing cylinder shaft. A left grinding driving motor is fixedly mounted at the bottom of the left carrying plate. A left grinding driving shaft is mounted in the left grinding driving motor. A right grinding driving motor is fixedly mounted at the bottom of the right carrying plate. A right grinding driving shaft is mounted in the right grinding driving motor. A left grinding ball is welded to the bottom end of the left grinding driving shaft. A right grinding ball is welded to the bottom end of the right grinding driving shaft. A left grinding cavity is formed under the left grinding gall. A right grinding cavity is formed under the right grinding ball. The forcing type efficient double grinding machine is scientific and reasonable in design and simple in structure.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

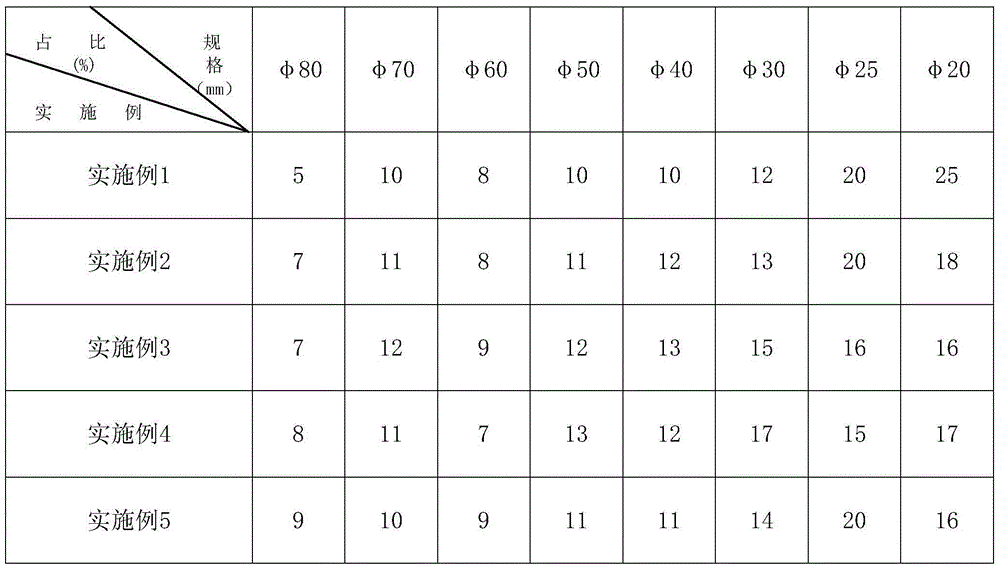

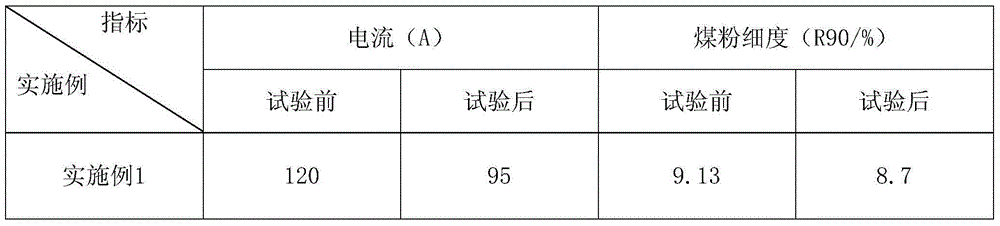

Grading method of coal mill steel balls and application thereof

The invention discloses a grading method of coal mill steel balls. The method comprises the step of filling steel balls with different sphere diameters in a ball mill according to the following weight ratios: 5-10% of steel balls with sphere diameters of 80mm, 10-15% of steel balls with sphere diameters of 70mm, 8-10% of steel balls with sphere diameters of 60mm; 10-15% of steel balls with sphere diameters of 50mm, 10-18% of steel balls with sphere diameters of 40mm, 12-18% of steel balls with sphere diameters of 30mm, 15-30% of steel balls with sphere diameters of 25mm, and 15-30% of steel balls with sphere diameters of 20mm. The grading method disclosed by the invention is used for reasonably grading the steel balls to reduce the energy consumption of a coal mill while ensuring the output of the coal mill, and meanwhile since the attrition of the steel balls is small, the production cost of the coal mill is reduced.

Owner:QINGDAO CHUTIAN ENERGY SAVING TECH

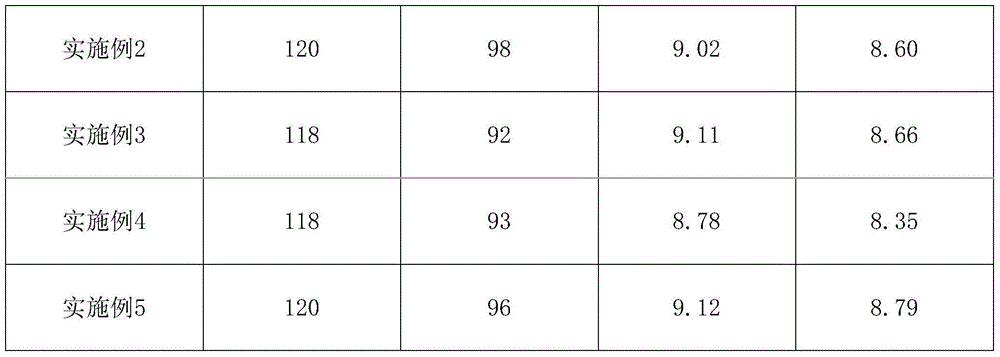

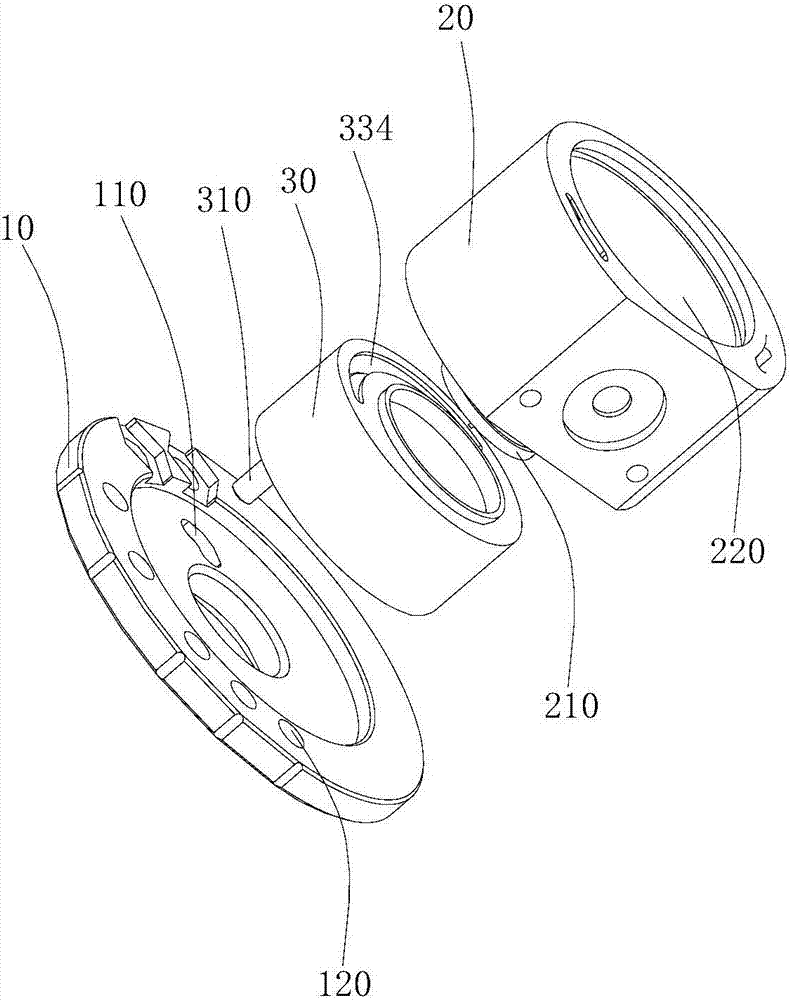

Grinding and polishing machine and auxiliary mechanism thereof

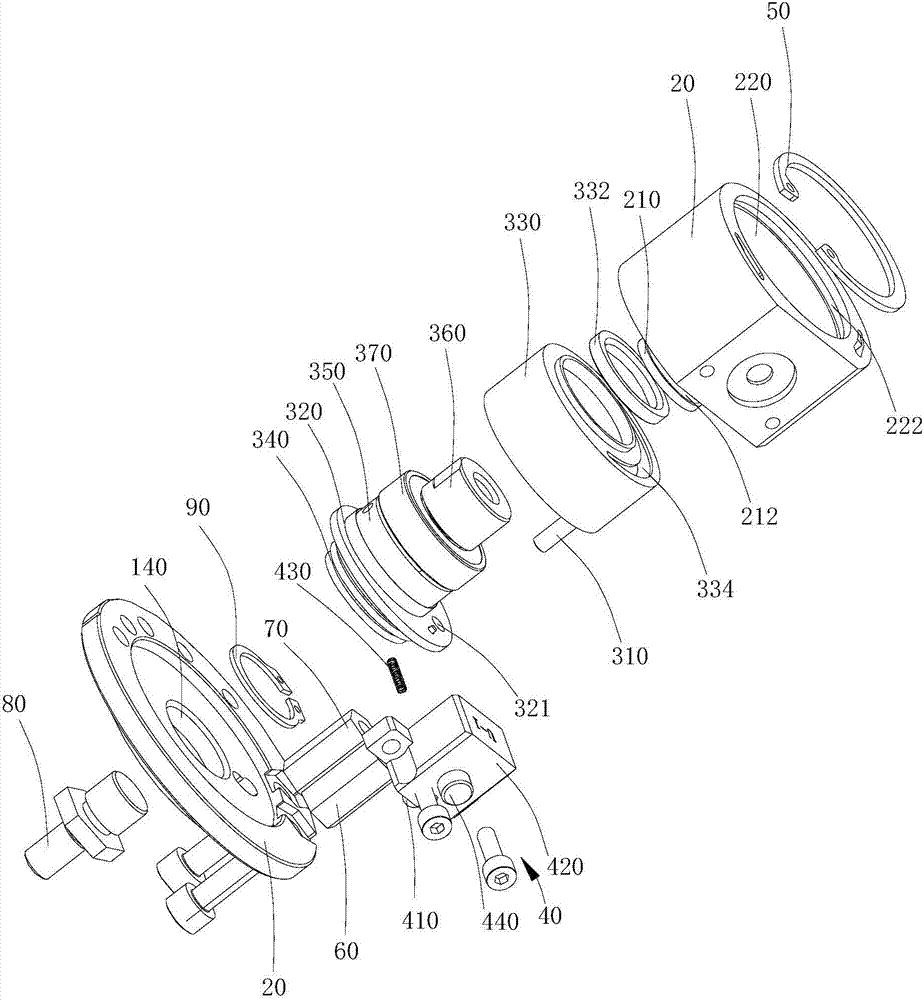

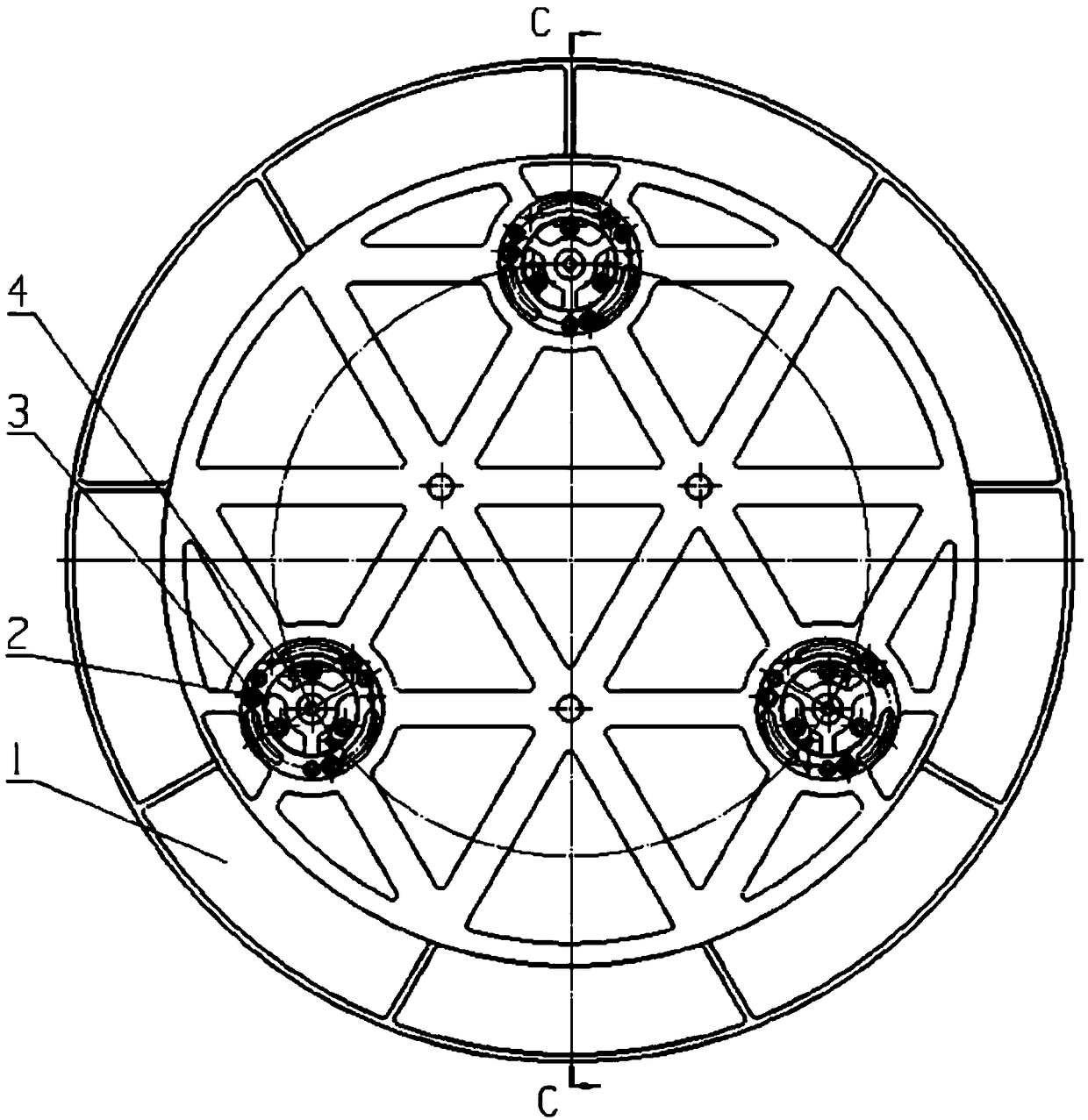

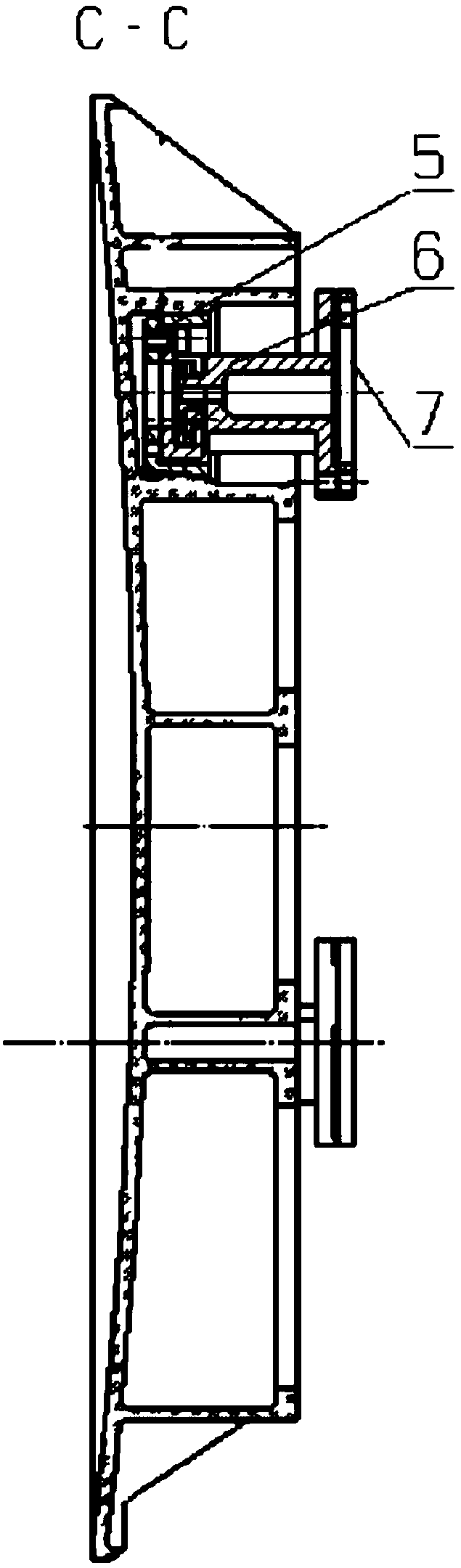

ActiveCN107457690AChange trackReduce labor intensityGrinding machine componentsLapping machinesPulp and paper industry

The invention relates to a grinding and polishing machine and an auxiliary mechanism thereof. The auxiliary mechanism of the grinding and polishing machine comprises an index plate, an axle sleeve and an eccentric module, wherein a rotating shaft is arranged at one end of the axle sleeve; a first axle hole is formed in the other end of the axle sleeve; the center of the first axle hole is not coaxial with the center of the rotating shaft; the rotating shaft is rotatably connected with the index plate; a limit pillar is arranged at one end of the eccentric module; a polishing wheel is connected at the other end of the eccentric module; an arc-shaped hole is formed in the end face, which is close to the index plate, of the axle sleeve; an adjusting hole is formed in the index plate; the eccentric module is arranged in the first axle hole; the limit pillar is sequentially arranged in the arc-shaped hole and the adjusting hole in the penetrating manner; a plurality of positioning holes are formed in the index plate; and the axle sleeve cooperates with one of the positioning holes to be limited on the index plate through a limiting mechanism. The eccentric distance between the eccentric module and the rotating shaft can be changed to achieve the purposes of adjusting the rotating curvature radius of the polishing wheel and changing the moving trajectory of the polishing wheel, so that different polishing effects are realized.

Owner:GUANGZHOU YONGHEXIANG AUTOMATION EQUIP TECH CO LTD

Production method of no-network polyester fabric

ActiveCN102634903AGuaranteed StrengthHigh strengthWoven fabricsMonocomponent polyesters artificial filamentYarnPolyester

The invention relates to a production method of a no-network polyester fabric, which belongs to the field of textile technology and aims to solve the technical problem that complex preparation processes in the prior art require production of network yarns to enhance product strength. The production method includes: A, preparing polyester chips; B, preparing master-batches; C, preparing draw textured yarns, and D, preparing the no-network polyester fabric. The production method is simple in process and requires no processing of network polyester yarns or setting via a second hot box, and the high-strength fabric can be obtained. The fabric produced by the method is high in color fastness.

Owner:台州东海翔织造有限公司

Positioning assembly for a back support of a mirror of an optical remote sensor

The invention relates to a positioning assembly for a back support of a mirror of an optical remote sensor, which comprises a substrate; a first fixing component arranged on the substrate and used forfixing the mirror of the optical remote sensor; a bearing component which comprises a bearing piece arranged on the substrate and a second fixing component arranged on the bearing piece; the bearingpiece is used for bearing a contact pad of the mirror of the optical remote sensor, and the second fixing component is used for fixing the contact piece on the bearing piece. According to the invention, the mirror body and the contact pad are relatively fixed through the first fixing component and the bearing component; when grinding is carried out, the grinding force directly acts on the end faceof the contact pad at the back of the main mirror component and is directly transmitted to the substrate through the bearing component, the back support piece does not bear alternating stress so as to avoid fatigue damage, and meanwhile, the grinding force when grinding the end face of the contact pad can be greatly improved so as to improve the grinding efficiency of the coplanarity grinding ofa flexible end face.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

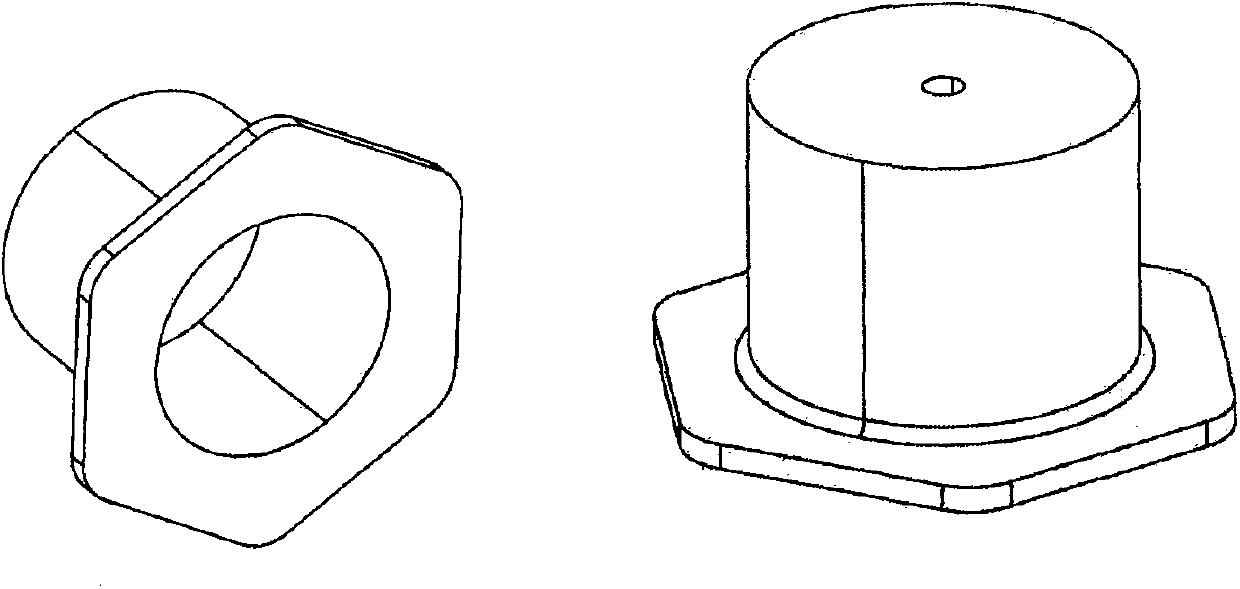

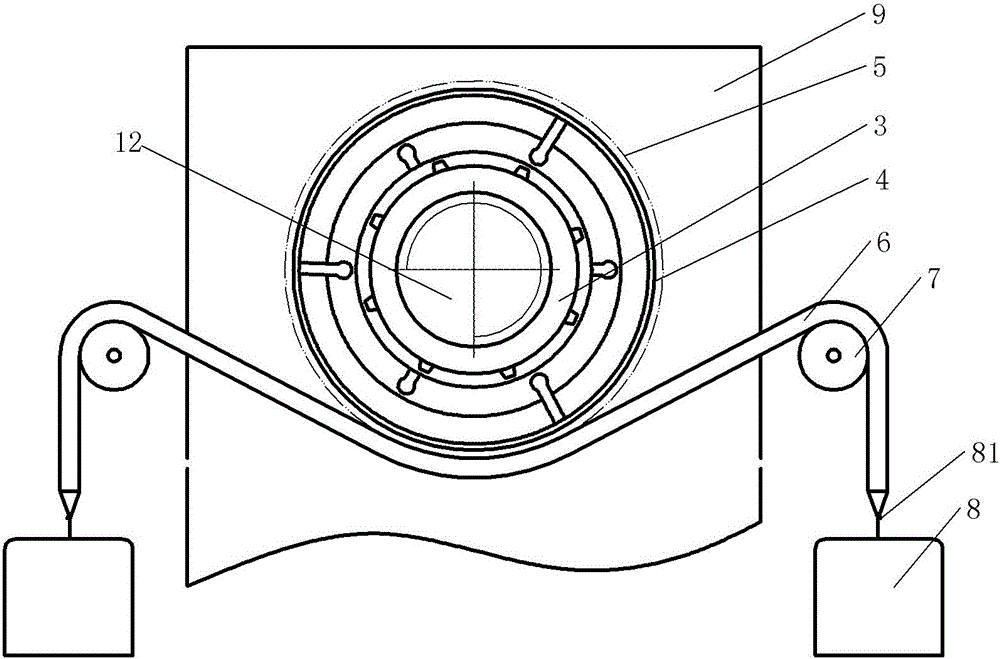

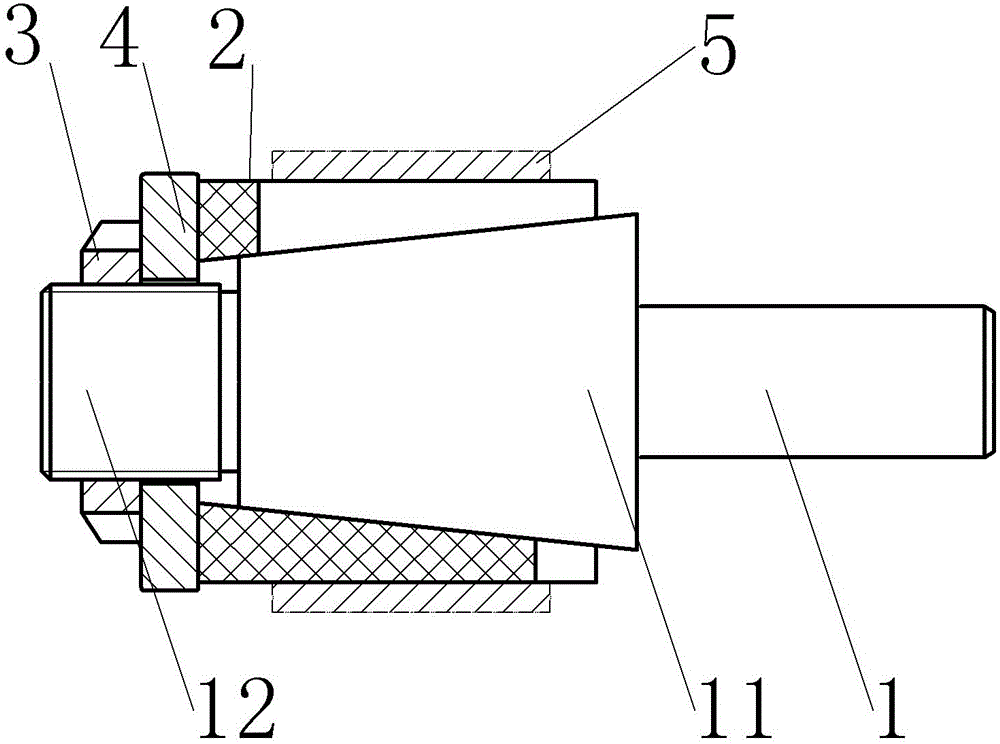

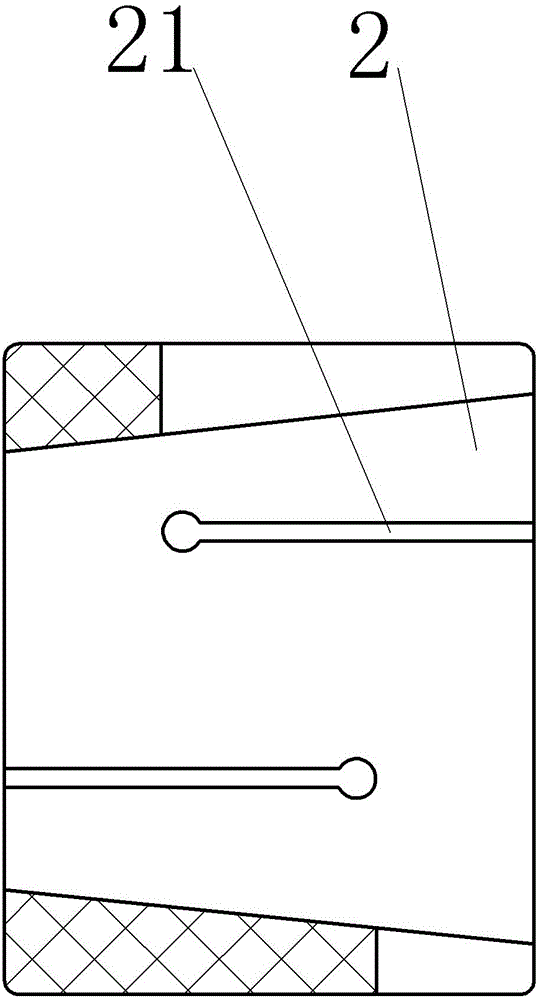

External grinding device for thin-walled part for motor

InactiveCN105033823ASimple structureLow costBelt grinding machinesGrinding work supportsEngineeringMechanical engineering

The invention discloses an external grinding device for a thin-walled part for a motor. The external grinding device comprises a rack, a clamp, a three-jaw chuck fixed to the rack, a spindle box driving the three-jaw chuck, and a grinding tool. The clamp comprises a mandrel, an expansion bushing, a pressing plate and a gland nut. The mandrel is provided with a threaded section and a conical section. The small-diameter end of the conical section is close to the threaded section. The gland nut is in threaded connection with the threaded section. The expansion bushing is a polyurethane expansion bushing. The inner working surface of the expansion bushing is arranged to be a taper hole. The conicity of the taper hole is matched with that of the conical section of the mandrel. The pressing plate is located between the gland nut and the expansion bushing. The pressing plate is annular. The inner diameter of the pressing plate is smaller than that of the expansion bushing and larger than the large diameter of the threaded section. The outer diameter of the pressing plate is larger than that of the expansion bushing. The grinding tool comprises two bearing rollers fixed to the rack, two counterweights and an abrasive belt. The abrasive belt is located between the expansion bushing and the bearing rollers. The two ends of the abrasive belt are wound around the bearing rollers and connected with the counterweights in a hanging mode. The external grinding device is easy to design and manufacture and capable of being applied to small-lot or single-piece production.

Owner:CHONGQING SHANGZE ELECTROMECHANICAL

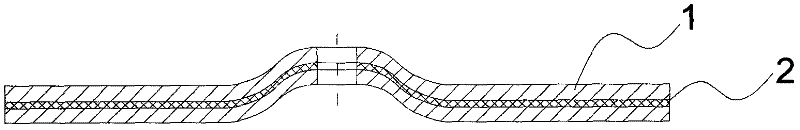

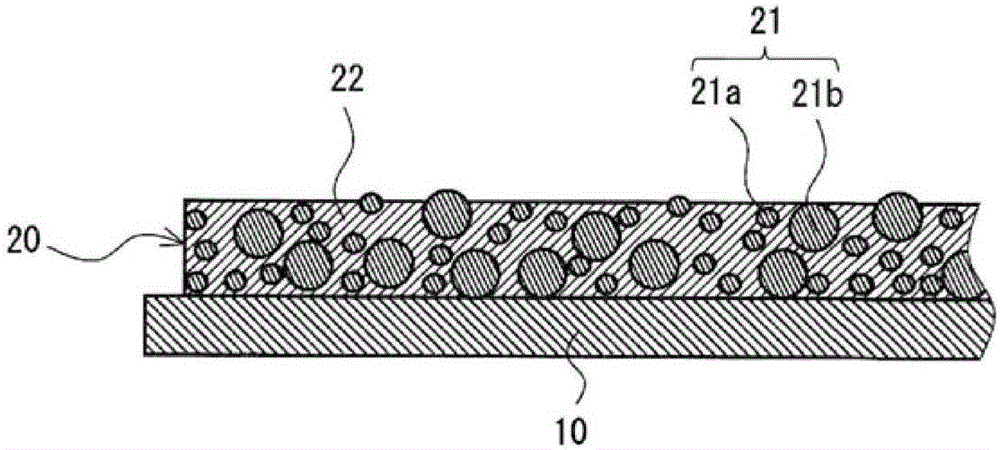

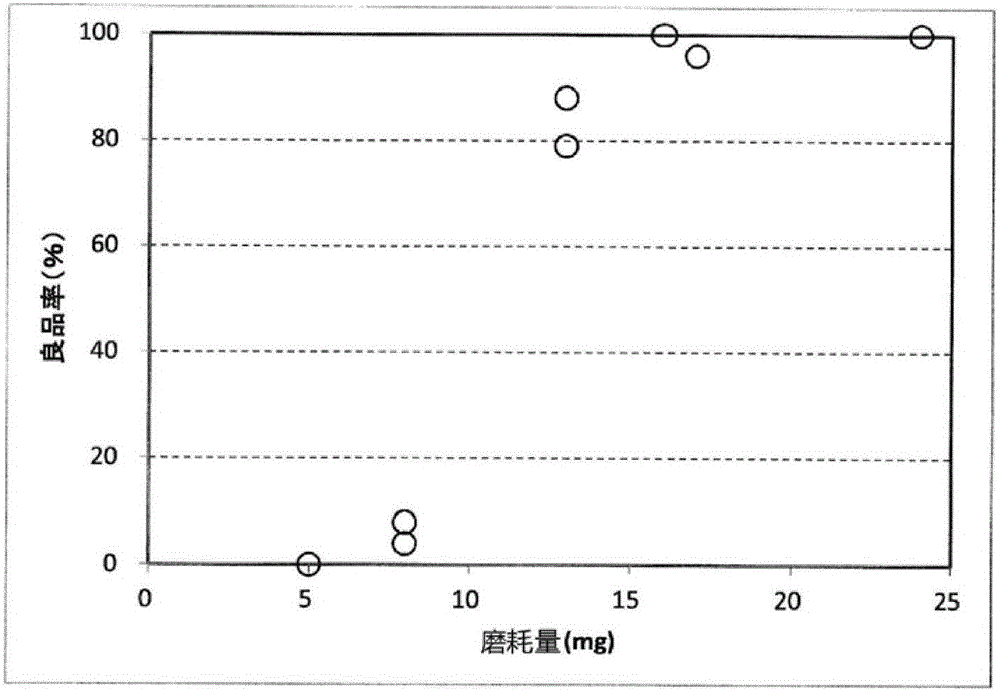

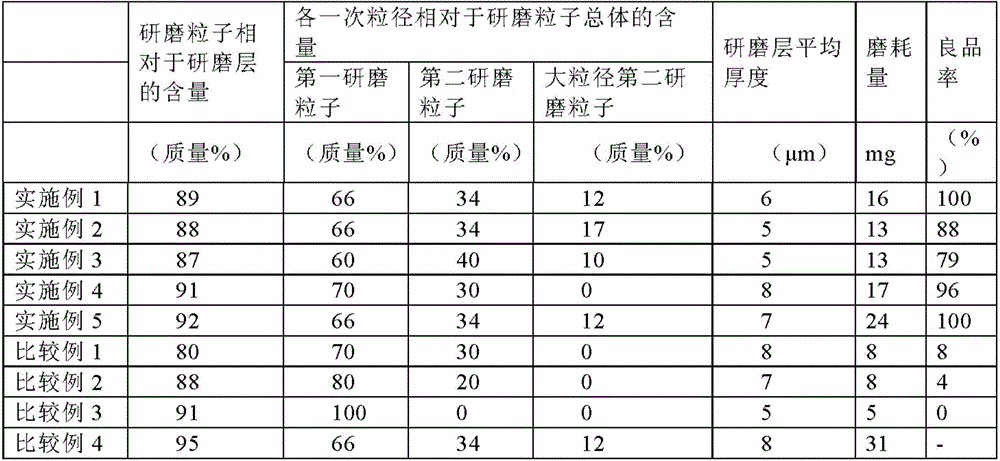

Polishing film

ActiveCN106573362AImprove grinding forceLess prone to end-face defectsAbrasion apparatusOptical light guidesSilica particleLapping film

The purpose of the present invention is to provide a polishing film which has high grinding power and is not susceptible to causing a defect in an end face of an optical fiber connector due to change in the loading conditions during polishing. The present invention is a polishing film which comprises a base film and a polishing layer that is laminated on the front surface of the base film. This polishing film is characterized in that: the polishing layer contains polishing particles and a binder therefor; and the amount of wear of the polishing layer in a Taber abrasion test is from 10 mg to 25 mg (inclusive). The content of the polishing particles in the polishing layer is preferably 85% by mass or more. It is preferable that the polishing particles contain first polishing particles having a primary particle diameter of 10 nm or more but less than 50 nm and second polishing particles having a primary particle diameter of 50 nm or more but less than 250 nm. The average thickness of the polishing layer is preferably from 4 [mu]m to 15 [mu]m (inclusive). It is preferable that the polishing particles are silica particles.

Owner:BANDO CHEM IND LTD

Method for manufacturing sponge polishing wheel

The invention discloses a method for manufacturing a sponge polishing wheel. The method comprises the following steps that a steel roll core is manufactured; a steel roll core coating is manufactured; the periphery of the coated steel roll core is evenly coated with a layer of glue bonding agent, and the glue bonding agent comprises epoxy resin, a polyamine curing agent and reinforcing filler; and a fiber rope is wound on the periphery, coated with the glue bonding agent, of the steel wire rope, and the sponge polishing wheel is formed through qualitative curing. Compared with the prior art, the method has the following beneficial effects that special synthetic resin is adopted in the polishing wheel manufactured through the method for manufacturing the sponge polishing wheel, the wear resistance and grinding force of the polishing wheel are enhanced, grinding scraps can be rapidly removed, and no stuffing or heating happens; and workpieces are prevented from being burnt by heating, and the method is suitable for long-time grinding work.

Owner:JINGDE ANDELI GRINDING TOOL CO LTD

Method for preparing waterborne epoxy resin for manufacturing polishing cloth and application of waterborne epoxy resin

The invention discloses a method for preparing waterborne epoxy resin for manufacturing polishing cloth. The method includes steps of S1, dissolving, by weight, 500-580 parts of epoxy resin in 500-580 parts of mixed organic diluents to obtain solution A; S2, dissolving, by weight, 200-230 parts of diethylenetriamine in 500-580 parts of organic solvents to obtain solution B; S3, dropwise adding the solution A into the solution B to obtain solution C when the solution A is completely dropwise added into the solution B; S4, cooling the solution C until the temperature of the solution C reaches 20 DEG C, dropwise adding, by weight, 470-575 parts of organic acid into the solution C and stirring the solution C and the organic acid for 0.5 hour to obtain the transparent orange waterborne epoxy polyamine resin for manufacturing the polishing cloth. The temperatures of the solution A and the solution B are 40 DEG C when the solution A starts to be dropwise added into the solution B, the dropwise adding speeds are controlled in dropwise adding procedures, and the reaction temperatures are 40-50 DEG C. The method has the advantages that the polishing cloth with phenolic resin can be toughened by the waterborne epoxy resin prepared by the aid of the method; the polishing cloth manufactured by the aid of the method is excellent in tearing and tensile strength, cutting force can be enhanced, and the moisture absorption can be obviously improved.

Owner:WUXI PERMANENT IND

A kind of spring end surface grinding device and grinding method thereof

InactiveCN111037389BLower the altitudeImprove grinding performanceGrinding carriagesGrinding drivesElectric machineryGrinding wheel

Owner:CHENGDU CHENHUI SPRING MFG

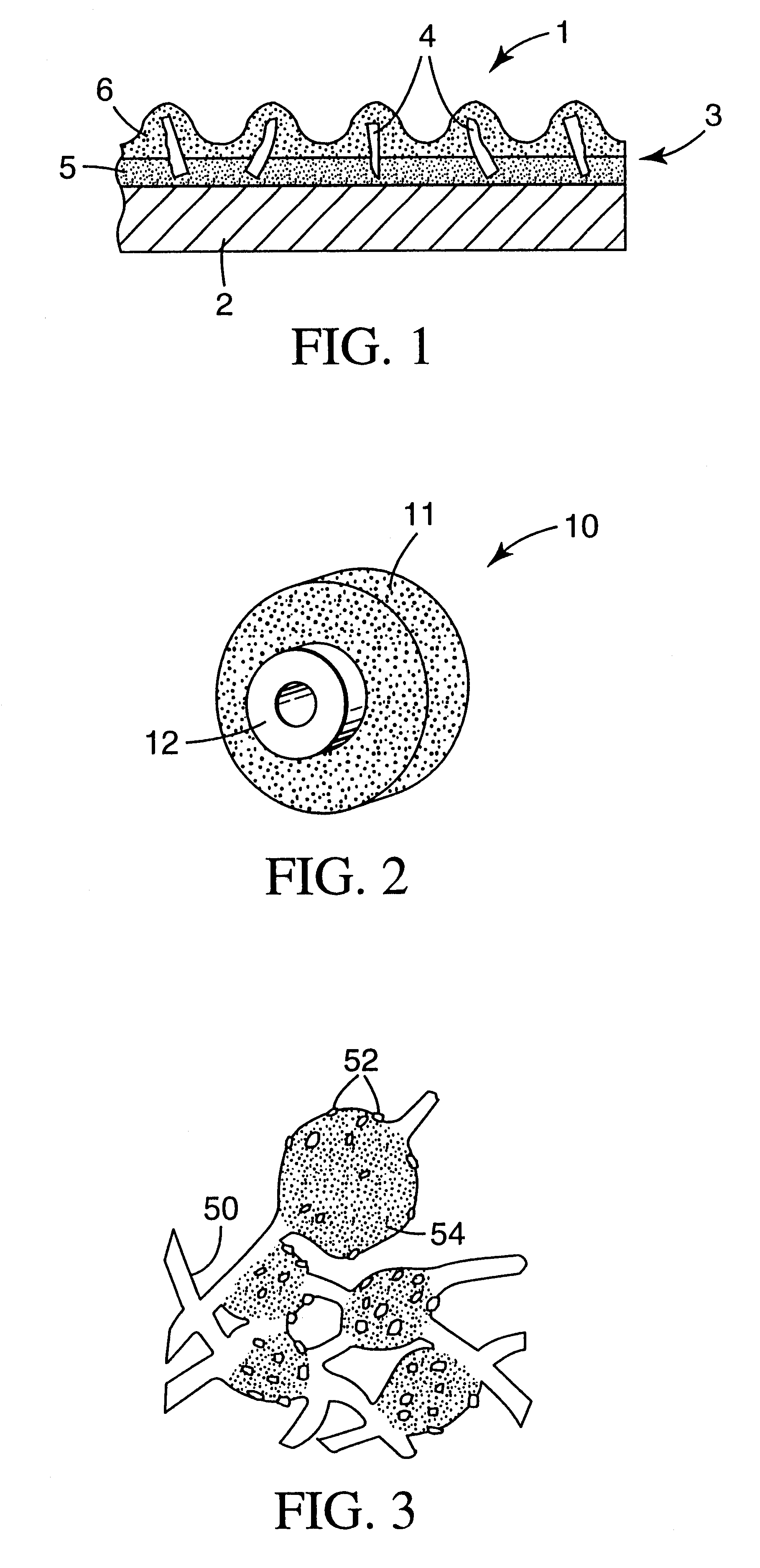

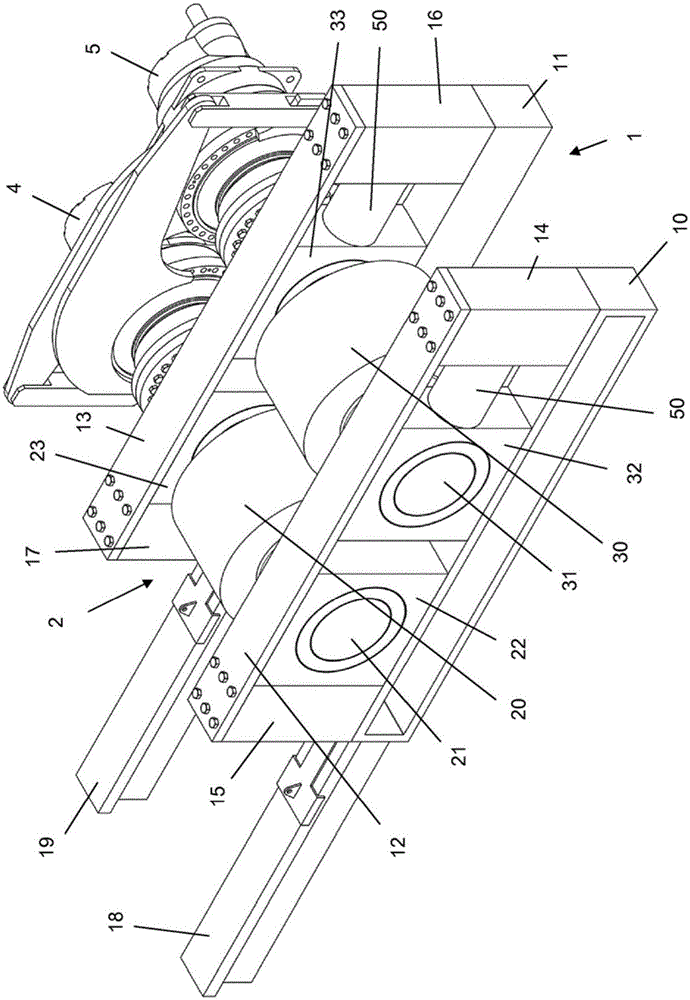

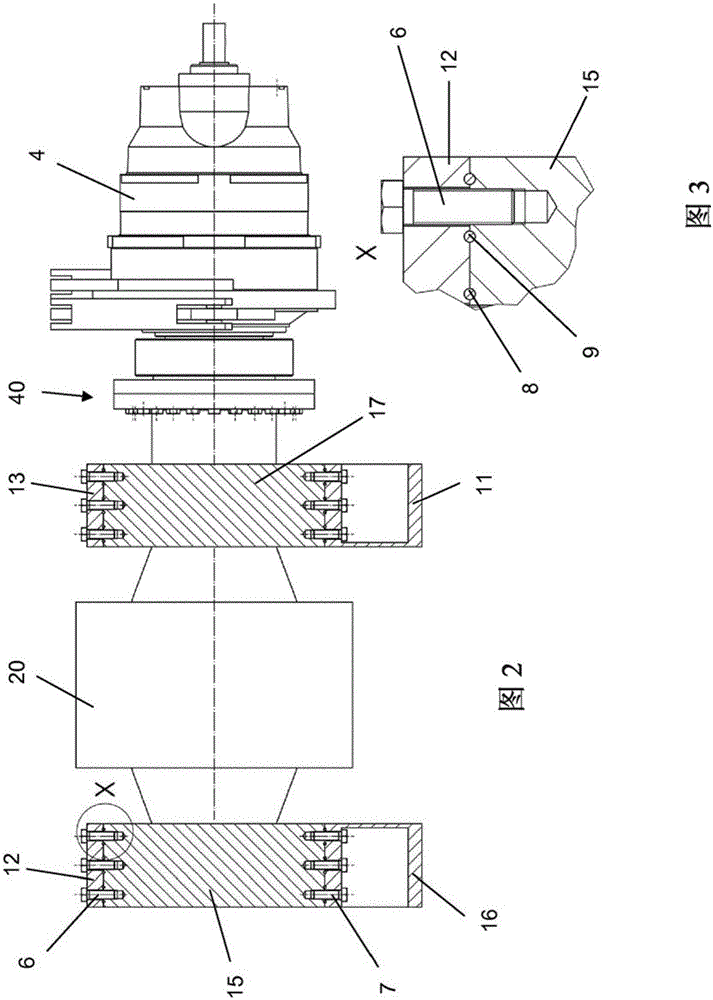

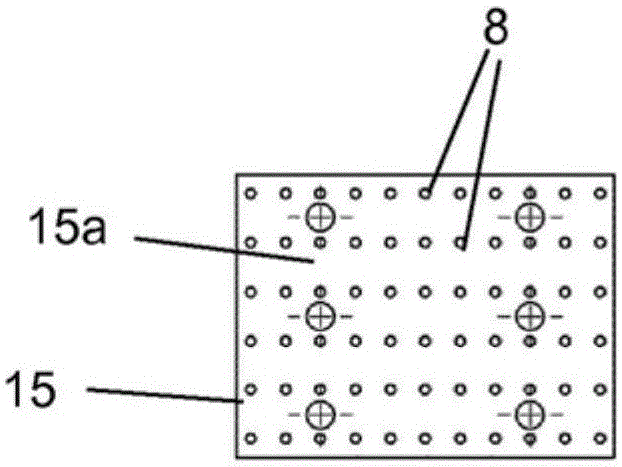

Roll mill

ActiveCN105142791AImprove grinding forceEliminate connectionGrain treatmentsRotary pressEngineeringRolling mill

The invention relates to a roll mill with two roll units (2, 3) which are arranged in a machine frame (1) and each comprise a grinding roll (20, 30) rotatably mounted in two bearing blocks (22, 23, 32, 33), wherein: the two grinding rolls (20, 30) are disposed opposite one another and are each coupled to a drive (4, 5) for driving the grinding rolls in opposing directions; a force-application system (50) for generating a grinding force is provided between the machine frame (1) and at least one roll unit (3), the grinding force being transferred via the machine frame (1) and the bearing blocks (22, 23, 32, 33) to the grinding rolls (20, 30); and the machine frame (1) consists of a plurality of frame parts (10, 11, 12, 13), a detachable, interlocking connection having two connecting surfaces (15a, 12a) pressed against each other being provided between at least two interconnected frame parts and / or between at least one frame part and one of the bearing blocks in order to transfer the grinding force, at least one of the two connecting surfaces (15a, 12a) pressed against each other having a coating (8, 9) which generates a microscale interlocking connection.

Owner:F L SMIDTH & CO AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com