Polishing film

A technology of grinding film and grinding layer, applied in abrasives, instruments, optics, etc., can solve the problems of sufficiently high grinding force, occurrence rate of end face defects, rise, etc., and achieve the effect of high grinding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0062] The present invention is not limited to the above-described embodiments, and can be implemented in embodiments to which various changes and improvements have been added other than the above-described embodiments.

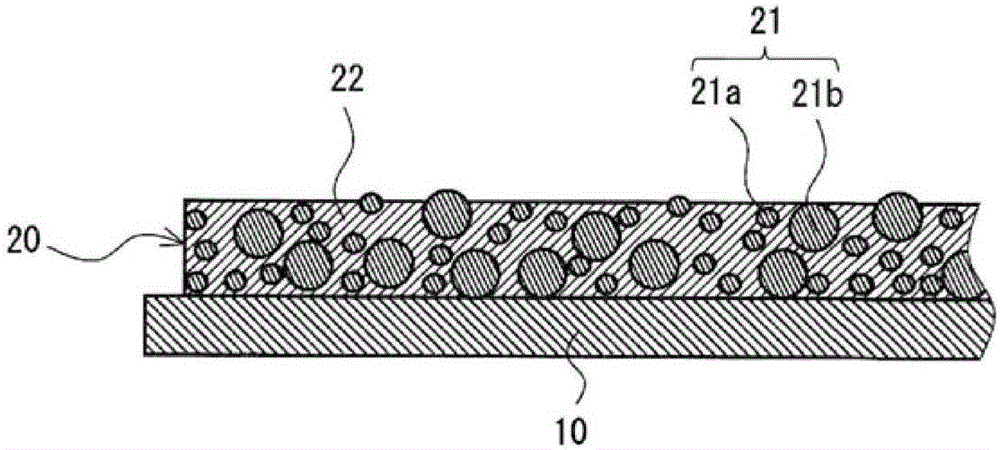

[0063] In the above-mentioned embodiment, the polishing film in which the polishing layer is directly formed on the surface of the base film has been described, but it is also possible to install between the base film and the polishing layer to ensure the close contact between the base film and the polishing layer. permanent primer treatment. The main component of the primer treatment layer is not particularly limited as long as the adhesion between the base film and the abrasive layer can be ensured. For example, water-soluble or water-dispersible polyester or acrylic resin or unsaturated bond-containing A resin obtained by grafting a compound on a water-soluble or water-dispersible polyester containing a hydrophilic group.

[0064] The primer-treated layer c...

Embodiment 1

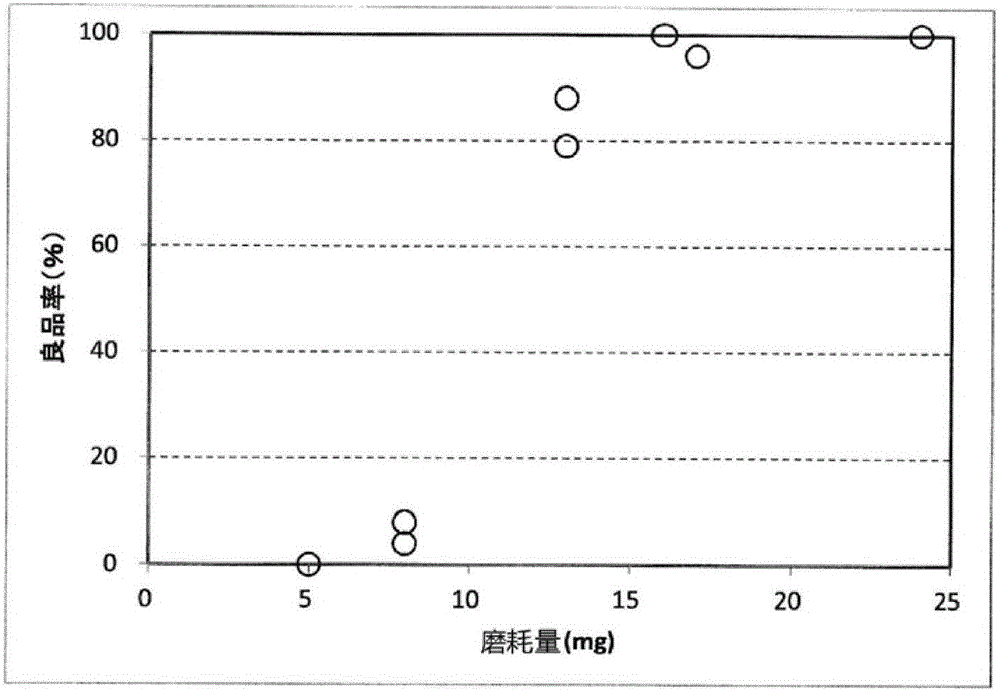

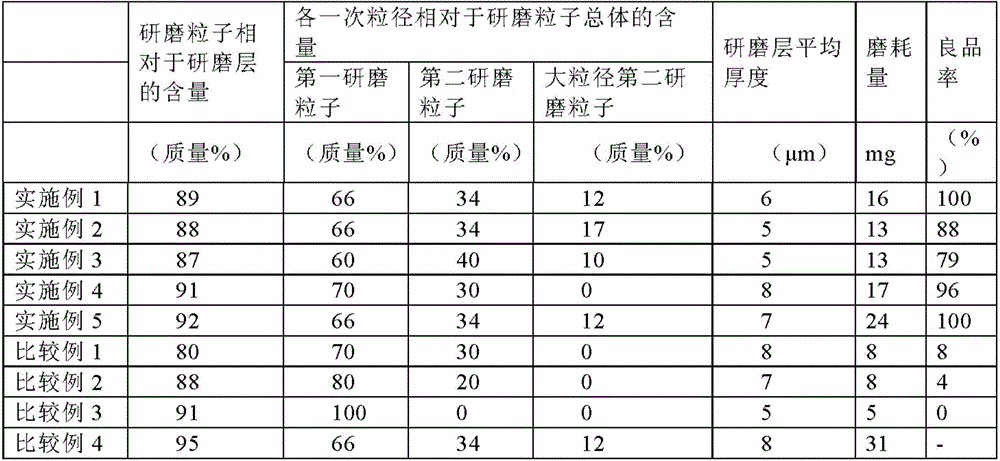

[0069] 100 parts by mass of organosilica sol (Nissan Chemical Industry Co., Ltd. "MEK-ST", primary particle diameter of 10 nm to 20 nm, solid content of 30 mass %) as the first abrasive particles, 50 parts by mass of Organosilica sol ("PL-7L-IPA" of Fuso Chemical Industry Co., Ltd., the average primary particle diameter is 75 nm, and the solid content is 20% by mass) as the second abrasive particles, 13 parts by mass of Organosilica sol (Nissan Chemical Industry Co., Ltd. "MEK-ST-2040", average primary particle diameter of 200 nm, solid content of 40% by mass), 27 parts by mass of organic silica sol containing 5% by mass of N,N-dimethylformamide solution of acrylonitrile-butadiene rubber ("N230S" of JSR Co., Ltd.) as a binder, 27 parts by mass containing 5% by mass of Binder cellulose resin ("Ethocel (ethyl cellulose) 100" of Nissei Co., Ltd.) methyl ethyl ketone solution and 3 parts by mass of polyisocyanate (Sumika Bayer) as a binder Polyurethane ("Desmodule L75C" of Sumika...

Embodiment 2

[0072] 100 parts by mass of organosilica sol ("MEK-ST" of Nissan Chemical Industry Co., Ltd., primary particle diameter of 10 nm to 20 nm, solid content of 30 mass %) as the first abrasive particles, 39 parts by mass of As the second abrasive particles, organic silica sol ("PL-7L-IPA" of Fuso Chemical Industry Co., Ltd., the average primary particle diameter is 75nm, and the solid content is 20% by mass), 19 parts by mass of Organosilica sol (Nissan Chemical Industry Co., Ltd. "MEK-ST-2040", average primary particle diameter of 200 nm, solid content of 40% by mass), 30 parts by mass of organosilica sol containing 5% by mass of the second abrasive particle N,N-dimethylformamide solution of acrylonitrile-butadiene rubber ("N230S" of JSR Co., Ltd.) as a binder, 30 parts by mass containing 5% by mass of The cellulose resin of the binder ("Ethocel (ethyl cellulose) 100" of Nissei Co., Ltd.) dissolved in methyl ethyl ketone and 4 parts by mass of polyisocyanate (Sumika Bayer Polyur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com