External grinding device for thin-walled part for motor

A technology for thin-walled parts and outer circle grinding, which is applied in the direction of grinding machines, abrasive belt grinders, grinding workpiece supports, etc. It can solve the problems of complex design, processing and manufacturing, unstable clamping force of workpieces, and inability to clamp workpieces, etc., to achieve Guaranteed machining accuracy, improved machining efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below by means of specific embodiments:

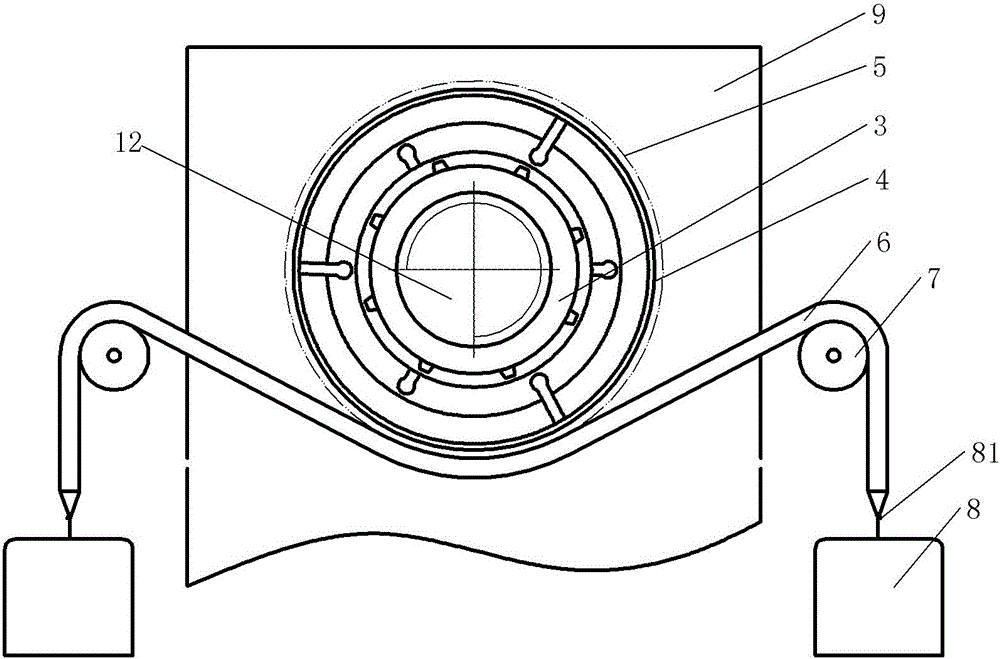

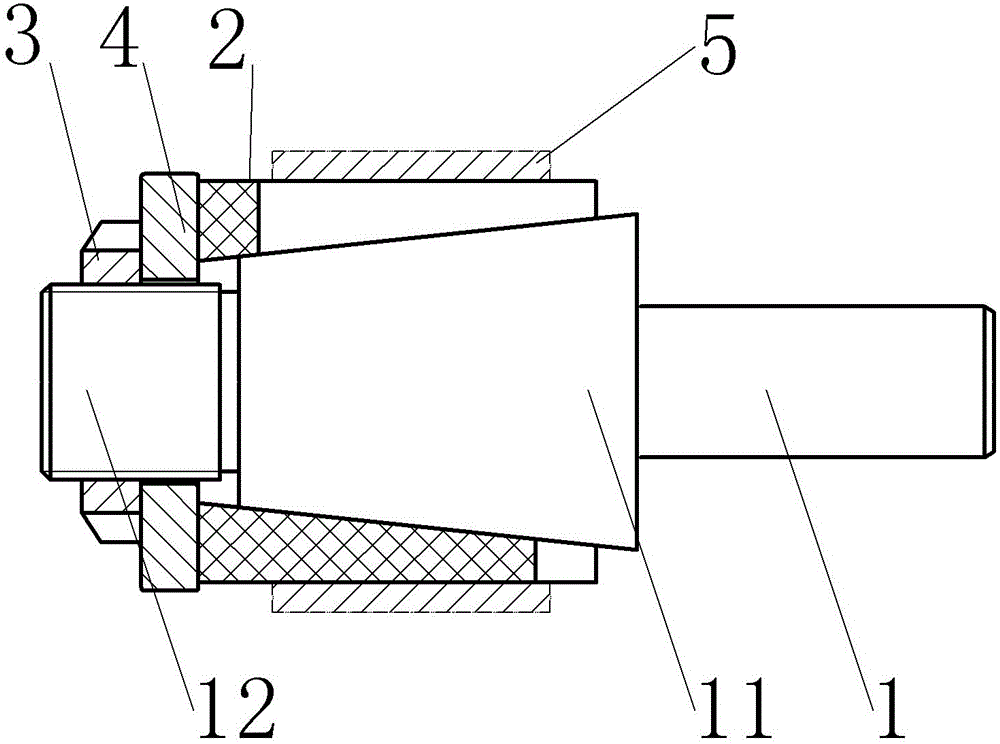

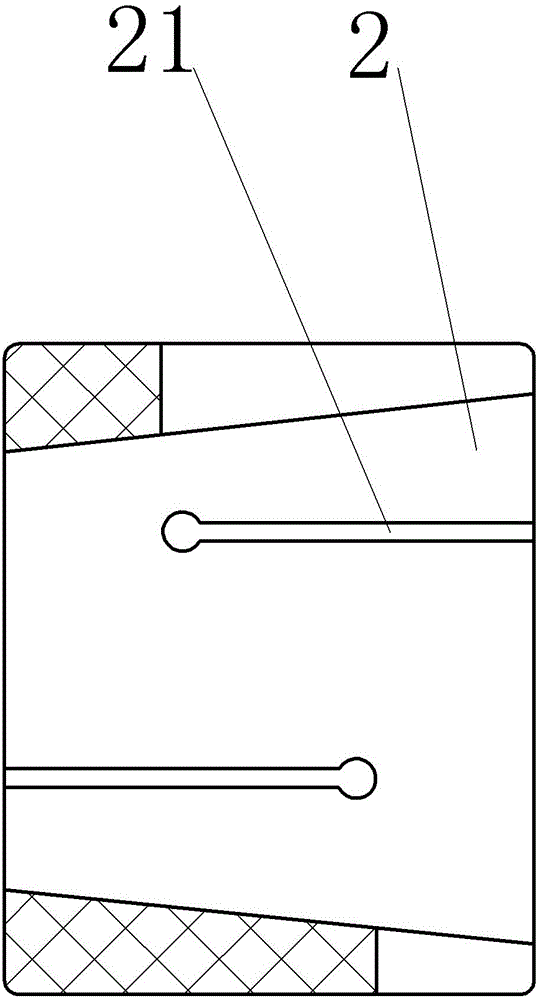

[0032] The reference signs in the drawings of the specification include: mandrel 1, expansion sleeve 2, compression nut 3, conical section 11, threaded section 12, pressure plate 4, workpiece 5, abrasive belt 6, support roller 7, counterweight 8, Hook 81, frame 9.

[0033] The embodiment is basically as attached figure 1 Shown:

[0034] The device for grinding the outer circle of thin-walled parts for motors includes a frame 9, a three-jaw chuck fixed on the frame 9, a spindle box for driving the three-jaw chuck, and an abrasive tool, and the abrasive tool includes two screws fixed on the frame 9 The support roller 7, two counterweights 8 and the abrasive belt 6 on the top, the abrasive belt 6 is located between the expansion sleeve 2 and the support roller 7, and the two ends of the abrasive belt 6 respectively bypass the support roller 7 and hang the counterweight 8; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com