Patents

Literature

39results about How to "Avoid assembly difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

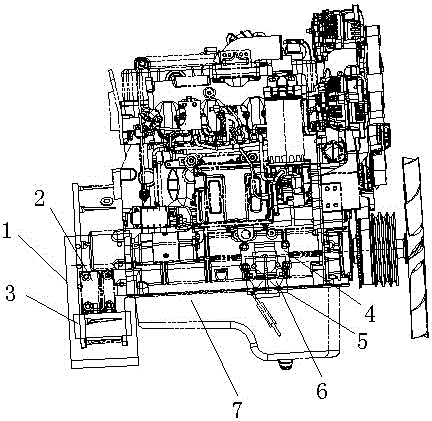

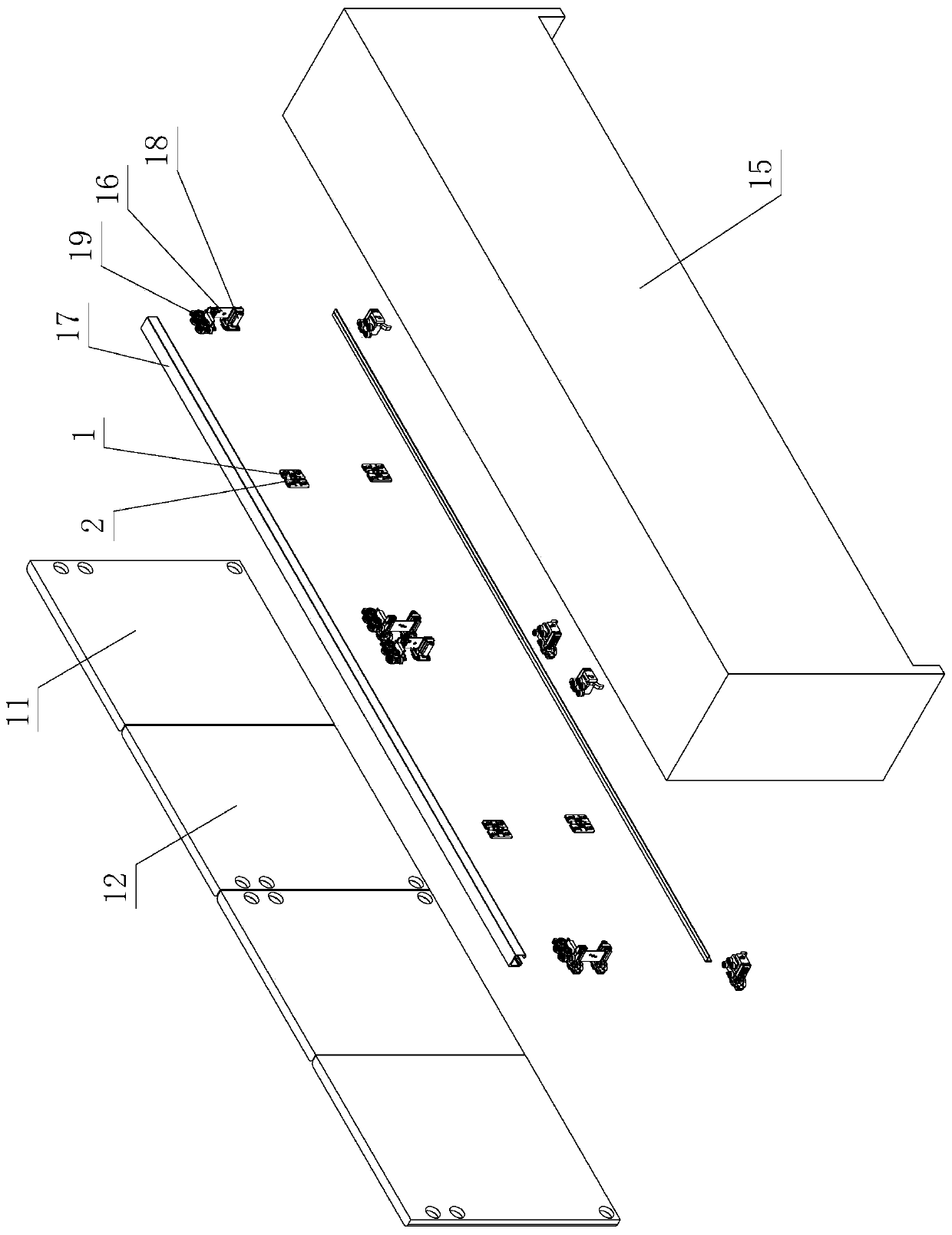

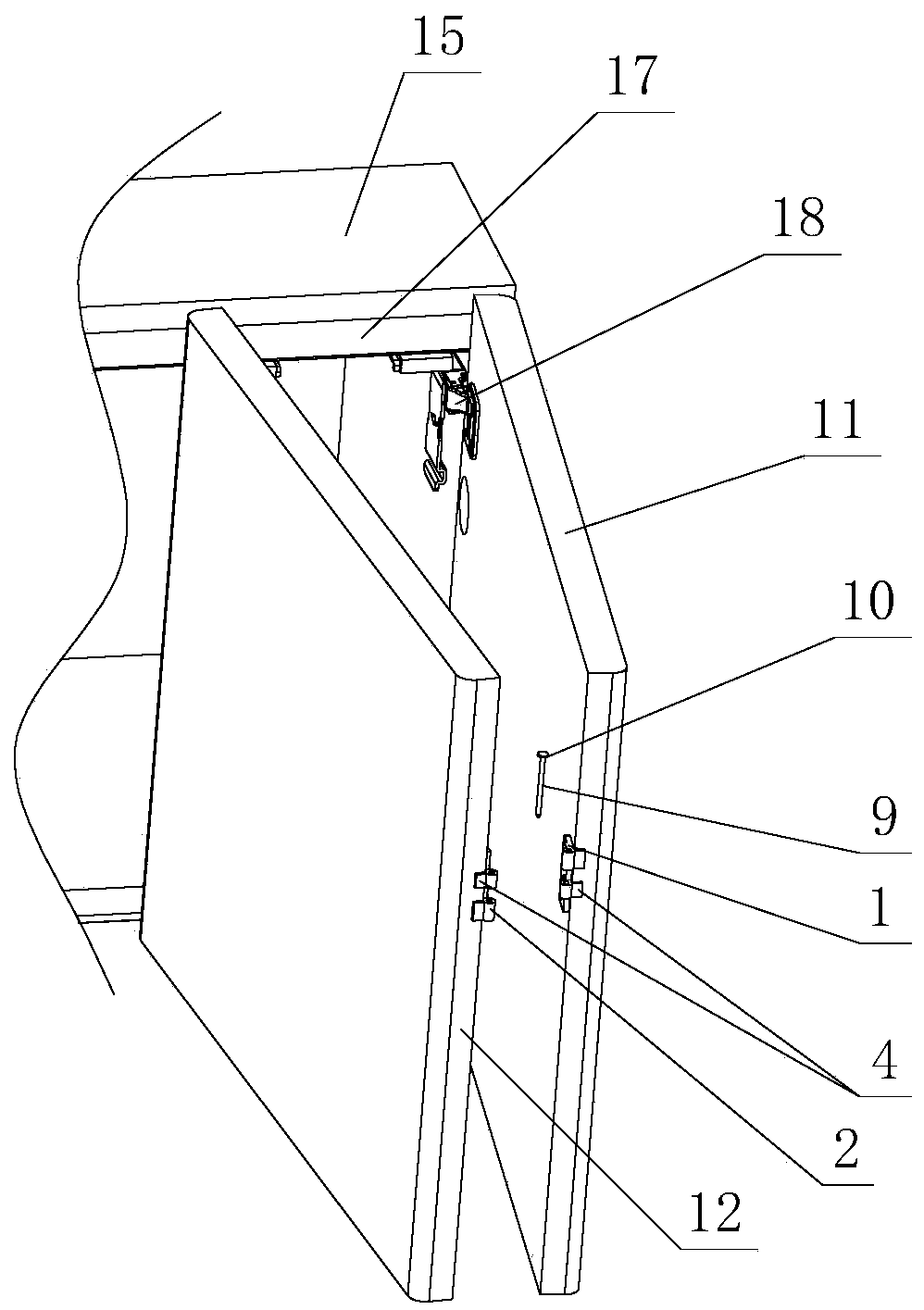

Front bus engine mounting system

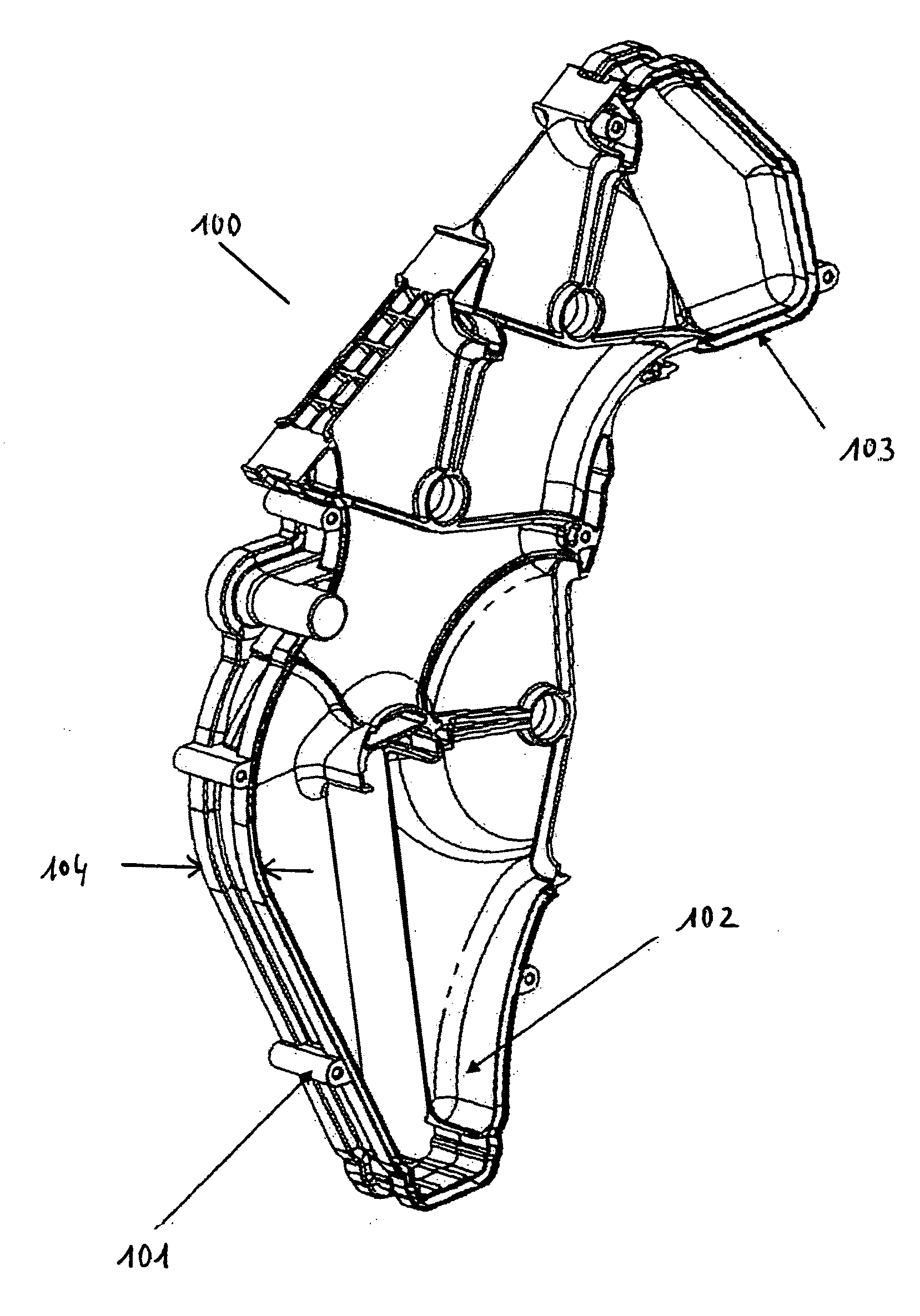

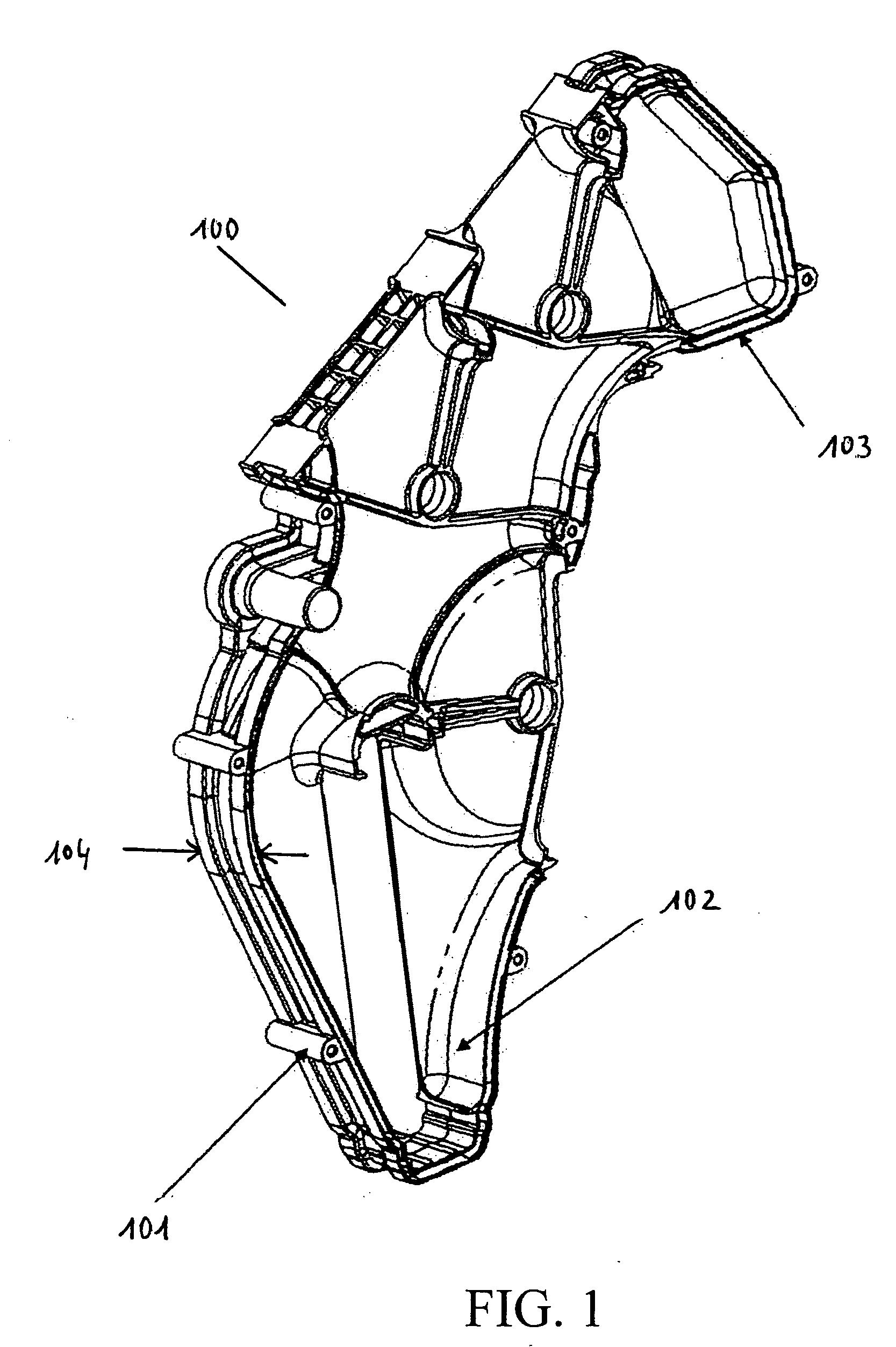

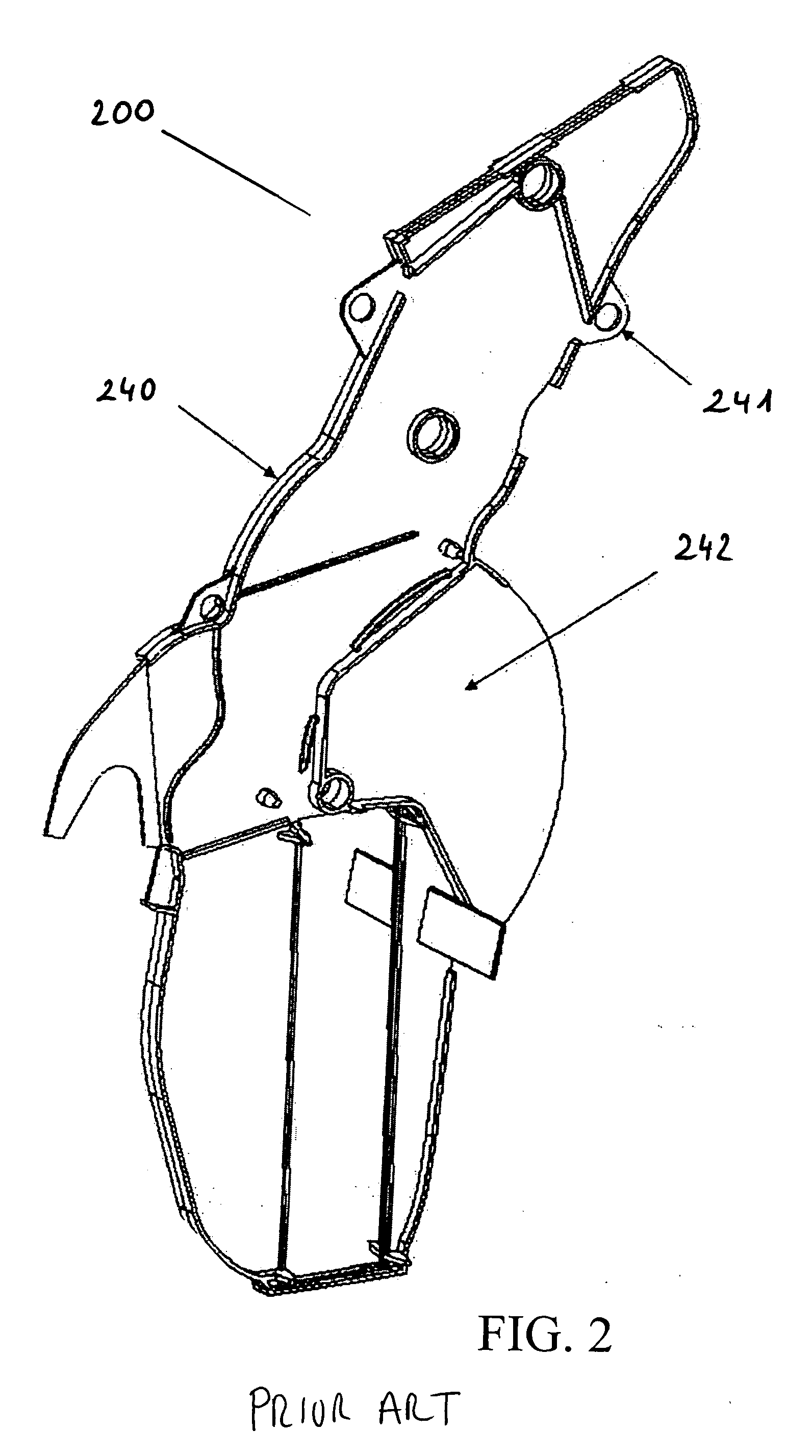

InactiveCN105109323AImprove shock absorptionStable supportJet propulsion mountingInternal combustion mountingDrive shaftEngine mount

The invention relates to a front bus engine mounting system. The front bus engine mounting system comprises a left engine front support, a right engine front support, an engine front bracket, a left engine front mounting cushion, a right engine front mounting cushion, a left engine rear support, a right engine rear support, a left engine rear bracket, a right engine rear bracket, a left engine rear mounting cushion and a right engine front mounting cushion, wherein the left engine front support and the right engine front support are symmetrically arranged on the left side and the right side of the front end of an engine; and the left engine rear support and the right engine rear support are symmetrically arranged on the left side and the right side of the rear end of the engine. According to the front bus engine mounting system provided by the invention, shortcomings in the prior art can be avoided; the assembling efficiency is increased; the shock absorbing effect is improved; assembling errors can be avoided; the transmission efficiency can be ensured; and the normal use of a transmission shaft can be also ensured.

Owner:ANHUI ANKAI AUTOMOBILE

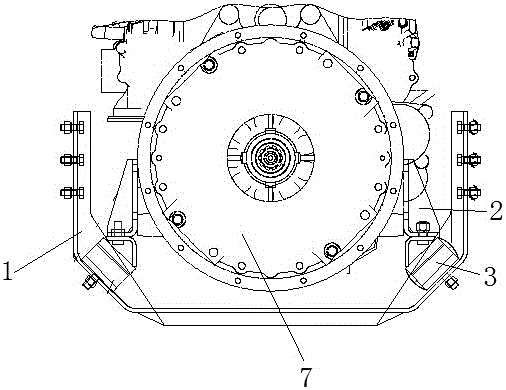

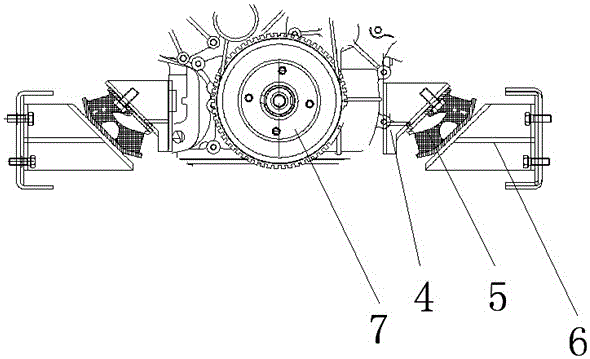

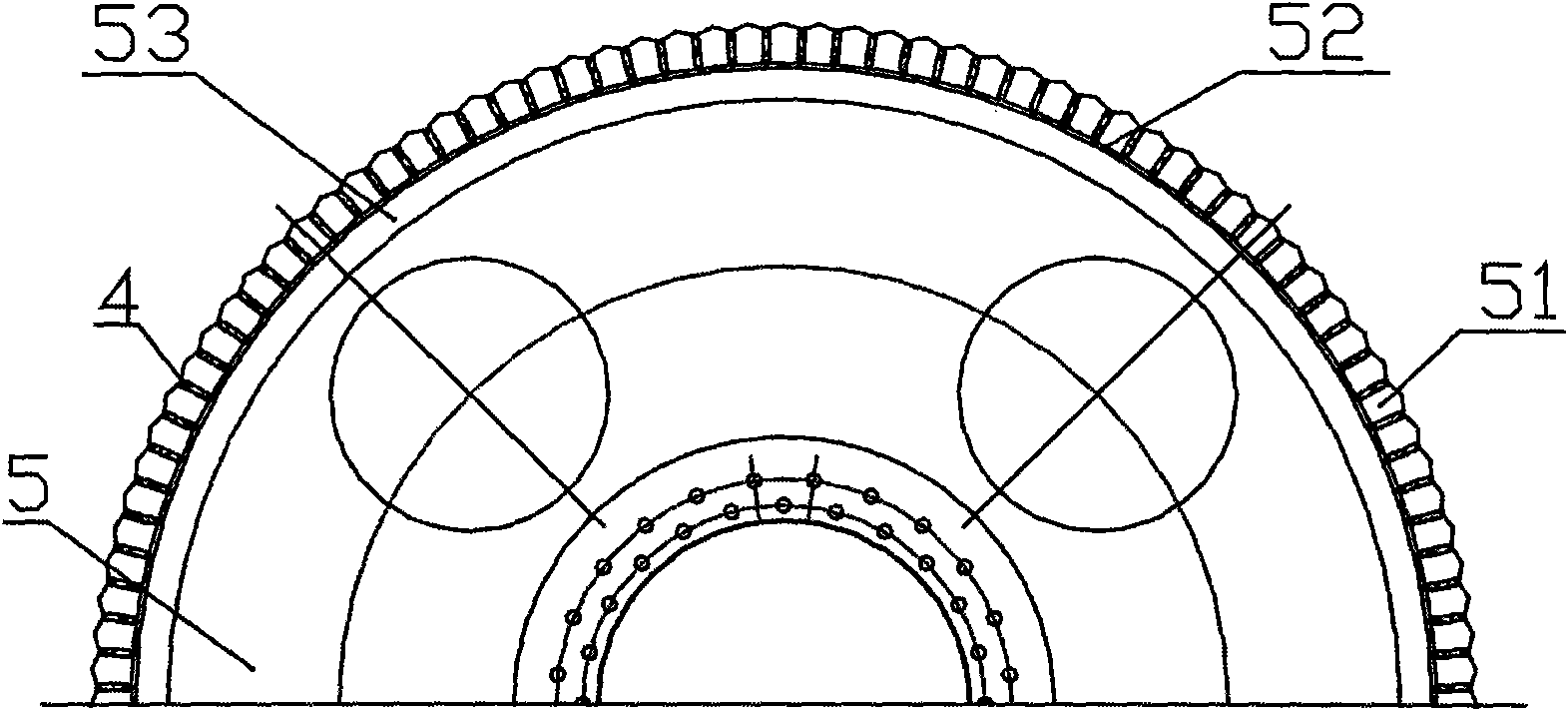

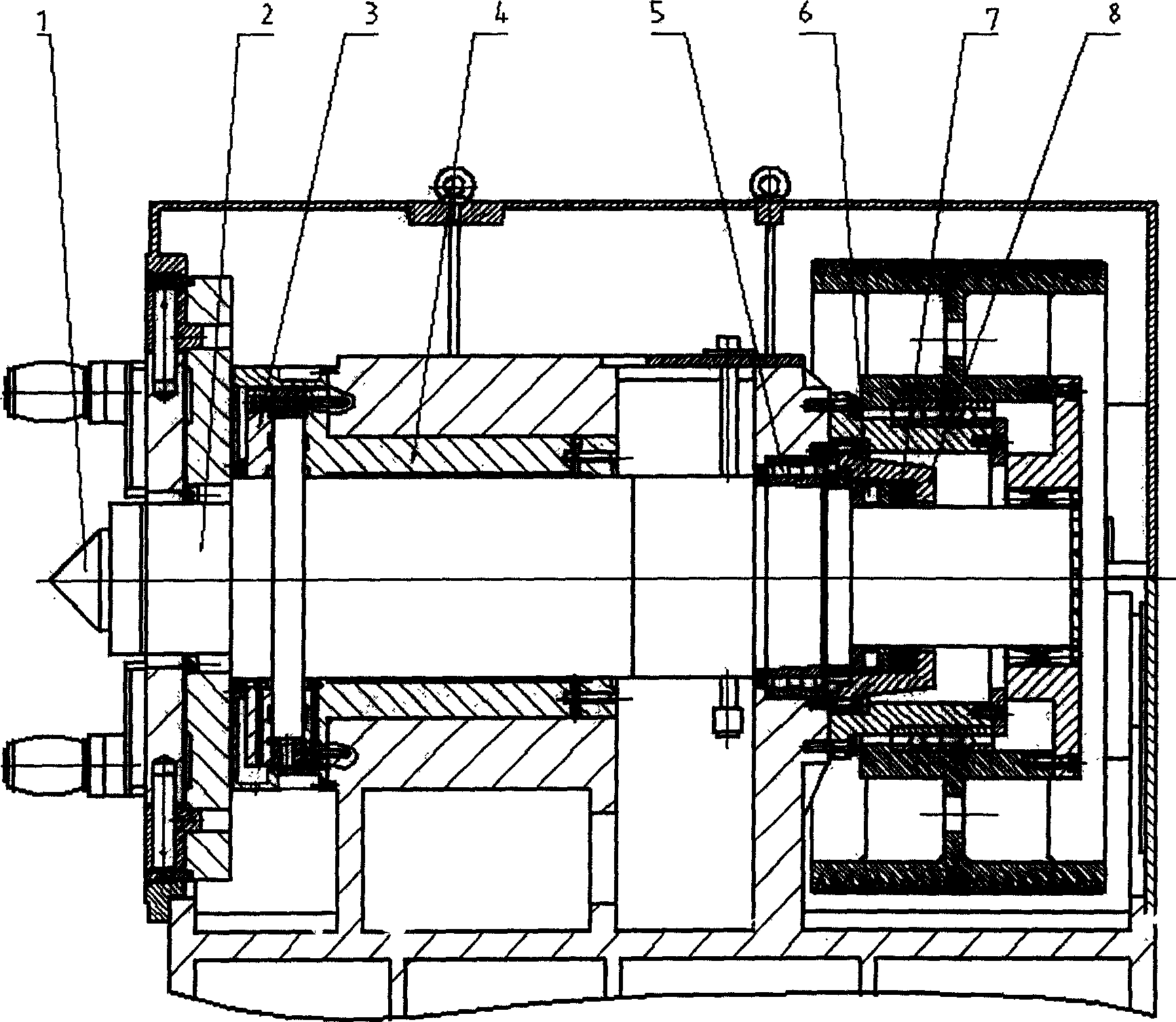

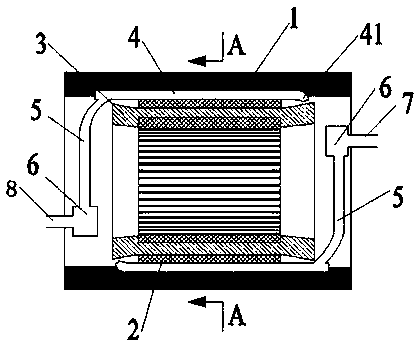

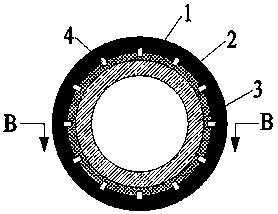

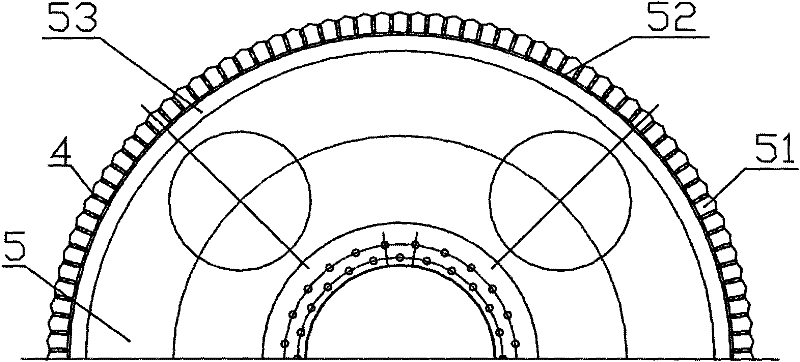

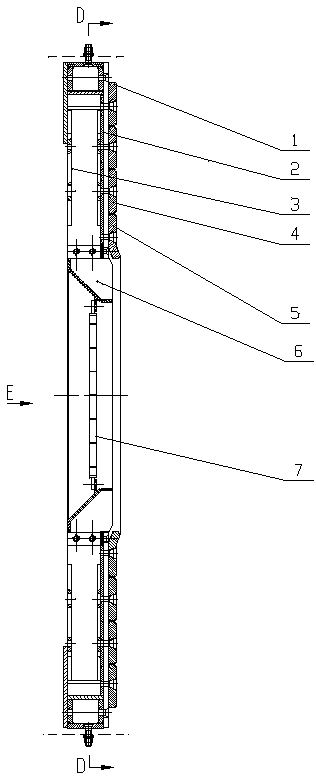

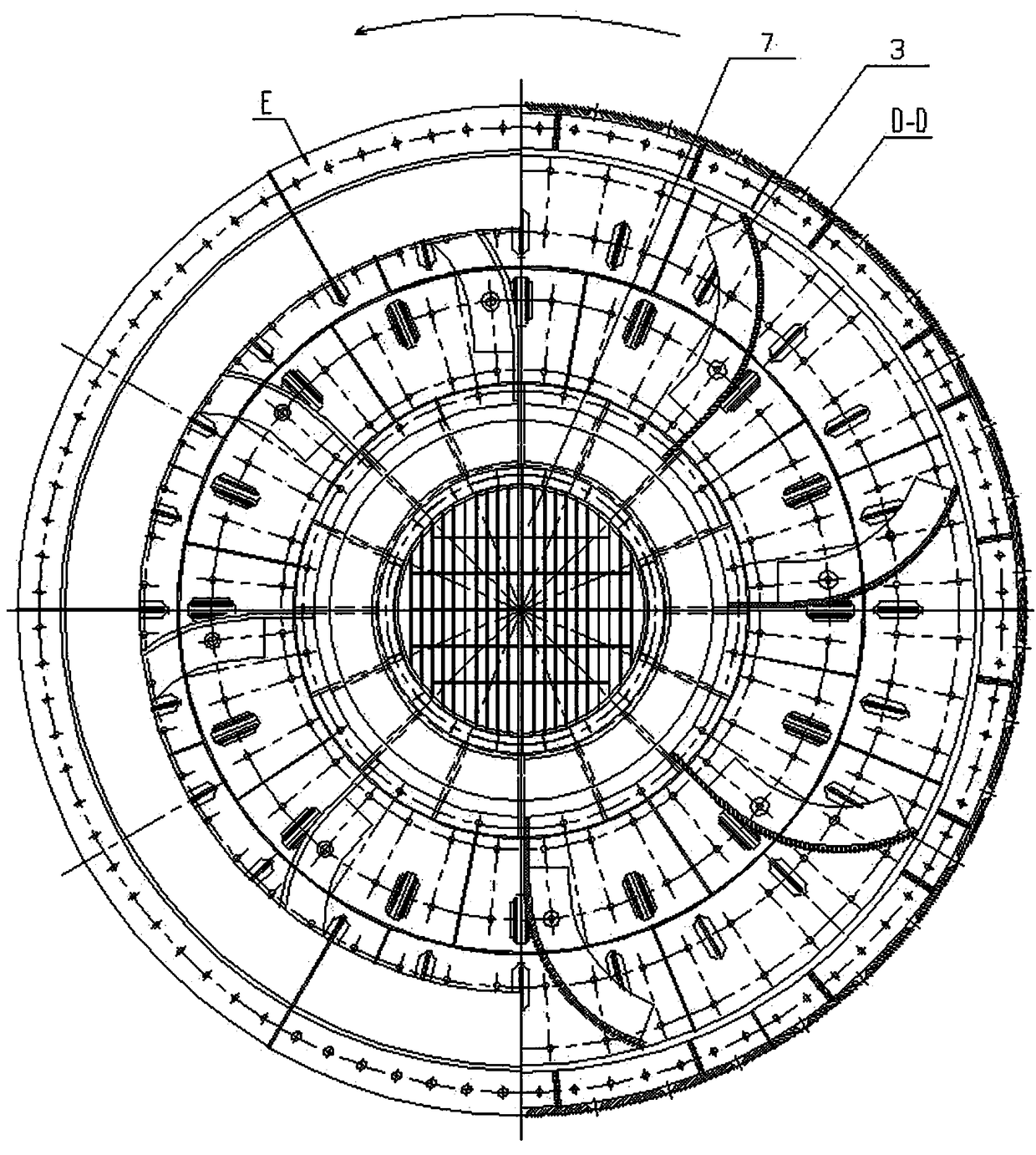

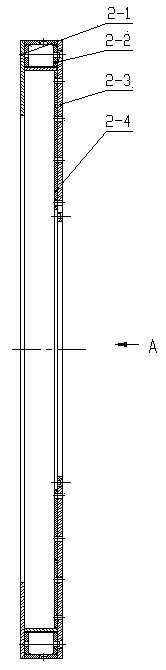

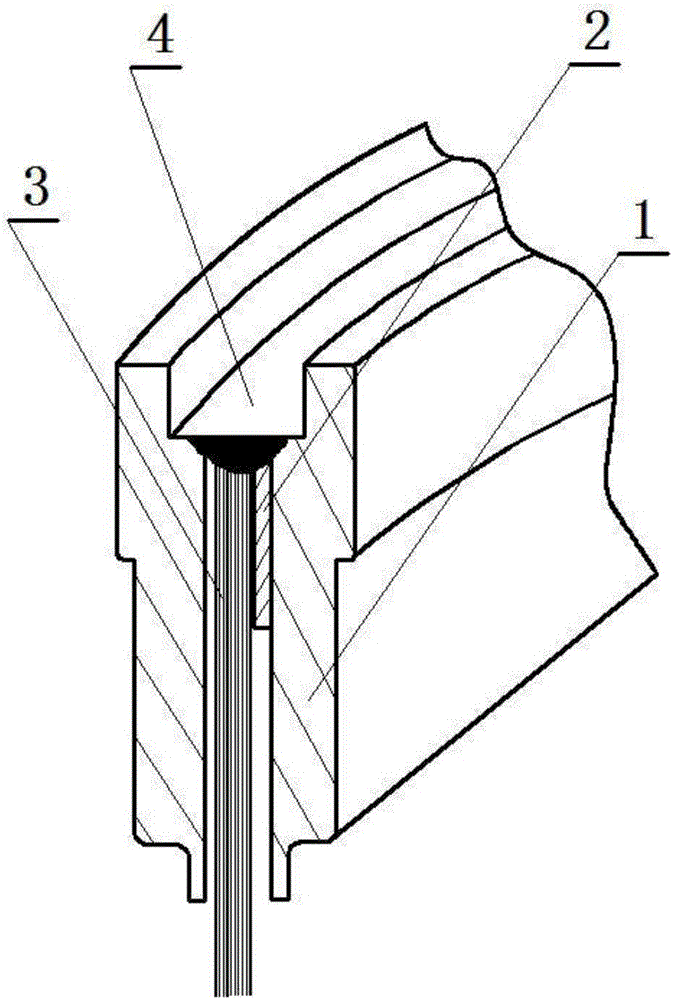

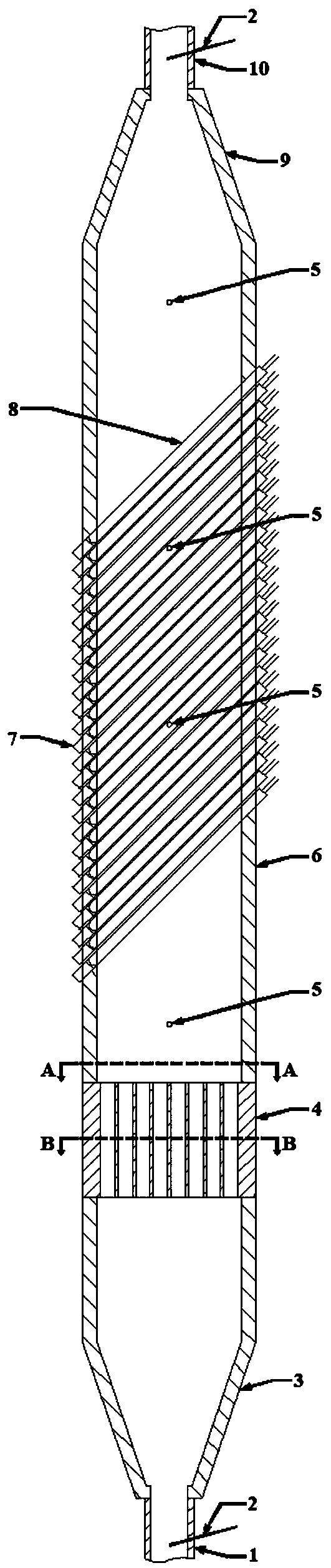

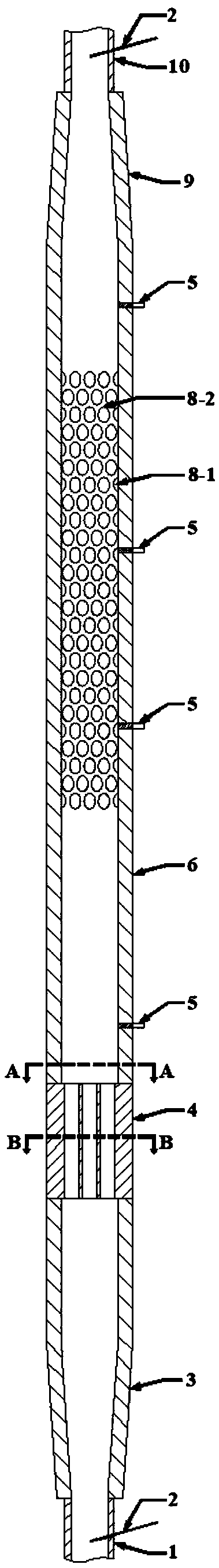

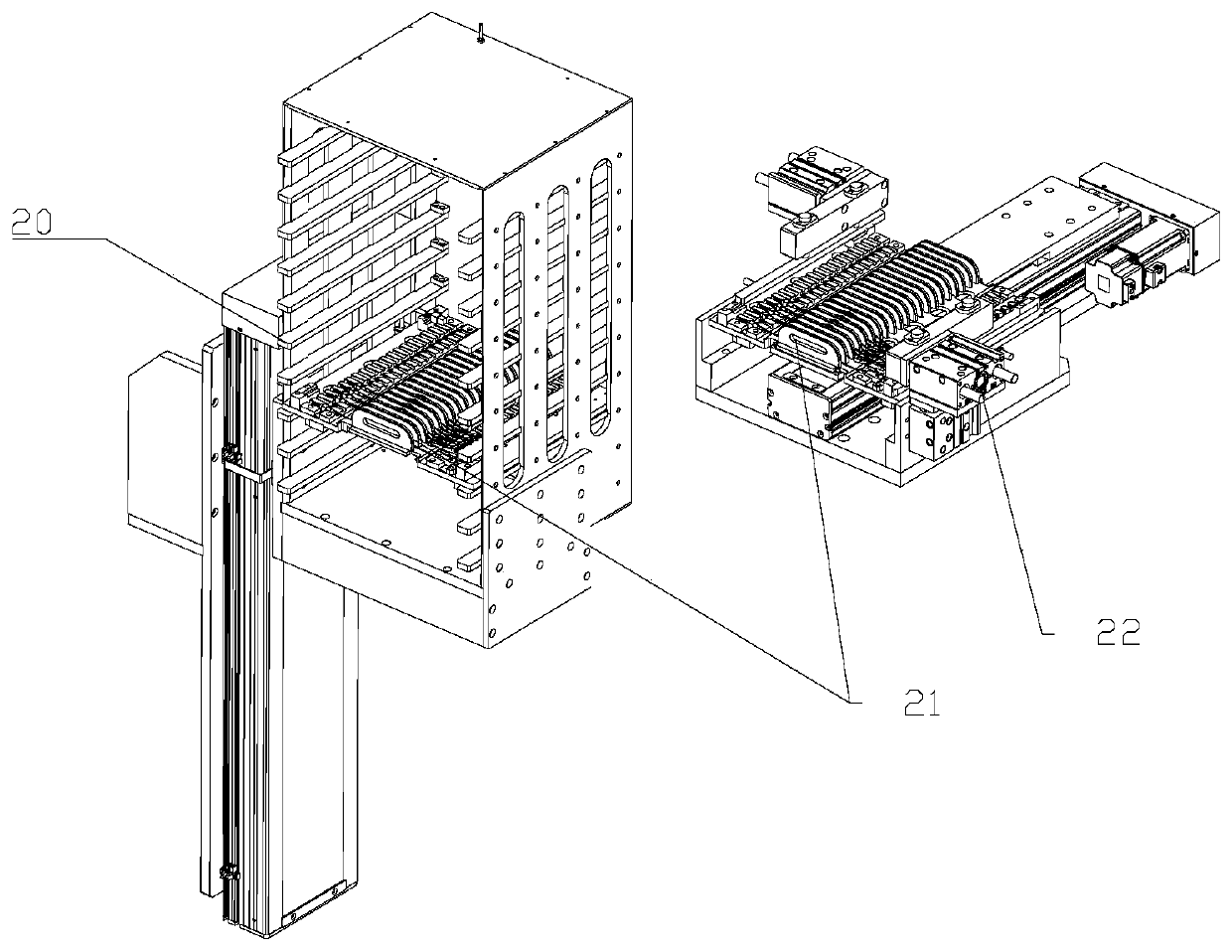

Permanent magnet synchronous motor for hoisting mechanism of direct-drive crane

InactiveCN101662195AImprove transmission efficiencyImprove reliabilityMagnetic circuit rotating partsSynchronous machinesLow speedElectric machine

The invention discloses a permanent magnet synchronous motor for a hoisting mechanism of a direct-drive crane; the permanent magnet synchronous motor comprises a permanent magnet synchronous motor shell, a stator winding, a stator iron core, a permanent magnet, a rotor, a winding drum revolving shaft and a winding drum; and the permanent magnet synchronous motor has more than 20 poles. In the invention, by increasing the number of the poles of the permanent magnet motor, a variable-frequency power source is adopted to realize low-speed operation of the motor, high torque is output, the motor directly drives the load to work, a speed reducer is canceled, the structure is simple and practical, and the working efficiency of the system is improved; a rotor structure adopted by the invention can effectively solve the problem of difficult assembly of the permanent magnet motor; rotor magnetic poles and magnetic separation steel rings commonly protect the permanent magnet from being damaged when in assembly; reluctance torque is reduced to be zero in the installation process, the installation difficulty is reduced, and requirements and dependence to installation tools (special mounting equipment) is reduced, and the quality of the rotor and the complexity of the rotor structure are greatly reduced.

Owner:大连伯顿冠力电机有限公司

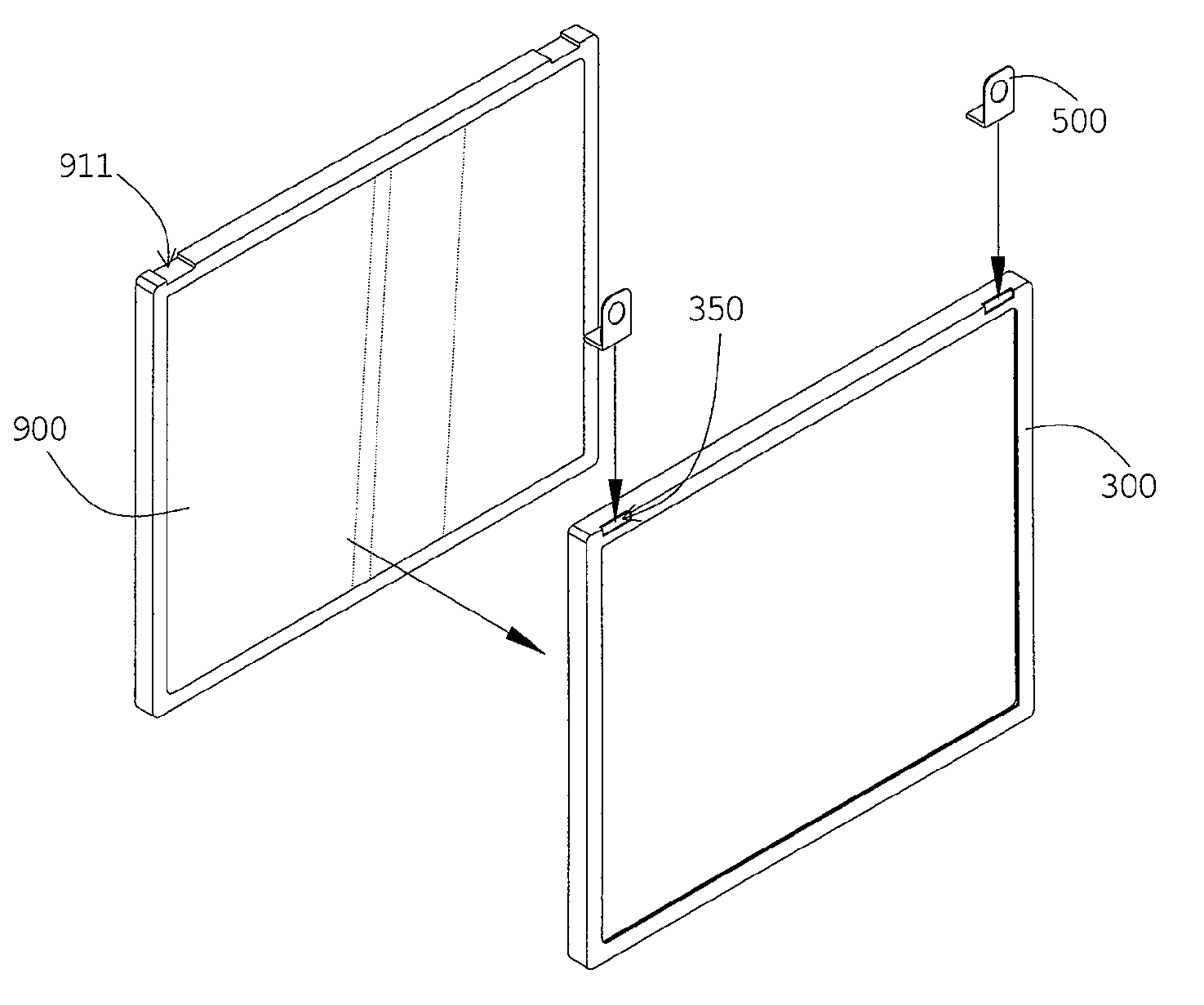

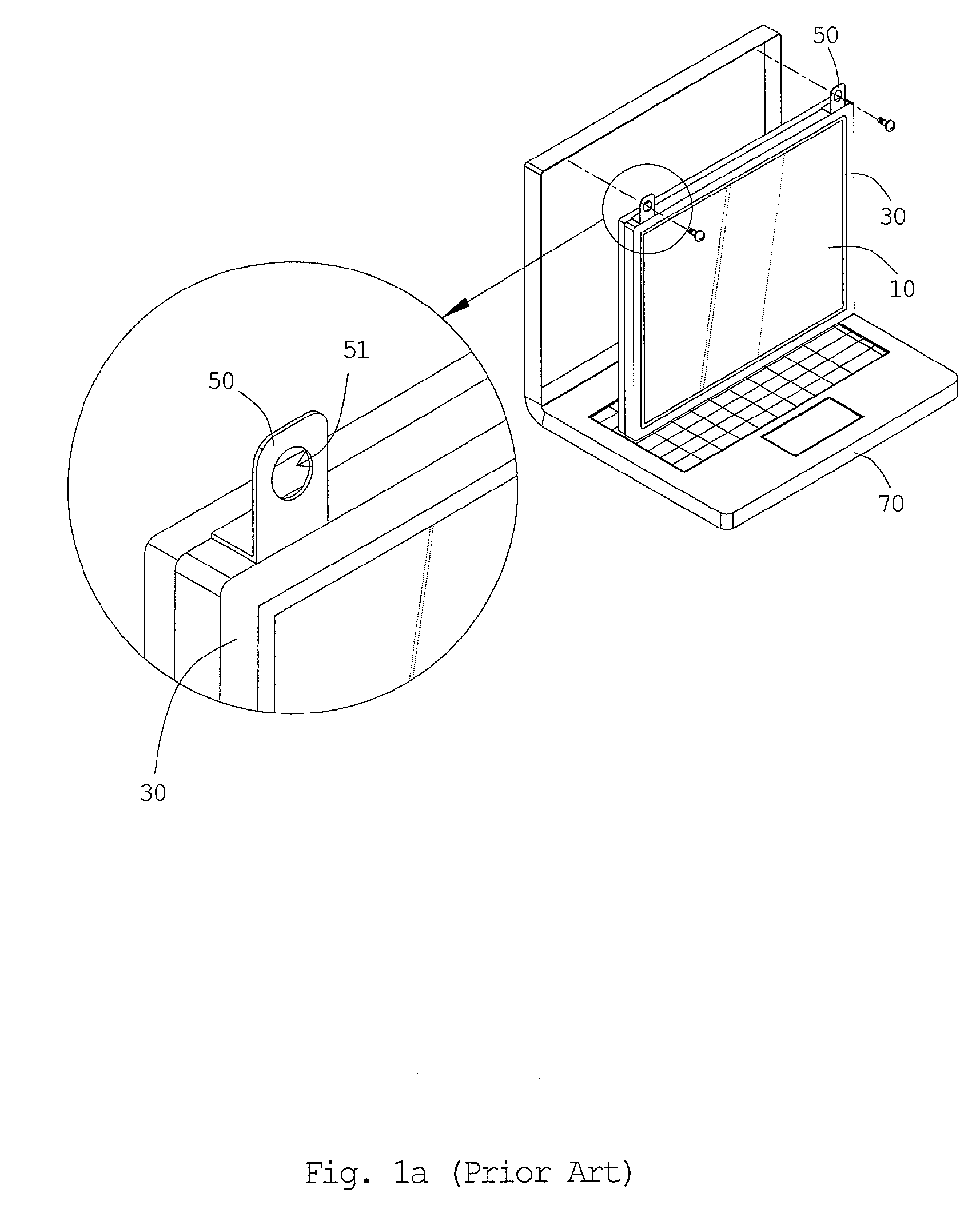

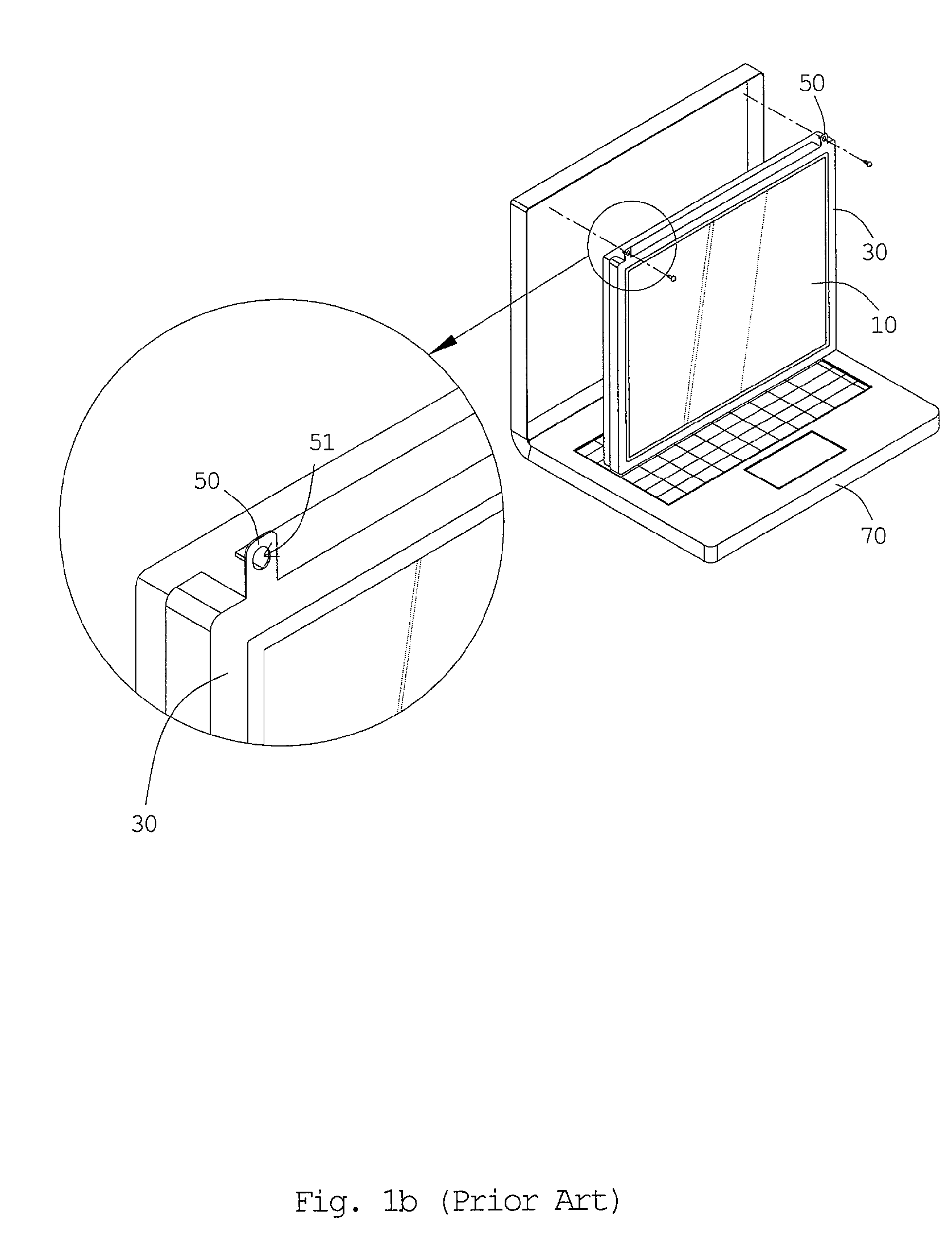

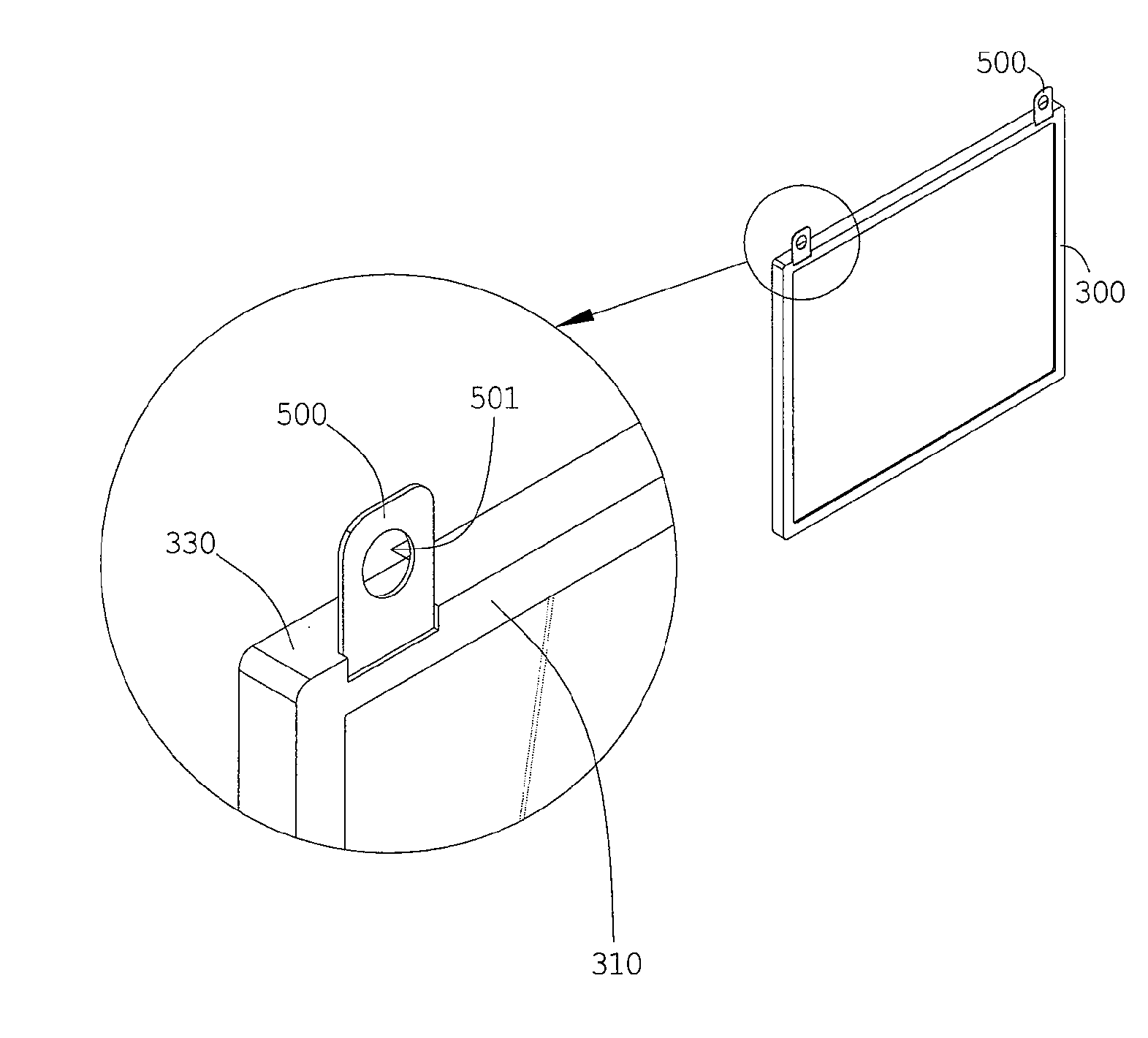

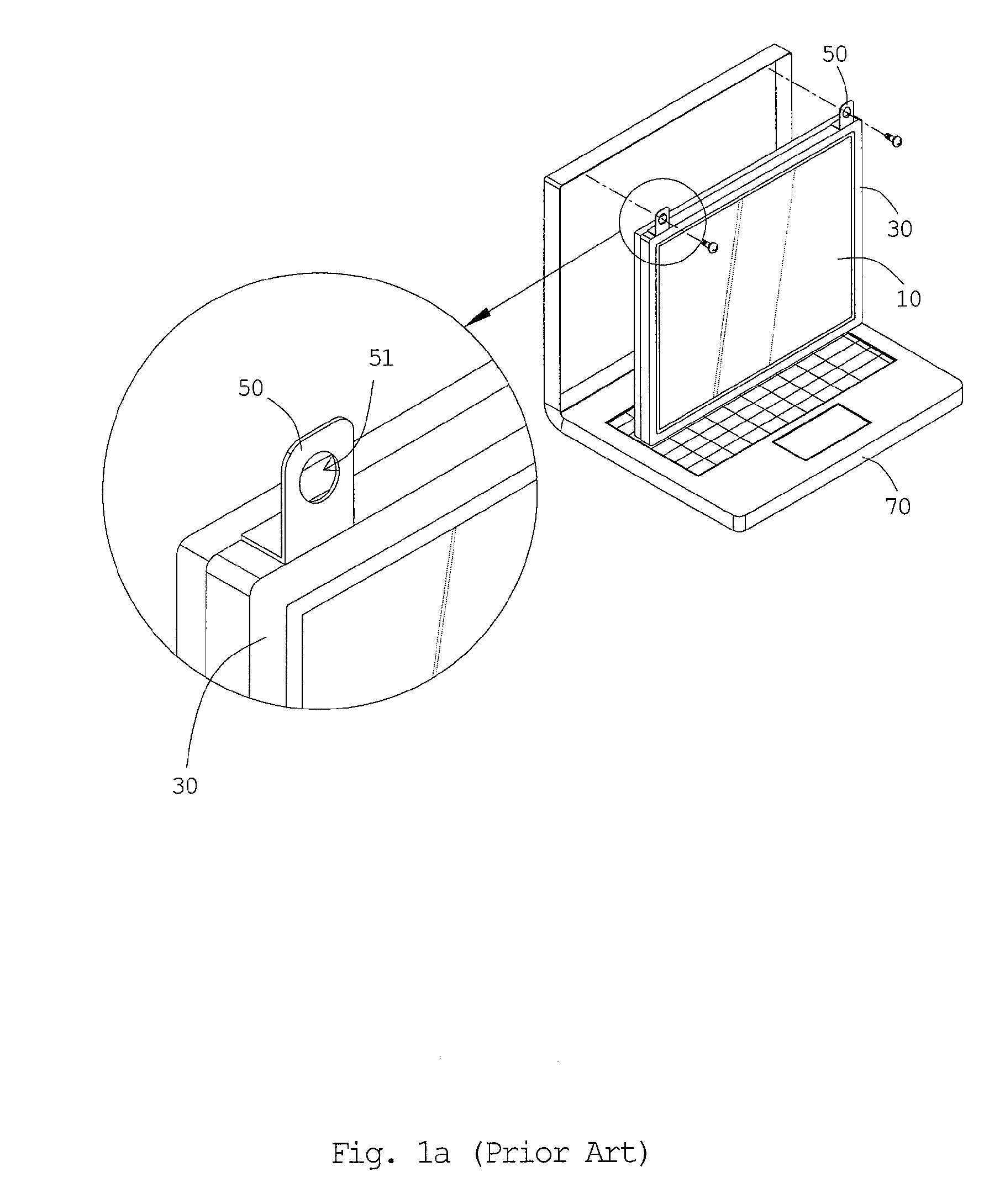

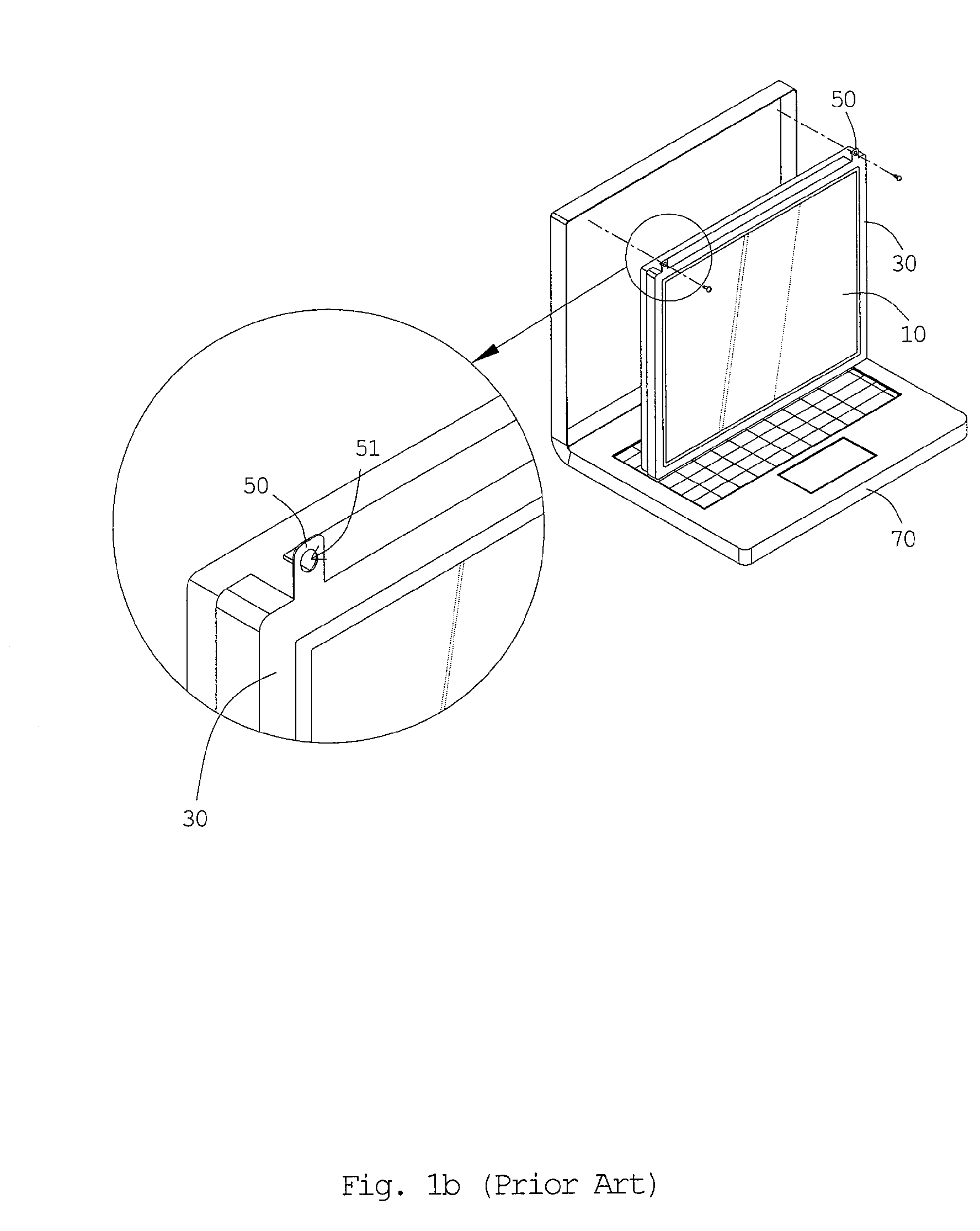

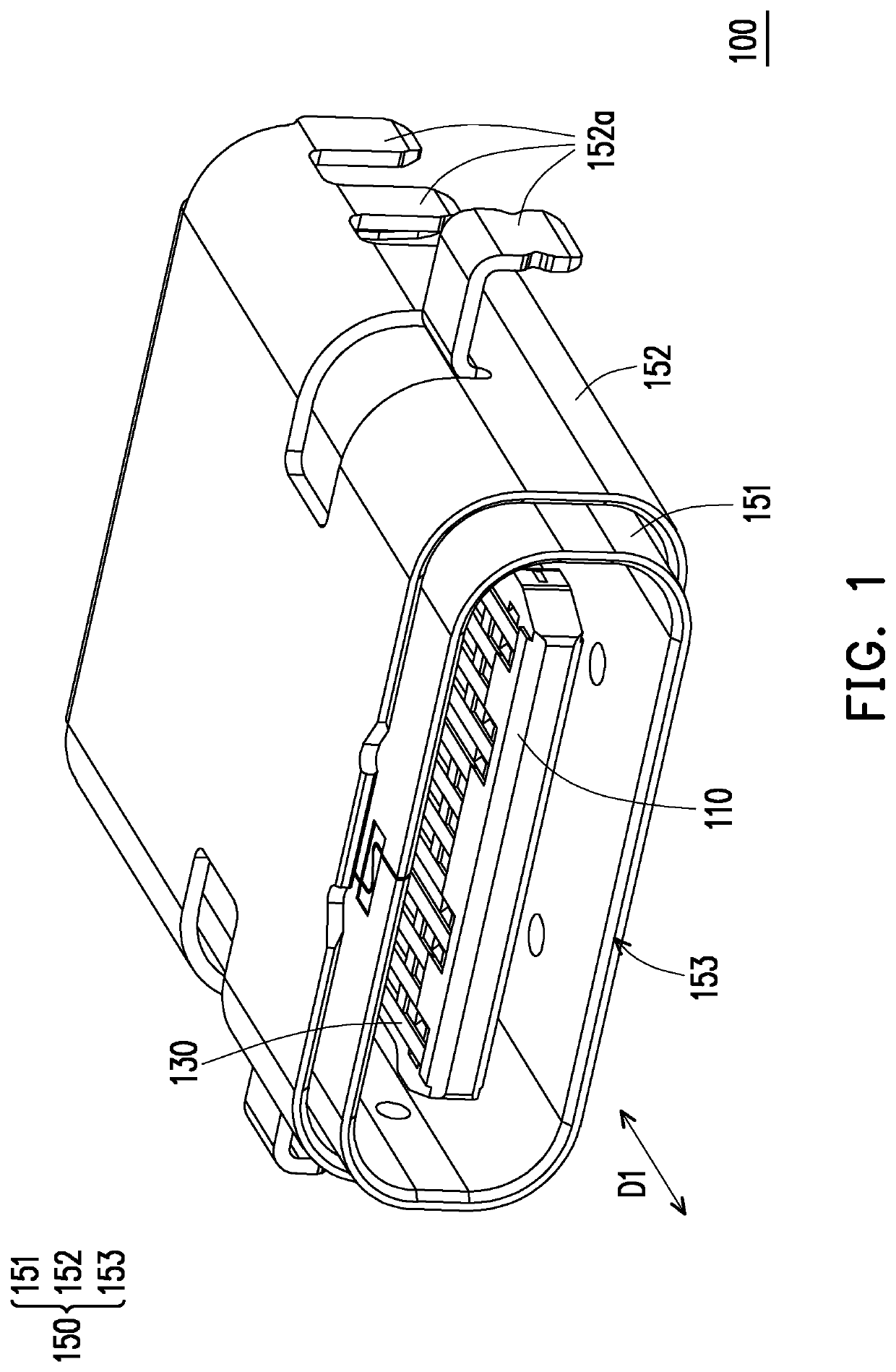

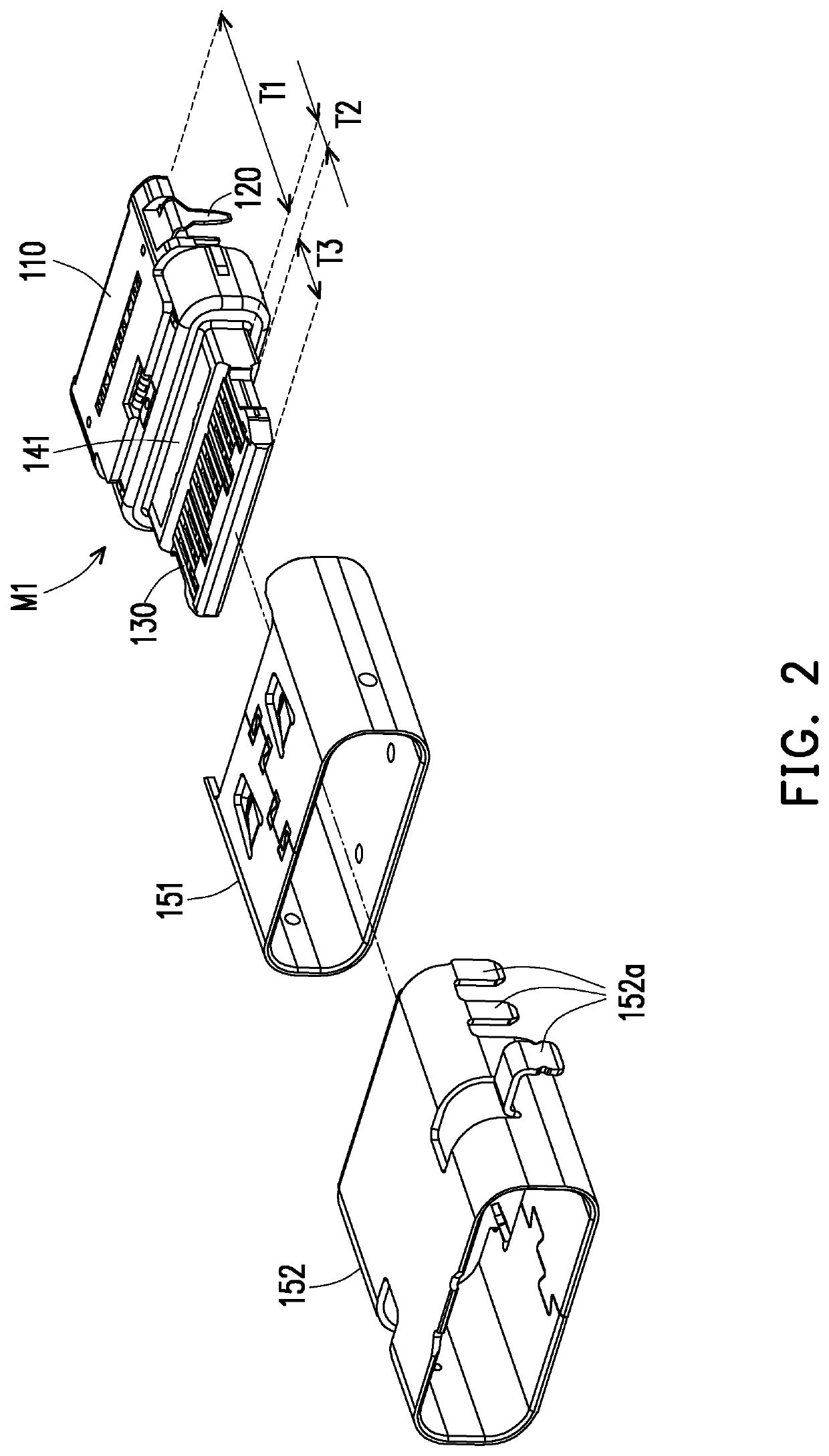

Frame with a mounting ear, display device using the frame and a method of manufacturing the same

ActiveUS8050023B2Small volumeAvoid assembly difficultiesDigital data processing detailsCasings/cabinets/drawers detailsDisplay deviceComputer module

Owner:AU OPTRONICS CORP

Automotive HVAC with integral dividing wall connectors

InactiveUS20080146138A1Improve sealingAvoid assembly difficultiesAir-treating devicesVehicle heating/cooling devicesHVACEngineering

An automotive HVAC unit with a dividing wall comprising 3 dimensional dividing wall contour is provided. Connectors and / or fixation devices are used on the dividing wall so that the wall, along with the main housing wall, forms an air tight seal at an area of connection of the dividing wall and the housing.An integral dividing wall connector allows other main housing and / or dividing wall connectors to further stabilize and / or enhance the seal between housing and wall parts by use of various fixation devices or attachment means, such as snaps, screws, or clips.

Owner:VALEO CLIMATE CONTROL

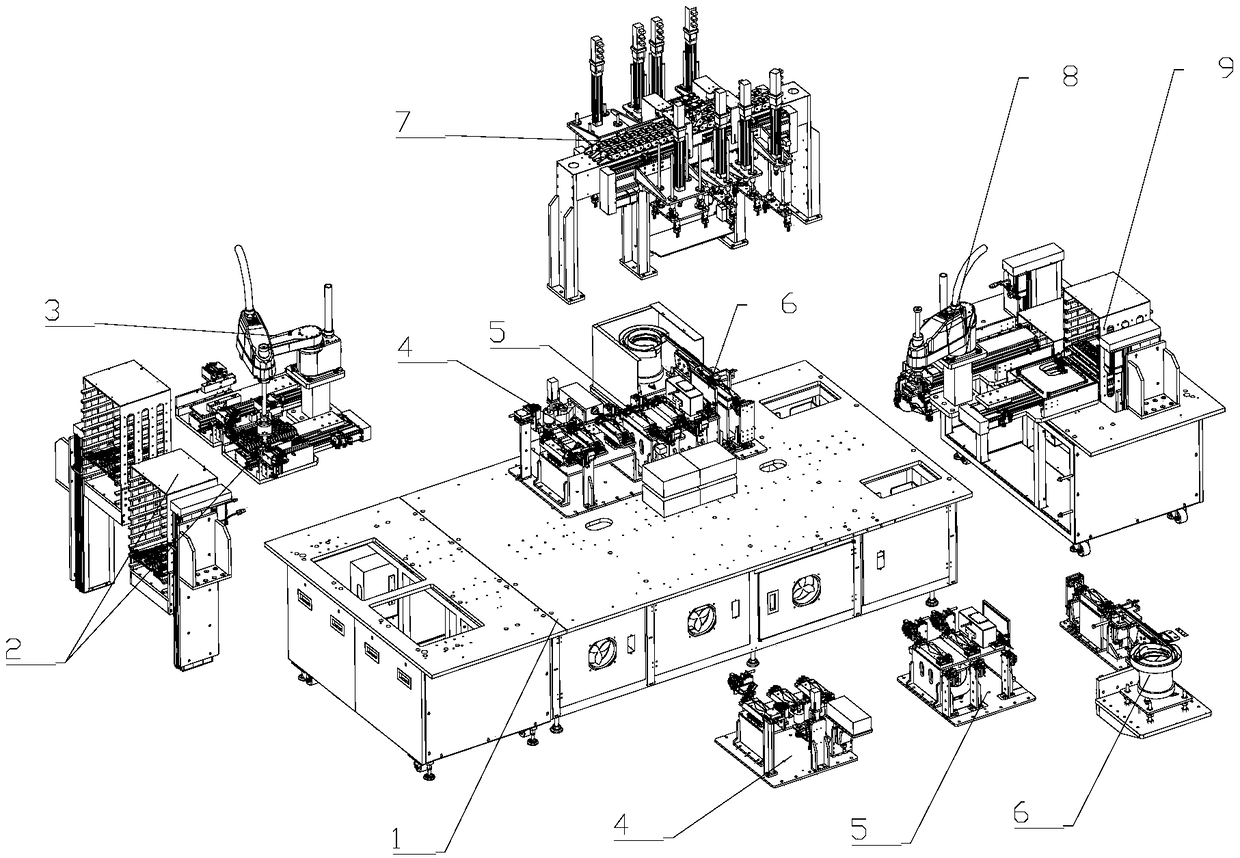

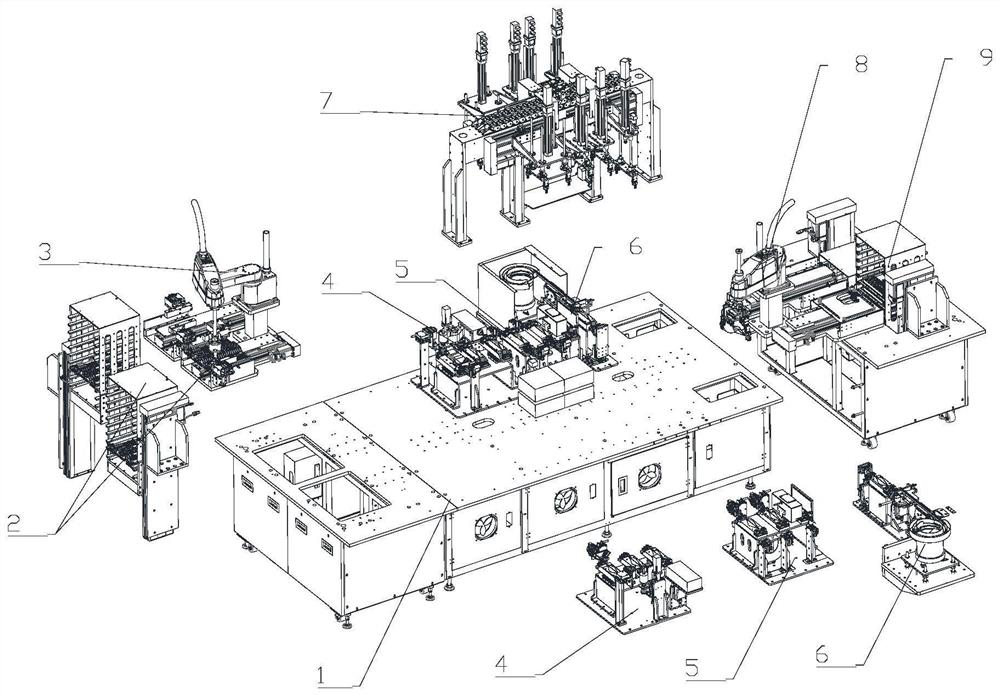

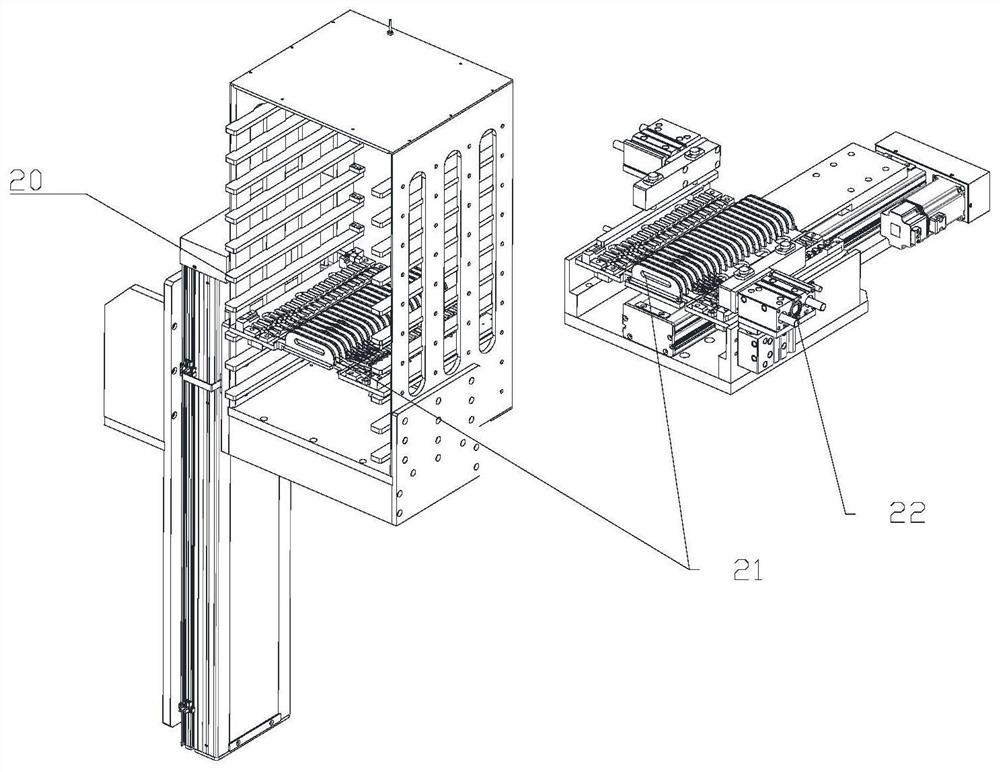

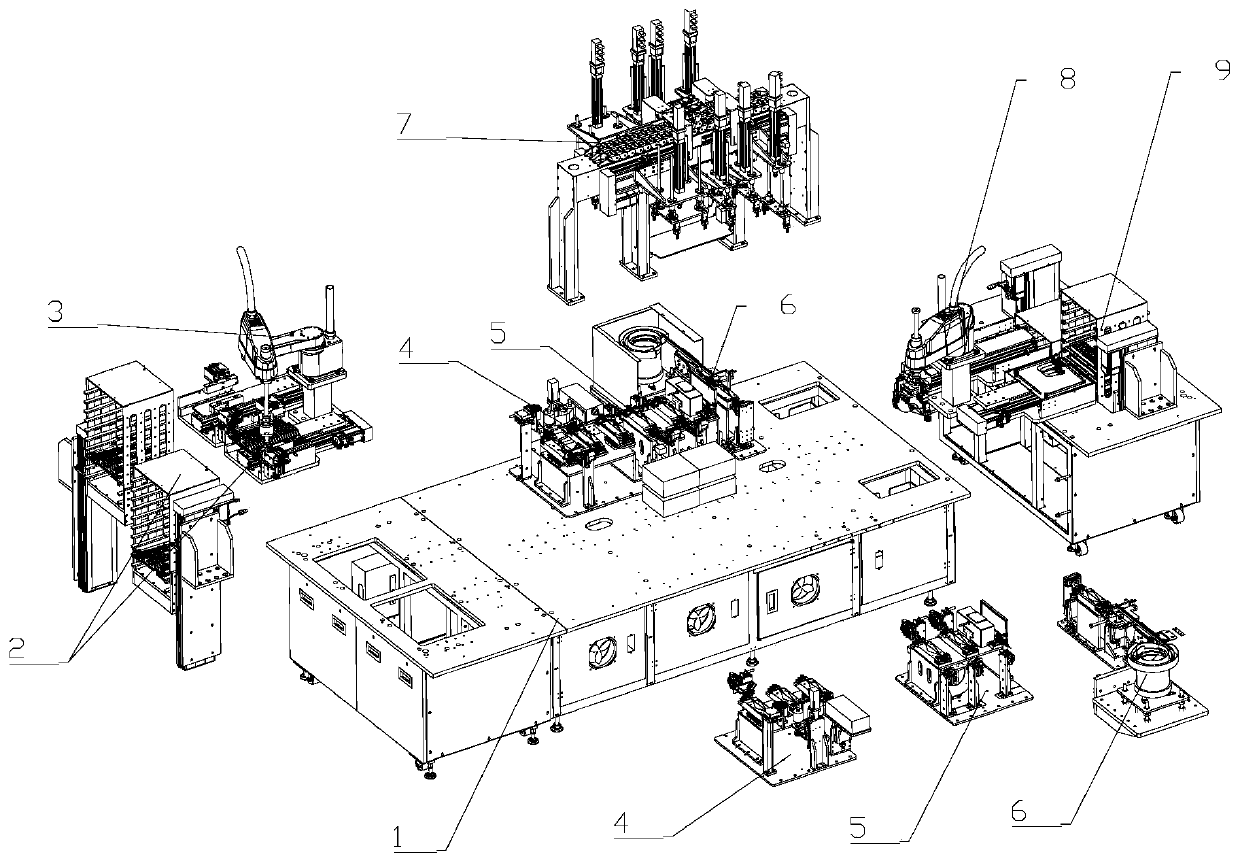

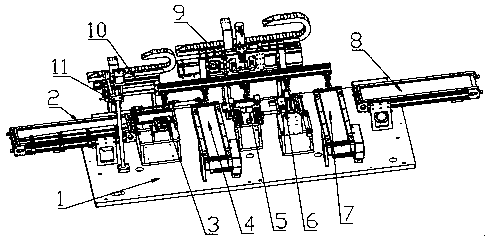

Optical fiber device test equipment

ActiveCN109186952AAvoid interferenceEasy to carryTesting fibre optics/optical waveguide devicesEngineeringManipulator

The invention relates to the technical field of the communication. Optical fiber device detection equipment comprises a rack and a feeding device, a feeding manipulator device, a before-detection analysis module, an optical fiber device performance detection module, a protective cap mounting device, a stepping conveying device, a foldable manipulator placing device and a blanking device which arearranged on the rack; the feeding device is joined with the before-detection analysis module through the feeding manipulator device; the before-detection analysis module, the optical fiber device performance detection module and the protective cap mounting device are orderly joined; the location of the stepping conveying device is corresponding to the before-detection analysis module, the opticalfiber device performance detection module and the protective cap mounting device; and the protective cap mounting device is joined with the blanking device through the foldable manipulator placing device. The optical fiber device detection equipment has the advantages of being high in automation degree, high in working efficiency, high in finished product yield and extensive in testing range.

Owner:SHANDONG JIANBO TELECOMM EQUIP

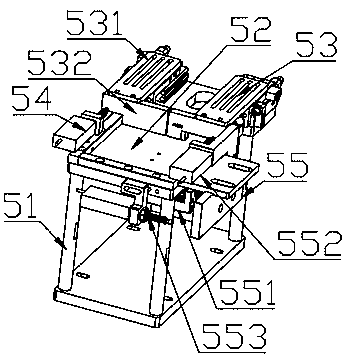

High precision overloading composite bearing structure

InactiveCN1907648AReduce processing stepsAvoid Assembly DifficultiesGrinding drivesElastomerRolling-element bearing

The invention relates to a high-accuracy heavy load composite bearing, which comprises a main axle, an inner taper rolling bearing, a pushing bearing, an end cover, an axially static bearing, a radial static bearing and an elastomer, wherein two ends of front axial should of main axle are mounted with axial static bearing and radial static bearing which are connected and fixed inside the front support of main axle box via the axial static bearing; the back end of main axle is mounted with inner taper rolling bearing, pushing bearing; the back end of pushing bearing via the elastomer is axially connected to the end cover; the end cover is fixed with the back support of main axle box. The inventive bearing system has high support ability, high rotation accuracy, which can support the 20t work piece to be grinded.

Owner:SHANGHAI MACHINE TOOL WORK

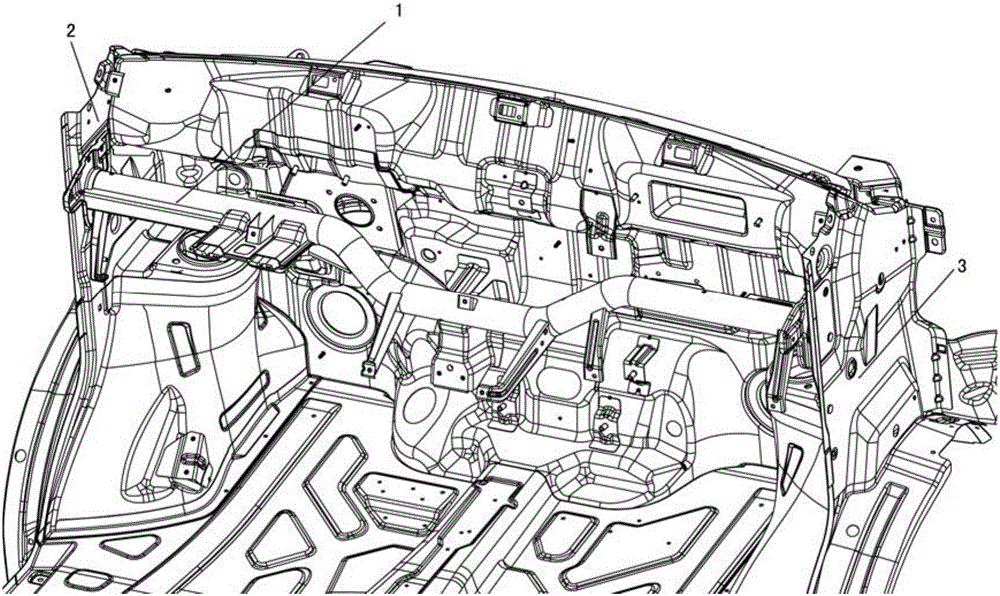

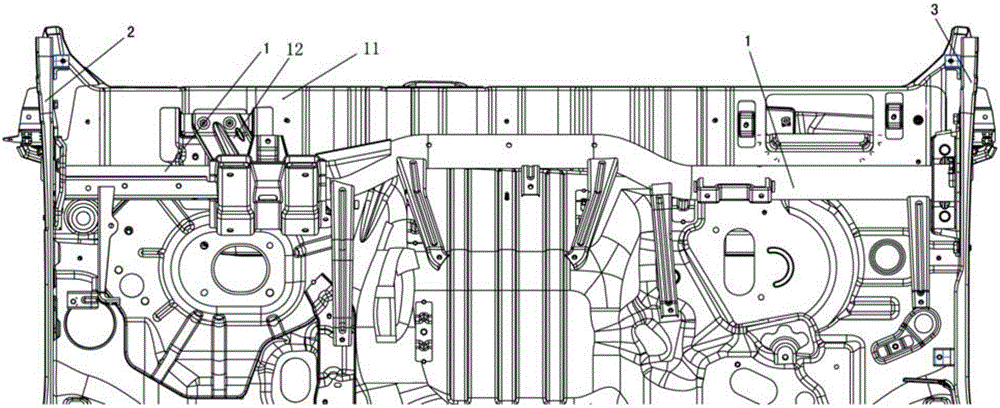

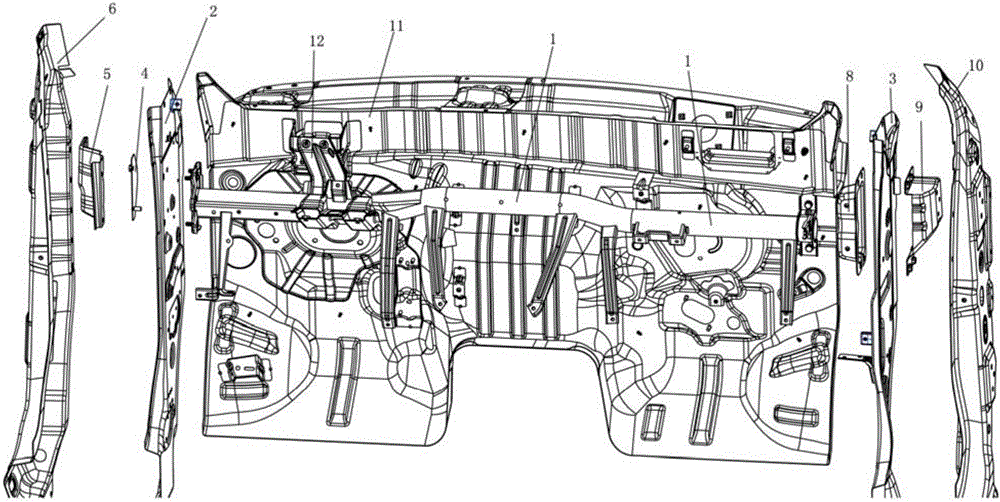

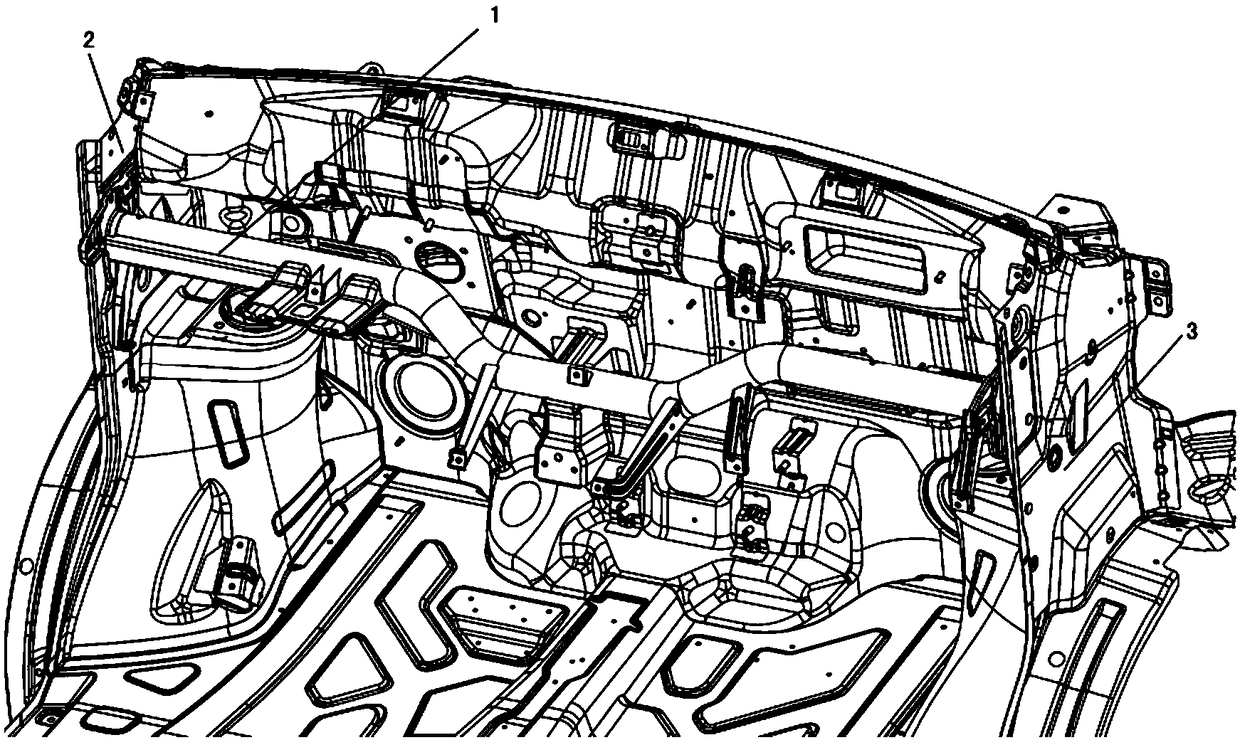

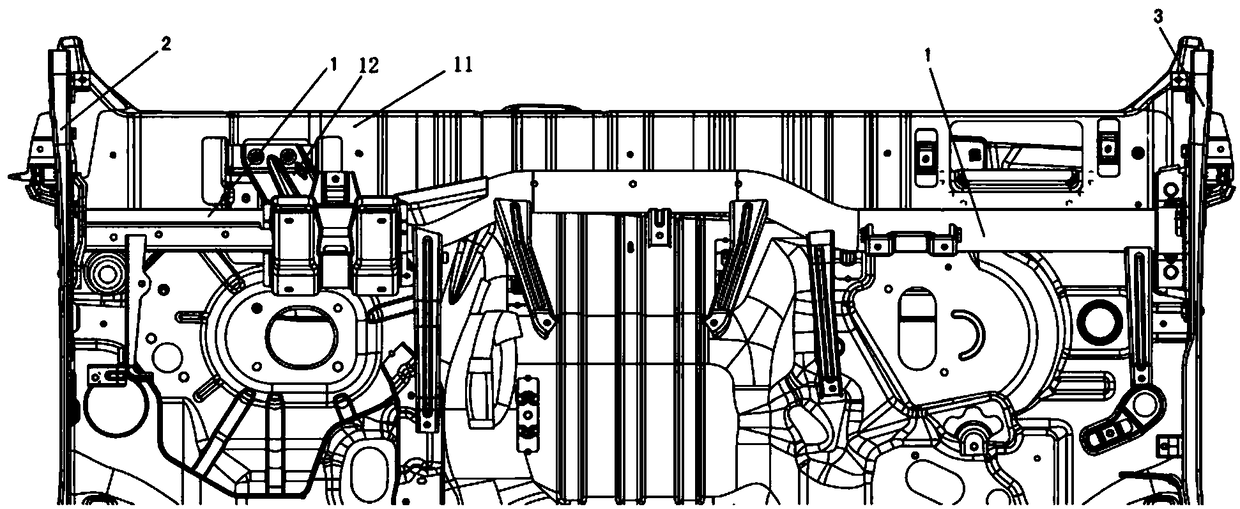

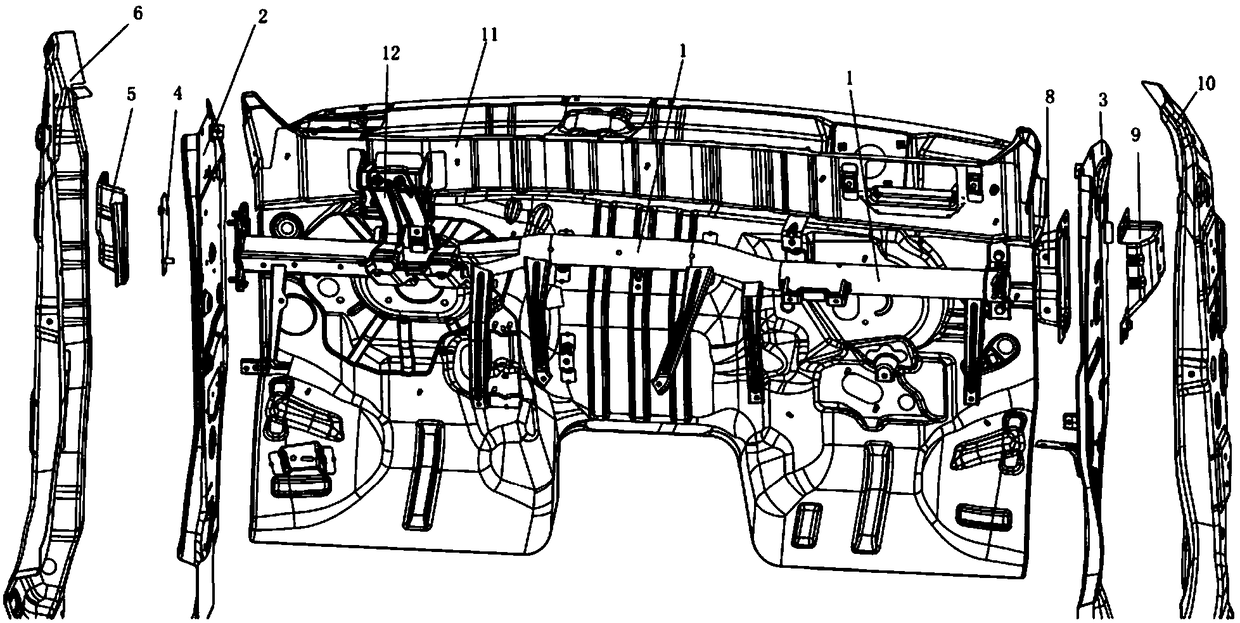

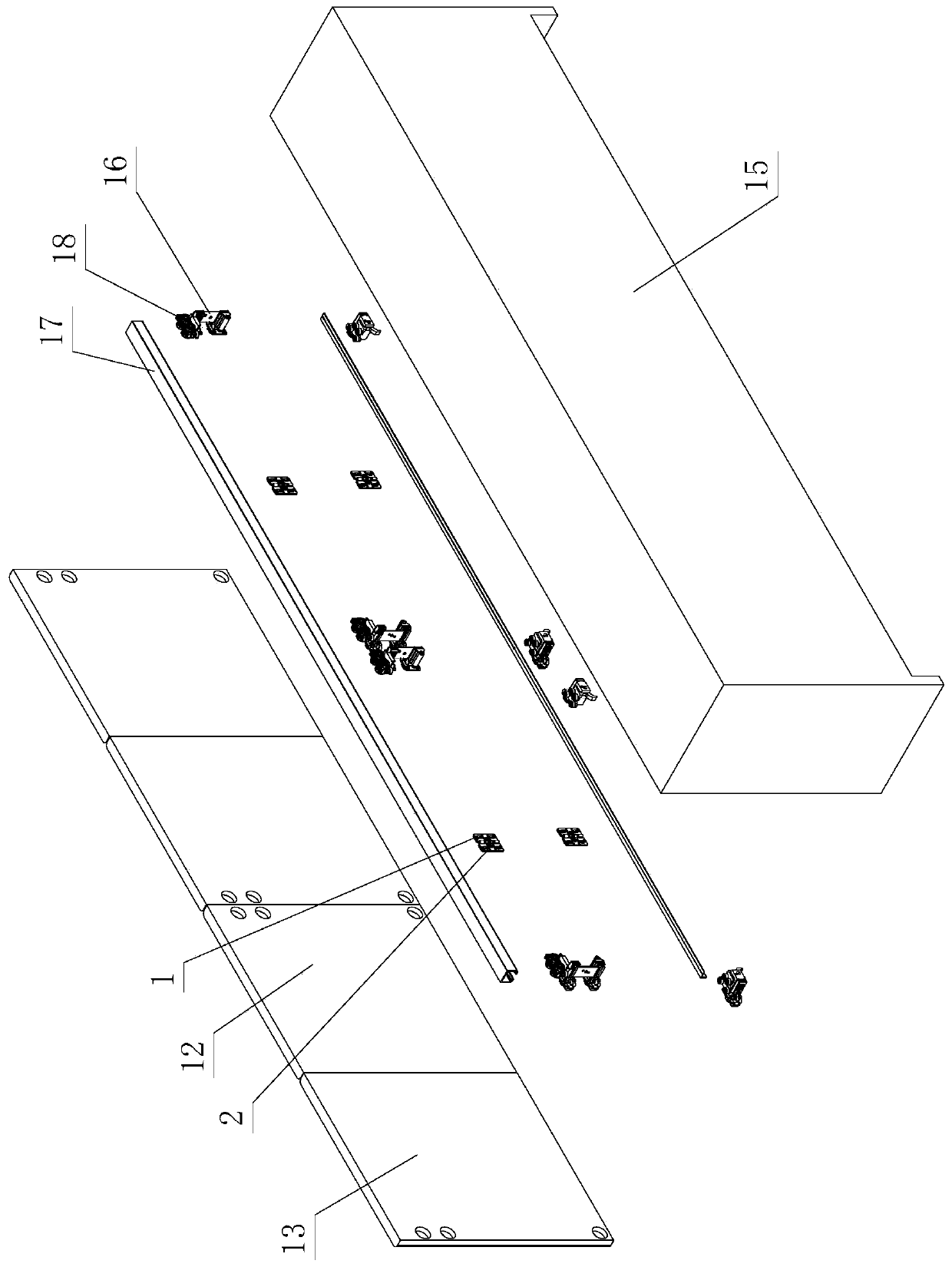

Gauge board beam installation component

ActiveCN106347495AEasy to installRealize three-point installationSuperstructure subunitsSteering wheelArchitectural engineering

The invention discloses a gauge board beam installation component which consists of a left installation component used to install the gauge board beam to the weld assembly of the left front side plate, and a right installation component used to install the gauge board beam to the weld assembly of the right front side plate. The right installation component comprises a U-shape right mounting bracket of the beam with flanged edges on both sides and a U-shape reinforcing plate with flanged edges on both sides set between the weld assembly of the right front side plate and the right internal plate. The right mounting bracket of the beam is fixed with the gauge board beam along X direction. Both sides of the weld assembly of the right front side plate are respectively fixed with the right mounting bracket of the beam and the U-shape reinforcing plate. The other side of the U-shape reinforcing plate is fixed with the right internal plate. The gauge board beam installation component has a simple structure and can be installed conveniently. Besides, the installation component also has enough rigidity and a high mode, and can prevent the steering wheel and gauge board from shaking at a low speed.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

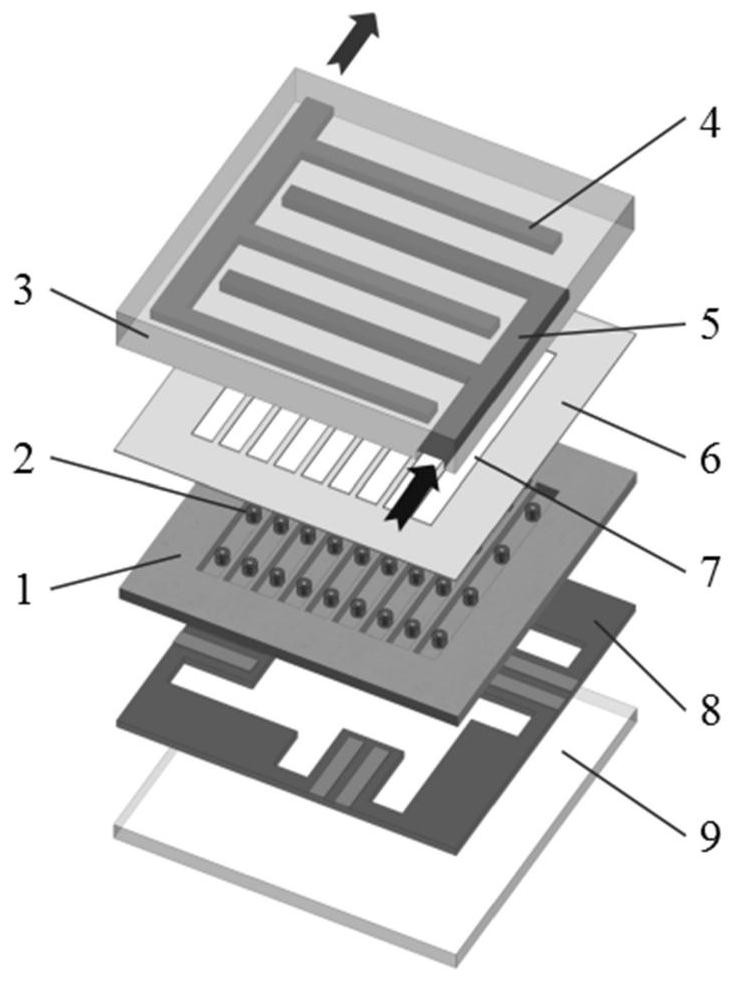

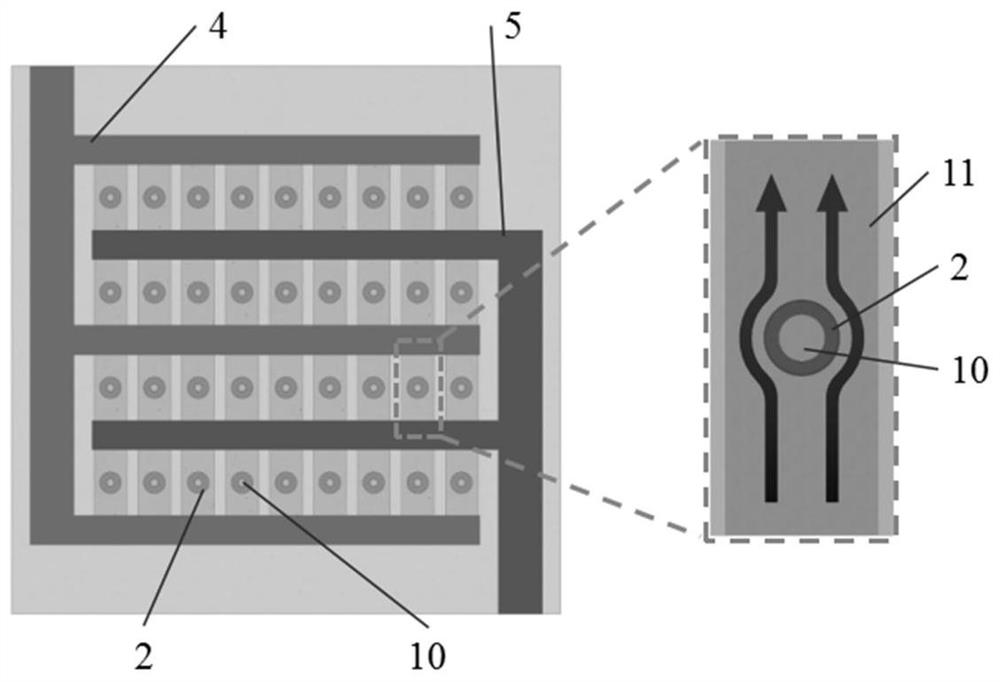

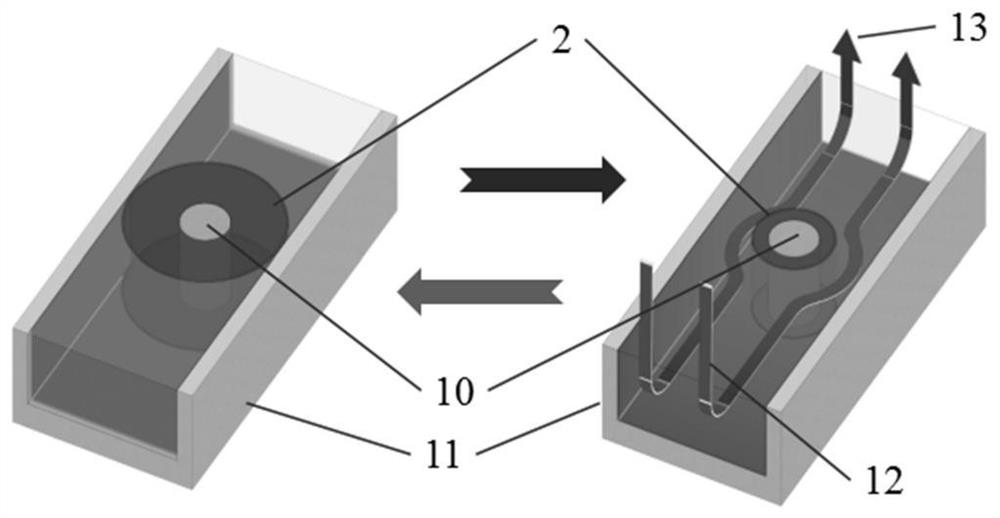

Electronic chip self-adaptive micro-channel cooling device and manufacturing method thereof

ActiveCN112185914ASimple structureSimple waySemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic chip

The invention discloses an electronic chip self-adaptive micro-channel cooling device and a manufacturing method thereof.The electronic chip self-adaptive micro-channel cooling device comprises an analog chip with one face provided with a micro-channel structure, a hydrogel micro-valve, a manifold distributor / collector, a sealing film layer, a PCB and a substrate. The hydrogel micro-valve realizesintelligent regulation and control on the flow of the micro-channel through the change of the volume of the hydrogel micro-valve along with the thermal load. When the self-adaptive micro-channel cooling device is manufactured, firstly, the micro-channel structure and the metal coating are machined, molten paraffin is filled, the periphery of the micro-column structure is embossed with the hydrogel micro-valve outline, then the embossed outline is filled with the hydrogel solution, paraffin is cleaned after polymerization is completed, and the hydrogel micro-valve integrated in the channel isobtained. Finally, the components are pressed and compacted. The micro-channel cooling device is simple in structure and easy to manufacture in batches, has a good flow adjusting effect, and can solvethe problems of pump power waste and cooling economy of traditional micro-channel cooling.

Owner:NANJING UNIV OF SCI & TECH

Frame with a Mounting Ear, Display Device Using the Frame and a Method of Manufacturing the Same

ActiveUS20090122473A1Small volumeAvoid assembly difficultiesTube/lamp screens manufactureDigital data processing detailsDisplay deviceEngineering

A frame with a mounting ear, a display device using the frame and a method of manufacture thereof are provided. The frame includes a frame body and a mounting ear. The frame body has a top frame and a sidewall extending from an edge of the frame top frame. A tap hole is formed on the frame body, and the ear passes through the tap hole to connect with an inner surface of the sidewall. Besides the frame, the display device further includes a display panel module. The display panel module is disposed inside the frame and outwardly displays images via a transparent area enclosed by the frame.

Owner:AU OPTRONICS CORP

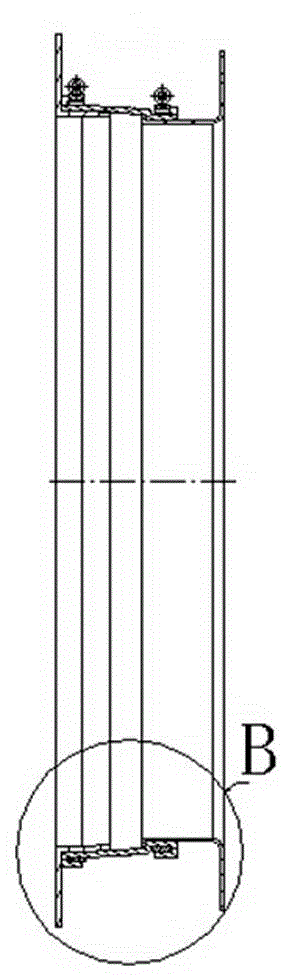

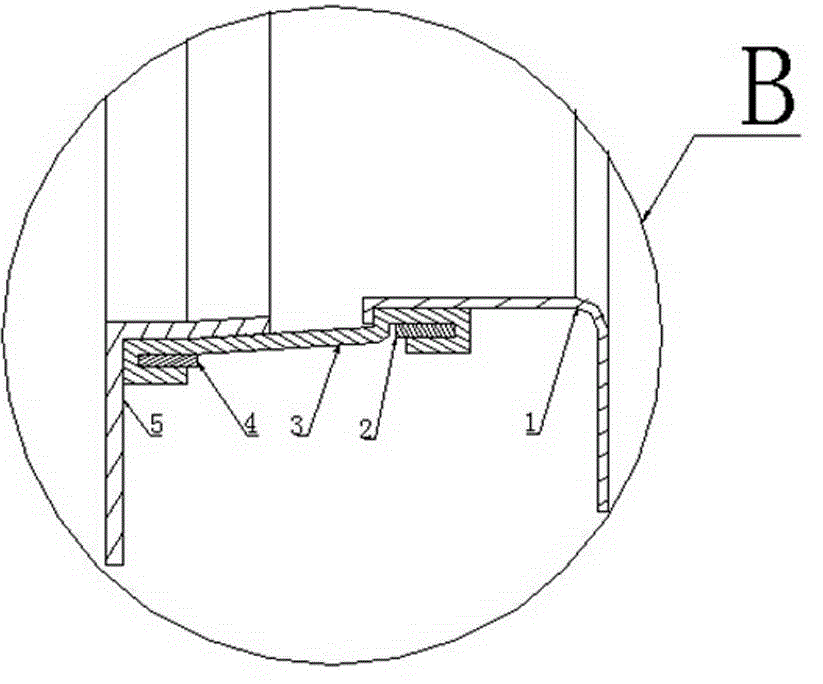

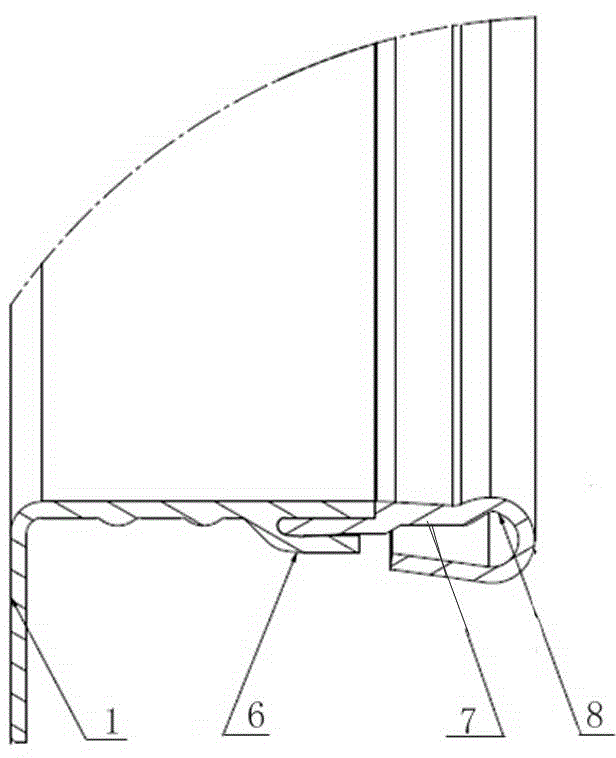

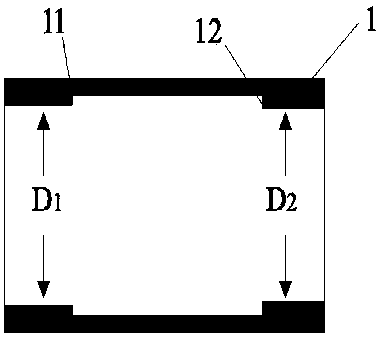

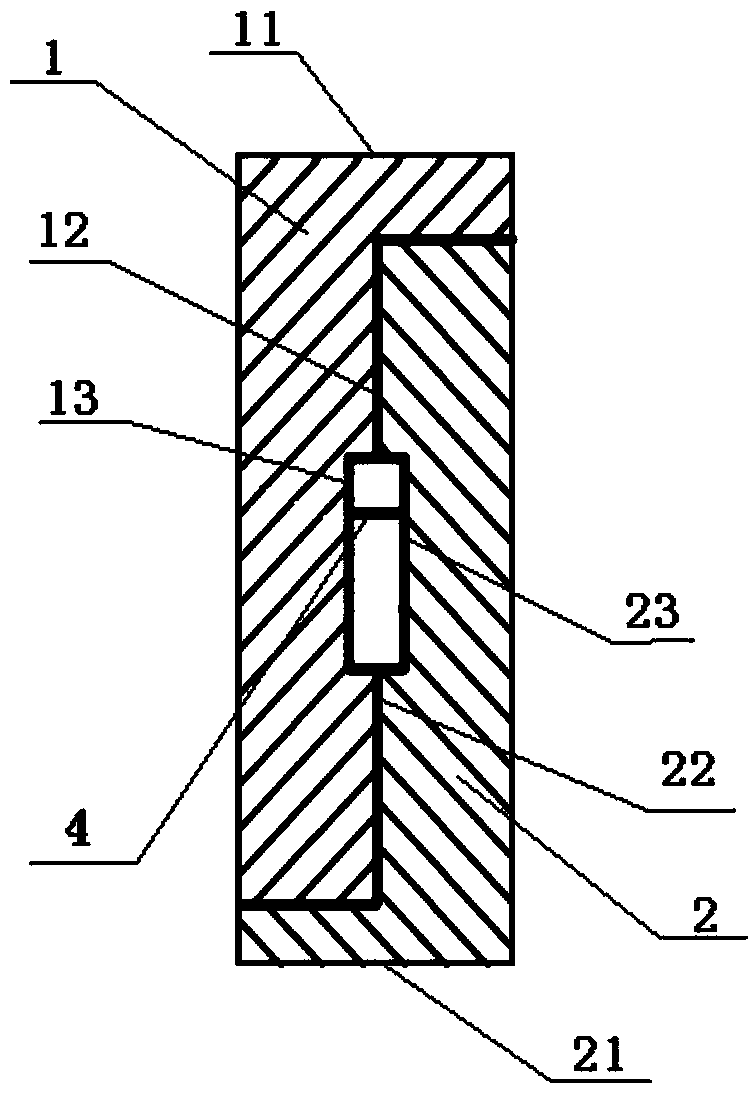

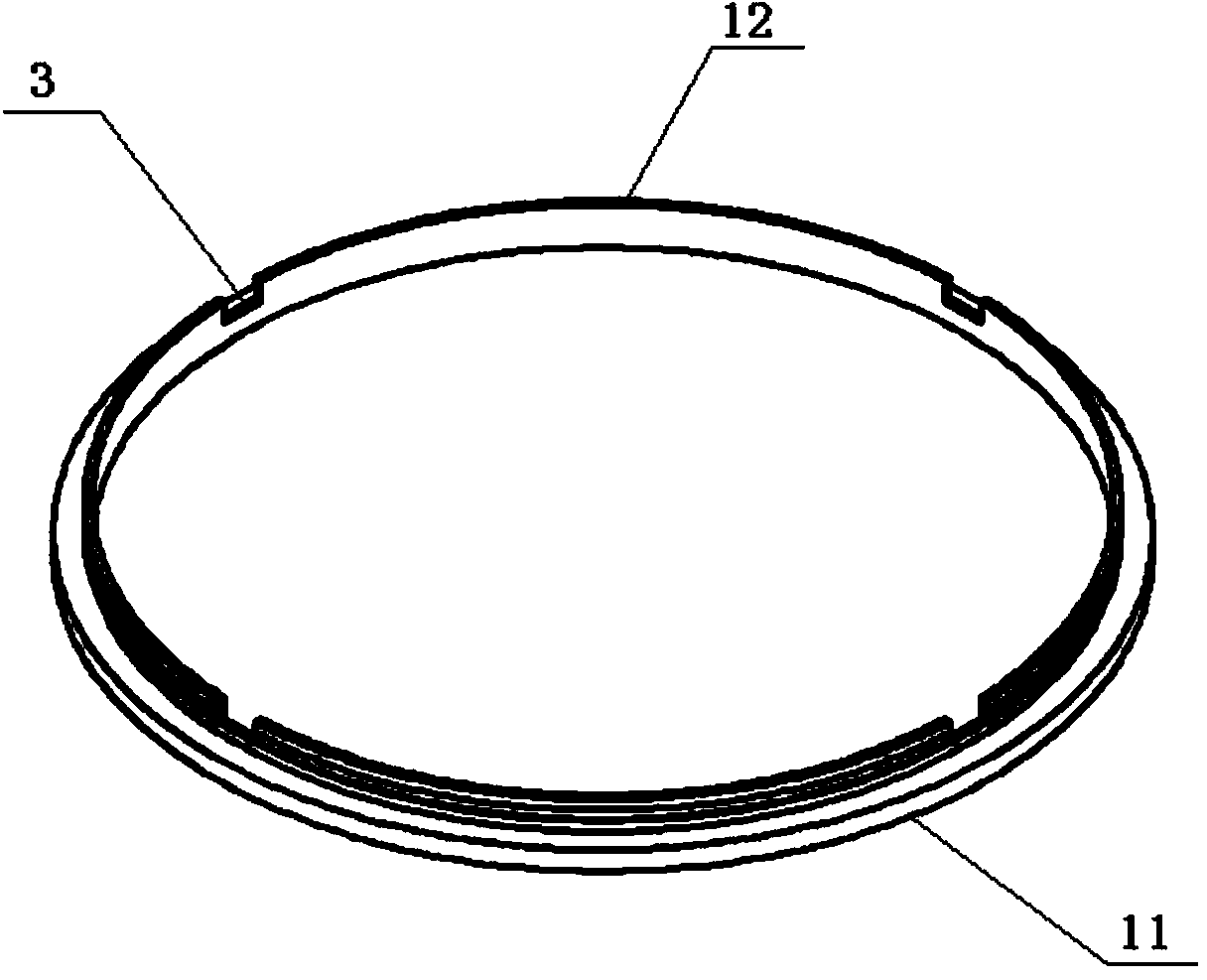

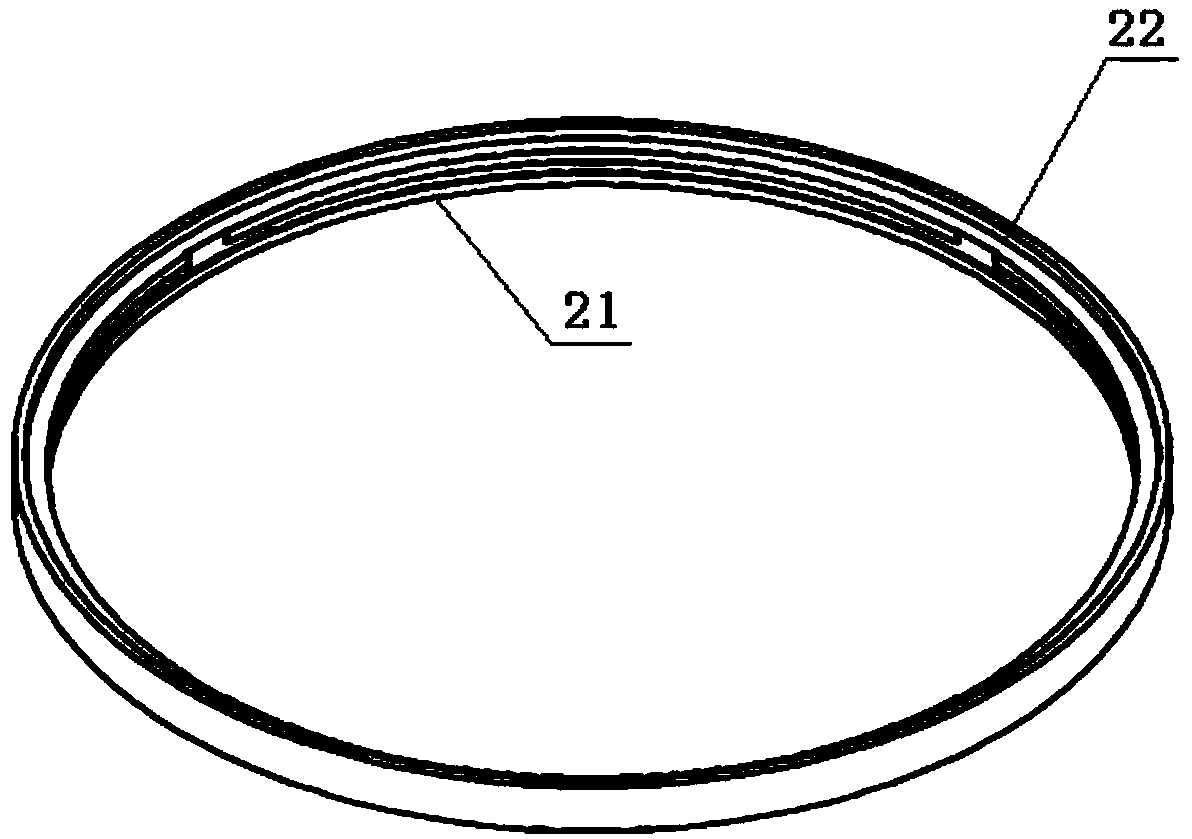

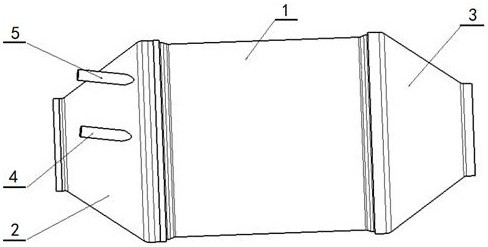

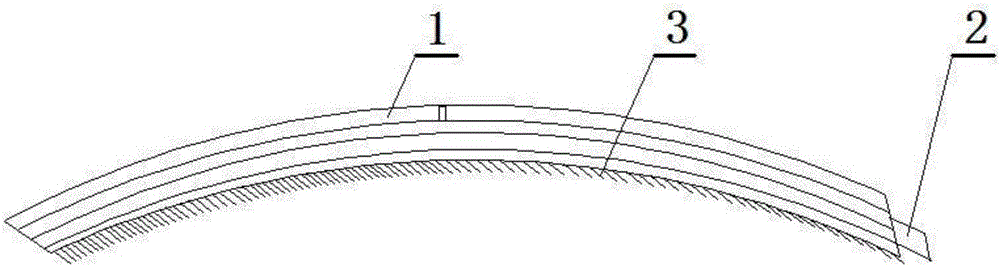

Novel wind ring assembly of automobile engine

ActiveCN106150664AReduce axial sizeShorten the lengthMachines/enginesEngine cooling apparatusRubber ringEngineering

The invention provides a novel wind ring assembly of an automobile engine. The novel wind ring assembly comprises a wind ring, and an open type pressing rivet structure is formed in the axle journal of the wind ring. The open type pressing rivet structure is stressed after a rubber ring is arranged into the open type pressing rivet structure, and an opening of the open type pressing rivet structure is contracted to clamp the rubber ring and the wind ring assembly is formed. The rubber ring is extended in the axial direction to form a horn mouth. A thickness sudden-change structure is arranged on the connecting section between an extended part of the rubber ring in the axial direction and a wind cover, and the rubber ring can be freely turned and folded. The opening angle alpha of the horn mouth is 10-50 degree. According to the novel wind ring assembly, the open type pressing rivet structure is formed in the axle journal of the wind ring, the open type pressing rivet structure is pressed after the rubber ring is arranged into the open type pressing rivet structure, and the opening of the open type pressing rivet structure is contracted to clamp the rubber ring and the wind ring assembly is formed, the rubber ring is extended in the axial direction to form the horn mouth, the thickness sudden-change structure is arranged on the connecting piece between the extended part of the rubber ring in the axial direction and the wind cover, and the rubber ring can be in the state of being freely turned and folded, so that the axial dimension, namely the total length, of the wind ring assembly is reduced.

Owner:湖北晟正汽车零部件有限公司

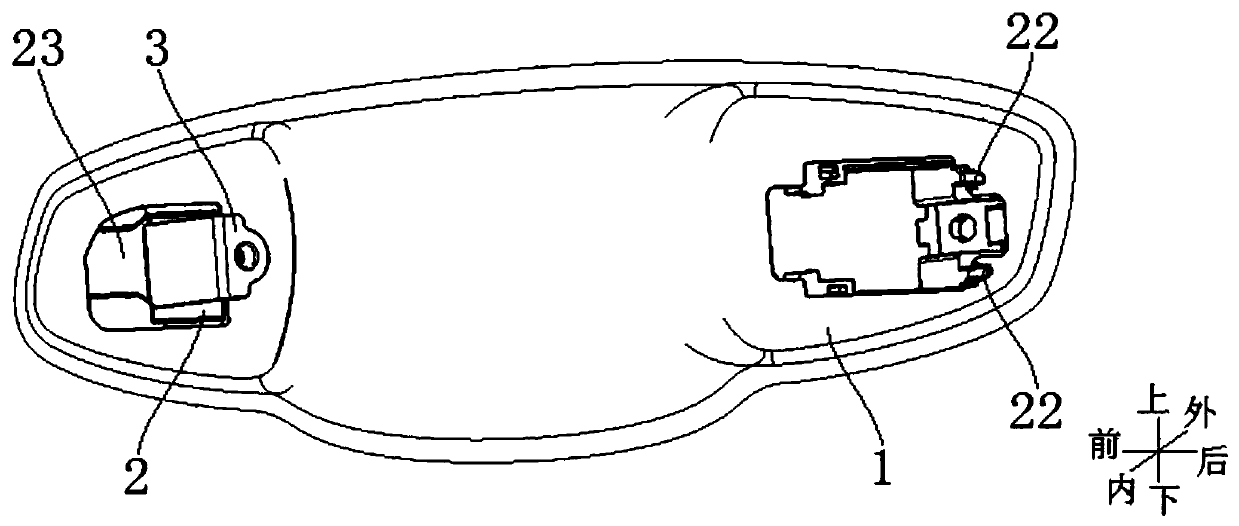

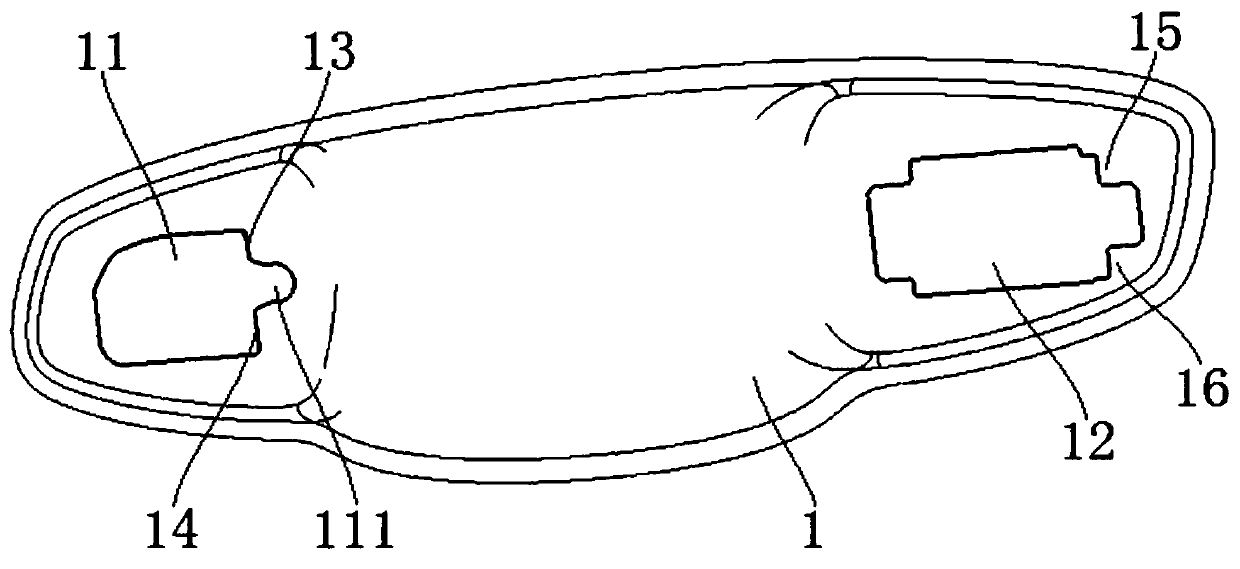

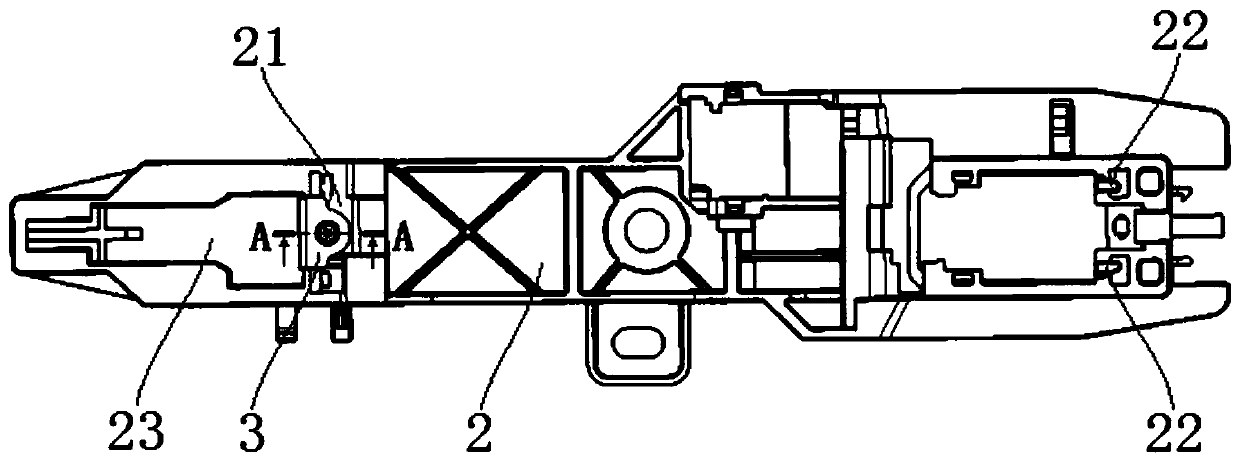

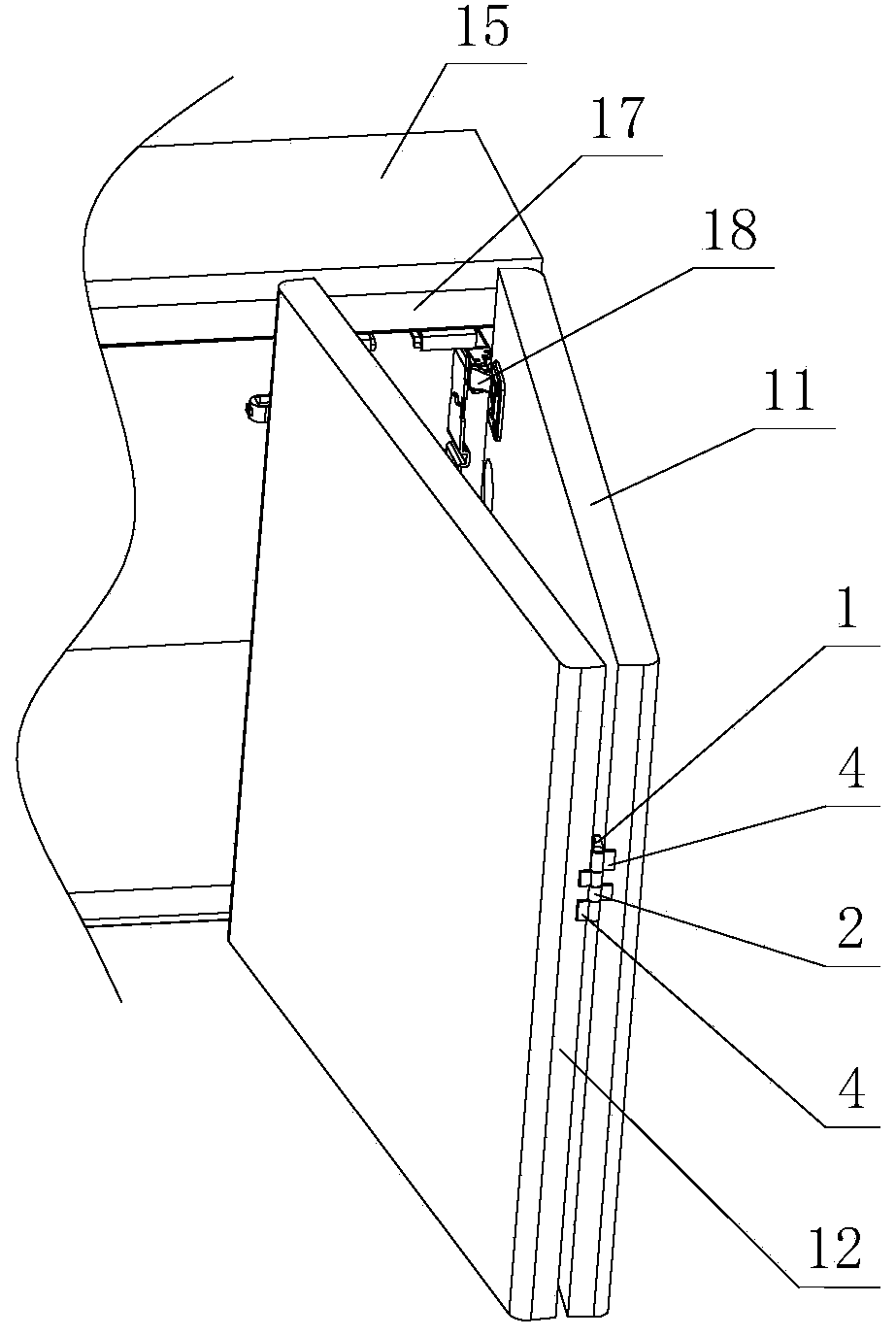

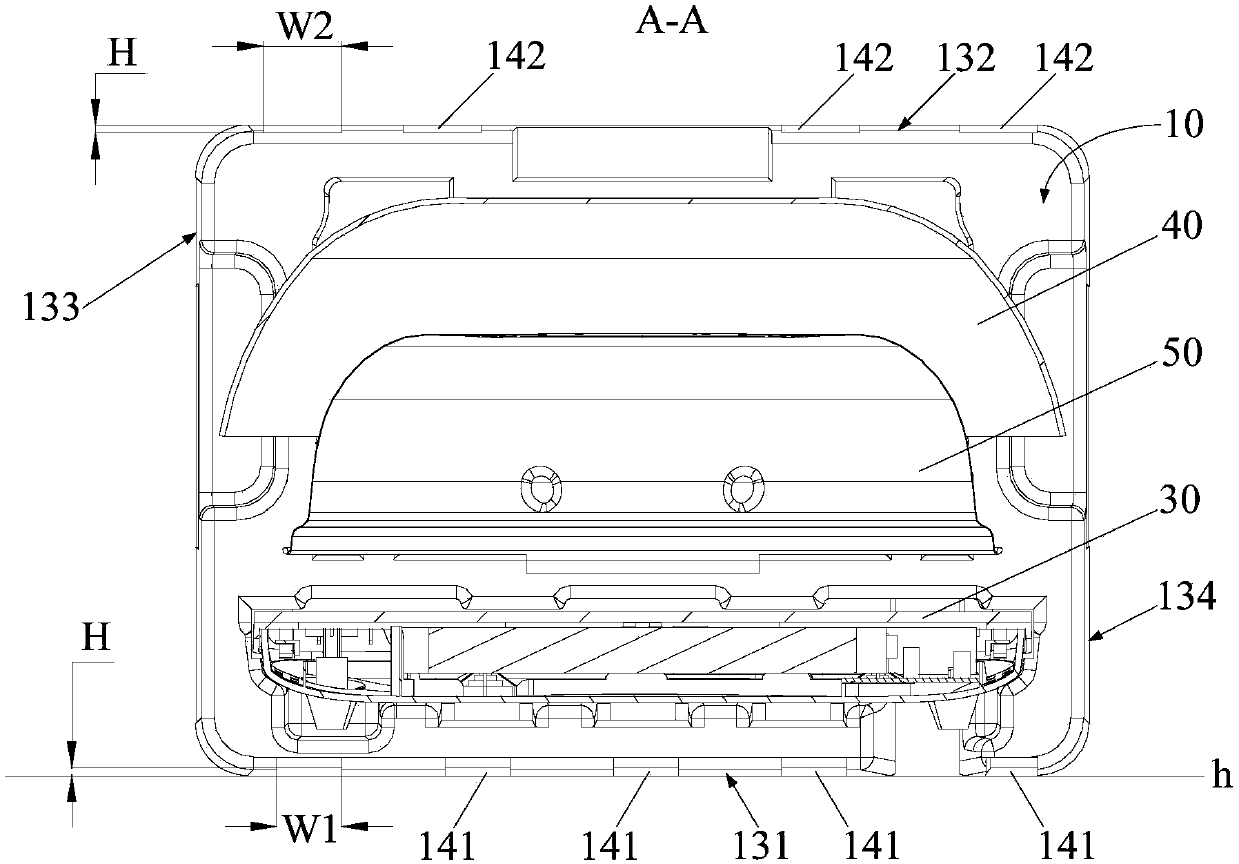

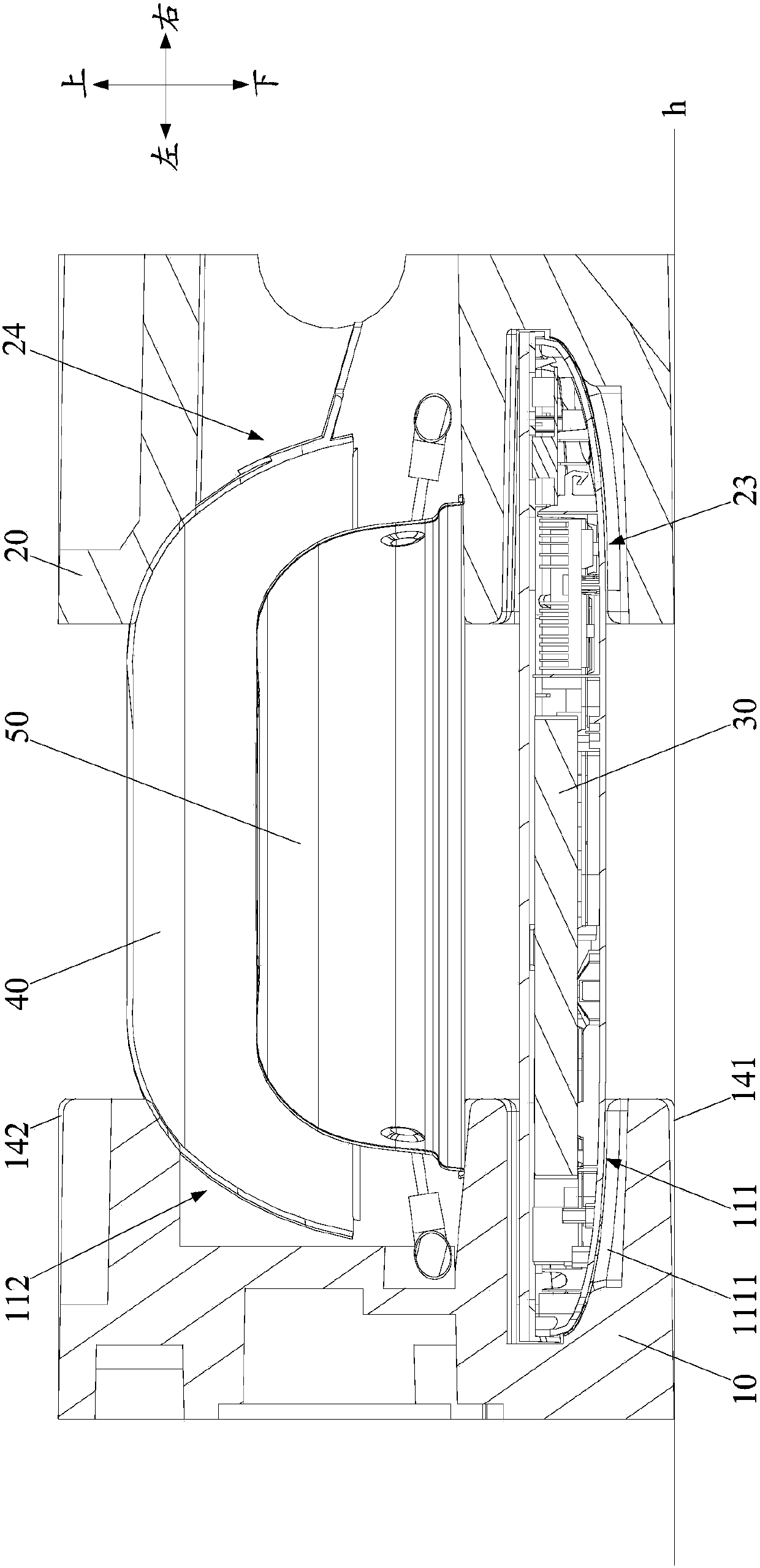

External opening handle support mounting pre-hanging structure

The invention relates to an external opening handle support mounting pre-hanging structure. The structure comprises a vehicle door outer plate and a handle support and is characterized by further comprising a pre-hanging rubber mat. A front matching hole and a rear matching hole are formed in the vehicle door outer plate. The handle support is provided with a through hole corresponding to the front matching hole, a limiting part is arranged on the portion, close to the through hole, of the handle support, clamping feet are arranged on the rear end of the handle support, the pre-hanging rubber mat is in fit connection with the limiting part of the handle support, the edge portion, close to the front matching hole, of the vehicle door outer plate is clamped between the pre-hanging rubber mat and the matching portion of the handle support, and the clamping feet penetrate through the rear matching hole to be matched with the edge portion, close to the rear matching hole, on the vehicle door outer plate. Mounting pre-hanging of the handle support on the vehicle door outer plate can be effectively achieved, assembling of the handle support is facilitated, the problems of difficult assembling, poor assembling and the like caused by insufficient metal plate manufacturing precision can be effectively avoided, assembling efficiency is improved, the abnormal sound generated between the mounting bolt and the vehicle door outer plate and the handle support can be avoided, and the use comfort of a user can be improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Motor stator and shell installation structure designed with spray bars and design method for spray bar

PendingCN107342666AImprove cooling effectSimplified structure design methodManufacturing dynamo-electric machinesCooling/ventillation arrangementEngineeringOil intake

The invention relates to a motor stator and shell installation structure designed with spray bars and a design method for a spray bar. Compared with the prior art, the deficiency that the motor stator and shell installation structure cannot meet actual use requirements is solved. An annular bump A and an annular bump B are respectively arranged at two ends parts of the inner surface of the shell, the inner diameter of the shell positioned at the annular bump A is less than that of the shell positioned at the annular bump B, a plurality of grooves are arranged on the inner surface of the shell between the annular bump A and the annular bump B at equal intervals, and the grooves are parallel to the axial direction of the shell; the spray bars are placed in the grooves, an oil nozzle is arranged at one end of each spray bar, while an oil intake hose is connected with the other end of the spray bar, the oil intake hoses are connected with a right oil intake pipe via an oil intake tap, the spraying directions of the oil nozzles face to a winding at the end part of a stator iron core. According to the structure provided by the invention, the design method for an oil-cooling motor structure and the assembly technology of the stator shell are greatly simplified.

Owner:HEFEI JUYI POWER SYST CO LTD

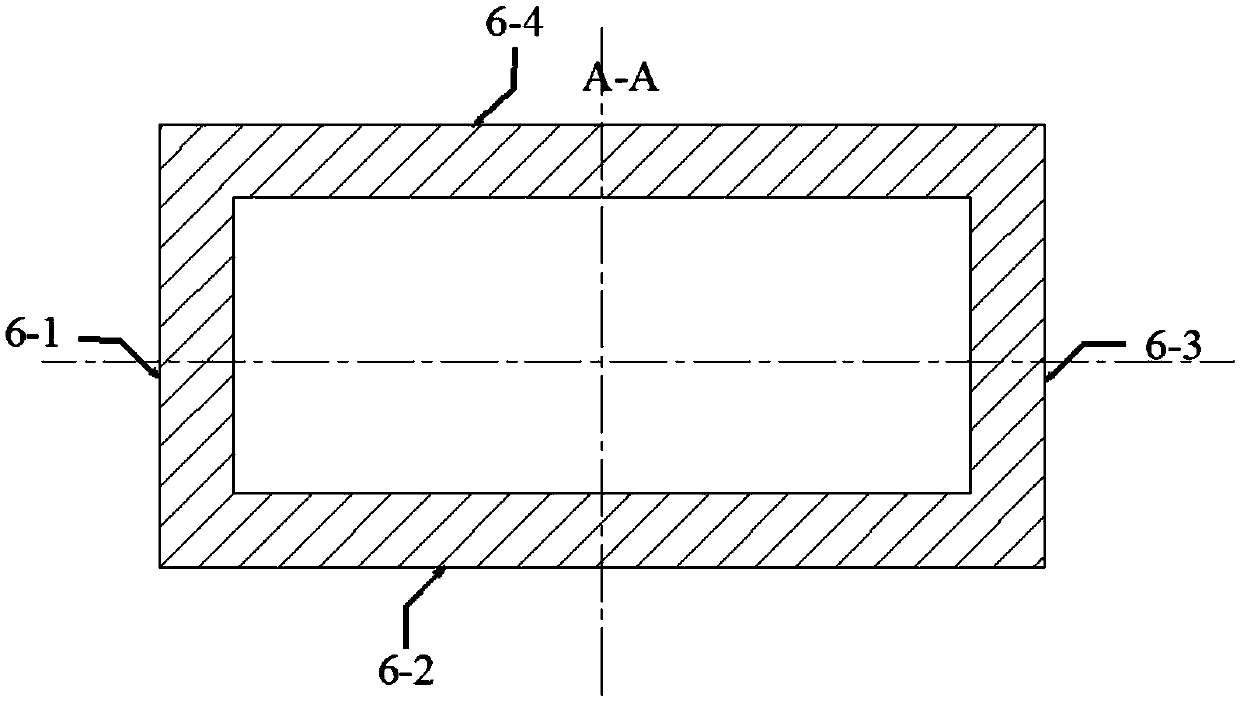

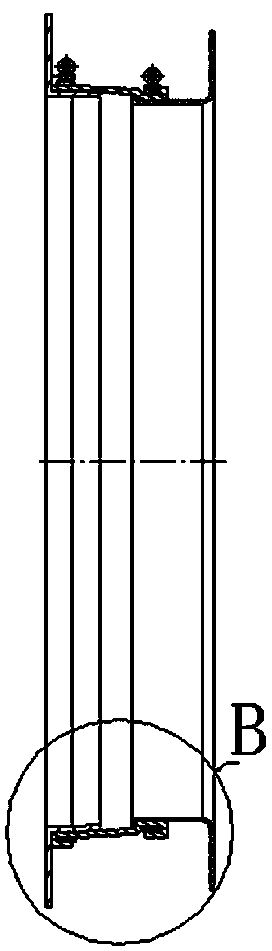

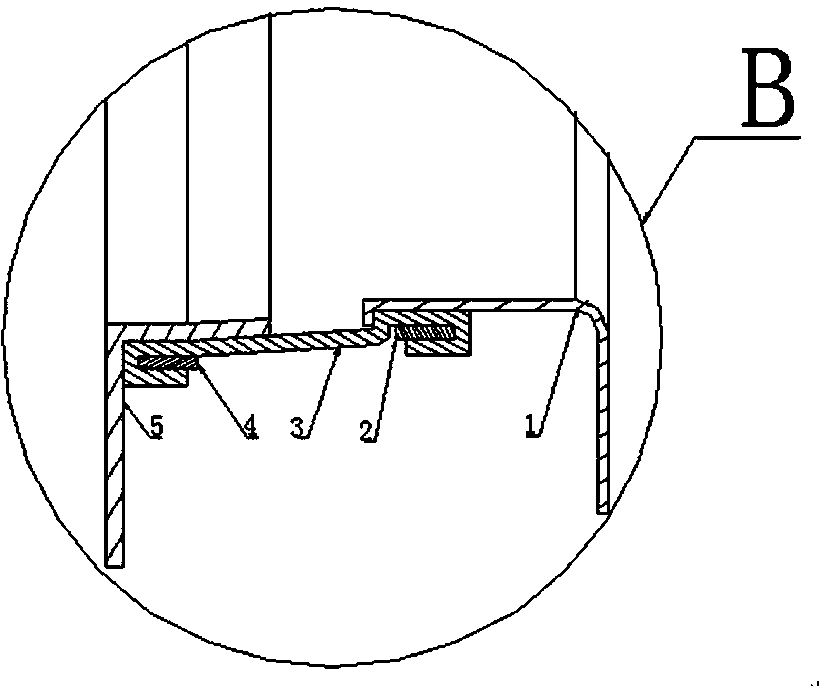

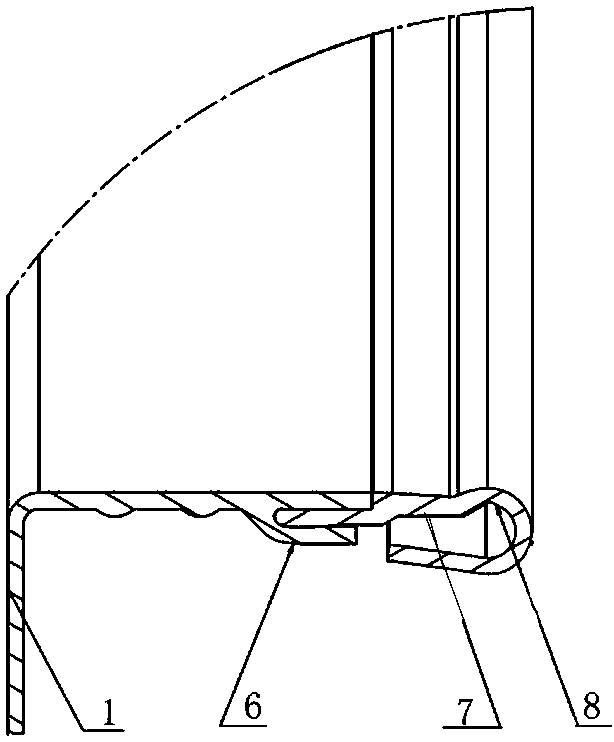

Flanged connection structure and anti-thunder segmented combined tower comprising same

ActiveCN104019003AWith lightning protection functionOvercome the shortcomings of easy fatigue fracture, large amount of operation and maintenance, etc.Final product manufactureWind energy generationInterference fitEngineering

The invention discloses a flanged connection structure. The flanged connection structure comprises an inner flange plate and an outer flange plate, and the horizontal circular plate face of the inner flange plate and the horizontal circular plate face of the outer flange plate are respectively used for being connected with a cylinder. The inner flange plate is inserted into the outer flange plate, the outer side wall of the inner flange plate and the inner side wall of the outer flange plate on the insertion portion intersect, a rectangular groove is formed in the intersection position, the rectangular groove is divided into multiple segments, and a wedge-shaped strip inserting opening is formed in the segment, between every two adjacent segments, of the inner flange plate; the flanged connection structure further comprises a plurality of sets of wedge-shaped strips, the number of the sets is equal to the number of the segments of the rectangular groove, each set of wedge-shaped strips is composed of one upper wedge-shaped strip and one lower wedge-shaped strip, the two wedge-shaped strips in each set are inserted into the rectangular groove from the two ends of the same segment of the rectangular groove respectively to form interference fit, and positioning plugs are fixed to the segments of the rectangular groove. The connection structure is simple, high in production efficiency, small in maintenance workload and low in cost. The invention further discloses an anti-thunder segmented combined tower comprising the flanged connection structure, reliability of tower connection is improved, and lightning current conduction performance of the tower is improved.

Owner:GUODIAN UNITED POWER TECH

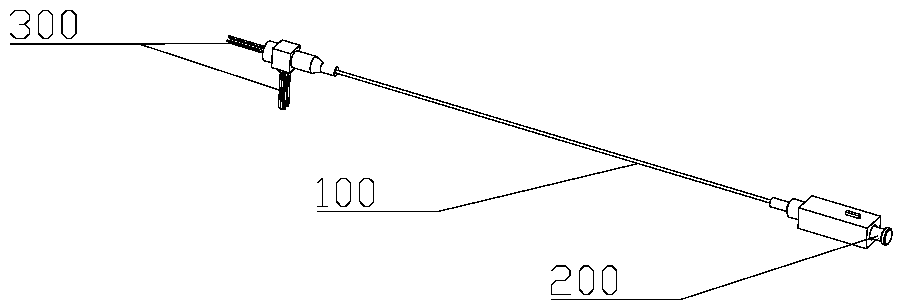

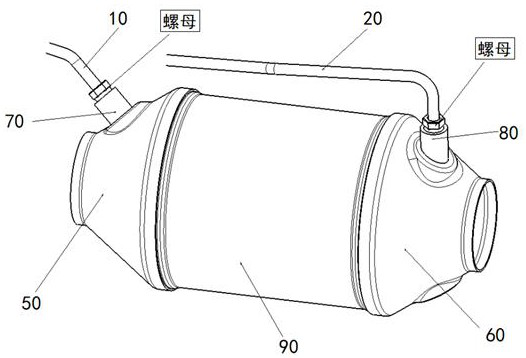

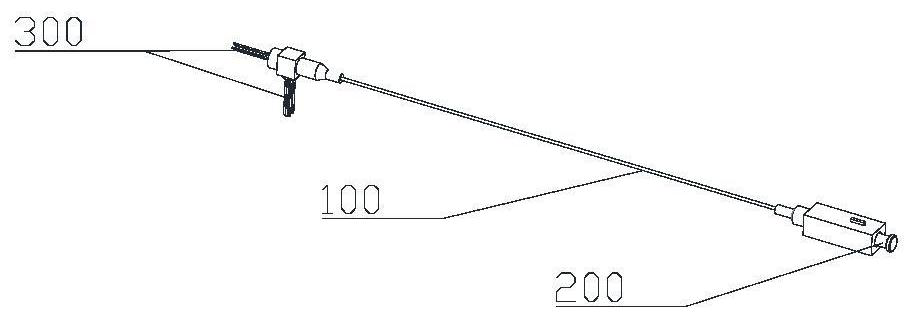

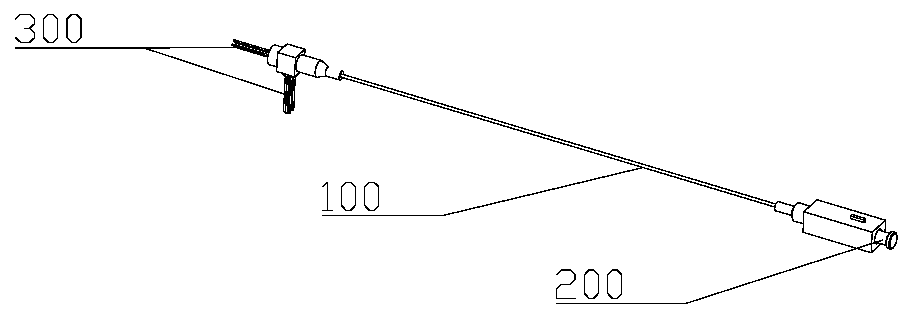

Gas taking pipeline structure of GPF differential pressure sensor

PendingCN114705350AAvoid exposureAccurate monitoringExhaust apparatusSilencing apparatusGasolineMechanics

The invention relates to a gas taking pipeline structure of a GPF differential pressure sensor. The gas taking pipeline structure comprises a first differential pressure sensor gas taking pipe and a second differential pressure sensor gas taking pipe which are arranged on a gasoline engine particle trap body. The gasoline engine particle trap body comprises a GPF barrel, a ceramic core, a front end cone and a rear end cone. An axial through hole is formed close to the edge of the ceramic core body, and a first welding hole and a second welding hole are formed in the conical surface of the front end cone; one end of a first gas taking pipe of the differential pressure sensor penetrates through a second welding hole of the front-end cone and extends into the GPF barrel, and the other end of the first gas taking pipe is matched and fixed with the second welding hole; one end of a second gas taking pipe of the differential pressure sensor penetrates through the first welding hole of the front end cone, extends into the GPF barrel and penetrates through the through hole in the ceramic core body, and the other end of the second gas taking pipe of the differential pressure sensor is matched and fixed with the first welding hole. The gas taking pipe can be prevented from being exposed in the air, the blockage of an icing assembly in the gas taking pipe is avoided, and the accurate monitoring of the GPF function is ensured.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Permanent magnet synchronous motor for hoisting mechanism of direct-drive crane

InactiveCN101662195BImprove transmission efficiencyImprove reliabilityMagnetic circuit rotating partsSynchronous machinesElectric machinePermanent magnet synchronous motor

The invention discloses a permanent magnet synchronous motor for a hoisting mechanism of a direct-drive crane; the permanent magnet synchronous motor comprises a permanent magnet synchronous motor shell, a stator winding, a stator iron core, a permanent magnet, a rotor, a winding drum revolving shaft and a winding drum; and the permanent magnet synchronous motor has more than 20 poles. In the invention, by increasing the number of the poles of the permanent magnet motor, a variable-frequency power source is adopted to realize low-speed operation of the motor, high torque is output, the motor directly drives the load to work, a speed reducer is canceled, the structure is simple and practical, and the working efficiency of the system is improved; a rotor structure adopted by the invention can effectively solve the problem of difficult assembly of the permanent magnet motor; rotor magnetic poles and magnetic separation steel rings commonly protect the permanent magnet from being damaged when in assembly; reluctance torque is reduced to be zero in the installation process, the installation difficulty is reduced, and requirements and dependence to installation tools (special mounting equipment) is reduced, and the quality of the rotor and the complexity of the rotor structure are greatly reduced.

Owner:大连伯顿冠力电机有限公司

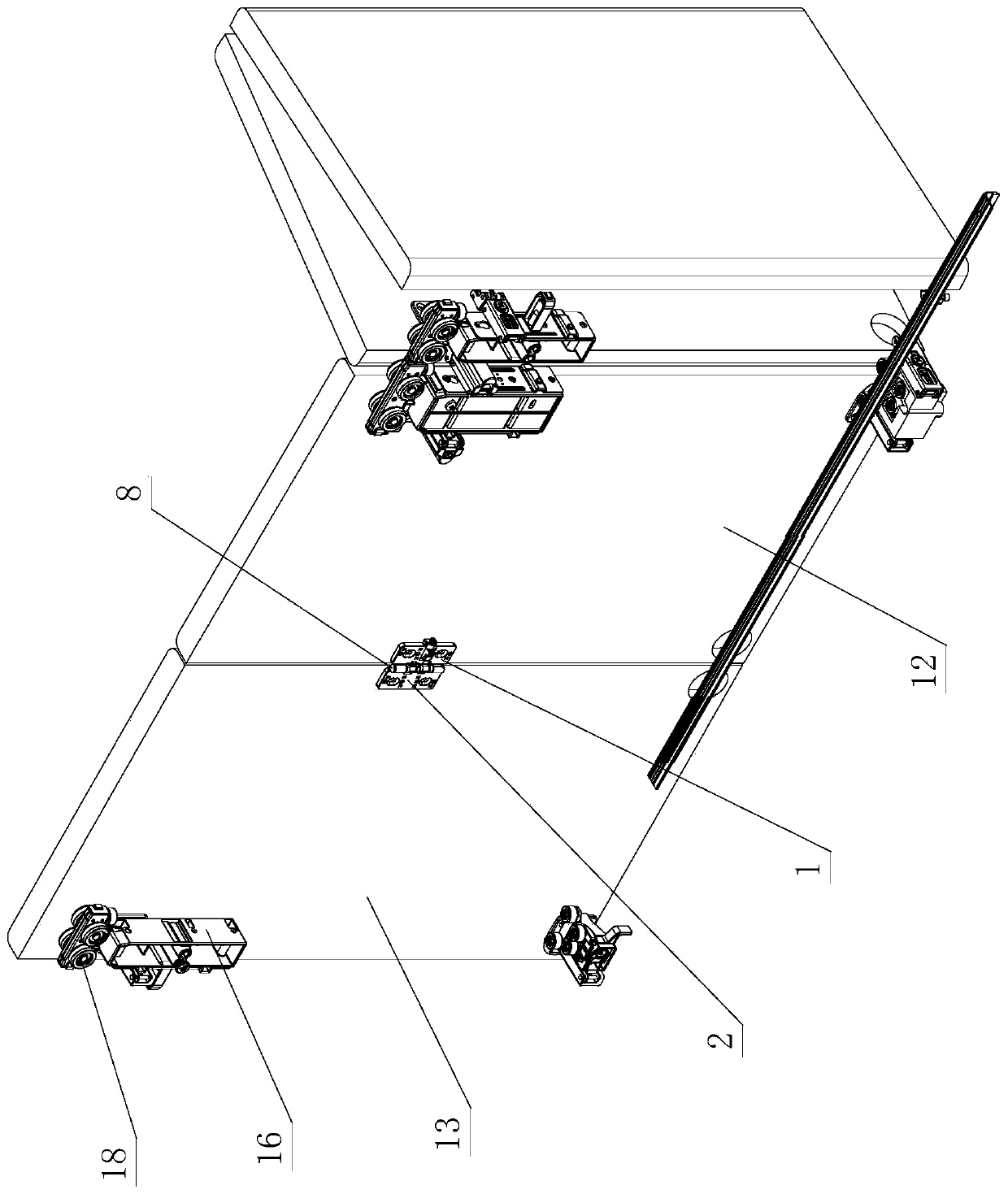

Furniture hinge structure

PendingCN109826520ARealize the assemblyEasy to assemblePin hingesWing arrangementsMechanical engineering

Disclosed is a furniture hinge structure. The hinge comprises a first fixing element and a second fixing element which are hinged to each other, the first and second fixing elements have a certain thickness and are provided with hinge parts and hinged through the hinge parts, one side of each hinge part is provided with an extension part, and each extension part is perpendicular to the first fixing element and / or the second fixing element; the first fixing element and the second fixing element are further provided with fixing holes and preinstalling holes. According to the furniture hinge structure, through the improvement of the structure, the assembly accuracy of the hinge can be effectively improved, the process of assembling the hinge and other furniture door assemblies is simplified accordingly, and therefore a user can quickly, conveniently and efficiently assemble the hinge to the furniture door assemblies; the furniture hinge structure has the advantages of being simple, reasonable, safe, reliable, convenient to use,, quick to assemble, long in service life, low in manufacturing cost, high in component connection compactness, high in practicability and the like.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

Dashboard beam mounting kit

ActiveCN106347495BEasy to installRealize three-point installationSuperstructure subunitsDashboardSteering wheel

The invention discloses an instrument panel crossbeam installation assembly, which includes a left installation assembly for installing the instrument panel crossbeam on the left front side panel welding assembly and a right installation assembly for installing the instrument panel crossbeam on the right front side panel welding assembly. The assembly includes a U-shaped crossbeam right mounting bracket with flanging on both sides and a U-shaped reinforcing plate with flanging on both sides arranged between the right front side panel welding assembly and the right side wall inner panel, the crossbeam The right mounting bracket is fixed to the X direction of the instrument panel crossbeam, the two sides of the right front side panel welding assembly are respectively fixed to the right mounting bracket of the crossbeam and the U-shaped reinforcing plate, and the other side of the U-shaped reinforcing plate The sides are fixed to the inner panel on the right side. The instrument panel beam mounting assembly of the invention has simple structure, convenient installation, sufficient rigidity and high mode, and avoids shaking of the steering wheel and the instrument panel at low speed.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

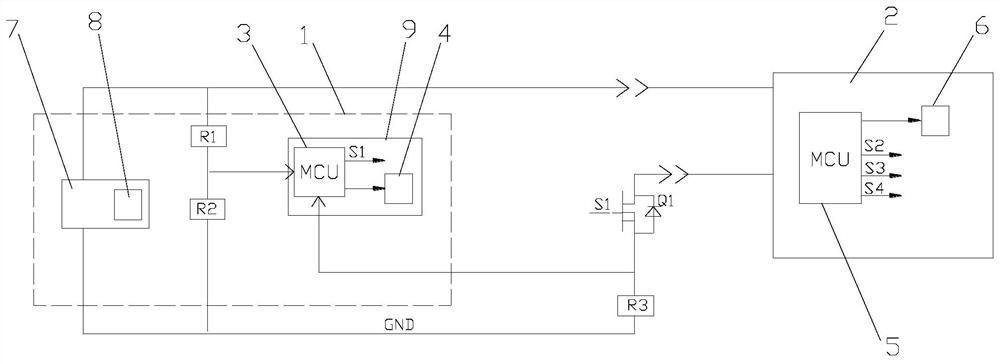

Dust collector capable of realizing wireless communication between motor and battery

PendingCN113712465AAvoid power supplyAvoid assembly difficultiesElectric equipment installationTelecommunicationsElectrical battery

The invention discloses a dust collector capable of realizing wireless communication between a motor and a battery. The dust collector comprises a dust collector main body and a ground brush. The dust collector main body is internally provided with the motor and an energy storage unit used for providing electric energy, and the motor is provided with a main control unit and a first wireless communication module; and the main control unit is electrically connected with the first wireless communication module, the motor, the main control unit, the first wireless communication module and the floor brush are electrically connected with the energy storage unit, the energy storage unit is provided with a second wireless communication module, and the second wireless communication module is in communication connection with the first wireless communication module. By adopting a wireless communication scheme between the motor and the battery, the problem that the battery continues to supply power to the motor when the motor breaks down is avoided, meanwhile, the use of wires can be reduced, product installation is facilitated, and the problems of difficult assembly, poor contact and the like caused after the wires are increased are solved.

Owner:苏州铭炜智能科技有限公司

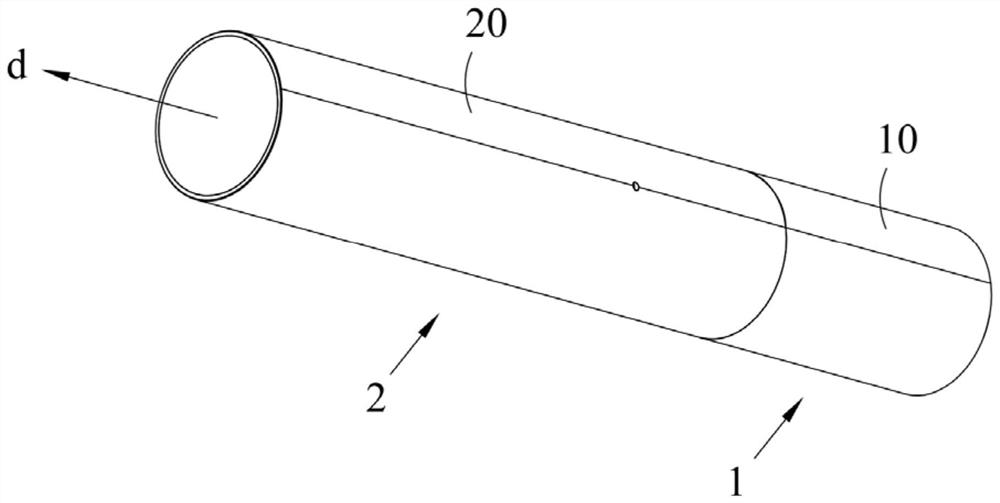

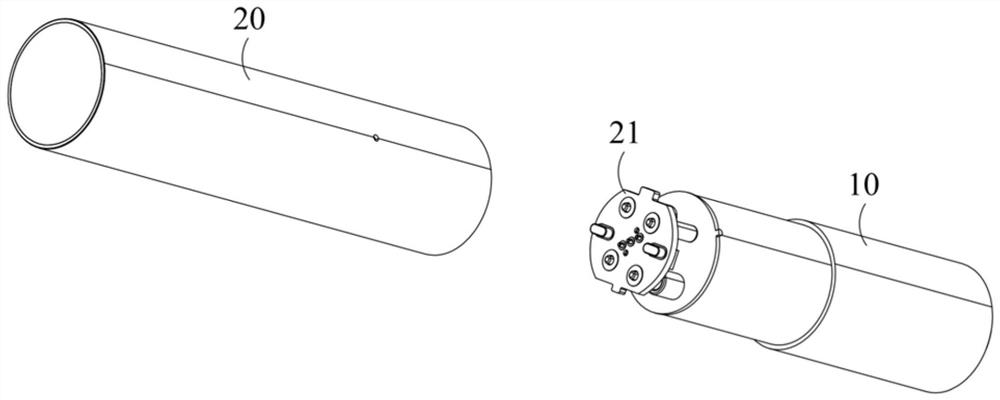

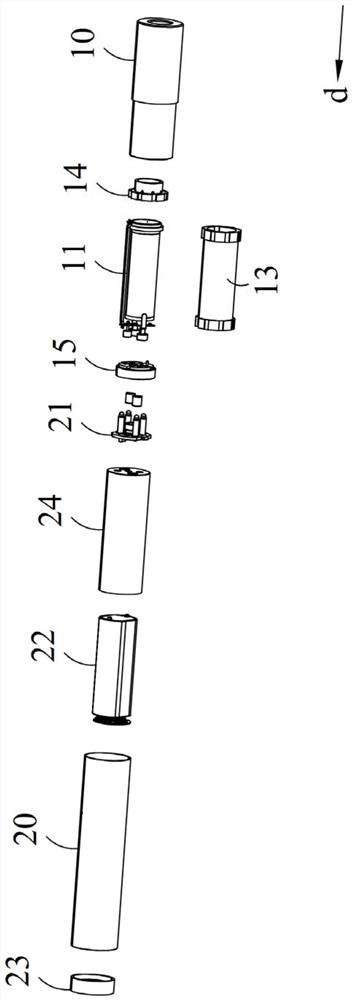

Atomization device and assembly method thereof

PendingCN113519905AAvoid assembly difficultiesTobacco devicesCell component detailsEngineeringSimple mode

The invention discloses an atomization device and an assembly method thereof. The atomization device comprises a first main body and a second main body. The first main body comprises a first shell and an atomization assembly. The atomization assembly is arranged in the first shell. The second main body is detachably connected to the first main body, wherein the second main body comprises a second shell, a control assembly and a battery assembly. The control assembly is arranged on the side, close to the atomization assembly, in the second shell, and the control assembly is electrically connected with the atomization assembly. The battery assembly is arranged on the side, away from the atomization assembly, in the second shell, and the battery assembly is electrically connected with the control assembly. The atomization device is composed of the first main body and the second main body, and the atomization assembly, the control assembly and the battery assembly which are modularized are contained in the first shell in the first main body and the second shell in the second main body respectively. Therefore, all the elements of the atomization device can be connected in a simple mode, and therefore the problems that assembly is difficult and maintenance is not convenient are solved.

Owner:LUXSHARE PRECISION IND SHENZHEN

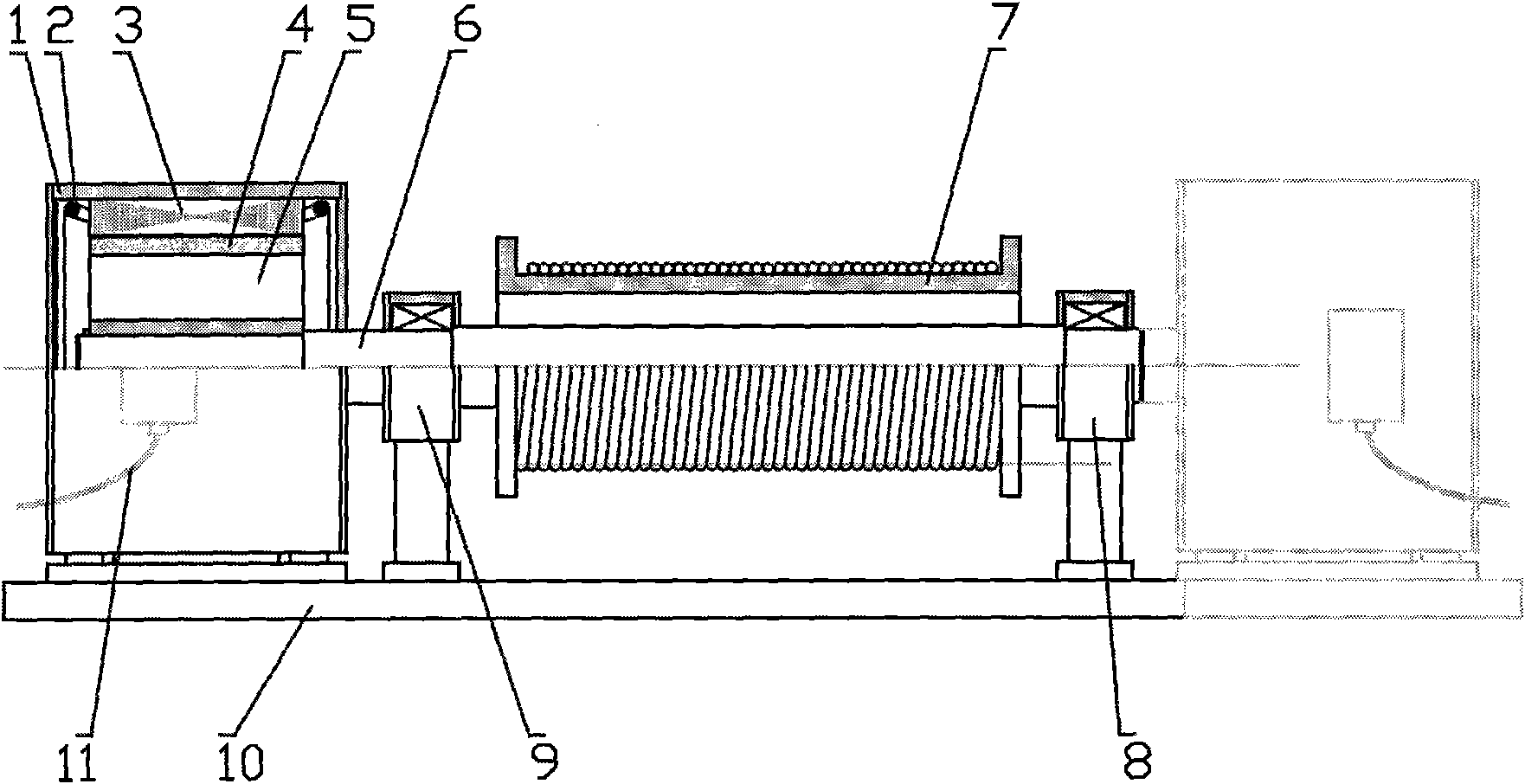

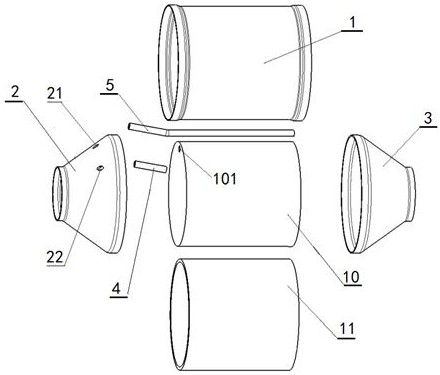

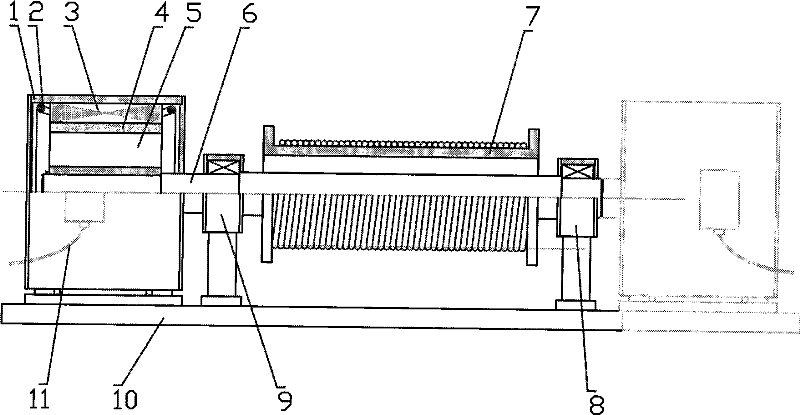

An interchangeable drying compartment device for air-swept coal mill

ActiveCN105772175BEasy to disassembleEasy to replaceDrying solid materialsDrying machines with local agitationFixed frameEngineering

The invention relates to the field of ball mills with drying bins, in particular to an interchangeable drying bin-separating device for an air-swept coal mill. The interchangeable drying bin-separating device comprises a combined supporting frame, a conical discharging body, a plurality of lifting plates and bin-separating grid plates; the combined supporting frame comprises an annular fixing frame with the U-shaped section, the periphery of the fixing frame is fixed to a mill cylinder, and a supporting plate with a central hole and a baffle are connected to the two sides of the fixing frame respectively through bolts; the bin-separating grid plates are connected to the side, facing a grinding bin, of the fixing frame through bolts; the conical discharging body is arranged in the central hole of the combined supporting frame and is connected and fixed to the supporting plate, and a plurality of butt plates used for fixing the lifting plates are arranged in the peripheral direction of the conical discharging body; each lifting plate is composed of one arc-shaped curved plate and two side plates, is embedded between the baffle and the supporting plate and is connected to the supporting plate through one side plate and a bolt. According to the interchangeable drying bin-separating device, the interchangeability of the bin-separating device can be improved, the material accumulation problem of a drying bin can be solved, the mill efficiency can be improved, assembly is easy, and the potential safety hazard of bolt breakage is avoided.

Owner:CITIC HEAVY INDUSTRIES CO LTD

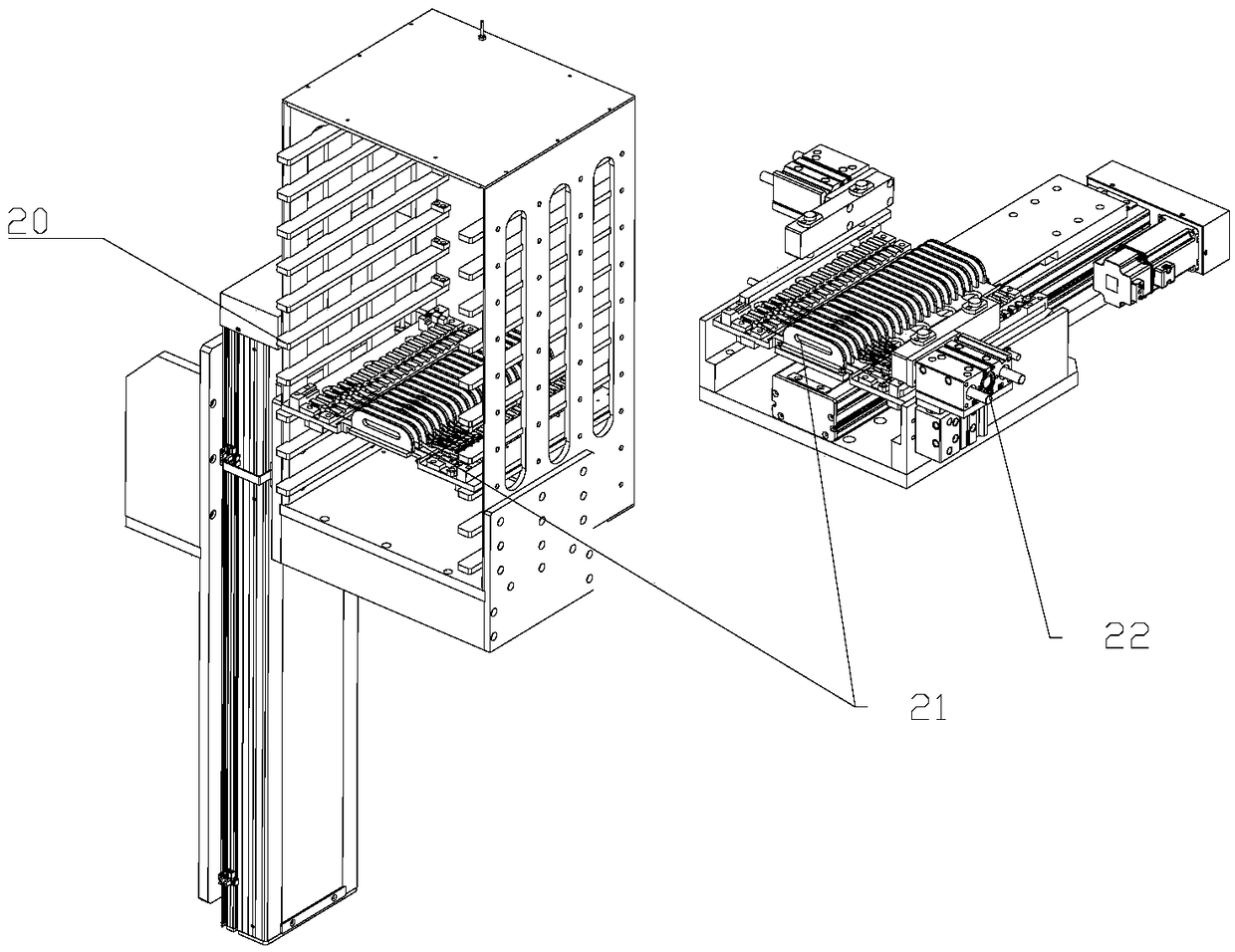

Optical fiber device loading and unloading module and optical fiber device testing equipment

ActiveCN109513621BAvoid interferenceHigh degree of automationSortingStructural engineeringMechanical engineering

Owner:SHANGHAI ZHENGHE INTELLIGENT EQUIP MFG CO LTD

Novel industrial type gas turbine brush gas seal and manufacturing method thereof

InactiveCN106677835AHigh strengthAvoid assembly difficultiesLeakage preventionMachines/enginesEngineeringGas turbines

A novel industrial type gas turbine brush gas seal is formed in the manner that two symmetrical pressure bearing plates in upright ring shapes are welded at the top ends; brush wire bundles which are closely and evenly arranged are arranged in the middles of each pressure bearing plate body; a sunken cooling groove body is formed in the top end of each pressure bearing plate body; and a flow guiding piece is arranged on one side of the upper portion of the middle of each pressure bearing plate body. The novel industrial type gas turbine brush gas seal effectively reduces the production cost of manufacturers; and because the manner that the brush wire bundles, the pressure bearing plates and the flow guiding pieces are welded as a whole is adopted, the welding deformation of the brush gas seal caused when a welding part is too thin in the welding process is effectively controlled, and meanwhile, the overall strength of the brush gas seal is improved; cooling grooves formed in the pressure bearing plates guarantee the welding convenience, the problem that a sealing piece deforms and loses efficacy due to high temperature can be prevented, and therefore the service life of the sealing piece is prolonged; and meanwhile, the problem that secondary machining is needed because part assembling is difficult is avoided, and machining work procedures are reduced.

Owner:江苏透平电力技术有限公司

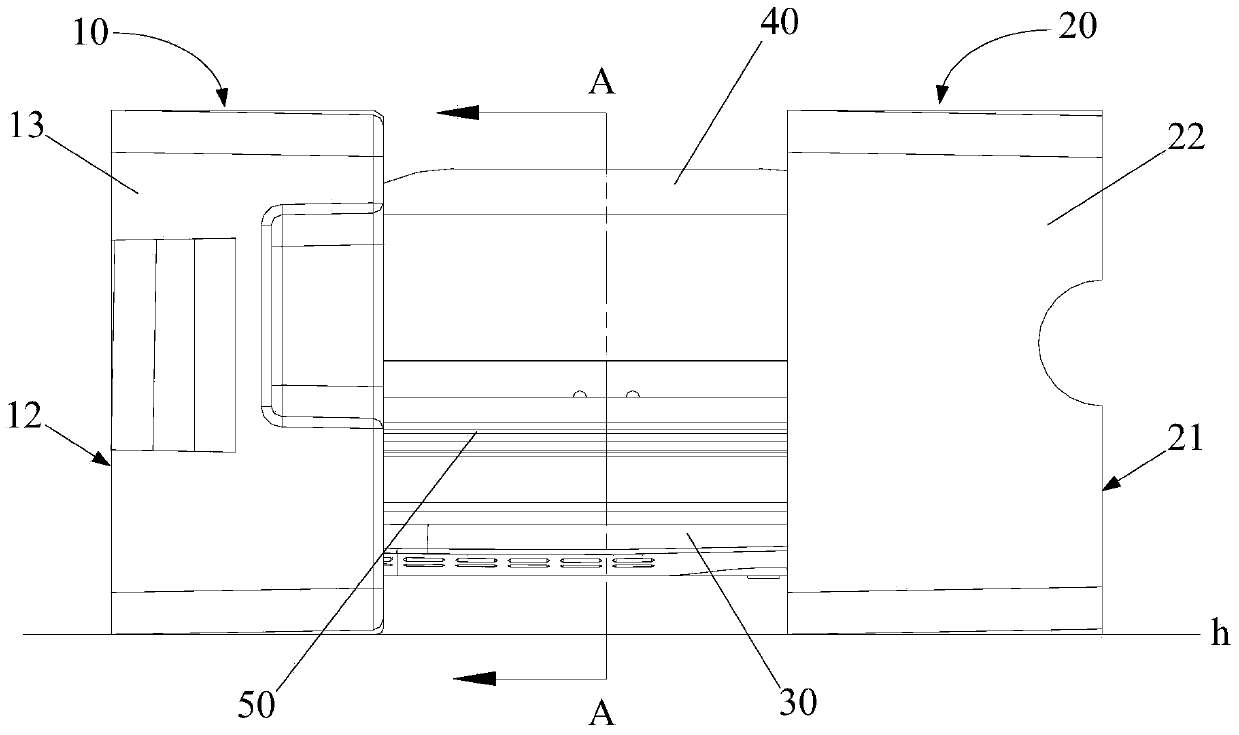

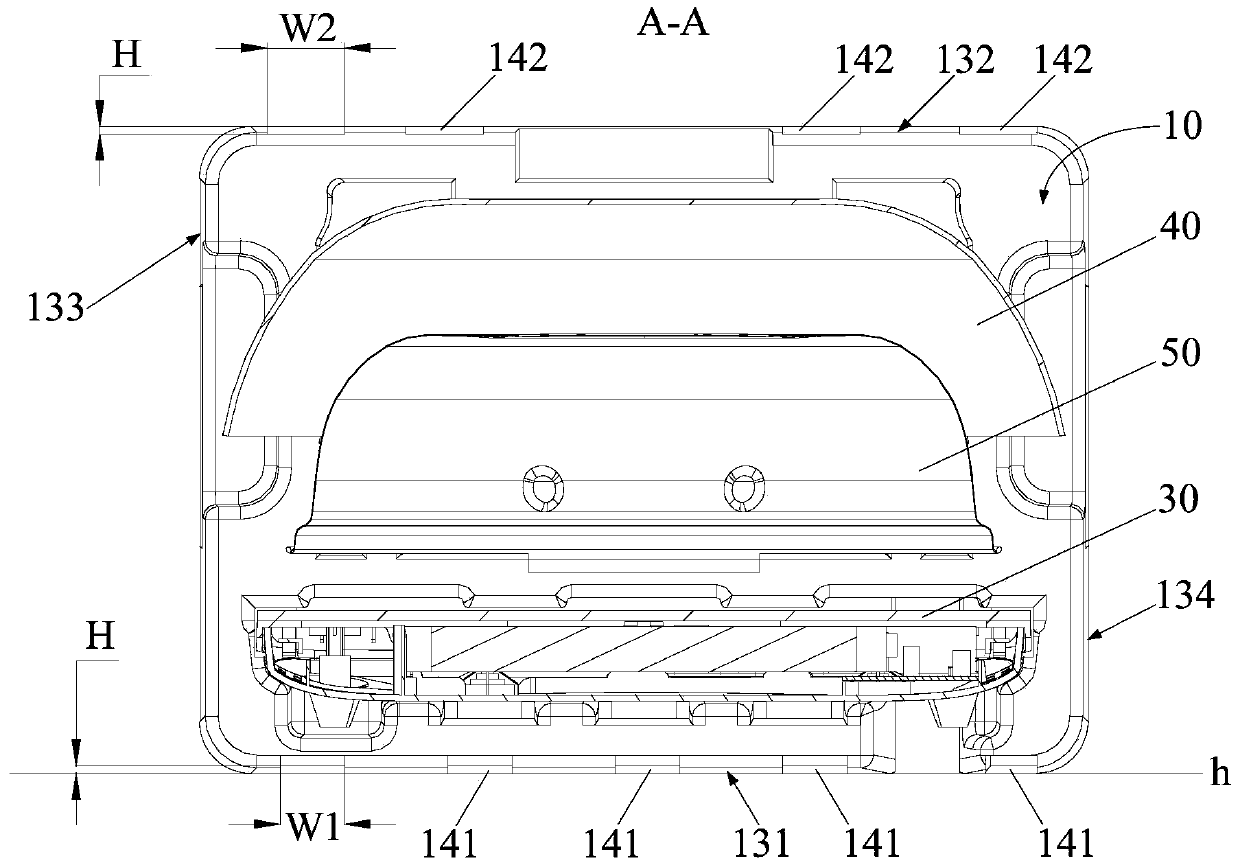

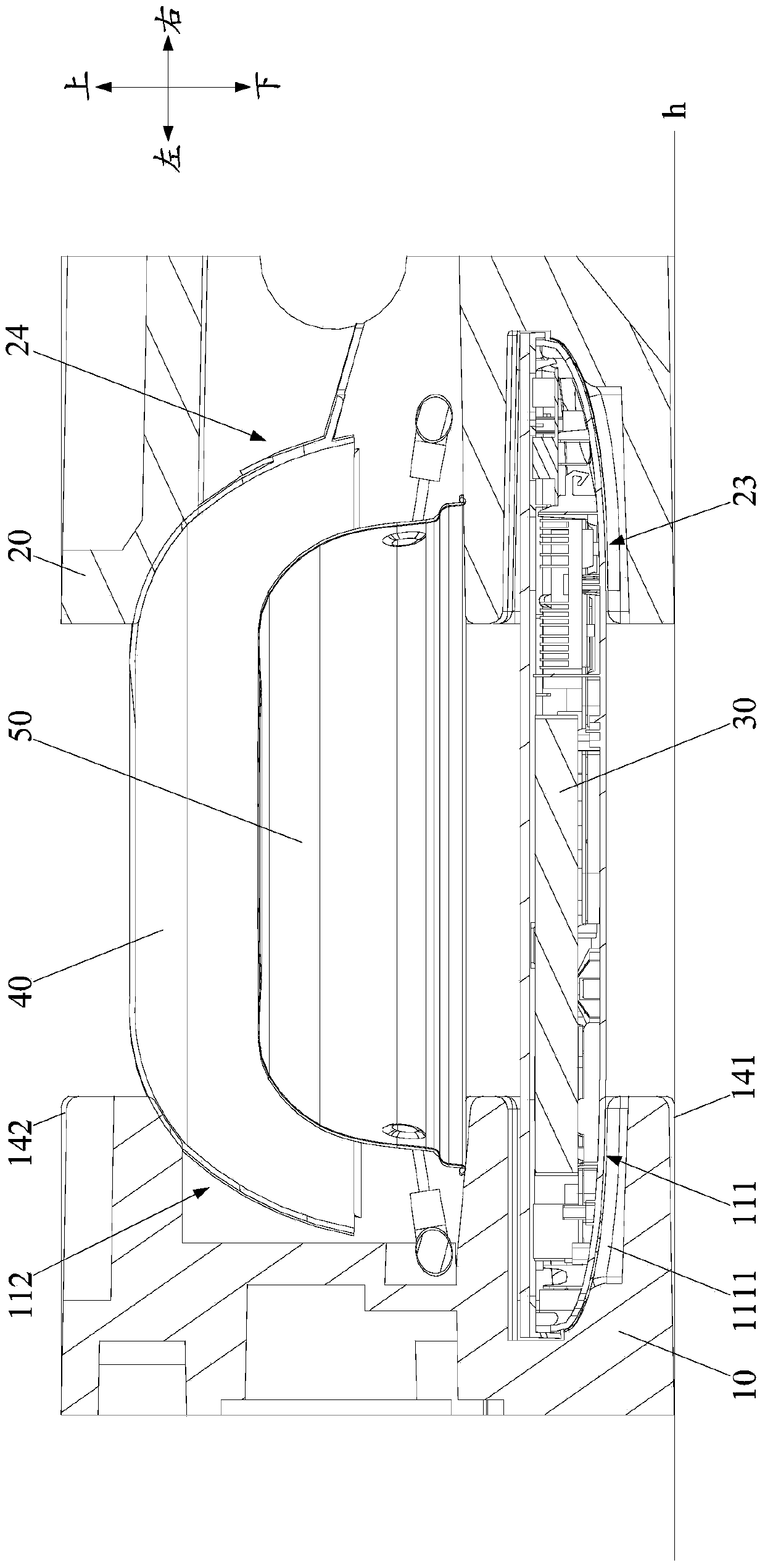

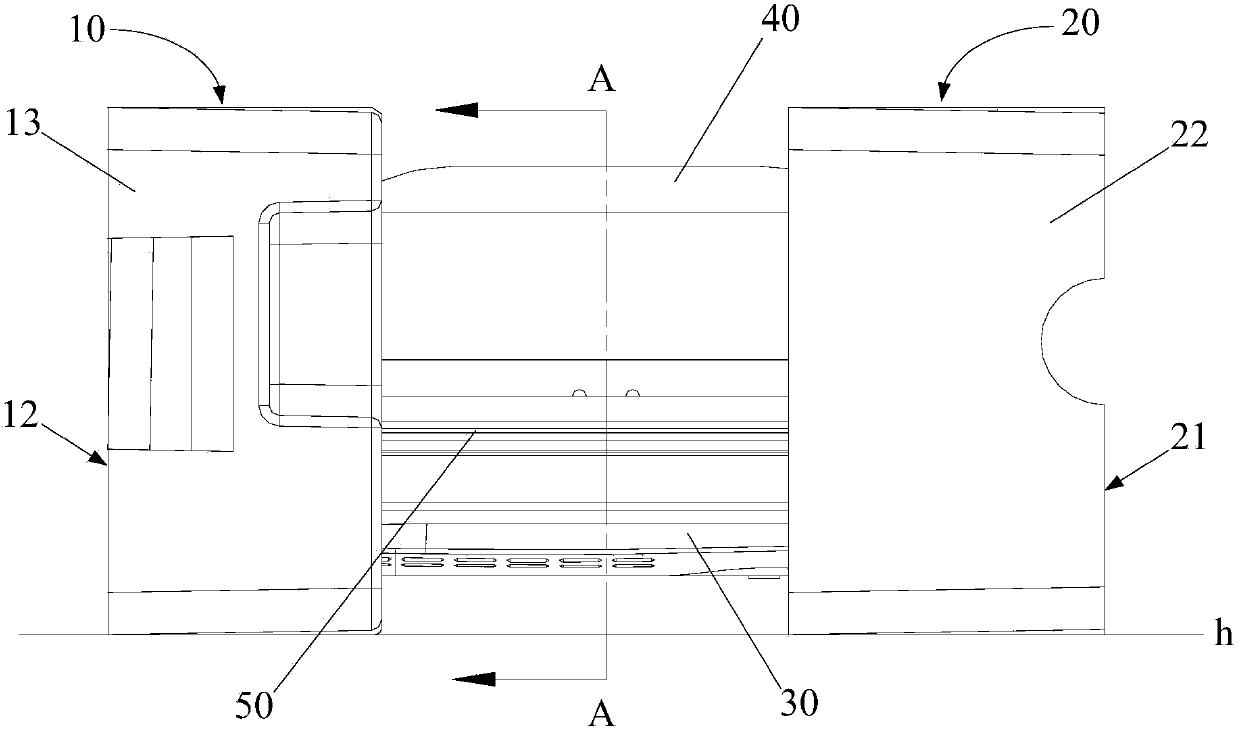

Packaging liners and home appliance components for home appliances

ActiveCN107640440BWith structural rigidityPrevent collapsePackaging vehiclesContainers for machinesAppliance componentHome appliance

The invention provides a packaging liner for household appliance and a household appliance component, wherein one end of the packaging liner is provided with a first mounting groove for mounting the home appliance and the other end of the packaging liner has a bottom surface, and the packaging liner has a side surface which is connected between one end of the packaging liner and the other end of the packaging liner in a transition mode. The side surface includes an inclined surface area which is inclined in a direction from one end of the packaging liner to the other end of the packaging linerand is provided with a boss structure. The packaging liner for the household appliance can take both the assembly efficiency and the protection reliability of a product into consideration, so that the overall quality of the product is effectively improved and the promotion of the product in the field is facilitated.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Packaging liner for household appliance and household appliance component

ActiveCN107640440AConsider assembly efficiencyTaking into account the reliability of protectionPackaging vehiclesContainers for machinesAppliance componentEngineering

The invention provides a packaging liner for household appliance and a household appliance component, wherein one end of the packaging liner is provided with a first mounting groove for mounting the home appliance and the other end of the packaging liner has a bottom surface, and the packaging liner has a side surface which is connected between one end of the packaging liner and the other end of the packaging liner in a transition mode. The side surface includes an inclined surface area which is inclined in a direction from one end of the packaging liner to the other end of the packaging linerand is provided with a boss structure. The packaging liner for the household appliance can take both the assembly efficiency and the protection reliability of a product into consideration, so that the overall quality of the product is effectively improved and the promotion of the product in the field is facilitated.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

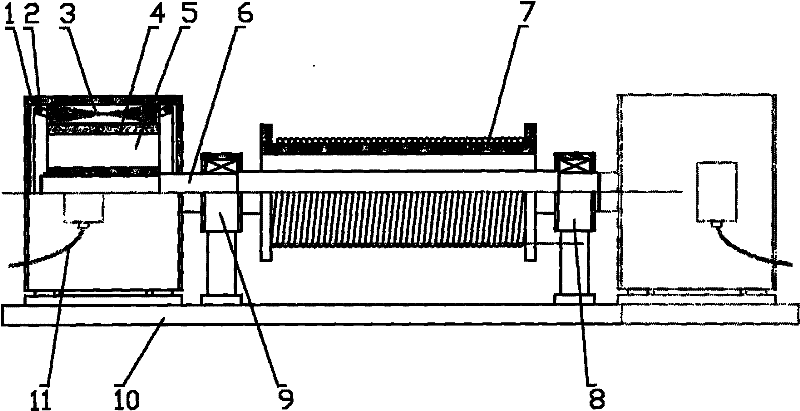

A steam generator inclined tube bundle heat exchange experimental device and method

ActiveCN108872304BSimple structureEasy to processMaterial heat developmentExperimental methodsEngineering

Owner:XI AN JIAOTONG UNIV

A new type of automobile engine wind protection ring assembly

ActiveCN106150664BReduce axial sizeShorten the lengthMachines/enginesEngine cooling apparatusRubber ringEngineering

The invention provides a novel wind ring assembly of an automobile engine. The novel wind ring assembly comprises a wind ring, and an open type pressing rivet structure is formed in the axle journal of the wind ring. The open type pressing rivet structure is stressed after a rubber ring is arranged into the open type pressing rivet structure, and an opening of the open type pressing rivet structure is contracted to clamp the rubber ring and the wind ring assembly is formed. The rubber ring is extended in the axial direction to form a horn mouth. A thickness sudden-change structure is arranged on the connecting section between an extended part of the rubber ring in the axial direction and a wind cover, and the rubber ring can be freely turned and folded. The opening angle alpha of the horn mouth is 10-50 degree. According to the novel wind ring assembly, the open type pressing rivet structure is formed in the axle journal of the wind ring, the open type pressing rivet structure is pressed after the rubber ring is arranged into the open type pressing rivet structure, and the opening of the open type pressing rivet structure is contracted to clamp the rubber ring and the wind ring assembly is formed, the rubber ring is extended in the axial direction to form the horn mouth, the thickness sudden-change structure is arranged on the connecting piece between the extended part of the rubber ring in the axial direction and the wind cover, and the rubber ring can be in the state of being freely turned and folded, so that the axial dimension, namely the total length, of the wind ring assembly is reduced.

Owner:湖北晟正汽车零部件有限公司

A kind of optical fiber device testing equipment

ActiveCN109186952BAvoid interferenceEasy to carryTesting fibre optics/optical waveguide devicesComputer hardwareEmbedded system

The invention relates to the technical field of the communication. Optical fiber device detection equipment comprises a rack and a feeding device, a feeding manipulator device, a before-detection analysis module, an optical fiber device performance detection module, a protective cap mounting device, a stepping conveying device, a foldable manipulator placing device and a blanking device which arearranged on the rack; the feeding device is joined with the before-detection analysis module through the feeding manipulator device; the before-detection analysis module, the optical fiber device performance detection module and the protective cap mounting device are orderly joined; the location of the stepping conveying device is corresponding to the before-detection analysis module, the opticalfiber device performance detection module and the protective cap mounting device; and the protective cap mounting device is joined with the blanking device through the foldable manipulator placing device. The optical fiber device detection equipment has the advantages of being high in automation degree, high in working efficiency, high in finished product yield and extensive in testing range.

Owner:SHANDONG JIANBO TELECOMM EQUIP

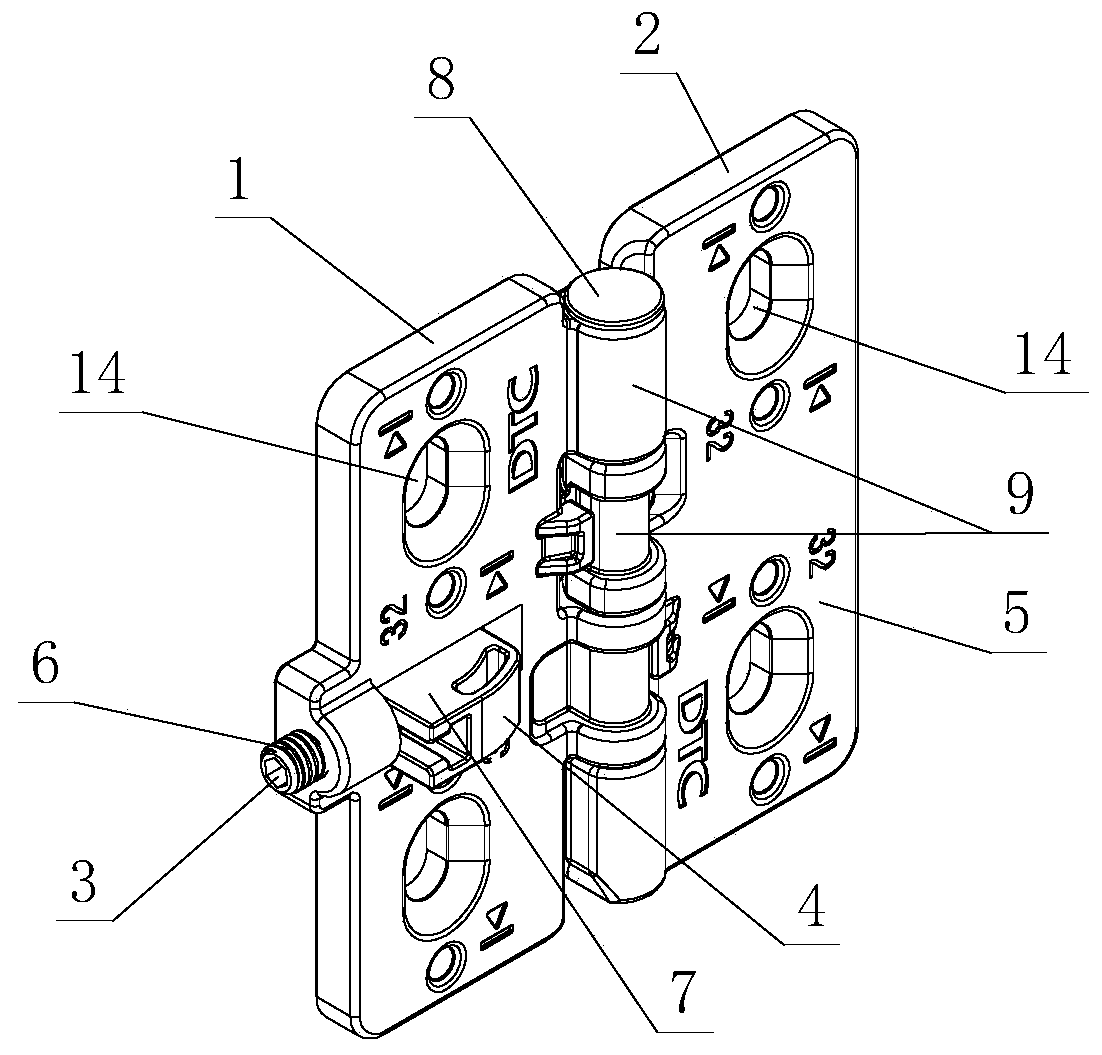

Locatable adjusting structure of furniture hinge

PendingCN110173179ASimplify the assembly processEasy to assembleHingesEngineeringMechanical engineering

The invention provides a locatable adjusting structure of a furniture hinge. The hinge comprises a first fixing element and a second fixing element which are hinged and matched in an opening and closing mode. An adjusting assembly is arranged between the first fixing element and the second fixing element. The adjusting assembly at least comprises an adjusting part and an acting part. The acting part is driven through the adjusting part to move on the first fixing element or the second fixing element and achieves the mutual locating effect with the second fixing element or the first fixing element at least when the hinge is hinged and closed so as to achieve the hinge closing locating and closing angle adjustment of the hinge. Through the improvement on the above structure, the locatable adjusting structure has the characteristics of being simple and reasonable in structure, safe, reliable, quick in assembly, low in manufacturing cost, high in component connecting compactness, convenient to use, wide in range, long in service life and the like, and has high practicality.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

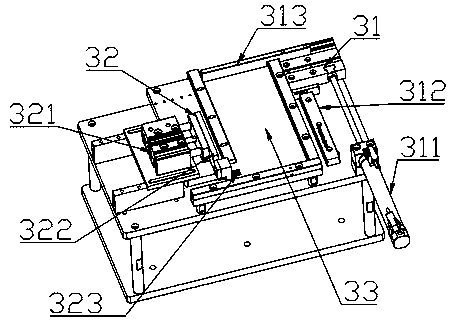

Battery size detection line used for electronic product

InactiveCN110174618ARealize offline processingRealize detectionElectrical testingProduction lineElectrical battery

The invention discloses a battery size detection line used for an electronic product. The detection line comprises a bottom plate and detection equipment fixed on the bottom plate, wherein the detection equipment comprises a material loading part, an electrification detection part, a first inferior-quality product conveyor belt, a length detection part, a thickness detection part, a second inferior-quality product conveyor belt, a discharged material conveyor belt and a transportation part; the material loading part, the electrification detection part, the first inferior-quality product conveyor belt, the length detection part, the thickness detection part, the second inferior-quality product conveyor belt and the discharged material conveyor belt are arranged and fixed on the bottom platein sequence; the transportation part is arranged on the side part of the bottom plate; and in addition, the material loading part, the electrification detection part, the first inferior-quality product conveyor belt, the length detection part, the thickness detection part, the second inferior-quality product conveyor belt and the discharged material conveyor belt are all arranged in the movementjourney of the transportation part. By use of the detection line, an automation degree is high, space is saved, continuous production is realized, the detection line can be favorably combined into a production line, manpower is saved, production cost is lowered, production efficiency is improved, and the detection line has a good market application value.

Owner:XUCHANG UNIV

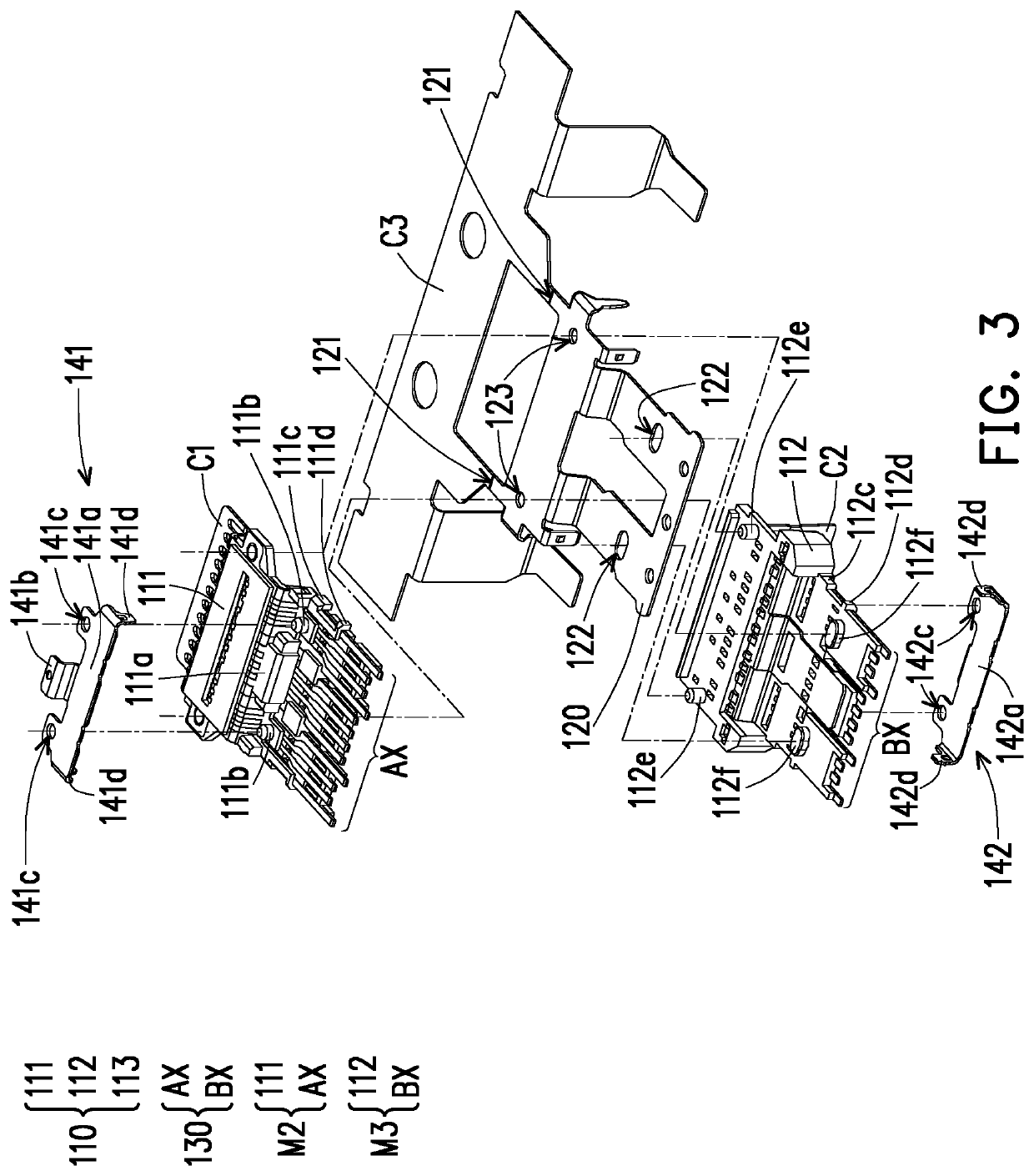

Electrical connector

PendingUS20220285889A1Improve structural strengthAvoid assembly difficultiesSecuring/insulating coupling contact membersCouplings bases/casesMetallic enclosureElectrical connection

An electrical connector including an insulating body, a first metallic member, a second metallic member, a plurality of terminals, and a metallic shell is provided. The insulating body has a base portion, a thickened step portion, and a tongue portion. The thickened step portion is located at a root of the base portion. The first metallic member and the second metallic member are disposed on an upper surface and a lower surface of the insulating body. The metallic shell is disposed on an exterior of the insulating body to surround the first metallic member, the second metallic member, and the terminals, wherein the front flat contact portion of each of the terminals is exposed out of the tongue portion, and a portion of the first metallic member and a portion of the second metallic member are exposed out of the thickened step portion.

Owner:ADVANCED CONNECTEK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com