An interchangeable drying compartment device for air-swept coal mill

An interchangeable, drying bin technology, applied in drying, dryers, dryers for static materials, etc., can solve the problem of the discrepancy between the plane of the grate plate and the plane of the support plate, difficulty in ensuring cylindricity and flatness, The problem of large shear force of the installation bolts is achieved to avoid overall scrapping, prevent assembly difficulties, and facilitate lifting and flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

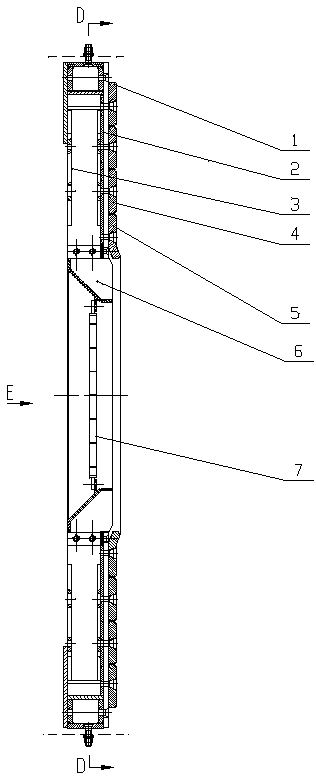

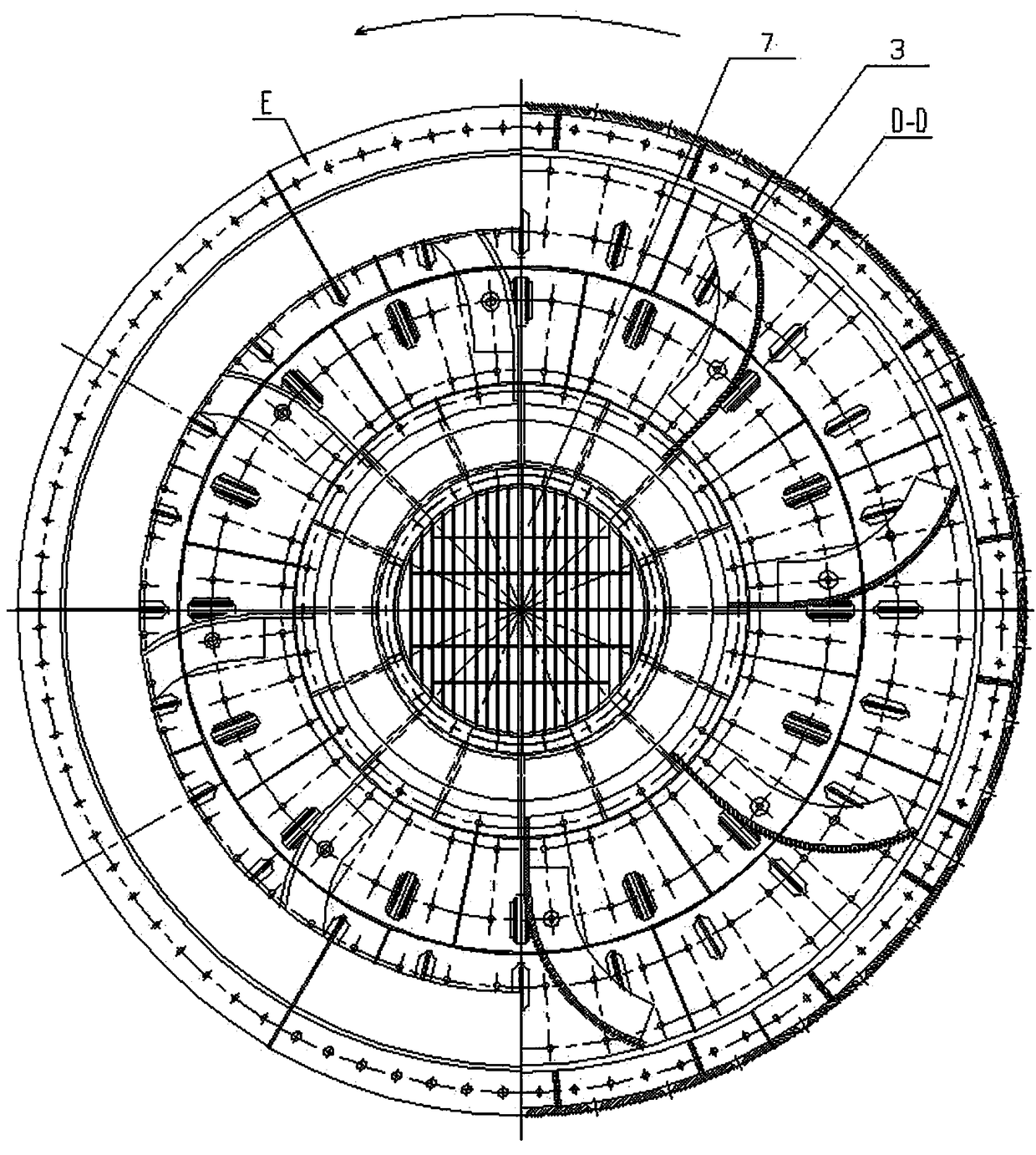

[0027] Such as figure 1 and figure 2 As shown, an interchangeable drying compartment device for air-swept coal mill, which is set in the barrel of the air-swept coal mill, and is located between the drying bin and the grinding bin of the air-swept coal mill. The compartment device is composed of a combined support frame 2, a conical discharge body 6, a lifting plate 3, an outer ring grate plate 1, a middle ring grate plate 4, an inner ring grate plate 5, a center plate 7 and accessories. The outer ring of the combined support frame 2 is fixed to the mill cylinder, and the inner ring is firmly connected by the conical discharge body 6 to enhance its strength and rigidity and offset the inclination force of the steel balls and materials in the mill. figure 2 The arrow in the upper middle indicates the direction of rotation of the mill barrel.

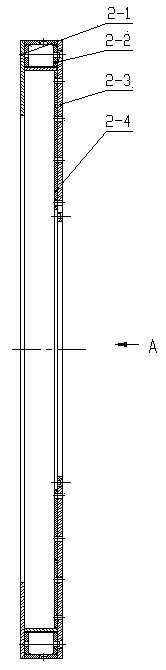

[0028] Such as image 3 and Figure 4 As shown, the combined support frame 2 is composed of a fixed frame 2-2, a baffle plate 2-1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com