Flanged connection structure and anti-thunder segmented combined tower comprising same

A connection structure and segmented combination technology, which is applied to wind turbine components, wind power generation, sustainable manufacturing/processing, etc., can solve the problems of inconvenient tower operation and maintenance, heavy maintenance workload, and complicated procedures, and achieve the goal of overcoming Low assembly efficiency, easy installation and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be described in detail in combination with specific examples and accompanying drawings.

[0034] In order to overcome the problems existing in the existing bolted flanges, the present invention provides a new flange connection structure, which can be used to connect any two cylinder structures, and the following is only the connection of the segmented combined tower of the wind power generator group As an example to illustrate.

[0035] Segmented combined towers for wind turbines, including multi-segment towers, such as Figure 7 As shown, it is a tower with a three-section tower, and a wedge-shaped strip connection flange connection structure a is used between adjacent towers.

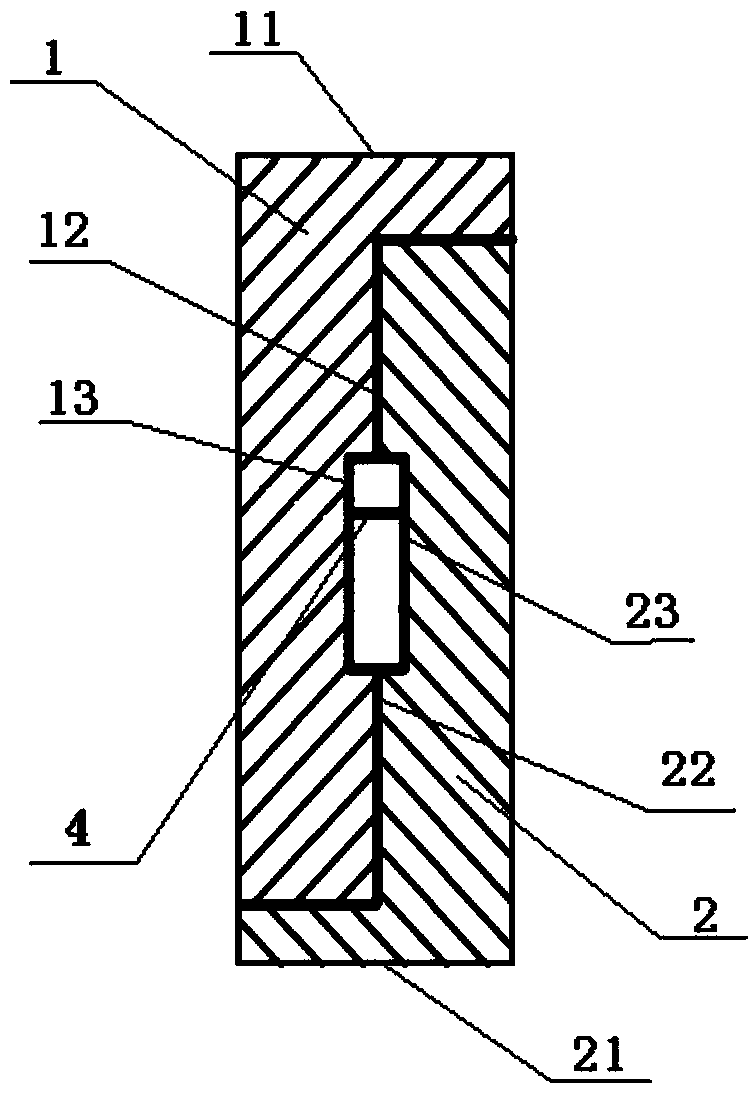

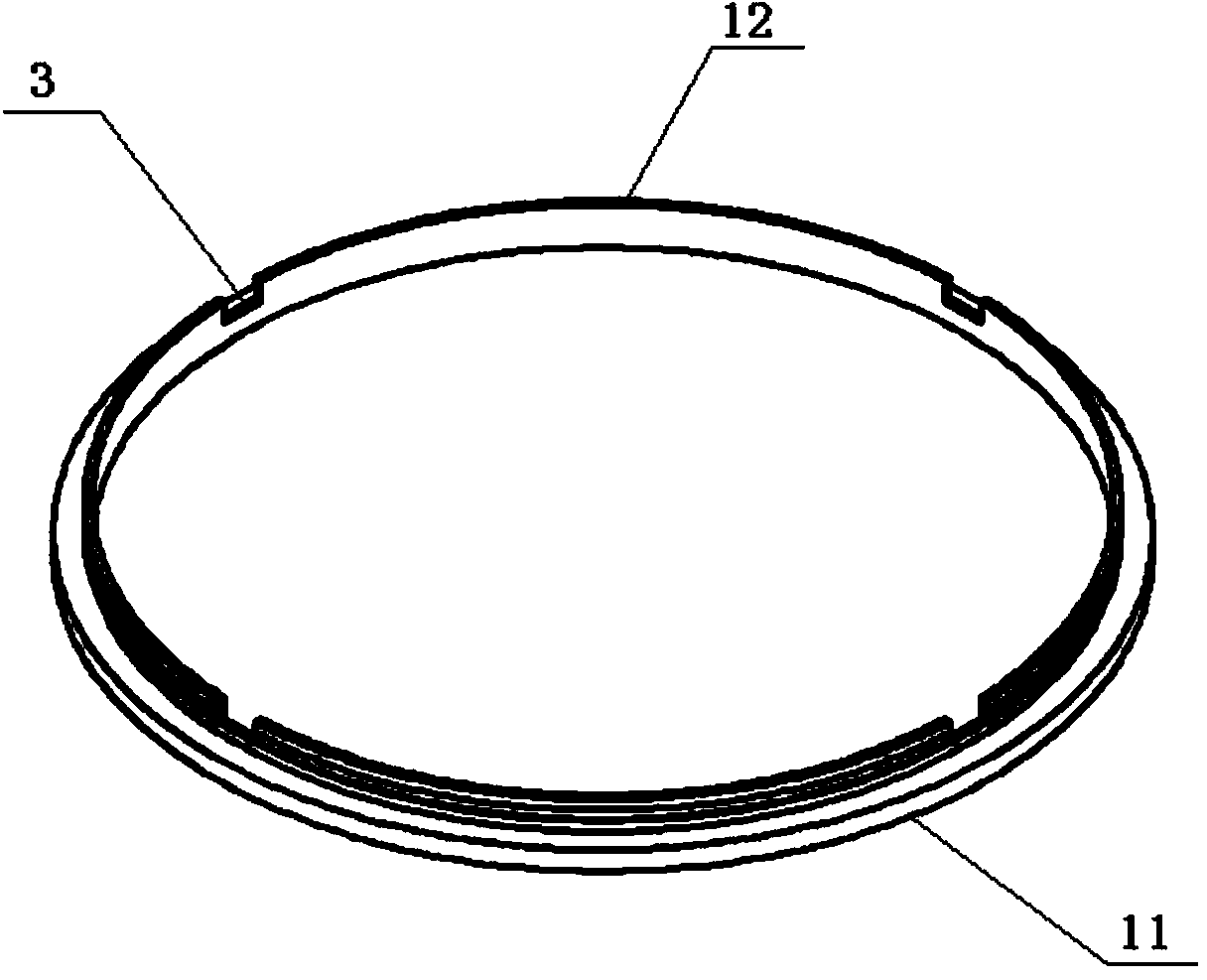

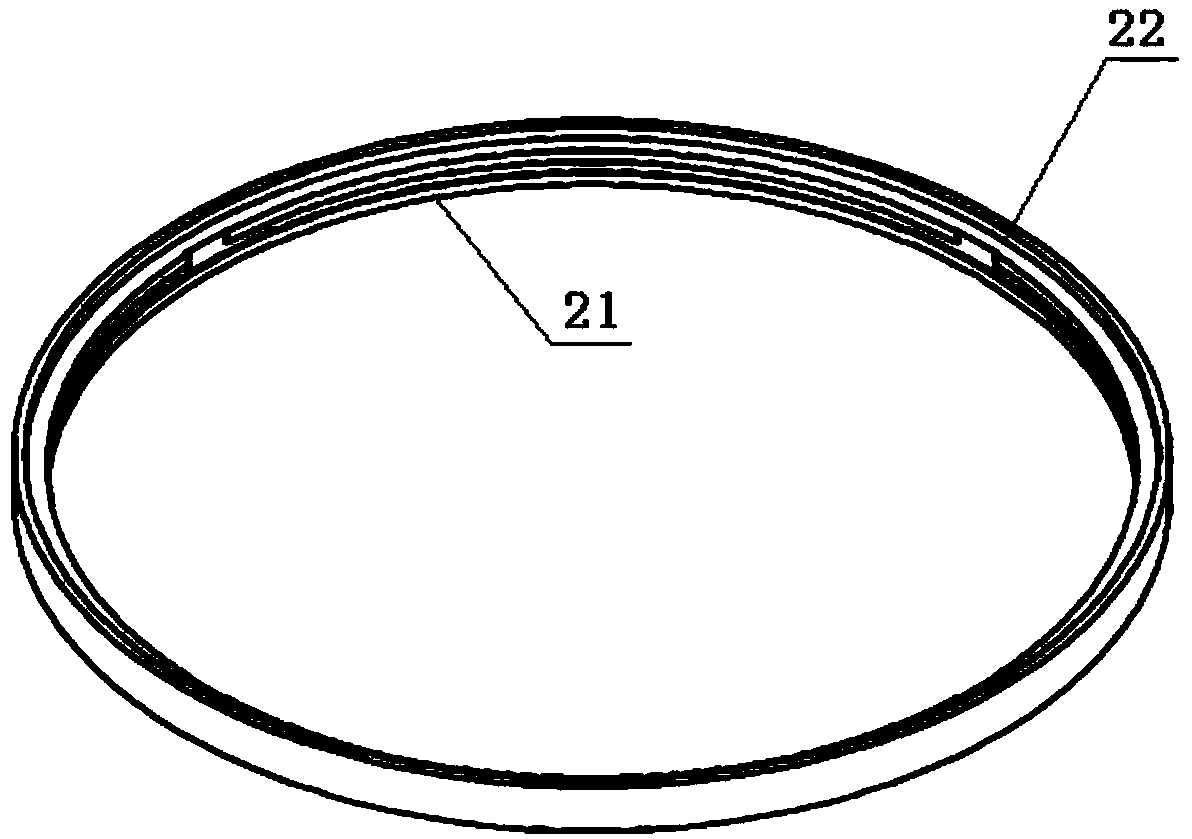

[0036] The flange connection structure is as follows Figure 1-3 As shown, the inner flange 1 and the outer flange 2 are included, and the horizontal disc surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com